Quote:

Originally Posted by Samurai  This part just went over my head. Can I see a circuit? Because I can analyse a circuit well enough. Today when the mechanic called me, I told him to replace the solenoid switch with the Premier Padmini diesel car solenoid switch. But I couldn't explain why or how. Meanwhile, he says all my brake liners are torn, need to replace them. Two of the axle bearings in rear and one in the front have also gone bad. How many axle bearings are there, is it 4 or 8? The differential side has bearings? Just wondering. |

Dear Sharath - I have made the circuit diagram on a piece of paper which I can scan and post to you if required. I am describing here in detail. It should be sufficient for a good technician to understand and implement. Please follow this process to integrate the Lucas TVS solenoid in the starter circuit.

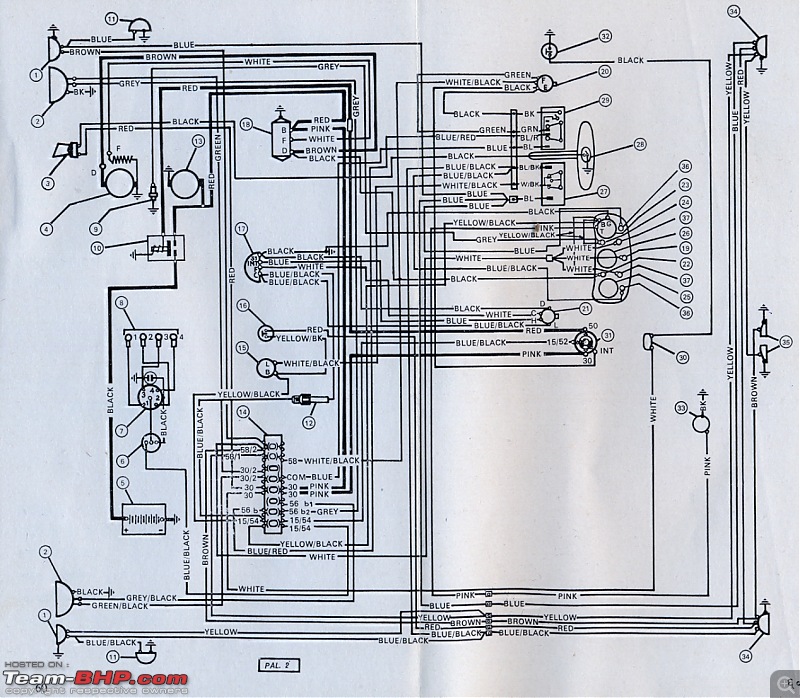

Existing system: There are 3 aggregates, the battery, the ignition switch and the starter motor.

Battery: Negative is connected to chassis and body as earth. Positive is connected to the main input terminal of the starter motor solenoid.

Ignition Switch: Terminal "30" is connected to battery positive. Terminal "15/50" is connected to the FIP solenoid. Terminal "50" is connected to the small solenoid actuating terminal of the starter motor solenoid.

Starter Motor: As explained, main terminal is connected to battery positive. Small actuating terminal is connected to the "50" terminal of the ignition switch. Second main terminal is connected to the starter motor brush positive. Starter moror body is connected to earth.

How to introduce the Lucas TVS solenoid in the starter motor circuit: Remove the battery terminals before starting this work on the car. Fit the Lucas TVS solenoid in the engine compartment, preferably near the battery. Vertical orientation is necessary for optimum performance. Remove the small wire from the starter motor solenoid and connect it to the small terminal of the Lucas TVS solenoid. As this wire comes from the "50" terminal of the ignition switch, instead of energizing the starter motor solenoid, it will now energize the Lucas TVS solenoid. Connect one of the major terminals of the Lucas TVS solenoid to the battery positive terminal with a thick automotive grade Finolex make wire (battery cable is not required, 84 specification will be sufficient). Connect the other major terminal of the Lucas TVS solenoid to the small terminal of the starter motor solenoid with a thick automotive grade Finolex make wire (again battery cable is not required). This is the terminal which has become free when you removed the original wire from it. That's it. When you turn the ignition switch, it will energize the Lucas TVS solenoid which will shunt the current to the starter motor solenoid which will in turn energize it and operate the starter motor drive gear. The advantage of this system mainly results in improved life, reliability and performance of the vehicle's starting circuit. Be careful to provide for eyelet terminals at the solenoid points, solder all joints, route and tape the additional harness properly. It must look like a work of automotive art. I have done it in my rally cars so I know.

Brake liners: Be careful, stay away from aftermarket liners, they will lead to "morning sickness" (grabbing in cold condition with high humidity). Use OE parts and rivet them on a press, not with a hammer. Tell Richie to help you out.

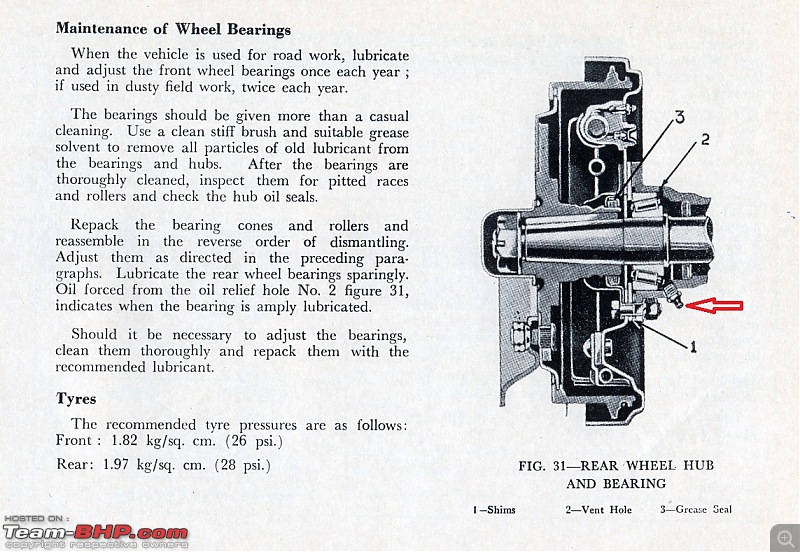

Wheel bearings: Front - there are 4 wheel bearings, 2 inner, 2 outer. In normal use, they must last for around 100000 kms. In CL340, as FAW is very much in design control, there have been instances where wheel bearings have exceeded this usage.

Rear - CL340 uses semi-floating axle shaft so there is 1 bearing each at the rear wheel ends. In addition, there are 4 bearings in the final drive assembly, 2 for the pinion and 2 for the crown wheel. The final drive bearings have design life of infinity, means that if properly lubricated and not overloaded, they shall last for the life of the vehicle which is 3,50,000 kms.

Please do not open the final drive module of the rear axle without proper root cause analysis. Overhauling a rear axle is not everybody's cup of tea. If preload is not set properly, it will play havoc with the axle and destroy it. I suggest you assemble "high mounted breathers" (plastic pipes mounted on the breather couplings, routed to high points in the chassis and clipped properly) to both the axle tubes / transmission / transfer case to completely prevent any water ingress in these aggregates. You can change rear wheel end bearings, they have a design life of around 100000 kms but considering the almost inept condition in which you picked up your vehicle, it is better to replace them and be done with it once and for all, as you intend to keep your vehicle in perfect order for a very long time.

Best regards,

Behram Dhabhar

PS - your vehicle must be prepared to such an excellent / perfect state of tune that if you want to go anywhere at any time, you just connect the battery terminals, add fuel and drive, that's all! By the way, that's how a certain black "MH01V521" went for the AKC/EXAMM and also to Hyderabad last year. Appearances can be deceptive. That's how a certain white "MH14CSXXXX" runs now also!

.

(6)

Thanks

(6)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(3)

Thanks

(3)

Thanks

(4)

Thanks

(4)

Thanks

(3)

Thanks

(3)

Thanks

(5)

Thanks

(5)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

.

.

-- only later to be converted to FFRA by me )

-- only later to be converted to FFRA by me )

- no wonder, during the recent FFRA rework I noticed water+grease paste over the axles (but thankfully due to inner oil seals - diff oil escaped) - (and thx to outer seal - hub grease too escaped)!!

- no wonder, during the recent FFRA rework I noticed water+grease paste over the axles (but thankfully due to inner oil seals - diff oil escaped) - (and thx to outer seal - hub grease too escaped)!!