| | #226 |

| Distinguished - BHPian  | |

| |  (26)

Thanks (26)

Thanks

|

| |

| | #227 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,004

Thanked: 26,437 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #228 |

| Distinguished - BHPian  | |

| |  (1)

Thanks (1)

Thanks

|

| | #229 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,004

Thanked: 26,437 Times

| |

| |  (3)

Thanks (3)

Thanks

|

| | #230 |

| Distinguished - BHPian  | |

| |  (3)

Thanks (3)

Thanks

|

| | #231 |

| Distinguished - BHPian  | |

| |  (4)

Thanks (4)

Thanks

|

| | #232 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,004

Thanked: 26,437 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #233 |

| Distinguished - BHPian  | |

| |  (3)

Thanks (3)

Thanks

|

| | #234 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,004

Thanked: 26,437 Times

| |

| |

| | #235 |

| Distinguished - BHPian  | |

| |

| | #236 |

| Distinguished - BHPian  | |

| |  (2)

Thanks (2)

Thanks

|

| |

| | #237 |

| Distinguished - BHPian  | |

| |  (4)

Thanks (4)

Thanks

|

|

Most Viewed

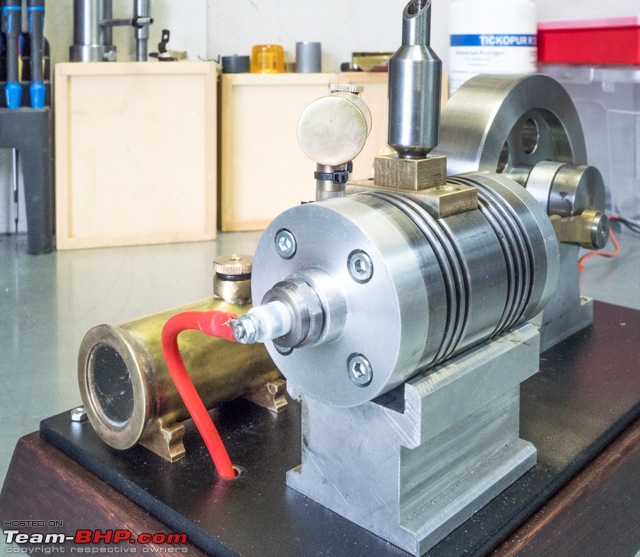

Brilliant, Jeroen.

Brilliant, Jeroen.

. This deserves a place in the Homepage of TBHP.

. This deserves a place in the Homepage of TBHP.