| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  229,036 views |

| | #211 |

| Senior - BHPian Join Date: Jul 2012 Location: Chennai

Posts: 1,762

Thanked: 4,719 Times

| re: The R-E-A-L BHP Giants: Maritime (Ship) Engines One of the best threads in team-bhp!Took almost an hour just to read some of the interesting bits of information about these floating wonders and its good to see that Mr.Vijay is patiently replying to all the queries  Last edited by giri1.8 : 9th November 2012 at 00:20. |

| |  ()

Thanks ()

Thanks

|

| |

| | #212 |

| Distinguished - BHPian  | So you like your diesel engines big and powerful? So I've been engaged in several threads here on various technical topics. I thought I'd share some of my past. In all honesty, it's a bit past my past, time wise, but still. I was a marine engineer until I "came onshore" as it is known, in 1986. But for the first eight years of my career i worked in engine rooms of all sort of ships. Made it all the way to Chief Engineer. Even today I'm licensed, though not current, to sail any Dutch registered ship, steam, diesel, electric or nuclear powered, as Chief! The below will give you some idea on what a modern two stroke diesel engine looks like. All the basics of your typical car diesel are there. But the scale of things is very different. If we would say on a ship, let's inspect the cylinder liner, we would actually, physically, go inside the cylinder liner. Not some two bit endoscope poking through the injector opening or so. Working on my car I use torque wrenches. On these monsters we use sophisticated hydraulic equipment for tensioning. anyway, hope you enjoy1 Jeroen Take an additional look at this: |

| |  (12)

Thanks (12)

Thanks

|

| The following 12 BHPians Thank Jeroen for this useful post: | amitoj, asingh1977, condor, GTO, oblivion, R2D2, scopriobharath, SS-Traveller, swarnava.m, Tapish, theexperthand, Warwithwheels |

| | #213 | |

| Senior - BHPian Join Date: Nov 2009 Location: Germany

Posts: 2,854

Thanked: 1,532 Times

| Re: So you like your diesel engines big and powerful? Quote:

If you could share some info about the fuel injection system, governor system and after treatment devices (if used), that would be great. How lean did these monsters run? Spike | |

| |  ()

Thanks ()

Thanks

|

| | #214 |

| Senior - BHPian Join Date: Nov 2009 Location: Adelaide

Posts: 1,193

Thanked: 706 Times

| Re: So you like your diesel engines big and powerful? Did you say two stroke? Could you shed some light on why it is not four stroke? I thought that four stroke engines are more efficient. But two stroke engines produce more torque. Is this the reason to use two stroke? |

| |  ()

Thanks ()

Thanks

|

| | #215 | ||

| Distinguished - BHPian  | Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Quote:

Quote:

On the fuel injection: Each cilinder has it's own dedicated high pressure fuel pump, typically driven of a cam. Each cilinder will have one or several fuel injectors. Maybe you have seen fuel injectors on a car. On a large car, maybe the size of spark plug. On these babies, the injectors could be well over 1 meter long, 15-20 centimeter diameter and weigh up to a 100 kilograms. Fuel tends to be directly injected. On the fuel; as stated on some of the previous pages, these engines run on what is known as heavy fuel. I won't bore you with the chemical details. Just think in terms of plain tarmac! Precisely, because that's more or less what it is. You have to heat it up to 100 - 150o C to be able to pump it! The high pressure pumpt get fed by a fuel circuit in which several low pressure pumps circulate the heated heavy fuel around. So just like in your car there is always a return feed from the high pressure pump back into the day tank. Using this heavy fuel means you need to keep these low pressure pump going, including the heating 24/7 even if the engine isn't running. Typically all the fuel lines are insulated and might even have heating elements around it to preven fuel solidifying. The alternative is that switch over to regular marine diesel fuel. Whilst the main engine was still running you would switch over the fuel supply to a tank with regular diesel. Takes a while to really flush all the systems. Governor systems are installed on all engines. When I went to sea, the transition from hydro mechanical to electronic was just starting. I've sailed mostly with Woodward governors. The hydro mechanical ones were extremely reliable, only maintenance was the occassional oil change. Not sure what you mean with after treat ment devices? I assume you mean anything in the exhaust? You will, always one or more turbo charges. Huge piece machinery. Depending on configuration you might have one turbo per two/three cilinders. In addition, some diesels have blowers installed that kick in at very low rpm. The turbo's simply don't spin fast enough and need a bit of help to blow fresh air into the cilinders. In my days nearly all merchant ships with these large two stroke engines also had an exhaust gas boiler. Typically fitted in the funnel. In the exhaust there are big doors that can divert the hot exhaust gasses to go through a boiler. Under full load exhaust gasses are upwards of 450 -500oC. Lot of energy. Sufficient to get a boiler going and to produce steam of 4-5 bars. The steam would be used, amongst others, to heat up the tanks and the fuel lines with the heavy fuel. These days you might find some more environmental protection equipement up the exhaust stack. Mainly against soot and ashes. Many port authorities monitor for "black smoke" and you could be fined heavilly. In an ideal world where everything is perfect a two stroke would be way more efficient than a four stroke. If anything you get a power stroke every second stroke rather than every fourth. In practive this, for many reasons this is not necessarily the case. Why they are used in marine application is because they simply pack an awfull punch. you get very low rpm with very high torgue. Meaning these engines are coupled directly to the prop shaft. There is no need for a (very expensive) gear box. They are also easily reverisble without the need of complicated adjustments on the valve and injector timings. These directly coupled engines can be started forward as well as astern. Also, they are more suitable to run on these very heavy (and cheap) fuels. I have run many different four stroke medium speed engines on heavy fuels as well. But it was never a big success. In many cases we referred back to just running them on plain regular marine diesel. The heavy fuel is very hard on everything in terms of wear and tear. | ||

| |  (10)

Thanks (10)

Thanks

|

| The following 10 BHPians Thank Jeroen for this useful post: | anky, Blue Thunder, condor, fiat_tarun, Ford5, Gannu_1, oblivion, rohanjf, rrsteer, Shridhar |

| | #216 |

| Distinguished - BHPian  | Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Was looking for some more information to share. Came across this really informative site: http://www.marinediesels.info They have very good detailed description and animation on both a two and four stroke marine diesel engine. If you're really interested go to the maintenance and repair section and have a browse. For instance the piston removal. The pictures will give you a good idea on how large all these parts are. At the very bottom you'll see the piston towering over the engineers. Also, you'll see the engineers using the hydraulic jacking equipment to undo/fasten bolts. It's the equivalent of using a torque wrench on your card. On these very large parts torqueing simply wouldn't be practical. What you do, by means of a hydraulic jack tension and stretch the bolt, tighten the nut (which as you will see is round!) and then release the pressure. You can very accurately calculate how much pressure is needed to stretch a bolt. Also, this way there is no additional load on the bolt other than to the level of stretching it. With torqueing you also introduce some twisting. So this method is much more precise, but does require very specialized hydraulic equipment. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Jeroen for this useful post: | mmmjgm, oblivion, Shridhar |

| | #217 |

| BHPian Join Date: Oct 2013 Location: Mumbai

Posts: 167

Thanked: 81 Times

| Also if interested there is Www.marineengineering.org.uk I used to use both the sites while preparing for my exams. |

| |  ()

Thanks ()

Thanks

|

| | #218 |

| BHPian Join Date: Apr 2011 Location: Bangalore

Posts: 484

Thanked: 268 Times

| Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Bumped into this thread and read it through in one go. I was telling a colleague that if there is something happening somewhere, there will be a TBHP member who was there or witnessed it. This thread proves that theory. Anyway, I have a question and though this thread is not really active (updates from Vijay) I need to ask it. These are big ships and need dozens if not more of crew. When you purchase a ship, do you purchase the crew along with it? Or do you have to continually staff your ships with your own crew? if its the later, i could be difficult getting rightly skilled people. If it was the earlier case, then how does it work? |

| |  ()

Thanks ()

Thanks

|

| | #219 |

| Senior - BHPian Join Date: May 2009 Location: Chennai

Posts: 4,534

Thanked: 5,544 Times

| Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines You buy the ship or have it built, and then crew it yourself! The crew can't really be bought , can they?! Even if you buy a second hand ship from another company, the crew will be employees of that company and may not be willing to come to your's! As an aside, you may be interested to know that specific classes of ships statutorily require certain positions to be manned all the time and those can't be left vacant under any circumstances. For example the posts of master (captain) and chief engineer. Those two posts must be manned, whether the ship is at sea or at port. Some other positions can be left vacant, with the job being shared among other crew members of the same rank. I am not a shippy but worked for the shipping division of our company for quite a few years, being in charge of payroll. I have been out of touch for more than a decade now. Current crew members can correct me if there is any change of rules. |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Gansan for this useful post: | Blue Thunder |

| | #220 |

| Distinguished - BHPian  | Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines A ship won't have the same crew all the time. The crew will rotate on and off. How much time you spent on board and how much time on leave depends a lot of which company you work for, which country the ship owner is from etc. Last weekend I happen to bump into an Indian marine engineer. We chatted for a bit. He told me he usually did 6-7 months on board and then a 3 months leave. I would say in most western countries that would be a bit better, say 4-5 months leave. The companies I worked for never rotated the whole crew. It was always a few individuals at a time. So every week a few left and a few new ones arrived. The main reason being that you want to ensure continuity. Although, I've also worked in the offshore and there typically the whole crew would get rotated in one go. I've sailed on ships under Dutch and various other flags, but in my time there was no rule that keeps the captain and chief engineer onboard in harbor. Might be different for Indian ships. There are minimum staffing requirements obviously. Under Dutch maritime law it would stipulate how many crew members with what qualifications need to be on board. Not sure how it is these days but it used to vary by gross tonnage and length overall. I.e anything considered a 'coaster' would requirer fewer crew with less qualifications. Again, not sure how it is in the Indian merchant navy, but in the Dutch merchant navy, other than the Captain and the Chief officer all the other ranks have merged, so there is no distinguision between engineer and nautical officers. Or to put differently, you would be doing your watches on the bridge as well as in the Engineeroom. Overseeing cargo loading, fixing stuff in the engine room etc. You would be surprised on how small crews are these days, even on very large ships. My first ship was the NedLLoyd Florida. I joined her in Singapore in 1978 or 1979. General cargo ship, about 120 meters, 12.500 tones, one B&W two stroke 12.500 HP engine. Originally this ship had a crew of 75, including stewards for the officers, two person laundry team, carpenter, four cook etc. etc. My last ship I sailed on was the SmitLLoyd 120 in 1986. A seventy meters, ocean going anchor handling vessel, with two main engines, 11.000HP each. We had a crew of nine: Captain, First officer, Chief engineer, second engineer, third engineer, oiler, cook and two sailors. That was all. Shift were 6 hours on, 6 hours off, 7 days a week. Unless we were anchor handling and all of us worked round the clock for as long as it took. Some of the largest containerships in the world only have a crew of thirteen! See http://www.emma-maersk.com/specification/ Jeroen |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank Jeroen for this useful post: | aaggoswami, Blue Thunder, Gannu_1, oblivion, Warwithwheels |

| | #221 | |

| Senior - BHPian Join Date: May 2009 Location: Chennai

Posts: 4,534

Thanked: 5,544 Times

| Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Quote:

I was given to understand bulk vessels spent considerably more time in our ports, so officers of those vessels will have to be onboard for longer durations to complete 183 days of foreign water stay. Calculation of this foreign water stay will create quite a bit of heartburn, as sometimes a fellow will miss out just by a couple of days and will have to shell out considerable amount of tax. If you cut some rope for them on that count, the tax authorities will have your hide! Therefore I visited all our vessels in Indian ports, met all the officers and with their consent, standardised the calculation like this: The duration between the first Indian port in, and last Indian port out, will be taken as Indian waters. If the ship arrives on the roads of a particular Indian port and the captain intimates the port authorities with a copy marked to office, the ship has arrived in Indian waters. It need not necessarily berth! If the intimation is before noon, the day will be counted as Indian waters. If it is after noon, it will count as foreign waters. Similarly while leaving, if the vessel reaches the roads and the pilot leaves before noon, the day will count as foreign waters; If after noon, then as Indian waters! And a few more stipulations, which I forget now; but you get the drift! A captain who served with us is even on TBHP now! A clue; he is the author of a Buick restoration thread! As for manning, once our gas carrier was waiting outside Fujairah, when the father of her master died. He simply could not be relieved from the vessel to reach Mumbai in time, as all flights towards Saudi were full; it was Haj time. We tried to send a reliever even through the other side of the world, via Singapore - Australia - US - but absolutely nothing was available. Without a reliever, the incumbent captain can't leave the ship. Finally he could arrive only ten days after the funeral. | |

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank Gansan for this useful post: | aaggoswami, Blue Thunder, DrPriyankT, Gannu_1 |

| |

| | #222 |

| Senior - BHPian Join Date: May 2009 Location: Chennai

Posts: 4,534

Thanked: 5,544 Times

| Re: So you like your diesel engines big and powerful?

Yes; that, and the ease of maintenance. That is why even the diesel locomotives of our railways are two strokes. |

| |  ()

Thanks ()

Thanks

|

| | #223 |

| Distinguished - BHPian  | Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Interesting, thanks for that. Even though the Netherlands has the busiest harbor in the world, Rotterdam, in all of my eight years of sailing I only departed from Dutch harbors twice. I always joined and left my ships all over the world! Singapore, Aberdeen, Great Yarmouth, Miami, New York, Tokyo, Durban, Colombo, Port of Spain, Port Gentil, Pointe Noire, Lagos, Bridgetown, Houston, the list goes on and on. At the time I was living in the UK and they had a similar rule for income tax. You could live in the UK but if you spent a certain amount of time per year outside the UK you were eligible for a much lower income tax bracket. I do remember it was just the total days per year, they did not have to be consecutive. Which was good as I was mostly working int he offshore in those days and they were shorter stints, about 9-11 weeks on board, with 4-5 weeks leave. Jeroen |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank Jeroen for this useful post: | Gannu_1, oblivion |

| | #224 | |

| Senior - BHPian Join Date: May 2009 Location: Chennai

Posts: 4,534

Thanked: 5,544 Times

| Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Quote:

PS: For land based employees like me, this NRI thing will apply only from the seventh year (I think), if I spend the previous six @ 183 days a year in a foreign country. Till then I will be taxed as a resident Indian. For merchant navy officers this rule is relaxed. They qualify as NRI from the very first year, if they spend 183 days in foreign waters each year. I am not sure if this applies to airline pilots as well. Last edited by Gansan : 4th November 2013 at 19:12. | |

| |  ()

Thanks ()

Thanks

|

| | #225 |

| Team-BHP Support  Join Date: Apr 2013 Location: Madras

Posts: 7,174

Thanked: 20,220 Times

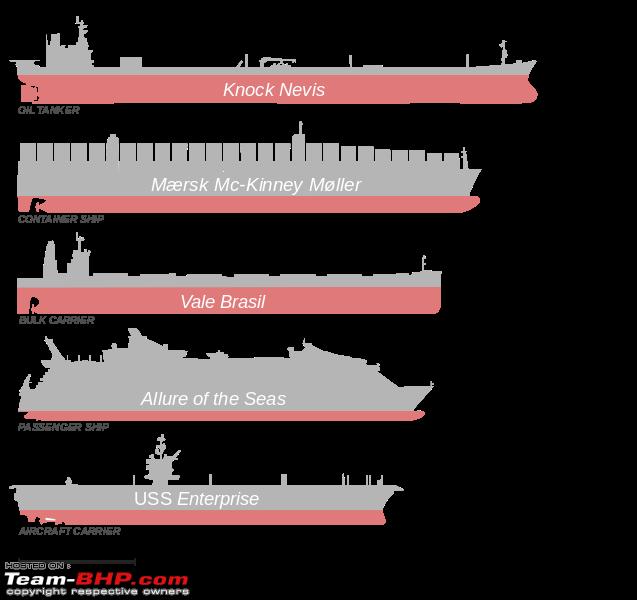

| Re: The R-E-A-L BHP Giants: Maritime (Ship) Engines Alright, I stumbled upon this thread some time back. Here’s my bit of contribution to the thread. I design ships for a living, have been in this industry from the start of my career spanning 5+ years and we rolled out a multi-purpose vessel for a Dutch heavy-lift company (Biglift) earlier this year, sometime during May. We did two more previously which were more or less similar but this one was on a different scale altogether, I couldn’t help but share it here! But first some blah-blah. Ships are magnificent constructions! Discounting the naval ships which aim to protect the country from the threats, commercial ships OTOH move cargoes worth millions of $ from one location to another. These could be virtually anything - raw material such as iron ore, grain, coal, leather, crude oil or perishable cargoes such as meat, fish, vegetables, fruits, dairy products or finished goods such as clothes, footwear, electronic appliances and devices, furniture, petroleum products or automobiles such as cars, trucks, earth-movers or even chemicals such as sulphuric acid, phosphoric acid, molasses etc. Then there are ships for merely sailing through a block of ice on the ocean and clearing the way for other ships called ice-breakers! There are research vessels which sail with an intention of carrying out research onboard. Ships are classified based on various factors - type of cargo is just one of them. Let us not get into the intricacies - it may become a bit too technical and unwarranted here! Ships can be huge, I mean very VERY huge! The largest ship ever built to date was the Knock Nevis (which has several other names as she exchanged owners!) but she was finally scrapped after reaching EOL (end-of-life) just as cars are scrapped in a scrap-yard after it has lived its life. Jeremy Clarkson who was the host for BBC’s Jeremy Clarkson’s Extreme Machines was fortunate to board this ship and an episode was telecasted on one season. Here’s a small excerpt from that episode, not lengthy but should give you an idea about the ship’s titanic dimensions! Knock Nevis built by a Japanese yard in 1979 (!), was 458 m long (that’s a little shy of half a km!), 68.8 m wide and 29.8 m deep. For reference, a standard soccer field measures 105 x 68 sq. m which means this ship could swallow 4 soccer fields and still have some space left. That is a lot of space because when the crew (a crude oil carrier hardly has 20 men onboard) has to man a ship of this dimensions, they really need not do any workout while sailing. Her anchor weighed in at 36 tonnes! The ship was broken at Alang, Gujarat during 2010 and the anchor was shipped to Hong Kong Maritime Museum where it is preserved. If we couldn’t build a vessel this big, let us at least have the honors of breaking it down!   And constructing behemoths of this size takes skill and experience - an art only the S. Koreans, Chinese and Japanese have pioneered to date! Some of the names we’ve heard before on this side build ships, heavy equipment and other constructions on the far side. Hyundai, Samsung, Mitsubishi, Fuji (owns Subaru), Daewoo etc. to name a few. Today, the world’s largest ship is Mærsk Mc-Kinney Møller (too lengthy a name, let us just call it MMKM for now), a container carrier named after the son of the founder of the APM-Maersk Group. Maersk is perhaps familiar to all of us and we’ve seen plenty of containers bearing this logo. They are the largest container shipping company today with a huge fleet. MMKM was built at Daewoo Shipping & Marine Engineering (DSME), S. Korea. With an overall length of 399 m, width of 59 m and depth of 30.3 m, she can carry 18270 containers with a crew of 19 members. She is propelled by two MAN diesel engines producing 29680 kW each. Here is an interesting time-lapse video of the construction courtesy Gizmodo: ------------------------------------------------------------------------------------------------------------------------------- Now, over to what we built here and delivered a few months back. We built a multi-purpose cargo vessel capable of carrying any type of cargo except crude oil and/or their by-products. This was a special type of ship because on her cargo hold, one could literally accommodate anything from military tankers to smaller boats to containers to cars to uranium ore, literally anything! She was capable of sailing in the artic regions and was designed to sail through oceans which had ice built up during winters. So we had an ice breaker on her bow. The basic specs. of the ship are as follows: Name: Happy Sky Port of Registry: Amsterdam Overall length: 154.8 m Overall width: 26.5 m DWT: 17775 t Lightship weight: 10471 t Cranes SWL: 2 x 900 t (can lift a combined load of 1800 t using a spreader beam) Cruising speed: 15.7 kn Max. trial speed: 17 kn Main Engine specs: Make: Wärtsilä 8L46C Stroke: 4 No. of cylinders: 8 Configuration: Inline Bore: 460 mm Stroke: 580 mm Speed: 500 rpm Power: 8775 kW (11767.47 bhp) Got bhp? YES Sir!  Torque: 603148 Nm @ 139 rpm Turbocharged, intercooled Ambient operating temperatures: -35°C to +45°C Crew complement: 34 Storage: Cargo hold capacity: 20561 cu. m Containers: 1237 TEU Can carry dangerous cargo including radioactive ores. Here are few snaps that were taken during her phase of construction and the sea trials:  Installing the blades of the propeller to the hub. The material of the propeller is Cunial which is a regd. trademark of Wartsila - an alloy of Copper, Nickel and Aluminium.  Note that the blades of the propeller can be rotated about a central axis. In order to stop the ship, the propeller need not be stopped from spinning. When the blades are oriented at a certain angle, the ship would stop its motion. Of course, reversing the ship requires counter-rotation which is enabled through the gearbox.  The blades are in place. The propeller measures 5 m in diameter.  During the painting phase. This happened immediately after the monsoons which explains the rusting on the living quarter decks.  The final coat of painting is done. There are multiple coatings applied just like an automobile.   The engine room. Those 2 green equipments are the aux. diesel generators. 6 cylinder inline turbocharged intercooled, producing 975 kW of power at 900 rpm. There are 3 of these which would be used when the ship is stalled and/or the cranes are being used. The cranes draw a lot of power during operation!  The third DG. Notice the hydraulic lines on top - these are meant for the hatch covers on the ship.  Those slots on the deck are meant for the main engine spare parts.  The spares are in place. Notice the connecting rod at the far right.  The silencer of the main engine exhaust.  The main engine! The engine is 3 storeys tall and that yellow equipment on top is the overhead crane for doing maintenance such as taking out the cylinder liners, pistons etc.  An alternate view. The turbocharger fresh air intake can be seen at the far right - the round thingy with the filter.  The piston with the connecting rod. The piston measures approx. 460 mm in diameter.  The forward store.  Notice the ventilation ducts.  The cargo hold. The small slots you see there are meant for supporting hatch covers in case the hold has to be divided.  The hold is now covered from the foldable hatch covers on top. The ship can sail with the hatch covers unfolded as well.  The anchor chain inside the chain locker. When a ship is stopped at sea, only one anchor is dropped (there are 2 at the FWD region) and ideally the anchor touches the sea bed. But sometimes it may not but regardless the ship's motion is stopped due to the waves. However, if the anchor becomes impossible to be recovered when it gets stuck at the sea-bed, the chain has to be broken to let go off the remaining links and the anchor.  The cold chamber of the galley. Perishable food items such as vegetables, fruits, meat and fish are stored here. There are different cold chambers operating at different temperatures. Meat chamber is kept at -22'C at all times - during the trials, I couldn't stand here for more than 15 seconds!  The mess room. The crew dines here.  The Chief Engineer's day room. The door at the far right leads to the bedroom.  The Captain's day-room. When the Captain is not at the bridge, he spends his time in this room. There is an adjacent bedroom where he crashes for the day.  While we were approaching the ship from the tug.  The hatch covers are now folded above the cargo hold. Notice the white blocks on the left - the cranes are outfitted here.  A random snap clicked at the sea during dusk. Every ship has to go through a phase of extensive testing and commissioning procedures prior to the delivery to the client, called the sea trials. When we buy a car, we take a test drive to ensure that the car suits our tastes and likes. When we buy a home appliance, we browse through the reviews on the websites, approach an outlet, see the appliance in person, take a demo of it and if we are convinced, we buy it. Similarly, when a customer asks a shipbuilder to build a ship as per the basic requirements, he needs to be convinced that the ship is built to the specifications, can take the specified amount of cargo and achieve the desired target cruising speed without violating the safety and pollution norms of the land. The sea trials of Happy Sky happened over a week’s time and there were a few minor niggles that had to be sorted out. Clicked this short clip while we were on a small tugboat headed to the ship: Once the sea trials were over, one last thing remained - outfitting the cranes. Sadly none of India’s present shipyards had the equipment to lift and install the 900 t cranes onboard her so she sailed to a yard in China where the cranes were outfitted:   And this is her sailing with the first cargo en route to Australia on her maiden voyage, shot by the client on a chopper:  A time-lapse video shot by the client: Let me know if you guys have any questions. I’d be glad to answer them to the best of my knowledge. PS: Jeroen Sir - Glad to have a marine engineer onboard! Some insightful information there. Last edited by Gannu_1 : 16th November 2013 at 11:22. |

| |  (18)

Thanks (18)

Thanks

|

| The following 18 BHPians Thank Gannu_1 for this useful post: | abishek2222, AlphaKilo, asingh1977, av8er, BeamerBoy, DrPriyankT, Gansan, giri1.8, jayakumarkp, Jeroen, manas27587, oblivion, prateekm, Rehaan, Ritzvxi, Shridhar, SmartCat, vibbs |

|