Team-BHP

(

https://www.team-bhp.com/forum/)

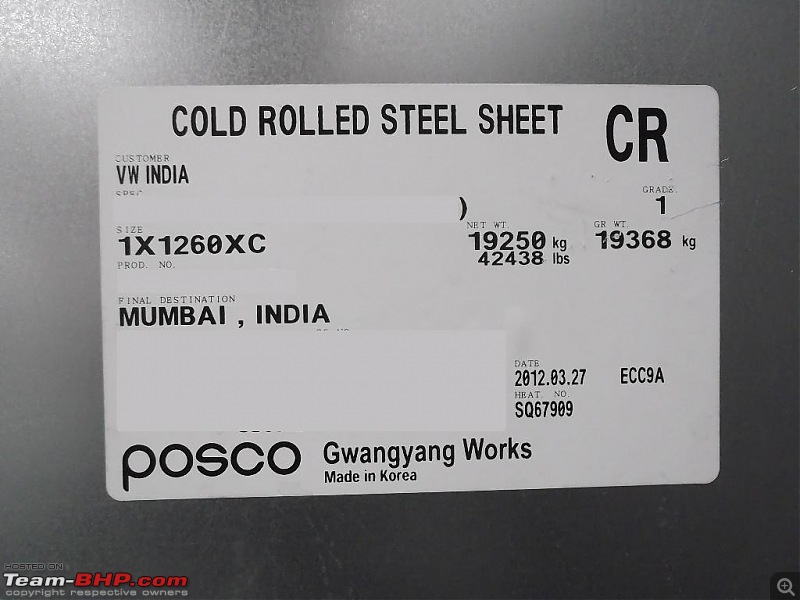

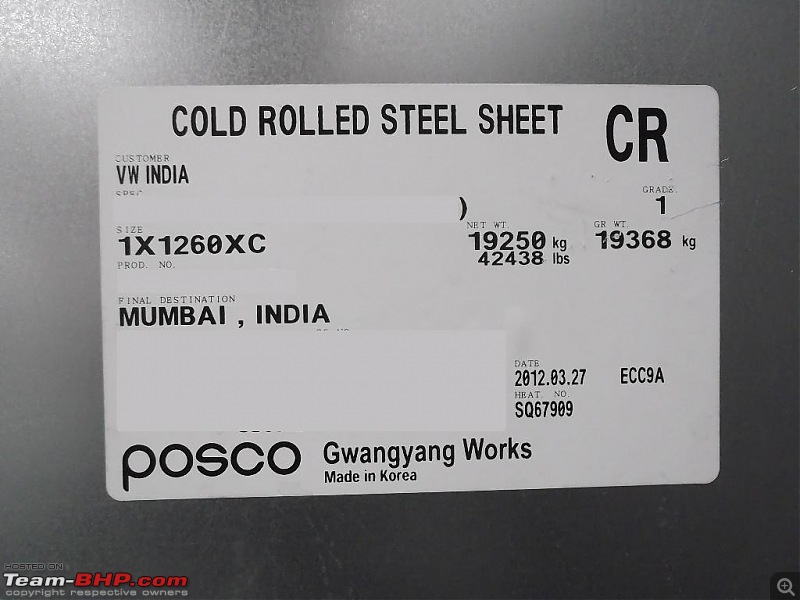

Even before the cars are put on design board, this is how they look as pure RAW material:

These will become your POLO, JETTA or PASSATS.

Raab Rakha.

Let me add a bit. There have been major developments in steel. As stated by Aditya Mittal some time back, over 70% of the steel they supply to the automotive industry did not exist five years ago.

German cars, built in India ---with steel from Korea!

Quote:

Originally Posted by dot

(Post 2715500)

All liquid coating formulations have the following generic composition

Media (solvent or water)

Binder (urethane, acrylic, alkyd)

Color (specially in base coat)

Additives of various kinds (eg, viscosity regulators, dispersants).

Next we will look at the painting process and touch upon the usage of various materials in different stages. Finally we will look at some non-paint, coating only applications.

|

Just a bit curious here, in what way does the paint job of a local workshop differ from that done by the A.S.S.

The local workshop guys too guarantee a perfect match based on 'computer shade matching'. So if the shade does not match for touch up jobs, is there a difference in quality of paint material used or is one or more of the above ingredient list missing? I intend to understand the difference between paints used by local workshops and A.S.S.

[quote=Rehaan;2715603

R&D and Paint booth are two areas that are very heavily guarded in most automobile factories.

R[/quote]

Paint booths are closed to keep out dust and other contaminants that can settle on the cars body during painting process which results in defects. Another reason is to avoid the risk of a fire, due to many flammable chemicals around. hence everyone entering a paint booth area has to be fully covered in anti static body suit, which is a special material woven with special strands to prevent static. A sudden spark could be catastrophic.

Some manufacturers even use special anti static shoes in paint booth areas.

In most manufacturing plants, visitors are kept out of paint booths, they otherwise can visit other parts like the press, weld, assembly areas with prior approvals and safety measures !

Any doubts, members please post, as i have worked in an automobile manufacturing facility, i will answer to the best of my ability :)

The door seal plays an important role in a car. It is a gasket made of rubber material to seal off the interior from external noise and wind. There are 2 parts in a seal. Primary seal and Secondary seal.

Can anyone please tell me the difference between the two? What are their functions? How are they connected? Tried searching online. Not much help. Couldnt find any details nor a proper picture explaining it.

Mods, COuldnt find this info on any other thread. Please delete if found inappropriate.

Thanks.

Zteg

All of us might have heard complaints from general public that todays cars are made from this sheets. Also we do not see the rusted door panels etc.

All this is made possible due to new automotive steels, which offer better strength at lower weight,higher performance in todays demanding world. The following link gives the details of automotive steels used nowadays

https://www.worldautosteel.org/steel...l-definitions/

The following two document gives the details about the evolving use of advanced high strength steels for automotive applications;

| All times are GMT +5.5. The time now is 01:15. | |