| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  15,780 views |

| | #1 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

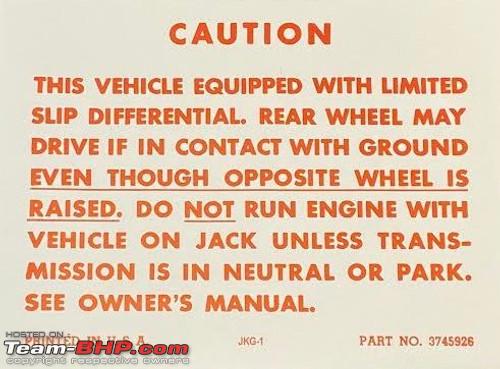

| Limited Slip Differential Install in Toyota Innova Why not traction control? 1) My Crysta is a 2016 GX it does not have traction control. 2) Traction control brakes the slipping wheel to transfer the power to the other wheel. 3) Whilst doing the above ECU reduces the engine power to limit the wheel spin and maintain traction. 4) Traction control or even a brake locking diff cannot do what a limited slip or auto(unlocker) could. Why a LSD? 5) It limits the slip and transfer a portion of the torque to wheel with traction. 6) Mechanical, simple, works. Does not reduce engine output if one wheel starts to spin. Note: Electronic limited slips are topic for another post or thread. 7) Traction control and limited slip differentials are different things and work differently. Some things can only be done with a LSD and traction control, if present, turned off. Cons? 8) Dont jack the vehicle with rear wheel in contact with ground and start the engine in gear or drive. Factory LSD equipped vehicles has a warning decal for this. Eg:  9) A RWD equipped with an auto(un)locker or LSD will powerslide accelerating hard with rear wheels on slippery conditions. A high power RWD equipped with LSD or auto(un)locker will do it on tarmac. Eg. Mustang fails on youtube :-) Note: This is a pro for a pro and a con for a noob. 10) Not a con but limited slips even on very mild offroading are seen as a joke by those who have experienced some very poor performing factory limited slip equipped vehicles with much marketing hype in the brochure. Whats a differential? A differential helps the driven wheels of a vehicle turn at different speeds so the vehicle can turn easy without the inside tyre scrubbing. Electric vehicles also have differentials unless they have a motor in each driven wheel. This 85 year old video explains the function of a differential better than any modern tutorial could. Around The Corner The disadvantage of open differential is that if either one of the two driven wheels is on a slippery surface or in air the differential will send the power to the wheel with least resistance. Which is why we see some vehicles stuck with one wheel spinning destroying the tyre and the surface while the other wheel is sitting there doing nothing. It can not transfer the power to the wheel with traction. Eg: A TUV3OO, this terrain shouldn't have been an issue on a vehicle with an open diff but I think TUV3OO has very limited articulation. M&M offers MLD to fix this. Xylo stuck due to parking spot selection error and bhpian tharian pulls it out with this Aspire. Innova stuck on uneven terrain requiring a lot of revving to escape the situation. This Crysta seems to be a ZX which has traction control but still spins. In all the above scenarios a proper working limited slip differential, a selectable locker, a MLD or an auto(un)locker would have saved the day. To be continued... Note: This post is in the DIY section because it was a DIY. |

| |  (38)

Thanks (38)

Thanks

|

| The following 38 BHPians Thank Sankar for this useful post: | AdityaDeane, amalji, anandhsub, arjunsatheesh, AROO7, CEF_Beasts, chinmaypillay, dailydriver, DicKy, Digital Vampire, famousshoes, GaryTSI, GForceEnjoyer, GTO, Guru_Shikhar, IcarusMan, landcruiser123, lonetraveller89, Mathan1130, Mi2un, RaceCyborg, raihan, ruzbehxyz, Samurai, sgmuser, shankar.balan, sierrabravo98, SS-Traveller, starter, Swarup5, tharian, tikku.dk, TrailBlazer007, TSIboy, Turbanator, vigsom, Vishal.R, WhiteSierra |

| |

| | #2 |

| Senior - BHPian | Re: Limited Slip Differential Install in Toyota Innova There are non off road applications for LSD too right. I had a civic with LSD in front and it steered like it was on rails. No wheelspin even on full lock turns. Have experienced what you're talking about whenever i tried to get an rwd vehicle into my house https://www.team-bhp.com/forum/techn...-inclines.html (Do RWD vehicles have lesser traction on inclines?) Last edited by greenhorn : 29th September 2022 at 16:53. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank greenhorn for this useful post: | InControl, k0p, Sankar |

| | #3 |

| Distinguished - BHPian  | Re: Limited Slip Differential Install in Toyota Innova LSD were pretty common on lots of cars in the 80-90s. Anything with a bit of power and rear wheel drive often had LSD. E.g. my Alfa Romeo Spider has LSD. You might still find them on modern cars too. Although in many cases electronics have taken over to provide the same and or even more and better functionality. Jeroen Last edited by Jeroen : 29th September 2022 at 20:05. |

| |  (8)

Thanks (8)

Thanks

|

| The following 8 BHPians Thank Jeroen for this useful post: | GaryTSI, InControl, landcruiser123, Maky, Mi2un, Reinhard, Sankar, vaasu |

| | #4 | |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| Re: Limited Slip Differential Install in Toyota Innova Glossary (not in alphabetical order) of a few terms which will be used in the posts below:- Differential/Axle housing = What seen under a RWD or 4WD as a large pumpkin connecting both wheels. The wheels, suspension, brakes are all bolted to the differential/axle housing and carries the load of the vehicle. Note: In a FWD the differential is inside the trans-axle/gearbox. Axle = Two long shafts within the axle housing connecting the differential inside the pumpkin to each wheel and not visible externally. Wheels are driven through these shafts. In a 4WD with transfer case front axles are either CV shafts or axle shafts open/closed knuckle joints depending on suspension type. Note: A FWD vehicle has CV shafts connecting the front wheels to the trans-axle. Differential = Short for differential carrier, located inside the differential/axle housing where all the driving and splitting happens. Differential carrier/Case = The differential carrier/case houses the side gears and the planetary gears on the inside and on the outside has ring gear bolted to it. The axle shafts go into the diff carrier and engages with the side gears. Crown/Ring gear = This is the largest diameter gear inside the diff housing, its bolted on the differential carrier and they always rotate together on the same axis. The ring gear is driven by pinion gear. Drive/Input pinion gear = This is housed inside the differential housing and sits perpendicular to the ring gear. The propeller shaft has one end connected to the gearbox/transfer case and the other end connected to the pinion gear inside the differential driving it. Ring gear and pinion as a set determines the final drive ratio. Note: FWD trans-axle does not have pinion gear, instead both ring gear and the gear driving it are helical gears and lie parallel to each other. Sun/Side gear = There are two side gears and are housed inside the differential carrier and axle shafts are connected/slide into to the side gears. They rotate on the same axis as differential carrier and ring gear but can rotate free from the movement of differential carrier. Planet gear drives the side gears. Planet gear = There is normally one pair of planet gears inside a differential carrier. Heavy duty differential carriers can have two pairs of planet gears. Planet gears are fixed on a spindle inside the differential carrier and lies in contact with the the two side/sun gears. The spindle move with the diff carrier and the planet gear fixed on spindle moves with it. The planet and sun gears have inter-meshed bevel tooth and drives the sun/side gear with it. When differential action is needed the planet gear allows the side/sun gears to rotate at a rate independent of each other and independent of the differential carrier. Most common types of upgraded differentials? The limitation of open differentials make them unsuitable for many applications from off-roading, most types of racing, military, mining etc. In rough roading an open diff equipped vehicle can get caught out. Front wheel drive vehicles fare better because they have the engine weight sitting on top of driven wheels. So for the serious enthusiast an upgraded differential is highly recommended. 1) Select able Lockers The off-roaders favourite is the select able locker. These differentials can be locked or unlocked, they are select able - on or off, till they are locked they work as open differentials except a very few which work as limited slips till locked. Once locked there will not be any differential action and both wheels turn at the same speed. When one wheel loses traction the driver will engage the diff lock and this locks the side gears to the differential carrier and the planet gears making them turn in unison transmitting the drive equally to both wheels. With both wheels receiving power the vehicle will pull itself out of the situation. Once clear the lockers are to be disengaged. The select able lockers are typically classified by how it is engaged. The most common types are:- a) Air locker - air pressure gets the locking done. Eg: ARB air locker b) E-locker - Electricity gets the job done using either an electromagnet or an electric motor. Eg: Eaton E-locker (electromagnet), Toyota OEM e-locking diff (motor), Auburn ECTED (e-locking limited slip). c) Manual locker - Pull a lever inside the cabin with a cable connected to it which goes into the differential housing actuating the locking mechanism. Both OEM and aftermarket use this type of select able locker. Eg: Force Gurkha (OEM), OX Locker and Lambda (aftermarket). 2) Auto locker This is a differential that locks automatically, but this is misleading classification for this type of lockers. Although they are called auto lockers technically they are auto un-lockers. In an auto(un)locker differential the side gears are locked to a central spider gear (in place of planet gear in an open differential) and the spider gear is firmly held in place in the differential carrier and they all turn in unison with no differential action. As the vehicle turns the side gears unlock momentarily from the central spider assembly and ratchet for differential action. To re-lock them in turns getting on the throttle is all thats required as these don't unlock under load. There are two types:- a) Lunchbox locker - Goes in a stock differential carrier replacing sidegear and planet gear. Eg: Aussie locker b) Full differential carrier assembly - Replaces the differential carrier. Stronger and reliable than lunchbox lockers. Eg: Detroit locker 3) MLD aka Governor based Mechanical Locking Differential This is the most popular aftermarket locking differential in India thanks to M&M offering it as an official accessory for their RWD and 4WD vehicles. MLD is Eaton G80 which is a governor based clutch pack locker it is not a limited slip differential. MLD is a true auto locker as it locks and unlocks automatically without driver input and until it locks its an open differential. It locks using a centrifugal governor activating on wheel speed difference of aprox 100 RPM causing to throw themsleves out catching a pawl which activates a cammed ramp causing the side gear to compress the clutch pack to the carrier and then all turn in unison with the carrier. The G80 lockers are also known as gov-bombs in its home base. MLD Types:- Only aware of the Eaton G80 aka the MLD. 4) Limited Slip Differentials A limited slip differential limits slip but it does not lock both wheels together like any of the above mentioned lockers. If one wheel loses traction partially or completely the limited slip differential transfers part of the torque to the wheel with traction. The torque transfer will not be 50:50 like a locking differential but in most cases enough to get going again. This is also the most exciting type of differentials because of the different types from passive to active with torque vectoring. The amount of torque transferred and behaviour depends on the type of limited slip it is etc. The most common type of limited slip diffs are:- a) Clutch pack limited slip diff - Eg. Eaton Positraction. Any one remember "My Cousin Vinny"? b) Cone clutch limited slip diff - Eg. Auburn Grip'n-Loc c) Helical gear/Torsen limited slip diff - Eg. Quaife d) Viscous limited slip diff - Eg. OEM only mostly Since each of these above types work differently each of them will have to be considered independently as its own type of differential. Exception is the clutch pack and cone clutch type diffs which work similarly except that one uses clutch pack and the other a solid block of metal as friction surface. Differentials and Traction Control Explained Reasons to love a limited slip differential! -- Yes, an upgraded differential can be of great advantage on the road as well as off the road. Just need to choose a type that works for the intended usage. Quote:

Last edited by Sankar : 29th September 2022 at 20:22. | |

| |  (17)

Thanks (17)

Thanks

|

| The following 17 BHPians Thank Sankar for this useful post: | AdityaDeane, amalji, dailydriver, DicKy, GaryTSI, GeeTee TSI, GForceEnjoyer, Sandy Damodaran, shivraj737, Shreyans_Jain, Swarup5, tharian, TrailBlazer007, Turbanator, v1p3r, vigsom, WhiteSierra |

| | #5 | ||

| Team-BHP Support  | Re: Limited Slip Differential Install in Toyota Innova Quote:

Quote:

Last edited by Samurai : 29th September 2022 at 21:35. | ||

| |  (18)

Thanks (18)

Thanks

|

| The following 18 BHPians Thank Samurai for this useful post: | AdityaDeane, amalji, arvind71181, GaryTSI, GreenerPlanet, IcarusMan, megazoid, nagr22, raihan, rajvardhanraje, Rocketscience, ruzbehxyz, sagarpadaki, Sankar, shankar.balan, tharian, TrailBlazer007, v1p3r |

| | #6 | |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| Re: Limited Slip Differential Install in Toyota Innova Quote:

| |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank Sankar for this useful post: | GaryTSI, megazoid, Rocketscience, Samurai, shankar.balan |

| | #7 | |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

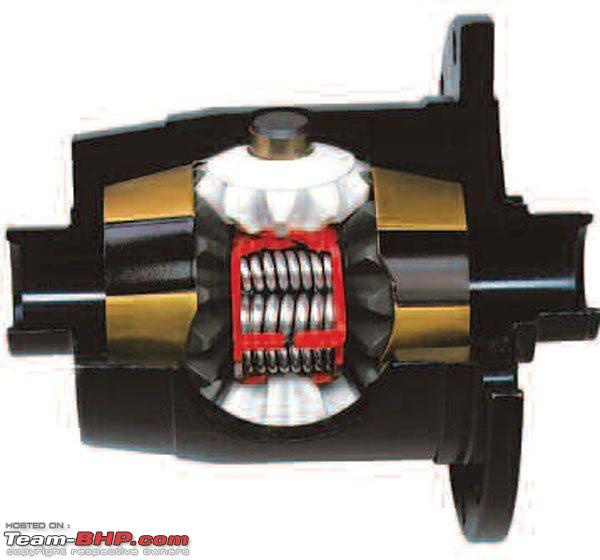

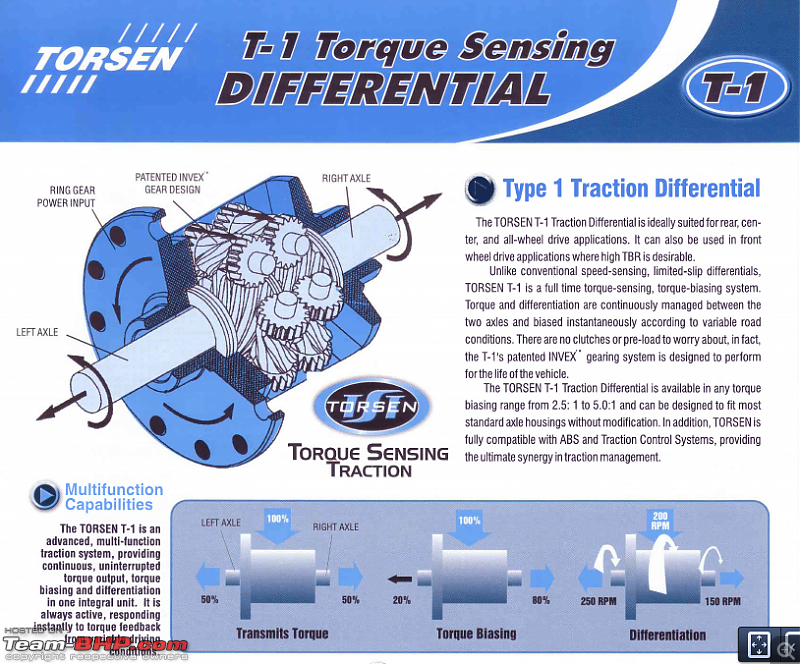

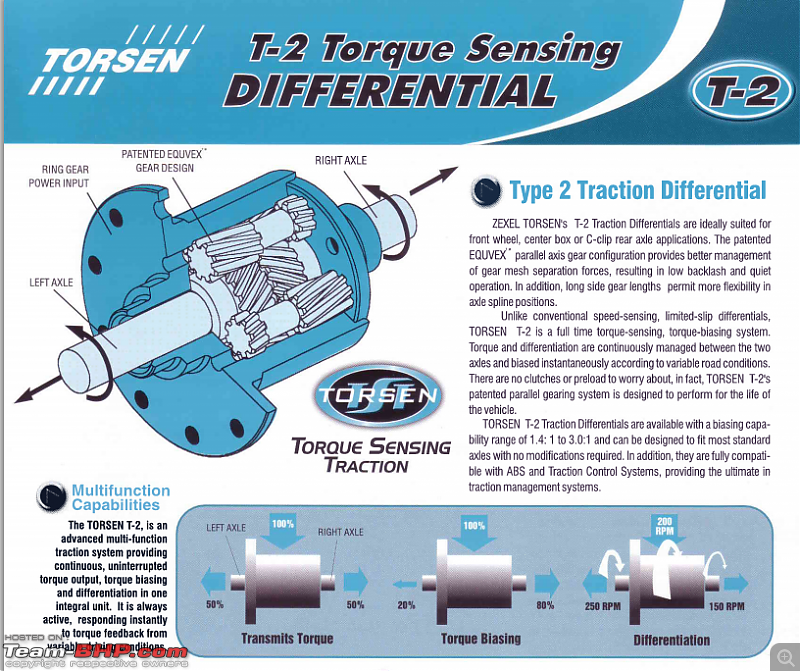

| Types of limited slip differentials Clutch pack LSD This type of limited slip differentials are the most common and the most widely used in the past as well as the present because they are not expensive to manufacture and can be rebuilt. In design this is not much different from an open differential and has all the standard parts of an open differential + two clutch packs, springs and pressure plate. In the clutch pack LSD between the side gears and the differential case lies a clutch pack with inter-spaced friction plates and steel plates. This is very similar in design to a motorcycle clutch. One set of clutch plates have internal splines in its center and they are locked to the side gears, another set of clutch plates have external tabs that is locked into a similar notch on the carrier. Very similar to a clutch pack in a 100cc motorcycle clutch basket. The differential and the clutch pack in its non-loaded state allows the side gear and its plates to turn rather free from the diff case and its set of plates for differential action. In the center of the differential case and between the two side gears there is a spring pre-load mechanism which is either a flat piece of metal in S shape called the S-spring pushing the side gears apart, or two metal plates with 4 coil springs in between pushing the plates apart. The function of the S - spring or the spring pre-load plate is to pre-load the clutch pack pushing the side gears apart. More pre-load for a stronger and quicker acting limited slip differential and less pre-load for a weaker and slower acting limited slip differential. The springs are for pre-load only, when under load it is the gear separation force between the beveled teeth of side gear and the planet gear that push the side gears apart compressing the clutch packs that limits the slip. More load more separation force and higher the clamping force, to a limit. In expensive aftermarket Japanese clutch pack limited slips there are cammed ramps with for 1 way, 1.5 way, 2 way action. 1 way - aggressive limited slip action while under load, 2 way - aggressive limited slip action when under load and while off the power (wheel driving diff) and braking, 1.5 way - aggressive limited slip action under load and less aggressive while off the pedal. Advantage of clutch pack limited slip is that, 1) they can be rebuilt, 2)they can be tuned - adjusting the pre-load, increasing or decreasing plates, re-arranging the plates. Disadvantage of clutch pack lsd is that 1) they need to be rebuilt, 2) more aggressive it is earlier the pack will wear out.  Cone clutch LSD Functionally it works like a clutch pack LSD. Pre-load can be tuned by springs and separation force between side gear and planet gear push the side gears apart, but there is no clutch pack to compress. Cone clutch LSD is different beast it does not have a clutch pack but there is solid chunk of cone shaped (with its pointy end cut off) metal just behind the side gear and on the differential carrier/case there is a respective cup for this cone to snugly fit. Side gears are the cone itself, or they are press fit into the cones, or they are connected via splines to the cone. The cup is part of differential case itself. The gear separation force push the side gears and the cones apart and into the cup, the friction between the cone and its cup limits the slip between the wheels. In lieu of clutch pack there is a cone and its cup. Advantage of cone clutch type is 1) they are said to last a lot longer than clutch pack type, 2) provide a more consistent performance than clutch pack type and 3) more agressive than clutch pack type. Disadvantage of the cone clutch type is that 1) its not rebuildable when the cones and cups wear out too much the diff will have to be discarded.  Torsen LSD Q: How do you check if your vehicle has a limited slip differential? A: Hoist the vehicle on a lift and rotate one tyre, if the other tyre rotates in the same direction you've got an LSD. While the above ^ is correct for clutch type LSD it does not hold true for the torsen. A torsen can turn the other way  This is a different type of beast, the planet gears and the side gears are unlike any other differential and they work unlike any other differential. The name Torsen is short for TORque SENsing and the three types of torsens used in auto drive train are the T1, T2 and the T3. I'll get the T3 torsen out of the way first, T3 torsen is a planetary gear diff and used in the center differential and not in the axles. Eg. previous generation full time 4WD Fortuner has a Torsen T3 in its center differential. T1 and T2 types are used in center differentials of Audis and also more commonly in the axles to replace an open differential. The side gear is a worm gear and worm wheels takes place of the planet gears. The basic principle is worm gear can rotate worm wheel but worm wheel cannot rotate worm gear. T1 and T2 torsens work similarly but they are of different designs. Torsens work on friction generated by the gears amongst themselves and against the case/carrier. T1 has worm wheels with spur gear ends laid perpendicularly across the worm (side) gears, where as the T2 has worm wheels lie in parallel to the worm (side) gears. T1 will have a minimum of two pairs of worm wheels and three pairs the norm and not more. T2 torsen will have usually three pairs of worm wheels minimum, four pairs in some, and six or more pairs in racing applications. T1 torsen was OE in many performance cars and they have more torque bias ratio (tbr) than the T2 design, but in the aftermarket T1 type is rare because they are weak. T2 due to the more robust design comes as OE in some pickup trucks and heavier vehicles and they are also popular in the aftermarket. T2 can generate more TBR using more pairs of worm wheels and/or tooth profile on helical gears. Torque Bias Ratio (TBR) Quote:

T1  T2  Img src: Google. Copyright respective owners. Viscous Limited Slip Differential VLSD The clutch and helical gear types are load sensing type differentials but the viscous lsd is a speed sensing type. The viscous lsd is a sealed unit containing set of plates and hydraulic fluid. Like in a clutch pack lsd here one set of slit plates is tied to the side gears and the other set of slit plates to the differential case, but unlike a clutch pack lsd the plates do not compress together to transfer drive, instead it is the hydraulic fluid that transfer the drive from one set of plates to the other. The basic principle is similar to how a torque converter operates. Both are viscous coupling devices. VLSD is used in axles and center differentials in OEM applications, and they are rare in the aftermarket and often if present is replaced with other types of limited slips. GKN Driveline Viscous LSD Last edited by Sankar : 30th September 2022 at 14:43. | |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank Sankar for this useful post: | AAD, ACMohan, AdityaDeane, CEF_Beasts, GaryTSI, Jeroen, Kumaran93R, ruzbehxyz, shankar.balan, shivraj737, SS-Traveller, tharian, TorqMaster, vigsom |

| | #8 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

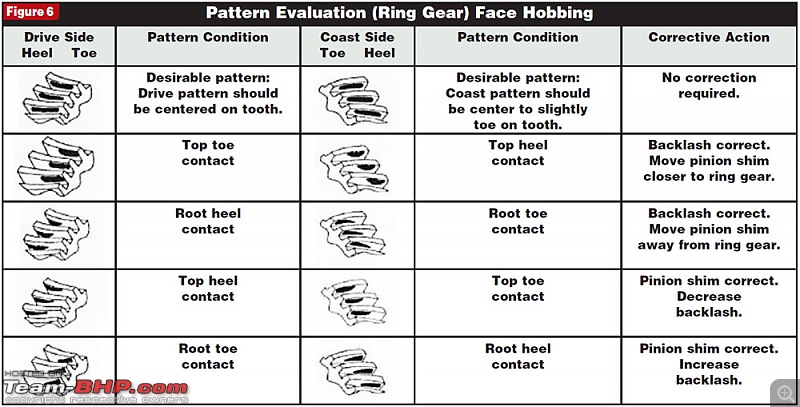

| Planning the installation Upgraded differential selection? For a road vehicle I need an upgraded diff which is always ON and safe for on-road use. That has ruled out select able lockers - not always ON, and auto(un)lockers - not safe for our road and traffic conditions as the rear can step out. That leaves me with limited slip differentials and the choices are are plated lsd, cone lsd and torsen lsd. Which one to choose? Planning the installation Before the parts are sourced I was wondering how to get the new diff set properly and installed? The only group of guys who play with differentials are off-roaders and jeep guys and if there's anybody who can do it properly it would be the jeep garages. Setting the differential is getting backlash, bearing preloads, and pinion depth all within spec. Backlash is the clearance between the ring and pinion gears in thousands of an inch or hundredths of a mm measured using a dial gauge. Inadequate backlash will bind and overheat the gears, and with excessive backlash gears crash into each other breaking teeth and makes a weak diff. A proper gear tooth contact pattern is the product of pinion depth and backlash. Similarly the carrier bearing pre-load has to be within specs, little or no carrier bearing pre-load and the carrier with ring gear will deflect under load, too much pre-load will eat the bearings. Similarly input pinion bearing pre-load should be within norms for the ring and pinion to maintain proper contact under load, but in this install I need not worry about pinion depth or pinion pre-load. In the shim adjusted gear carrier re-using original shims on each side respectively will bring backlash and bearing pre-load to before disassembly spec if carrier+ring gear is reused and drive pinion was left as is. In an adjuster nut type gear carrier once differential is taken out both backlash and bearing preload has to be set from scratch during re-assembly. Ring gear face type Gear contact pattern - Milled Gear contact pattern - Hobbed Unfortunately I couldn't find any differential specialists nearby who would/could do this properly. Also learned that an average differential repair is - taking the diff out, pulling the bearings off, tapping or pressing new bearings in, and reusing the shims or tightening the preload adjuster nuts till medium tight and putting it back in the vehicle. Probably works for most applications but may not be ideal when sending 5xxNM  torque down the prop shaft. torque down the prop shaft.So I wondered whether I could do it myself? I mean why pay some(not-an-expert)one to screw it up? If its going to be screwed up let me be the one to do it  and will be a learning experience in the process. So once this was clear and accepted in my head things started to properly fall in place. I had not yet sourced the actual diff yet. and will be a learning experience in the process. So once this was clear and accepted in my head things started to properly fall in place. I had not yet sourced the actual diff yet.Once it was decided that I am doing the diff I thought it will be wise to buy a brand new third member from the Toyota and install the limited slip in it. Third member/drop out is the removable front center section of the differential/axle housing and has the carrier, ring & pinion gears and bearings all set inside it. In this type of differential there is no rear cover on the pumpkin to access the diff and the whole thing has to come out from the front. Logic was to leave the factory set diff on the vehicle as spare/backup if I screwed up the install. In future if its ever needed to remove the limited slip it will be as easy as getting the third member swapped. So the parts order for a new third member was placed with the authorised Toyota dealer here. It was agreed that I will set the limited slip in the new third member and bring it with the vehicle for the swap. Being a genuine Toyota part sourced from them the dealer was OK installing it in the vehicle. -- Last edited by Sankar : 2nd October 2022 at 11:37. |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank Sankar for this useful post: | Abbas, ACMohan, AjayJoshuaN, GaryTSI, greenhorn, megazoid, Romeo_Mike, Samurai, shankar.balan, shivraj737, Sran, sunilg33, tharian, vigsom |

| | #9 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| Re: Limited Slip Differential Install in Toyota Innova I am yet to make a good outdoorsy video of the new diff in action. So once I have that ready I will complete this thread. The limited slip installation video (unlisted) is up on youtube since July, so that part is done. Next post should cover both the install and a proper demonstration of the limited slip working. |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Sankar for this useful post: | shankar.balan |

| | #10 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| Re: Limited Slip Differential Install in Toyota Innova This is the situation when reversing up the ramp. With an open differential the rear right wheel used to spin out and the rear left wheel sits there doing nothing and to get going I used to move forward and reverse faster and let momentum do its thing. Now with the limited slip diff I can crawl as slowly as I would like and reverse up the ramp. The surface is tiles with some sand here and there and wet. When driving into the compound nose-in at an angle one of the rear wheels would go up in air but with this limited slip diff it would still climb up, will make another video of that. |

| |  (8)

Thanks (8)

Thanks

|

| The following 8 BHPians Thank Sankar for this useful post: | ACMohan, ashis89, BigBrad, DicKy, GaryTSI, NewUser123, shankar.balan, ValuableRecluse |

| | #11 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| Re: Limited Slip Differential Install in Toyota Innova All sorts of lockers and limited slips can be used for this axle but based on my needs a limited slip differential was deemed best. Amongst the limited slip differentials the choice was further narrowed down to a torsen differential for its qualities which endeared to me. Amongst the torsen differentials I decided to go with Detroit Truetrac from Eaton. When I got the truetrac I wanted to open it up for 1) just wanted to see its guts and 2) I wanted to double check the orientation of the helical gears inside for rear axle application. The 12 bolts holding the diff together had factory applied blue loctite present on it. I scubbed the bolts clean and the hole the best I could to get them ready for the red loctite. During re assembly red was applied and all 12 bolts, 6 on each side, was torqued down to spec (as received from Eaton). Once Truetrac was done it was time to disassemble the brand new stock differential but before it could come apart the backlash and total bearing preload was measured and jotted down. This was done as secondary reference in addition to shop manual values in the book and the idea was to closely match it during re-assembly with truetrac differential. After the measurements were done the 3rd member was disassembled, took out the stock open diff and separated the ring gear from it and transferred it to the truetrac and torqued down to spec. Next job was not in my purview which was to approach a lathe shop to get the brand new Koyo bearings pressed down on the truetrac differential. The easy part was over. Coming up is the most tiring part of the job, setting up the differential. This differential doesn't use shims for backlash (BL) and carrier bearing preload (CBPL) adjustment but large nuts which when tightened apply force to the carrier bearing race. So once diff is opened BL and CBPL has to be set anew. Nuts are not really a negative unless one has a set of carrier bearing shims of varying thicknesses for shimmed diffs in which case its faster. With aftermarket carrier stock shims have less chance of getting BL and CBPL correct. Advantage nuts is one doesn't have to source a set of shims with varying thickness, but process takes time. When setting up the diff first BL has to be brought within tolerance and then CBPL is checked and adjusted, and when CBPL is adjusted BL will go out of spec, and then BL is adjusted and again CBPL is checked and adjusted... the process continues and takes time. Since measuring CBPL is not possible directly total bearing preload was measured and compared to the value jotted down before dis assembly. The measurements were taken at multiple ring/pinion meshing points, i.e., measuring from a starting point I marked as tooth 1 on the ring gear and from there tooth 5, tooth 10, tooth 15 till the 43rd tooth on ring gear. This is required due to the minor variations in ring gear runout. BL if tight will bind the gears and if loose ring and pinion gear tooth crash and break. CBPL if low will allow the carrier to deflect in its cradle when power is applied by pinion gear and if excessive will run hot and eat the carrier bearings. It took two days measuring and adjusting and it went on till I was happy with the result which I set slightly tighter than factory but within OE tolerance. Since the drive pinion was left untouched on this new differential I did not have to worry about gear tooth pattern. Once I got the BL and CBPL correct the gear pattern was found to be perfect. Now what remained was to get the 3rd member into the vehicle. This was done by the dealer workshop following their SOP. The axles slotted right into the new diff and the vehicle was out on the same day  We went for a test drive and I had my finger's crossed! Fortunately there were no abnormal sounds or vibrations when under power or when coasting. All is well!! I did well! We went for a test drive and I had my finger's crossed! Fortunately there were no abnormal sounds or vibrations when under power or when coasting. All is well!! I did well!Driving with a working limited slip differentials is a joy, can't express it in text but there is a sort of feeling of grip that can be felt when driving around and even while braking. When stomping the pedal there is no one-wheel-peel or one-tyre-fire anymore, both wheels get it. Its been 9 months now post the installation. The Crysta is now a proper 2 wheel drive and not afraid of one rear going up in the air or landing in a ditch or both wheels in slush (current tyres UC6 are not good for this, previous tyre GY Wrangler was) it will pull out. I was more excited about getting hands dirty and diving into the install than taking photos or videos. So its not a very professionally made video. |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank Sankar for this useful post: | brraj, GaryTSI, ruzbehxyz, shankar.balan, sudeepg |

| |

| | #12 | |

| BHPian Join Date: Feb 2006 Location: bangalore

Posts: 913

Thanked: 1,282 Times

| Re: Limited Slip Differential Install in Toyota Innova Quote: Anybody who can install this in bangalore ? | |

| |  ()

Thanks ()

Thanks

|

|