Hi Arka,

Ref -- (In Post 438 you will notice the hub has 5 wheel studs in it, which may mean the brake drum will sit over this hub, which seems the normal OE Way)

Have seem to hit a roadblock IMO and mechanic says/shows not so!

Quote:

|

1) Turning the drum inner dia for the new hub to fit

|

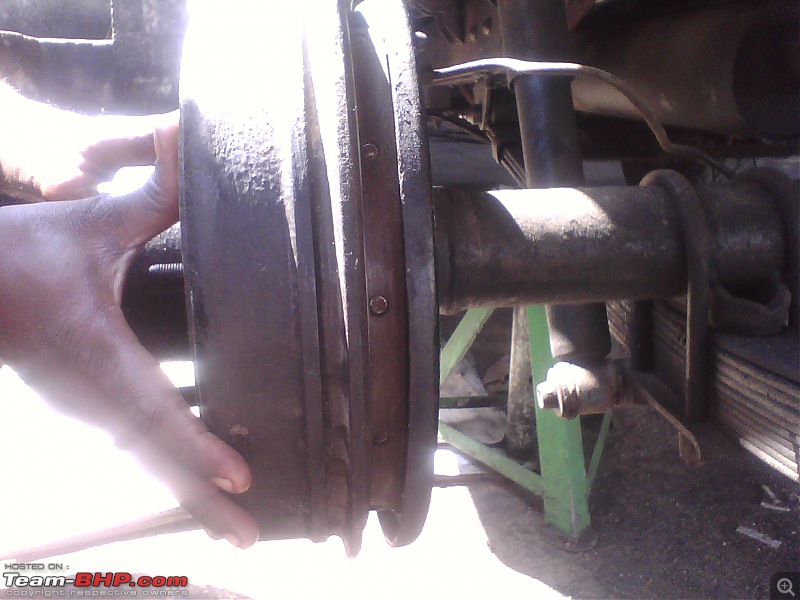

I made this comment because (the red line in pic^) was too large to go thru the current brake drum in my jeep. And me and mech went to the lathe shop to explain what needs to be done and the operator gave a wrap on the knuckle and

showed my mech this hub "is not supposed to sit/go thru inside the hub, but rather SIT OUTSIDE it.

How does the FC/Armada/etc hub and brake drum mate with each other?

Despite the lathe operator's words, my mech (and me), did what we had in mind and machined the drum for the hub to go thru!!

Now...!!

We came back, put the hub thru the drum (& studs), and placed it on the spindle only to find that the drum wont even reach the brake shoe area, or nearly just did, about a MM or 2!!

So, the operator was right, he had worked on a few pickup/bolero/FC van type hub/drums and he knew what he was saying...

Does this mean the brake drum between the rear of a 540/340/FC/Armada were ALL SAME? Only the hub position on drum differed?

I know, too many questions, but we roped in the boss (he doesnt come in until me and my employee-mech have thrown up our hands!!) - and he said all the pickups have the hubs over the drums!! So it is the studhead-drum-hub on the outer...

Even though we ended up turning a perfectly fine drum inner dia - it doesnt mean much now I think... I dont really know, I need to check on a TD.

As of now, the right (short axle) is completed and ready to take on the wheel, I am waiting to complete the right (long) side and do a on-jack test for any abnormalities! Not ready to take the jeep out on roads yet!!

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

I need to learn pnuematics and what components other than a compressor make it complete. I know for sure some metal pipes and a TANK are needed, but what about the auto-release valves and safety gauges... any pointers, anyone?

I need to learn pnuematics and what components other than a compressor make it complete. I know for sure some metal pipes and a TANK are needed, but what about the auto-release valves and safety gauges... any pointers, anyone?