| Re: My Bicycle Hobby: MTB Minor Service - adjustment of controls

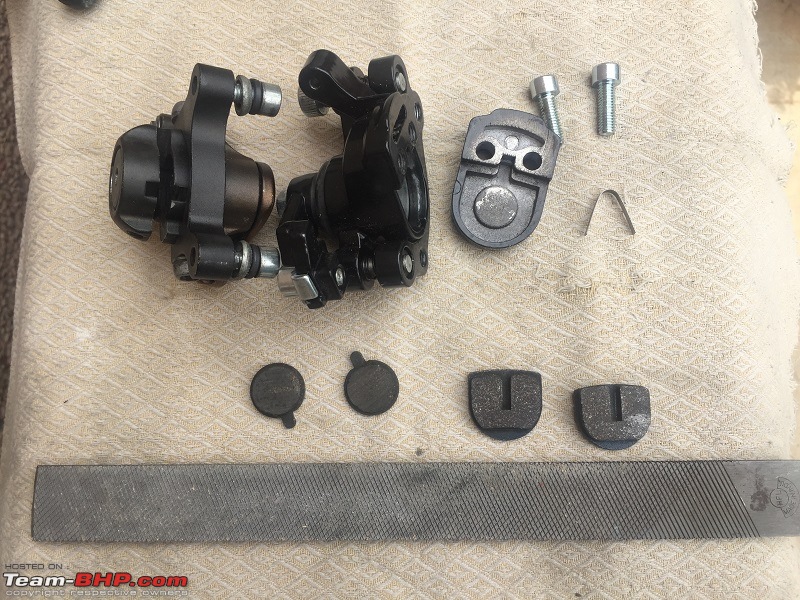

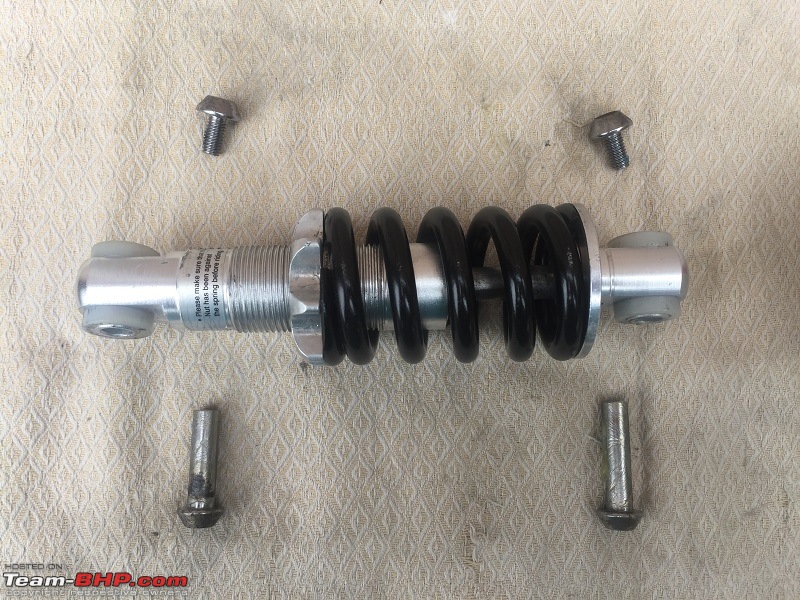

Now comes the tedious part. Adjustments to the controls of the bike require a thorough understanding of the components and how they function. Lets start with the disc brakes and then move on to the tricky derralieurs.

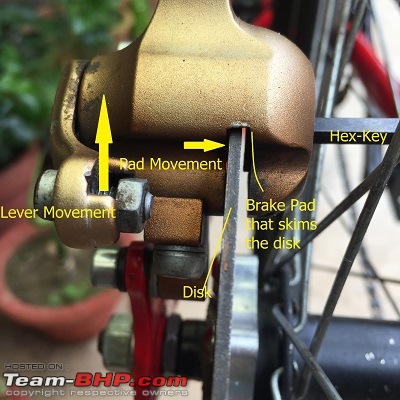

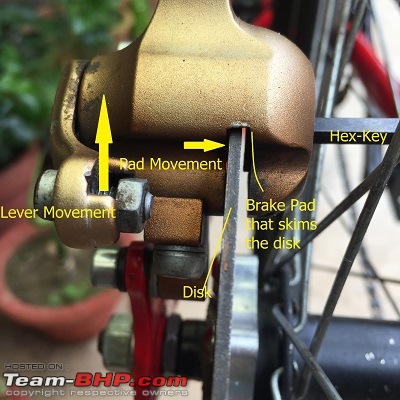

The rear caliper requires the cable to be clamped into the lever for operating it, but before that, the fixed pad needs to be drawn towards the disk. A hex key is required to rotate the pad backing plate which moves the pad closer to the disk. There is a similar arrangement for the moving pad too.

Thread the cable through the caliper lever clamp, move the lever up to make the pads calm the disc, retreat a little bit and tighten the clamping nut to secure the cable in the calmp. Test the rear brake and make adjustments if needed. That's the rear done.

Same goes for the front.

Move the lever up to make the pads calmp the disc, retreat a little bit and tighten the clamping nut to secure the cable in the clamp. Check that the floating action of the caliper is happening freely. If not, Slacken the cable a bit more.

Before understanding the derralieur adjustments one needs to get acquainted to the gearing convention on my bike. Greater Number = greater speed.

H / HIGH = gear which provides you more speed (smaller diameter on rear sprocket or bigger diameter on the front)

L / LOW = gear which provides you lower speed (bigger diameter on rear sprocket or smaller diameter on front sprocket)

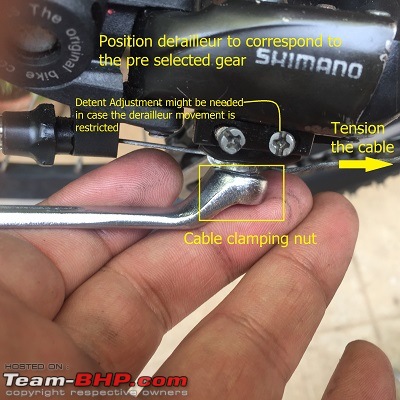

Select one gear for the front derralieur from the hand controls.

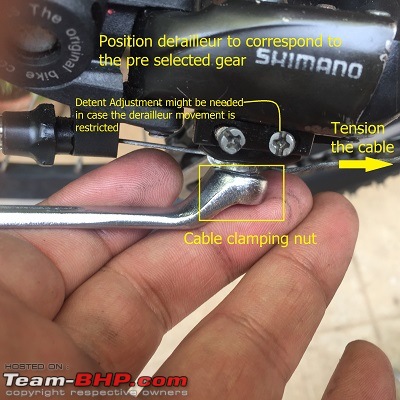

Thread the cable through the clamp. Move the derralieur to the position corresponding to the selected gear. Tension the cable so that the position of the derralieur is maintained and then tighten down the cable clamp. In theory, no further adjustments are required. however...

... one needs to be aware of the functions of these two screws. They look like detent screws. They restrict the movement of the derallaieur at its extremities thus determining its maximum allowable range of travel. The detent screws might be holding your derralieur back, thus not allowing the sprockets at that end to engage. On the other hand they might not be restricting it and an unchecked over-travel would slip the chain off the last gear (at the affected end of travel). A clearer picture is coming up for the rear.

Same goes for the rear. Select a gear..

Move the derralieur to the corresponding position and clamp down the cable.

High end detent screw doing its job (the chain is in the highest gear)

Low end detent screw at work (the chain is in the lowest gear)

Tidy up the excess cable like this if you cannot cut it off and solder the end.

And we are done. All the controls have adjustment screws on both end of the cables. These require a thorough re-visit (such as above) only once in 5-6 moths with my kind of usage of the bike (40-60 km per month).

Hope I was able to capture everything clearly. The tools required to work on bikes are very basic(Allen keys, screw drivers, pliers, simple spanners and an oiling can). Most of the parts are serviceable, and the confidence one builds up in the process of doing a DIY service on the bicycle can be carried over to take up bigger tasks like working on motorcycles and cars.

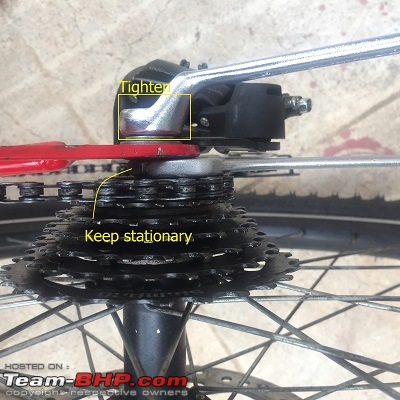

I still havent ventured to dismantle the crank assembly (pedal crank) and the head stock and front forks. Also I do not have the tools for opening the sprocket cassette. Over here I doubt one can find bike parts like in the Netherlands where there are dedicated shops which cater to smaller components. I have only seen plug and play accessory shops which deal with seats, lights, bottle holders etc. Would love to gather some leads regarding this. |  (16)

Thanks

(16)

Thanks

(12)

Thanks

(12)

Thanks

(12)

Thanks

(12)

Thanks

(14)

Thanks

(14)

Thanks

(27)

Thanks

(27)

Thanks

(5)

Thanks

(5)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

.

.