| Engine inclination and vibrations

Quote:

Originally Posted by fazalaliadil  Spike,

Thank you for your concern.

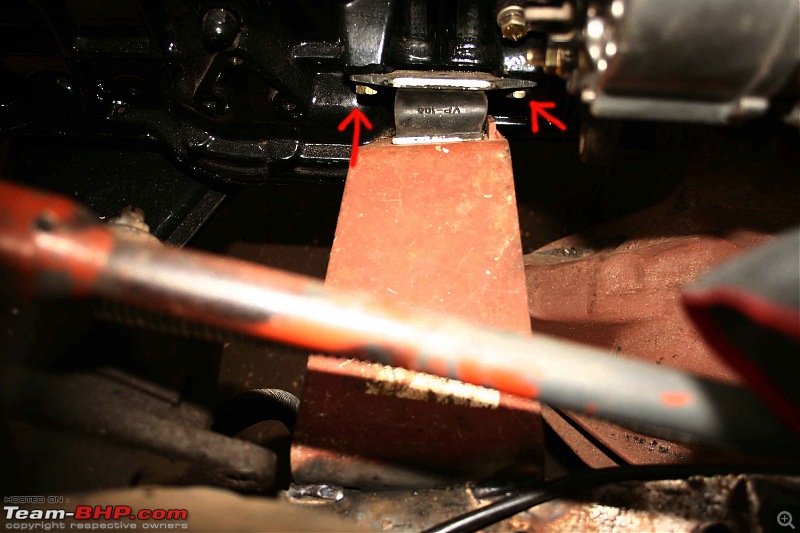

These brackets are original what come on the 540 and have been purchased from a Mahindra dealer here.

Important point brought up by you is, the value of engine inclination. What should it be, can you please elaborate on that and should I use a bubble gauge what should be the level of inclination or should the engine be zero level (bubble bang in center) ?

Regards, |

IIRC, original Jeep specifications refer to a 6 1/2 degree inclination (North-South). The specifications for CJ3B and MM series are also the same, the maximum variation that I can think of is +- 10' (minutes). The bubble gauge should give the same readings when measured from both sides of the engine. This means the installation of engine mounting brackets is correct.

In a manufacturing set up a lot of jigs and fixtures are used which also take care of manufacturing tolerances. A slight deviation even in minutes could lead to catastrophic results on a large scale setup. Although, I don't have the faintest of doubts on the workmanship, but still I would insist you to get this checked, if possible. The feeling of doing a perfect job is priceless, and you know that very well :-). Quote:

Originally Posted by headers  A noob question spike.. if the spike arrestor is set properly then does it matter if the engine has a slight tilt?

There are some modern engines that are mounted at an angle - But fortunately there are FWD vehicles

OT:

Another question - Why does the XD3P oscillate from side to side when floored? |

Vikram, engines may be kept at an inclination or otherwise, all depends on application and packaging factors. The spike arrestor will still work  , but for it to work perfectly the engine inclination must be correct.

The answer to your question on engine oscillations with a XD3P attributes to a beautiful theory on Vibration Isolation and Transmissibility. Without getting into much details, I would try and explain this in a simple way. The engine/transmission etc are mounted on resilient rubber mounts. As the torque produced by an engine fluctuates (fluctuation path traced by a sine curve) these disturbances travel through the brackets through the resilient mounts, the mounts flex unflex giving the oscillations. Hence, it is the property of the damping material (Hard/soft) which determines how the system vibrates. Also the amount of shocks/disturbances which transmits through depends on the material properties of the dampener, this is called as Transmissibility. I am attaching a pic which shows how a system vibrates under various conditions (hard,medium,soft)

Spike

PS- Have you ever noticed special care being taken while installing the foundation members for heavy machine beds? ^^ is the exact reason for doing this. |

. Refer my previous post, I've mentioned that the material in both the transmissions is the same. I have the Transmission from the NGCS army right in front of me, hope you will see a similar one soon.

. Refer my previous post, I've mentioned that the material in both the transmissions is the same. I have the Transmission from the NGCS army right in front of me, hope you will see a similar one soon.