Team-BHP

(

https://www.team-bhp.com/forum/)

Discussions with a friend gave me an Idea to collect information on this subject. ( which I already had & which is based on my own experience )

Propeller shaft is the most exposed (to elements) Part in the Jeep that is often neglected in terms of Lubrication.

Many dont know or understand the importance of its maintenance till it fails & the mech shows them the dry rusted & worn out parts.

But the Q remains is what kind of lubrication ?

Two types of grease is used

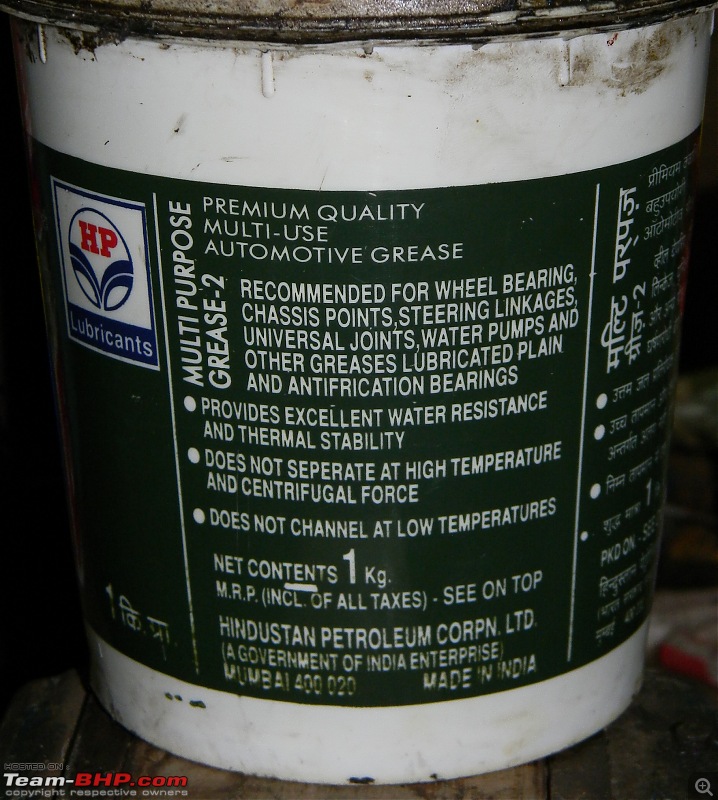

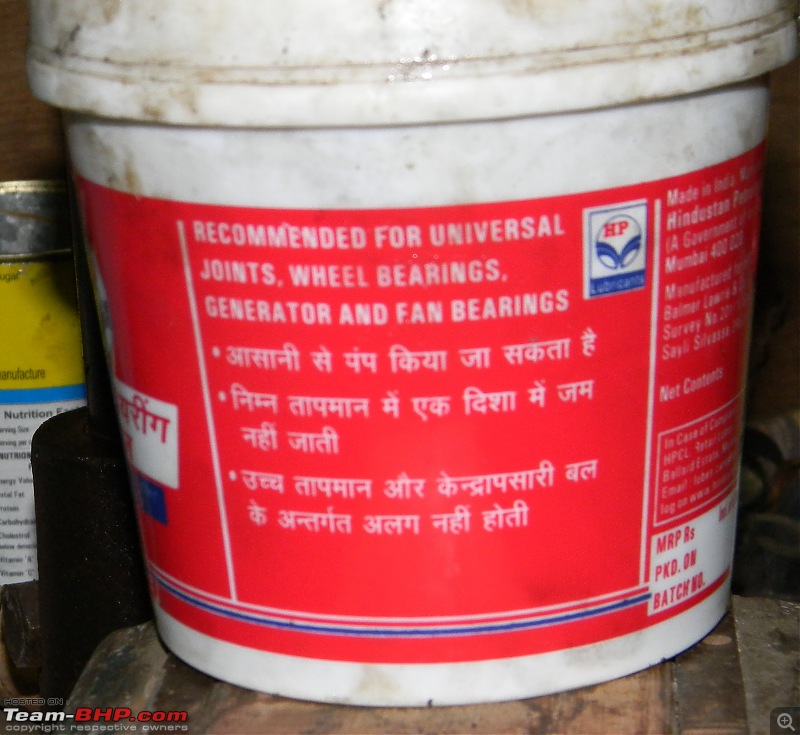

# 1 the Wheel Bearing grease particularly for the U Joint (U J ) cross bearings

UJ cross bearings work under extereme load conditions & work in different angles , so they need a very heavy duty grease

# 2 the Chassis Grease for slider portion

The slider portion also needs quality grease but can go with some lighter type of grease , however I will recommend a thick grease for old sliders .

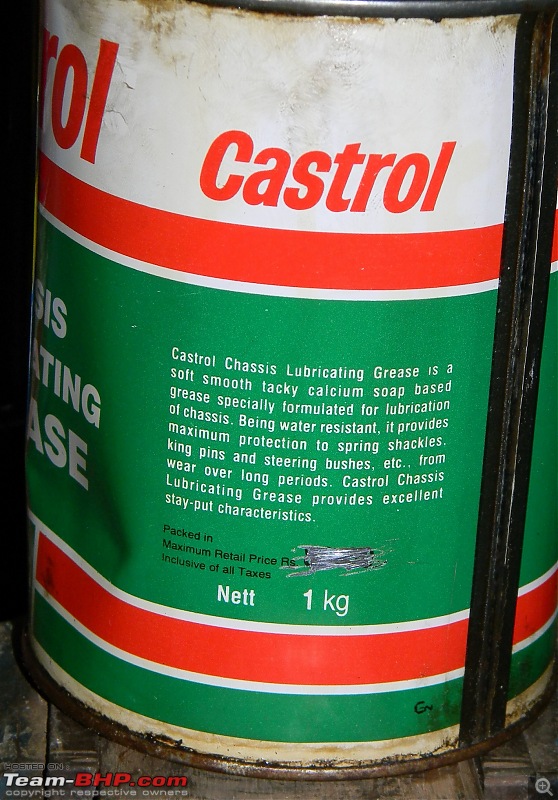

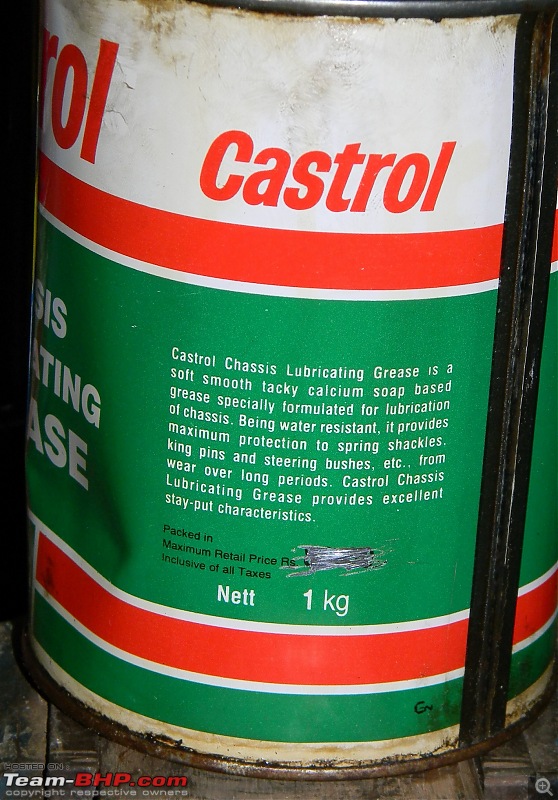

Heavy Duty castrol grease for UJ cross bearings

#

Castrol Chassis grease , good water resistant qualities

#

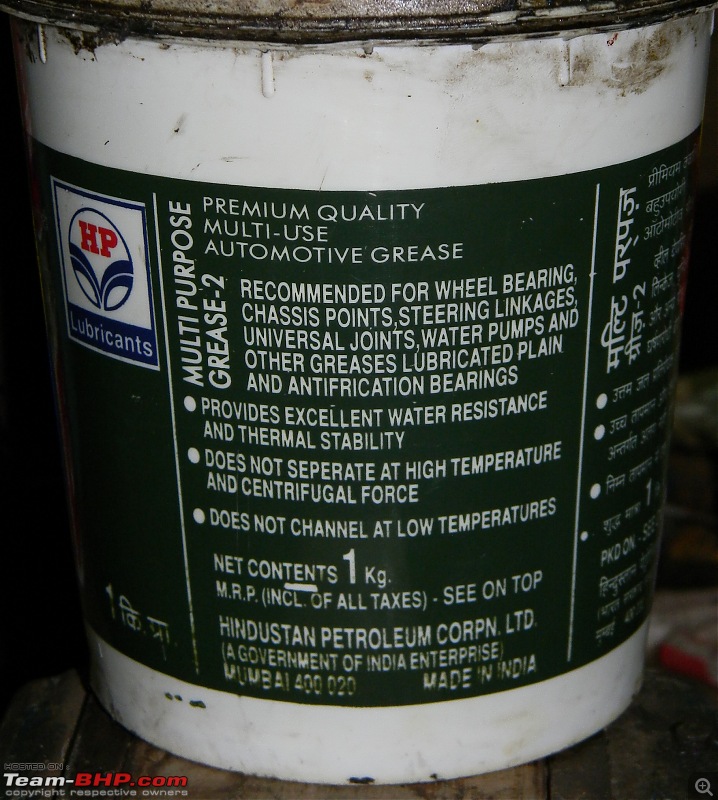

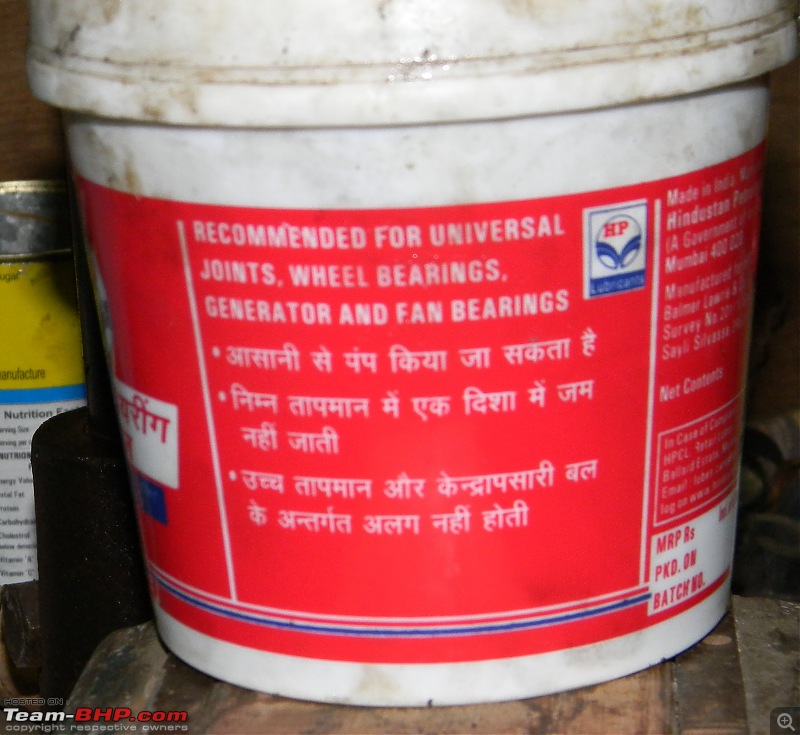

Other available from the H P

Notes :

#1)there was a grease available for the second purpose specially ---- called Castrol chassis grease -- see if its still available -- otherwise use # 1 moly grease or the one used in front wheel drive car's CV joint or # 2 any multi purpose one -- castrol ( yellow ) is good

do not ever use the locally made greases .

Lastly never grease at the ramp guys -- they have these cheaper greases .

#2)Keep your own small grease gun , filled with wheel bearing grease , especially for propeller shaft greasing points --- those will last for years if you do them for every 1 k km , in toughest conditions

#3)if you are really interested / capable in doing it , keep two of them --- but remember wheel bearing grease is for the prop shaft cross bearings mainly / only .

# second grease gun goes with a thinner water resistant grease for all those leaf spring points & steering linkages .

Hand Held Grease Guns For DIY

These hold some 200 Gms of grease , can be kept in tool kit & used at service ramps at your own will .

Note from Mod : Thread moved to 4X4 technical forum. Thanks for sharing

Something to add to.

If any one wants to do the grease the DIY way , here is a tip

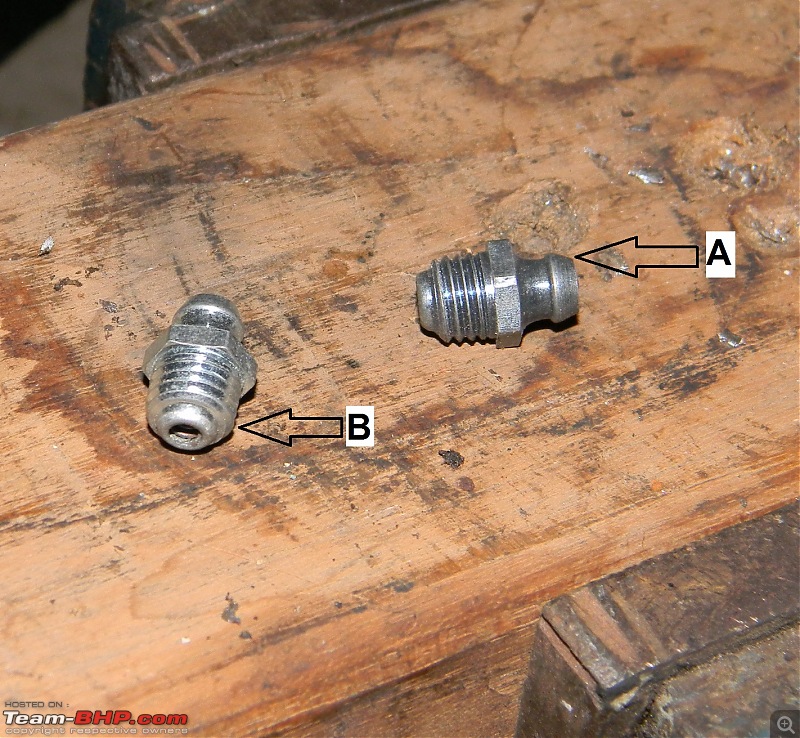

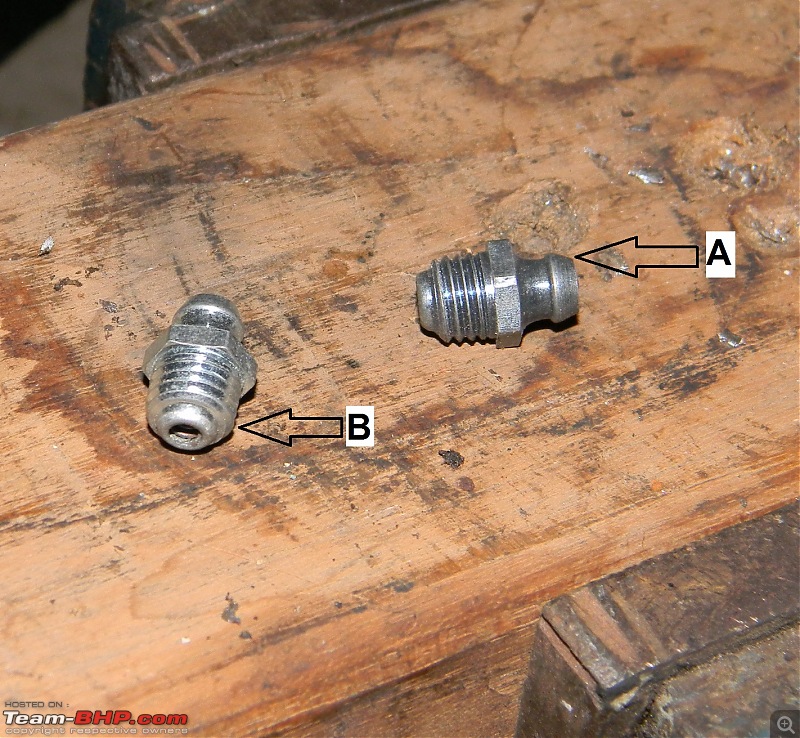

# remove the original grease nipples & take them as samples to the Jeep parts shop

# buy spare grease nipples , exactly matching the sample [threading particularly shown

B in the pic].

# This will help you in greasing when a particular nipple is jammed or damaged. Simply remove the damaged [this portion

A in the pic]/ jammed nipple, replace with spare & continue .Re fit the original after greasing if you want to

# Spanners needed will be 6,7,8,9 or 10,11 mm max

Here a pic

If I can add...

Grease nipples are rarely found in automobile spare parts shop. May be because the Jeep is a dying brand!

They are plenty and in a INDUSTRIAL SUPPLY shop. I guess heavy machinery uses them! I picked up around 10 the time i realized they are not a regular spare part. Costs about 2Rs each.

Sudershan ji,

Very informative thread.

Could you also please share how many types of grease guns available? I regualrly depend on ramp guys, however always avoided the ones standing on highways the reason is that they boil discarded potatoes:D, mash them and mix with their cheap grease and take you for a royal mushy ride.

I have seen a grease box push-cart manual,non pneumatic type, however you have to pump in one hand and hold the nozzle in other hand at the grease nipple. I dont think I can put it to use single handedly.

Andy

OT: Do you have a compressor in your tools collection?

@SV, grease nipple available in JC road 3rd cross, opposite Chandra Glass house. Ask there for Sardarji's dukaan, anybody will point you out over there.

Quote:

Originally Posted by svsantosh

(Post 3197461)

They are plenty and in a INDUSTRIAL SUPPLY shop. I guess heavy machinery uses them! I picked up around 10 the time i realized they are not a regular spare part. Costs about 2Rs each.

|

Sir, you got them from Bangalore or Hosur?

and where if I may?

Quote:

Originally Posted by svsantosh

(Post 3197461)

If I can add...

Grease nipples are rarely found in ===

===They are plenty and in a INDUSTRIAL SUPPLY shop. I guess heavy machinery uses them!

|

Yes ,as progress is made in automobiles in general, greasing (points) is becoming a thing of the Past .First steering linkages became free from greasing points , then the Kingpin etc . Sealed for lifetime lubrication parts are fast becoming the order of the Day.

But we Jeepers (& classic vehicle owners) still have plenty of service greasing left on our vehicles.

My Jeep has ,6 steering linkage points + 6 Prop shaft points + 12 points on leaf springs ( shackles & all that ) + a point on the T case shifter rod pin . All these parts will COST if not greased in time & at timely intervals.

More than costs to bear, there will be a break-down in the middle of nowhere & you will be royally stuck .

Quote:

Originally Posted by Grace

(Post 3197485)

Sudershan ji,

Very informative thread.

Could you also please share how many types of grease guns available?===

==with their cheap grease and take you for a royal mushy ride.

OT: Do you have a compressor in your tools collection?

|

Thanks.

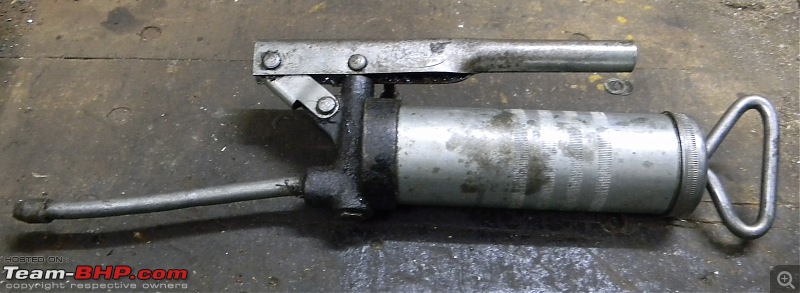

Here is some more gyan as per your request :D

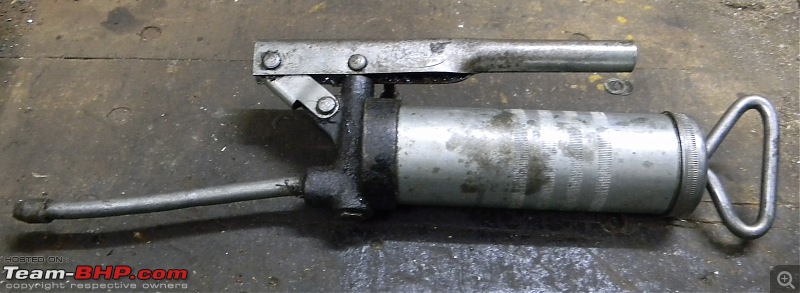

Adding a pic of a larger grease gun, which I also use. This one has a handle to pump grease. But this is a cheap local copy of some good " English " design .

I use this mainly to pump grease & oil mixture in the Jeep's & Land Rover's front closed knuckle, where two very vital parts get lubricated . One is the King Pin bearings & second is the Universal joint on the front live axle . This is also a neglected area.

# Caution , over lubrication of the front closed knuckle has its own perils.

Here to share, a larger grease gun (mostly used by the " Line " truckers)

Sudarshan

P.S. : Grace; I do have a compressor in the "garage"

You get smaller lever type grease guns also. The push type don't work well.

Regards

Sutripta

Quote:

Originally Posted by Sutripta

(Post 3197887)

You get smaller lever type grease guns also. The push type don't work well.

Regards

Sutripta

|

Totally Disagree SIR , they do work well :)

Anyways, after my first bike came in 85 (Yezdi 250), my good friend's father gifted me one of such smaller grease gun, actually he was quite amused with my chidish efforts in " Maintaining " the bike " properly". Then came the Jeep in 89 & I bought another & started using it.

Moral of the story; using these since then & also tried my hand on the other types with few friendly mech's courtesy. So I found them quite convenient.

# These are smaller in size to be carried with the vehicle, it doubles as a storage of grease in case of need en route .

# These contain very less amount of grease , so wastage gets controlled & one gets proper track of consumption (my pockets were always less filled)

# Another feature is these do not have a spring " preload " on plunger, so oil from the grease does not drip in storage (Kit). It happens in handle walla type

Note ; most of the time jammed nipples or bushings/parts need excess pressure, but if done regularly one just needs few strokes & the grease erupts from the other side.

Sudarshan

Sudershan ji,

To what use have you put the compressor to? Is it for painting, tyre pressure, or do you use a powered pneumatic grease pump?

Actually I am in the market for a compressor, are there any pointers to what I should look at or merely size of the airtank? I have seen LG and Hitachi. Hitchi has better finish,looks good etc, however LG looks more functional. My budget would around 25k (i need attachments for car pressure washing,painting etc).

Any inputs from you will be greatly appreciated.

EDIT:

Would you please share what kind of compressor would be rough n tough, long lasting. Whether Rotary or single / double piston... in short I am totaly confusedplease:

Andy

Quote:

Originally Posted by Grace

(Post 3198233)

Sudershan ji,

To what use have you put the compressor to?

Actually I am in the market for a compressor,=====

==My budget would around 25k (i need attachments for car pressure washing,painting etc).===

Any inputs from you will be greatly appreciated.===

EDIT: ==

===. in short I am totaly confusedplease:

Andy

|

Sirji, you are asking for more Gyan & probably making some people uncomfortable, because they know I am going to answer for sure & shine myself :D

Anyways, answers; (trying to be short)

# 1) Mine is a half hp unit with a 50 Lit tank . I use it for pressure cleaning of parts , spray paint & Tyre filling

# 2) for Pneumatic tools, you will need a 2 hp minimum unit with a 100 lit tank as per my commonsense

# 3) for 25 K you will get the above, but it will occupy a 3 x 5 feet space

# # my advice , get a 1 hp unit that will be enough for spray paint ,Tyre filling . Pneumatic tools is an investment done against amount of work which we dont have

## also electrical load will be a concern along with single phase / 3 phase issues. Any 1 hp single phase motor typically consumes 4 amps of current & for the start it takes more than 12 amps . be sure of your house electricals are worth that load.

## always choose a brand that is locally repairable.

Sudarshan

Quote:

Originally Posted by Sudarshan

(Post 3198277)

Sirji, you are asking for more Gyan & probably making some people uncomfortable, because they know I am going to answer for sure & shine myself :D

Anyways, answers; (trying to be short)

# 1) Mine is a half hp unit with a 50 Lit tank . I use it for pressure cleaning of parts , spray paint & Tyre filling

# 2) for Pneumatic tools, you will need a 2 hp minimum unit with a 100 lit tank as per my commonsense

# 3) for 25 K you will get the above, but it will occupy a 3 x 5 feet space

# # my advice , get a 1 hp unit that will be enough for spray paint ,Tyre filling . Pneumatic tools is an investment done against amount of work which we dont have

## also electrical load will be a concern along with single phase / 3 phase issues. Any 1 hp single phase motor typically consumes 4 amps of current & for the start it takes more than 12 amps . be sure of your house electricals are worth that load.

## always choose a brand that is locally repairable.

Sudarshan

|

Thank you for the valuable info shared.

As I went around the market today, I saw plenty of compressors with single and dual cylinder. There are various tank capacities. I understood your logic for pneumatic tools. However I am still unclear on what kind of pressure will be generated for car washing. The guy I spoke to referred as 8kg output for a model having 20 litre tank capacity cost 13k+taxes. The brand however sounded local (Metro) have you heard of it?

I have 3 phase & 4KW supply at my house, so power is not a problemclap:

Andy

Any idea on pressure output used by commercial guys?, I think preassure also depends on the kind of nozzle for water outflow.

Your thoughts please and any photos greatly appreciated. Also please share in detail, Short answers well accepted only in UPSC exams.

Quote:

Originally Posted by Grace

(Post 3198576)

Thank you for the valuable info shared.==

===Your thoughts please and any photos greatly appreciated. Also please share in detail, Short answers well accepted only in UPSC exams.

|

This air comp/ pressure pump , is looking bit OT here :D

BUT

Will certainly PM you shortly

Till then hold the horses,:D-- I mean Qs.

Sudarshan

Is there a separate thread for that? TBHP continues to fascinate me no end

Andy

but please remember to pm

Thanks Sudarshan Bhai.

Quote:

Originally Posted by Sudarshan

(Post 3197843)

My Jeep has ,6 steering linkage points + 6 Prop shaft points + 12 points on leaf springs ( shackles & all that ) + a point on the T case shifter rod pin . All these parts will COST if not greased in time & at timely intervals.

|

Any way you can put up pics of the exact locations? Would be great and very helpful for someone like me.

Quote:

Originally Posted by Sudarshan

(Post 3197843)

# Caution , over lubrication of the front closed knuckle has its own perils.

|

Can you elaborate why and what are the downsides of over-lubrication?

Good thread.

Cheers,

Adi

| All times are GMT +5.5. The time now is 05:47. | |