| | #136 |

| BHPian Join Date: Dec 2009 Location: Bangalore

Posts: 249

Thanked: 351 Times

| |

| |

| |

| | #137 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #138 |

| BHPian | |

| |

| | #139 |

| BHPian | |

| |

| | #140 |

| BHPian Join Date: Aug 2009 Location: New Delhi

Posts: 381

Thanked: 188 Times

| |

| |

| | #141 |

| BHPian Join Date: Feb 2006 Location: Gurgaon

Posts: 335

Thanked: 49 Times

| |

| |

| | #142 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #143 |

| Senior - BHPian Join Date: Jan 2010 Location: TSTN

Posts: 6,233

Thanked: 9,615 Times

| |

| |

| | #144 |

| BHPian | |

| |

| | #145 |

| Senior - BHPian Join Date: Jan 2010 Location: TSTN

Posts: 6,233

Thanked: 9,615 Times

| |

| |

| | #146 |

| BHPian | |

| |

| |

| | #147 |

| BHPian | |

| |

| | #148 |

| Senior - BHPian Join Date: Jan 2010 Location: TSTN

Posts: 6,233

Thanked: 9,615 Times

| |

| |

| | #149 |

| BHPian | |

| |

| | #150 |

| Senior - BHPian Join Date: Jan 2010 Location: TSTN

Posts: 6,233

Thanked: 9,615 Times

| |

| |

|

, Hats off to you.

, Hats off to you.

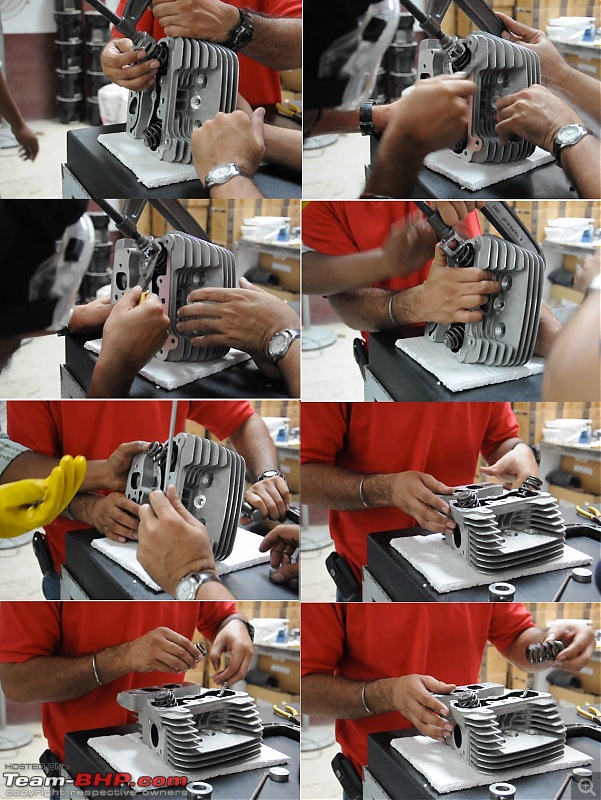

, the problem was this replacement was grey in colour. Next challenge, mask the head and a matching cylinder for powder coat. Removed both the valves and started the tedious process of masking.

, the problem was this replacement was grey in colour. Next challenge, mask the head and a matching cylinder for powder coat. Removed both the valves and started the tedious process of masking.