Team-BHP

(

https://www.team-bhp.com/forum/)

-

Road Safety

(

https://www.team-bhp.com/forum/road-safety/)

As per a new proposal under the corrosion prevention rule for motor vehicles, the Ministry of Road Transport and Highways could make the use of 70% galvanised steel for car body panels mandatory.

The proposal is pertaining to cars under Rs. 10 lakh, that are built in India and is based on a study conducted by IIT Mumbai in 2015 about how corrosion affects durability and safety of cars in India.

Reports suggest that the ministry has directed the Automotive Research Association of India (ARAI) and the International Centre for Automotive Technology (ICAT) to study the proposal and prepare a report.

Galvanisation is the process of applying a protective zinc coating on iron or steel to prevent corrosion. According to a media report, cars built for the domestic market have 30% galvanised steel but in the same models built for export markets the percentage rises to 70%, whereas the global average is 50%.

Source:

Economic Times Link to Team-BHP News

Can anyone break this news down for the layman?

1. Presently which companies practiced this technique of using 30% in India, and exporting with 70% galvanized Steel ?

The only ones I can presently imagine of is Suzuki.

2. Also, how much impact does galvanization have on the pricing of the products and overall weight of the car?

Wouldn't soon to be mandatory Airbags, ABS, BS-VI have a double whammy effect on the sales price, and would lead to massive lobbying from the manufacturers to prevent such rapid increase in costs?

Quote:

Originally Posted by sharktale

(Post 4450929)

2. Also, how much impact does galvanization have on the pricing of the products and overall weight of the car?

|

Zinc coating has only marginal impact on the total weight. And it varies a lot with the thickness of the part. Least % weight increase to thick/heavy parts, and more % weight increase to thin and light parts.

https://galvanizeit.org/design-and-f...eight-increase

Quote:

Originally Posted by sharktale

(Post 4450929)

Can anyone break this news down for the layman?

1. Presently which companies practiced this technique of using 30% in India, and exporting with 70% galvanized Steel ?

The only ones I can presently imagine of is Suzuki.

|

apart from a handful of OEMs, rest all have this differential treatment for Indian and export models. It's purely a decision driven from a business perspective. "When there is no regulation, why spend more?" In EU it is mainly the ELV regulation that is pushing OEMs for using higher percentage of galvanised steel panels.

Safety feature were also like this but now it is changing for good.

Quote:

2. Also, how much impact does galvanization have on the pricing of the products and overall weight of the car?

|

In fact, you can even reduce a small amount of weight by using thinner metal sheet and add coating to it.

"Kitna deti hain?"... "Ab aur zyada degi" Quote:

Wouldn't soon to be mandatory Airbags, ABS, BS-VI have a double whammy effect on the sales price, and would lead to massive lobbying from the manufacturers to prevent such rapid increase in costs?

|

To a certain extent, it will be offset by big volumes. Also OEMs need not maintain different variants based on country of sale which will mean less cost.

Why is it limited to cars under Rs.10 lakhs? Is it therefore, understood that cars costing upwards of 10 lakhs use galvanized steel, or have some other advanced means of corrosion protection?

There is another thread on the same issue and I feel this has to do something with the zinc industry lobby trying to sell more zinc in India. The lobby must have greased the right palms and so now it could become mandatory to use galvanized steel in cheaper cars. Why this bias based on cost of the car? Because they sell more?

https://www.team-bhp.com/forum/india...el-bodies.html

Thanks for sharing Tushar.

I have been reading up the subject and have come to the conclusion that only legislation could push this move towards better use of materials.

Some of the pros and cons on this.

Pros:

1. The biggest advantage is the corrosion resistance - along with it increased durability and longevity

2. Better finish ~ easy to paint and minimal defect corrections needed

3. Marginal improvement in weight as thinner panels with galvanisation could be used

Cons:

1. Cost is the biggest factor in a price sensitive market like India

2. Not all parts can be suitable for hot-dipping method (most common) due to size, requiring other techniques

3. With average ownership of car reducing to under 4 years in India, automakers might think that the extra effort for galvanisation is not worth it.

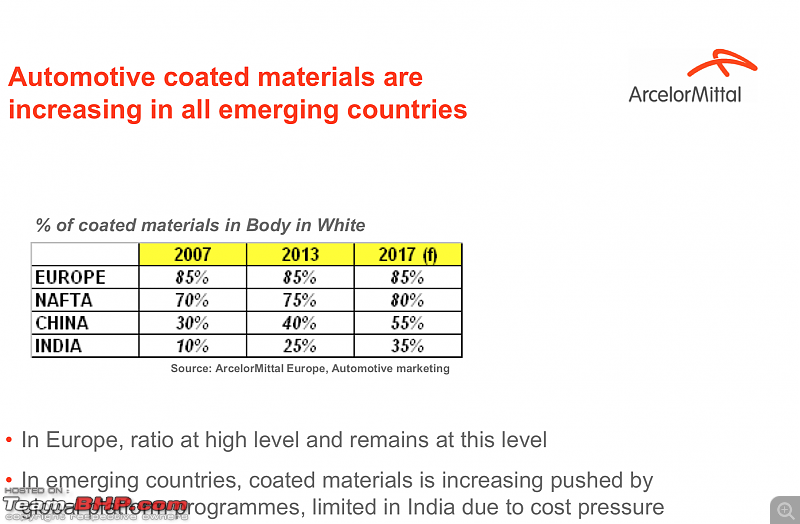

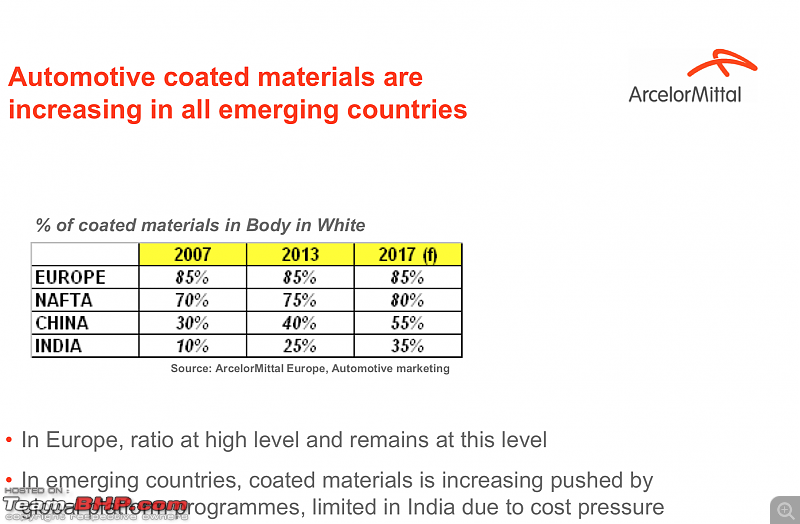

Here are some stats from a Arcelor Mittal

presentation.

Low penetration of galvanisation in India:

Places where steel is used in a car:

Reduction in weight of a car over the years:

Material composition used in cars is slowly moving towards the use of plastics and composites:

And now the lop-side of galvanizing, whether in part or in entirety :

- All of the different chemical baths used during the galvanizing process

present multiple sources of waste

- The pickling bath used in the preparation process consists of

hydrochloric acid (HCl). The acid becomes more dilute and less effective

with use and must be dumped out and refilled once it becomes too

dilute to be effective. Spent HCl is classified as hazardous waste and

must be treated accordingly.

- If the steel has not been cleaned enough or if there is carry-over from

the previous flux solution, lead and other elements can precipitate out

into the galvanizing bath. These contaminants are another source of

waste, and they lower the effectiveness of the galvanizing solution.

Eventually, there is too much precipitate for the solution to be effective,

and it must be dumped out and refilled. Used galvanizing solution is also

classified as hazardous waste.

Some actual events that happened in U.S of A due to galvanization :

- South Atlantic used to send some of their waste to Environmental Quality (EQ) North Carolina, an old solidification/stabilization facility in Apex, North Carolina. A chemical explosion caused the facility to burn down in 2006, and the resulting chemical haze was so hazardous that residents had to evacuate to Cary, North Carolina until the air was safe to breathe again.

- Once 2,700 acres of farmland, Chemical Waste Management in Emelle, Alabama is now one of the nationís largest hazardous waste dumps. One third of the people in the town live below the poverty line, and 90% of the people living directly near the dump are African-American.

- In 2004 and 2005, both the vice president and the plant manager of US Liquids (USL) City Environmental Inc. in Detroit, Michigan were sent to prison for conspiracy. The plant was charged with violating the Clean Water act for sending untreated waste into the Detroit River.

I like cars and love driving, but more than anything I love nature and what we call our home.. this earth. These points are merely food for thought, I'm not opposing people's rights to deserve an automobile of good quality and durability. Sometime down the line though, just like the popular press and public at large suddenly jumped to the notion that diesels may not be as clean as they were thought out to be, this too might be a cause for concern. Automobile industry which is an amalgamation of the best of plastics, leather, wood, aluminium, rubber, iron etc.. is among the most resource-hungry industries on earth. I'd like to repeat once more that, being a part of an automobile forum.. I have no problems when people's expectations are high for a particular vehicle as they spend good money on it, sometimes additional processes may not be all that they're cracked up to be. On the business side of things though.. even the manufacturers are fully correct in doing so.

http://www.bredl.org/pdf3/south_atla...alvanizing.pdf

As has always been stressed before.. balance is key.

Quote:

Originally Posted by dark.knight

(Post 4452019)

I like cars and love driving, but more than anything I love nature and what we call our home.. this earth.

As has always been stressed before.. balance is key.

|

:)

Cars, driving and nature - cannot be talked about in the same line.

Yes, so galvanizing will cause incremental harm to nature and environment, but so does the adhesives, primers and paints. Why not remove them altogether?

In fact why use metals for cars when we all (well at least some) are aware how much polluting industries are the mining and metal refining?

Oh, and what about using hydrocarbons for fuel?

As you said balance is the key, and the world/history has taught that the balance keeps changing with changing priorities and public perceptions.

Galvanization of steel is a good solution to reduce rusting and may lead to lesser usage of other chemicals like abrasive compounds (to remove rust), primer and paints.

Also corroded metal panels present a greater risk of bodily harm - compare running your hands on a flat smooth metal panel vs the one that has rusting, pitting and corrosion.

| All times are GMT +5.5. The time now is 19:28. | |