A closer look at what our tees are all about, as well as some interesting titbits we learned along the way:

Fabric

• Our tees are 100% combed cotton. Soft, breathable and ideal for Indian climatic conditions.

• GSM (grams/sq m) is an incomplete way to gauge fabric quality, as it's based purely on weight. It's like judging a car based on kerb weight alone

. We've ignored GSM and instead focused on all the individual parameters that make a great fabric.

• Yarn count is pretty damn important. The higher the number, the finer the yarn. Cheap tees are made of coarse 20s yarn, while 24s yarn is used in your average tee. Our coloured tees are made from super-fine 30s yarn...

you can feel the difference.

• Our white tees are made from 26s, and that's because when we saw the 30s white, it was slightly see-through. So, we chose a little thicker 26s for the white instead.

• The thinner the yarn, the tighter it has to be knit. This higher knitting gauge helps the fabric hold its shape for longer too.

• The black fabric is a bit stretchier than the white. Some people even assume it has Lycra blended in, but nope - it's pure cotton!

• The fabric used is '

open panna' (non-looped panels). Meaning, it comes to the factory like a sheet, rather than a tube. This type of knit means the fabric is more resistant to torqueing. Ever have a tee where the seams that are supposed to be on the sides start to spiral around your torso after a few washes? That's torqueing.

• Trivia: When buying knit fabric for mass production, it isn't measured in meters... it's measured in tons! You get about 4,200 T-shirts per ton.

Dyeing

• Every colour can be made using several different 'dye recipes' (which are usually trade secrets). Even when dealing with a colour like black, there are multiple types (e.g. reddish & bluish blacks - each with their own characteristics). We chose between very similar looking swatches to get the richest, longest-lasting black.

• Interesting fact 1: Since white fabric requires less processes and time at the dyeing stage, it is cheaper to produce than coloured fabric.

• Interesting fact 2: If you use the exact same fabric to make white & coloured tees, the white tee will actually weigh lesser! This difference is due to the weight of the dye that attaches to the fabric.

• We've put our fabric through specialized garment lab tests to ensure it meets the standards for shrinkage and colour fastness, although if you're particular - it doesn't hurt to wash them separately the first time.

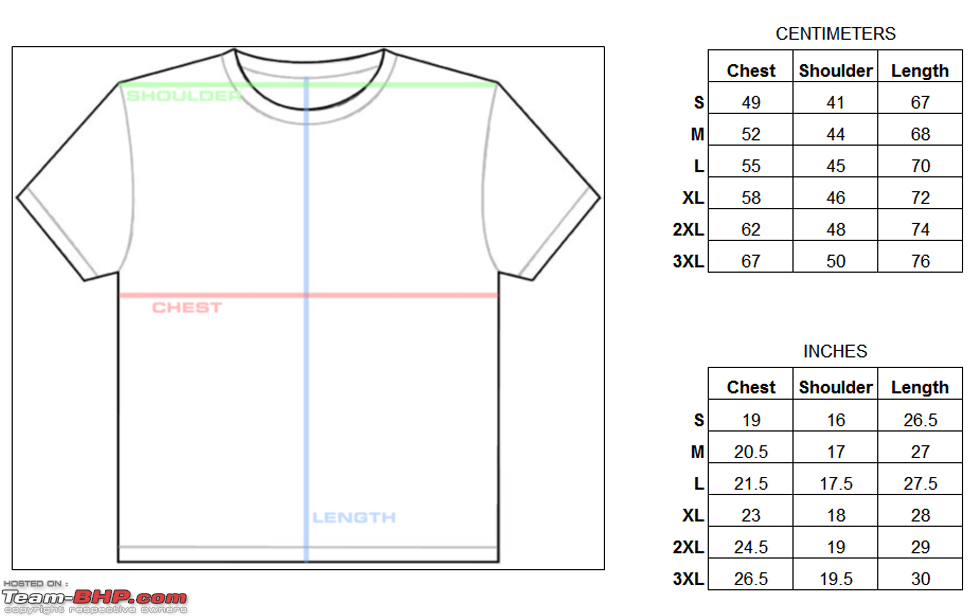

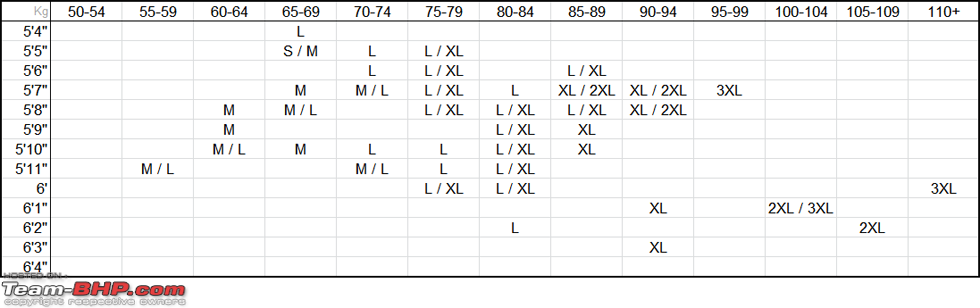

Fit & Sizing

• There is no standardized reference for sizing, resulting in a huge difference between brands and different parts of the world.

•

Fit is incredibly important, and we've customized ours specifically to the Indian frame. Read on...

• Usually, a 'fit' is perfected for a middle-size (e.g. Large) and then, simple additions/subtractions are made to the individual dimensions to create the other sizes. This formulaic approach is called 'grading', and it's rather lazy & inaccurate. People don't increase in all dimensions proportionally! Instead of doing it this way, we've fine-tuned the fit of

each size individually, based on feedback from several people who tried our samples.

• Manufacturers typically make just 1 pre-production set. Much to our manufacturer's chagrin, we went through

FIVE pre-production sets, making very minor adjustments until everything was absolutely perfect.

• We worked in centimeters (not inches). This gives a greater resolution, and also makes the workers be more accurate when cutting & stitching.

• My personal pet peeve is when t-shirt sleeves stick out with pointy tips - like they've been starched flat in 2D. We've adjusted measurements and tweaked cut patterns to prevent this from happening.

• There's a mentality in the garment industry of not making 2XL & 3XL too big, since the fabric saved there can be used to make additional smaller pieces (manufacturers get paid per piece). We've not cut corners here, and our 3XL is B-I-G!

Construction

• Fabric is stretched when it is knitted, rolled & packed, so it tends to contract when opened up. We made sure to unravel and 'relax' the fabric for a whole 24 hrs before cutting it, which lets it contract to its natural length (prevents dimensional changes later).

• There are several small tricks and construction processes that add to the longevity, comfort and fit of the tee. Our manufacturer had a handful of these, thanks to their years of experience, and they've all been applied to the Team-BHP Tees.

• Shoulder to shoulder tape adds to the structure, comfort & feel of the tee (a lot of tees don't have it, or have it just on the neck).

• Good production houses will cut all the pieces of a single garment from the same roll of fabric. This prevents colour variations on different parts of the garment. Think of it like painting a car! Two body panels that were not painted (dyed) at the same time will always have a slight colour difference. Now imagine that between the body and the sleeves of your tee.

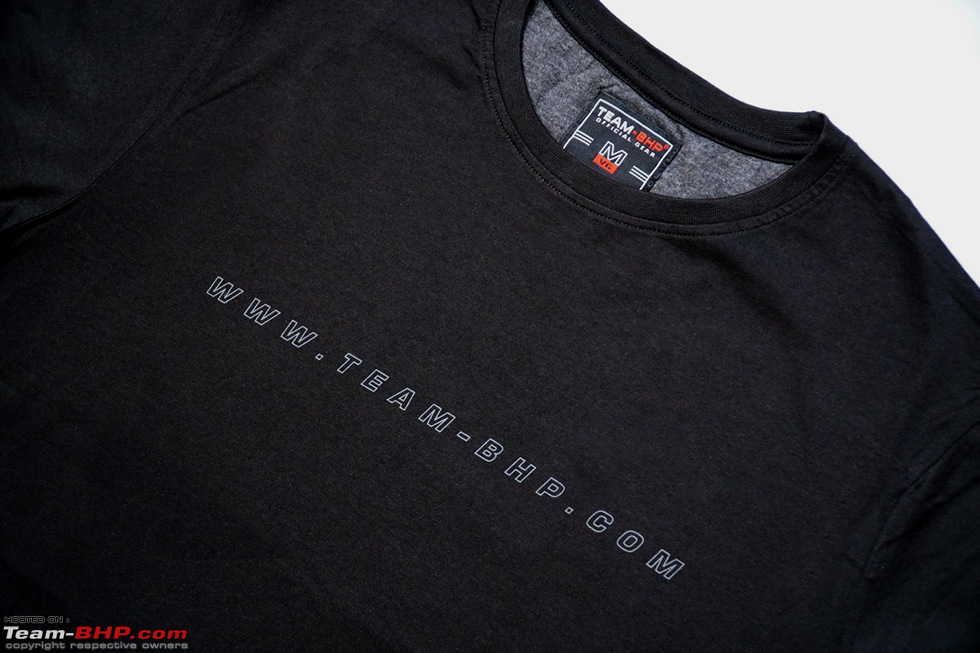

• The anthracite grey "moon-patch" inside the collar serves the purpose of preventing the label stitching from showing on the rear of the tee. The contrast looks awesome too (the white tees get a lighter grey, to prevent it from showing through the white fabric).

• The Team-BHP labels are digitally woven (rather than printed or heat-transferred). This means they won't rub off or fade, even after several washes.

• The printing of the designs is done on a totally automated machine where the screens and squeegee move automatically. This guarantees screen alignment, and provides consistency.

• We tried to stay eco-friendly by avoiding unnecessary tags and packaging material. There's still some room for further optimization here, which we hope to do soon.

(75)

Thanks

(75)

Thanks

(43)

Thanks

(43)

Thanks

(48)

Thanks

(48)

Thanks

(36)

Thanks

(36)

Thanks

(49)

Thanks

(49)

Thanks

(65)

Thanks

(65)

Thanks

(33)

Thanks

(33)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(3)

Thanks

(3)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

.

.

Looks awesome. For the price itís been offered, looks like a good deal. Looks really good on DBHPns in the pics. Will get mine soon. Looking forward for more great products from Team BHP.

Looks awesome. For the price itís been offered, looks like a good deal. Looks really good on DBHPns in the pics. Will get mine soon. Looking forward for more great products from Team BHP.