| | #16 |

| BHPian Join Date: Jul 2006 Location: hyderabad

Posts: 54

Thanked: 27 Times

| |

| |

| |

| | #17 |

| Senior - BHPian | |

| |  (2)

Thanks (2)

Thanks

|

| | #18 |

| Senior - BHPian | |

| |

| | #19 |

| Team-BHP Support  Join Date: Feb 2004 Location: Bombay

Posts: 24,046

Thanked: 34,074 Times

| |

| |

| | #20 |

| BHPian Join Date: Sep 2009 Location: pune

Posts: 343

Thanked: 311 Times

| |

| |

| | #21 |

| Senior - BHPian | |

| |  (2)

Thanks (2)

Thanks

|

| | #22 |

| Senior - BHPian Join Date: Apr 2007 Location: LandOfNoWinters

Posts: 2,093

Thanked: 2,604 Times

| |

| |

| | #23 |

| Senior - BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #24 |

| BHPian Join Date: Oct 2009 Location: Delhi

Posts: 597

Thanked: 449 Times

| |

| |

| | #25 |

| BHPian Join Date: Feb 2013 Location: Space-Time

Posts: 484

Thanked: 342 Times

| |

| |

| | #26 |

| Senior - BHPian | |

| |

| |

| | #27 |

| Senior - BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #28 |

| BHPian Join Date: Feb 2013 Location: Space-Time

Posts: 484

Thanked: 342 Times

| |

| |

| | #29 |

| Senior - BHPian | |

| |  (2)

Thanks (2)

Thanks

|

| | #30 |

| Senior - BHPian | |

| |  (6)

Thanks (6)

Thanks

|

|

Most Viewed

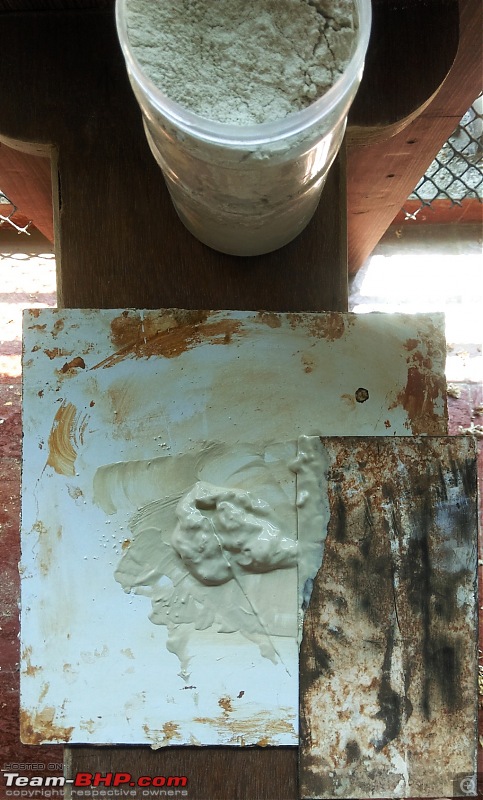

drawing I proceeded to cut two table tops from scarp pieces of plywood and shape it up.

drawing I proceeded to cut two table tops from scarp pieces of plywood and shape it up.