| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  203,081 views |

| | #16 | |

| BHPian Join Date: Feb 2012 Location: New York City

Posts: 169

Thanked: 631 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

1) ECU Tuning 2) Turbo size, pressure setting and also FGT vs VGT 3) Valves & such that allow air and fuel in to the engine. 4) Not related to power, but for reliability, some manufacturers may put stronger connecting rods, and other mechanical bits into their higher powered units compared to lower powered units. Now the official ARAI figures for these engines is actually misleading. Typically speaking, the 110 hp engine will pump less fuel into itself during acceleration from, let's say a traffic signal, than the 190 hp, under the same amount of accelerator input from the driver. Once cruising, say 50 km/h in city driving, both engines would use a similar amount of fuel to maintain a similar speed (of course assuming the same identical car). This is because you need a certain amount of power and torque at the wheels to move a particular mass at a particular speed. The real differences in real world driving are because the 110 hp can run more lean than the 190 hp as they are being asked for different outputs. In real-world conditions, an Octavia 110 2.0 would be more efficient than an Octavia 190 hp 2.0, by a fair amount of kmpl I might add. This is because lean, mechanically efficient engines use lower fuel than rich, mechanically efficient engines. The second part of this argument is reliability and longevity. In general, an engine tuned down and running efficiently will last longer than the same engine tuned up. This is the reason why cars have bigger engines. Example: VW's own 1.6 TDI makes the same power/torque figures as the 2.0 110 hp model, so why not put the 1.6 in - it's for reliability and longevity. VW's 110 version of their 2.0 liter is popular with their commercial van customers in EU and with taxi drivers all over Europe who drive Octavias. A similar example is the old Innova had a 2.4 diesel tuned conservatively to 101 hp/200 Nm, but the damn thing never broke! Even the new 2.4 is conservative by EU manufacturer standards at 143 hp/343 Nm, similar to VW 2.0 figures and much less than BMW/Mercedes new engines of smaller sizes. Again efficiency and reliability are key. Another factor in the reliability argument is that a tuned-down bigger engine tends not to struggle at low RPM, compared to a high-tuned smaller engine in the same car - hence the "driveable" nature of the old Innova even though it was underpowered. This is part of the no replacement for displacement argument. A similar example - Toyota Etios with just 68 hp from 1.5 liters. However, you will easily find a 5,00,000 km Etios taxi in the near future, once its old enough, with a smiling owner. In an ideal scenario - I'd have a car with different maps that affect fuel flow as well as turbo boost, so I can drive a 110 hp in traffic, cruise in a 140 hp on the expressway and attack a ghat at 190 hp. Of course this may not be achieved in non-fantasy-real-world.  The relative difference in price of different engine options in the VW range, on the same car, depends on: 1) Components used within the engine - which is hardly different to be honest 2) Other things on the car, such as a 5 speed lower torque gearbox, Fixed rear suspension instead of multi-link, smaller brakes or drums at the rear instead of discs and many features such as different in-car entertainment, different interior trim, etc etc. Hope this helps! Last edited by carmayogi : 27th March 2017 at 20:34. Reason: Formatting | |

| |  (8)

Thanks (8)

Thanks

|

| The following 8 BHPians Thank carmayogi for this useful post: | bhpfaninblr, BlazzingInferno, H_Dogg72, LordSharan, Maverick_x1, MinivanDriver, racer_ash, SmartCat |

| |

| | #17 | |

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,668

Thanked: 6,217 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? If the engines are identical as far as major items go, it means the lower power engines are grossly overengineered => more expensive than it needs to be. And it is going to power a cheaper vehicle => positioned in a more price sensitive part of the market. Working at crosspurposes somewhere? In todays age of lean mean flexible manufacturing, the great god of parts rationalization has been greatly diminished in stature. Increasing power in a turbocharged engine (esp a diesel) is no big deal. Doing it while meeting statutory requirements, and delivering on reliability (and in the case of vehicles, drivability) - now that's a different ballgame. It would be interesting to separate the changes necessary to produce more power from those necessary for reliability when producing that power. And then study the different engines of the same family in that light. Quote:

Regards Sutripta | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Sutripta for this useful post: | SmartCat |

| | #18 | |||

| Senior - BHPian Join Date: Jun 2015 Location: Chicagoland

Posts: 2,985

Thanked: 6,857 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

I don't think the overall cost of the engine will vary more than 20% Quote:

Also, there are ways to get around these tests by playing with things like gearing, which shouldn't be a problem with these powerful torquey engines. Quote:

I read (on ET) a few years ago that Intel does not make any dual core processors at all. They make quad core processors, burn two cores off and sell the dual core unit to manufacturers to make lower end PCs. | |||

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks landcruiser123 for this useful post: | SmartCat |

| | #19 | ||

| Distinguished - BHPian  | Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

I would say, yes there is a fair bit of overengineering, but probably at no overall cost. At least not if you look at it from an overall points of view, including all the various design, production, logistics and maintenance processes. So itís the sheer volume of standardisation that gives you the overall edge. It would also mean each engine does have the exact same cost price. So how you work that into the sales price of your base model is a very different thing. You could take an approach that the premium cars ďsubsidiseĒ the base models. Accountants hate that by the way. Iím far from an expert in this field. Cost optimisation is a total production chain is a science into itself I reckon. I have been involved in investigations into my own field, telecommunications. And we found similar thoughts/patterns both on product development as well in areas as field services. Better to have as few components as possible, then to try to optimise each component on itís own. Quote:

I donít have stats at hand. But my feeling is that these days, engines themselves are extremely reliable. Iím talking here mainly about the mechanical aspects of engines. I mean when is the last time you heard about a car engine throwing a con rod? Or bust through a bearing? Reliability issues these days tend to come from the ancillaries, e.g. sensors, wiring and stuff like that. Jeroen | ||

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Jeroen for this useful post: | i74js, MinivanDriver, SmartCat |

| | #20 |

| BHPian Join Date: Sep 2014 Location: Noida

Posts: 332

Thanked: 617 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? The mercedes engine , 2.2 litre also had varied outputs from a measely 107 bhp in the old A Class to a double turbo blown 204 bhp in the E250 and C250 Similar with the 2.0 in BMW 1 and 3 and 5 and now even X5 and maybe a 725d soon All have one thing in common, around a 2.0 Similar Case with the outrageous Volvo Block |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks dhruvritzed for this useful post: | SmartCat |

| | #21 |

| BHPian Join Date: Sep 2015 Location: Bangalore

Posts: 167

Thanked: 260 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? It is a really interesting thread. It would be great if someone knowledgeable and resourceful could post the power and torque curves of different variants of the same sized engine from a manufacturer. I think that would provide a better insight. As someone else mentioned, at some point of boost, the efficiency would reduce from turbo charging. The engine would be able to burn only that much of fuel and air efficiently in the same volume. The engineer in me is screaming out "you've got to lose something for all that extra power and torque"  |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks MinivanDriver for this useful post: | SmartCat |

| | #22 | ||

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,668

Thanked: 6,217 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

Quote:

Sutripta | ||

| |  ()

Thanks ()

Thanks

|

| | #23 | |

| Senior - BHPian | Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

https://www.media.volvocars.com/glob...specifications Unfortunately getting the actual dyno graphs would be difficult. However one thing is easy to see. The RPMs at which the engine makes maximum power is restricted in the lower variants. Please ignore the T2 - it appears to have a 1.5l block and is not part of the same series. Last edited by reignofchaos : 28th March 2017 at 21:52. | |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank reignofchaos for this useful post: | MinivanDriver, SmartCat |

| | #24 | |

| Distinguished - BHPian  | Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

Just because you have the ability to do lean manufacturing doesn’t mean part rationalisation isn’t relevant anymore. But it needs doing in a different manner or rather context. Even in today’s lean manufacturing environment, every manufactured unique part comes at a cost. Producing two identical parts is always going to be cheaper than producing two unique parts. At the minimum you need two designs for a starter! So I think in the context of this thread, manufacturers will still try to have as many common parts for their cars. Think platforms, engines (parts), etc. I believe what you do see more and more is manufacturers in all sort of industries around the world taking a far more integral approach. From R&D, to design, into production, logistics, installation, maintenance, support. In our industry we have some of our R&D types going out with our field technician to understand how things get installed in the field. Similar for instance on Software support. A lot of requirements for the design phase of a software release come from our SW support organisation. Some organisations have this integral approach at least in their design from very early on. E.g. Mercedes is probably a good example. Look at my W123. Somebody really thought that through from very early on, not just on how it would drive, but how to maintain it, how to take it apart easily etc. I believe 3D printing has the ability/potential to do away with parts rationalisation all together. If you can produce each and every part more or less on the spot at a competitive cost price, who needs warehouses full of parts? You would only produce what you need, when you need it, where you need it. When 3D printing starts delivering on that promise the world will become a very different place. It will have huge impact on society, with huge changes. It can be / is a hugely disruptive technology with an impact that is just hard to grasp. I will be 3D printing bits and pieces for my classic cars soon. That means nobody will need to manufacture, store or transport them anymore! So it’s probably true that "the great god of parts rationalization has been greatly diminished in stature”. But he isn’t gone completely. He is working in tandem with various other techniques and technologies! Jeroen Last edited by Jeroen : 28th March 2017 at 22:18. | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Jeroen for this useful post: | SmartCat |

| | #25 | |

| Team-BHP Support  | Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

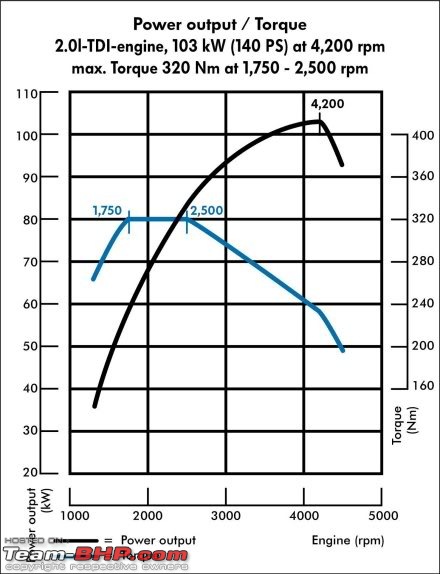

140 BHP/320 Nm  170 BHP/350 Nm (Superb has 177 BHP/350 Nm output while Q3/Q5 has 177 BHP/ 380 Nm)  190 BHP/400 Nm  So what can we infer from this? Last edited by SmartCat : 28th March 2017 at 22:54. | |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks SmartCat for this useful post: | i74js |

| | #26 | |

| Newbie Join Date: Apr 2014 Location: Nashik

Posts: 14

Thanked: 17 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

The generated torque is directly proportional to the amount of fuel burnt in the 4 stroke cycle. This clearly indicates that the engine is burning different amount of fuel at each configuration which also means that it is also supplying different amount of fuel at each configuration. For a same injector the fuel supply can be controlled by varying the fuel injection pressure. Thus i feel that every engine has the same hardware when it comes to fuel supply and control and the computer electronically controls the system i.e a different engine map. Now when it comes burning the supplied fuel in the cylinders completely, a certain amount of air in proportion to the supplied fuel must be available (these ratios are governed by the fuel stoichiometric ratios). This air availability is governed by the pressure at which air is fed to the engine. This air feeding pressure is generated by the turbo / supercharger. So the 190 HP engine's turbo will have to supply air at higher pressure compared to 140 HP engine. Now if the same turbo configuration can provide the required pressures in the above cases, the turbo hardware will remain same and the computer will control the feeding pressure. If the same turbo can't provide both pressures then the turbo hardware will be different in both the engines. When it comes to engine efficiency, manufacturers will try to keep the efficiency same. The engine efficiency is primarily dependent on the combustion efficiency and to ensure even combustion efficiency the manufacturers may be varying the piston surface geometry and fuel spray pattern (this requires a variation in injector nozzle geometry) while keeping the cylinder block and cylinder head same. By keeping a slight variation between the configurations, they can prevent aftermarket engine remaps from reproducing the power outputs from different configurations. I mean that a suitable aftermarket remap on a 140 HP engine to produce 190 HP will provide a lower efficiency than the stock 190 HP engine and may not be even able to give an output of 190 HP sustainably. Now an higher output engine will definitely consume more fuel but the difference will be clearly seen if the engines are made to run at an specific rpm. Fuel economy cannot be directly co-related to engine efficiency. Its is infact the averaged efficiency over the entire rpm range and is heavily influenced by the driving parameters. It is evident from the fact that different driving behaviors can deliver different fuel economy in a same vehicle. When the two cars (140 HP and 190 HP) are evaluated for the fuel economy the real difference between their engine power outputs will be during the acceleration phase and contribution of the acceleration phase in the entire test run is very less. Hence the marginal difference between fuel economies. | |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Par_neon for this useful post: | bhpfaninblr, drift87, SmartCat |

| |

| | #27 | |

| BHPian Join Date: Feb 2012 Location: New York City

Posts: 169

Thanked: 631 Times

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

The point is, for a more commercial or fleet use, a lower tune engine is the choice. As a petrolhead I hate it, but manufacturers are always on the conservative end of power outputs because if it ain't broke, don't go ahead and break it!! | |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank carmayogi for this useful post: | bhpfaninblr, Researcher, SmartCat |

| | #28 |

| Team-BHP Support  | Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Oh great. According to this link, Audi Q3's engine has been updated http://www.team-bhp.com/forum/indian...4-20-lakh.html So now, the 2.0 TDI produces - 148 BHP/340 Nm in FWD variant 182 BHP/380 Nm in AWD variant Maybe we are all thinking too much. Maybe there are two (hidden) knobs inside the engine to select the power and torque outputs.  |

| |  ()

Thanks ()

Thanks

|

| | #29 | |

| Distinguished - BHPian  | Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? Quote:

This to me sounds like a case of up selling to either cover badly designed products or up selling for no other reason than up selling and cheating your customers. This 75% rule is often quoted, but to my knowledge has no fundamental basis in terms of engineering or design. It’s a rule of thumb at best, most likely part myth. At least when I was involved in engine design, we certainly did not have such rule. If I buy a 1000Kw engine, it needs to deliver 1000Kw and not break down, unless the specification tells me it can’t handle a continuous 100% load. Some engine actually do have such a specification/rating. So it can handle a peak load only for a short period and a lower continuous load permanently. So going by your rule of thumb if I need a continuous 1000 Kw, I need to buy a 1000/0.75 = 1333 Kw or it would become unreliable? That doesn’t make sense. I have run medium speed diesel engines (4000Kw) at full load for 24/7 for months at an end. No problems. Contrary to popular believe many engines actually have the smallest amount of wear and tear at the highest loading. It’s very often the low and medium loading that will give problems. It’s more difficult to get a good clean combustion and your balancing might be off, due to low loading (pressure) on the piston, especially on constant RPM applications, so the bearings wear. I worked for/in the offshore. Ocean going tugs, supply vessels and Anchor Handling vessels are incredibly hard on their engines. They could be running at idle for sometimes days, whilst on standby near an oil rig. Some did that on heavy fuels to make matters worse. And then need to be able to deliver 100% load for for running anchors or months of non stop towing! We designed the engines for a given continuous output and then made sure they could handle all those other criteria as well. When our design told us we needed a 5000Kw Engine, running at such and such RPM/Torque and fuel efficiency, that’s what we got. We did not get a 33,3% bigger one to make it more reliable. It would have come at a financial and weight penalty from a design point of view whilst it doesn’t add anything. In another thread, a long time ago, I wrote about my experience with (marine) diesel. We have seen some serious reliability problems. Not because of heavy loading, but because of low loading at (two high) constant speed. Caused the bearing saddles to crack. Jeroen Last edited by Jeroen : 29th March 2017 at 02:12. | |

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank Jeroen for this useful post: | MinivanDriver, Numb_Locked, R2D2, SmartCat |

| | #30 |

| BHPian Join Date: Nov 2008 Location: Bangalore

Posts: 914

Thanked: 4,076 Times

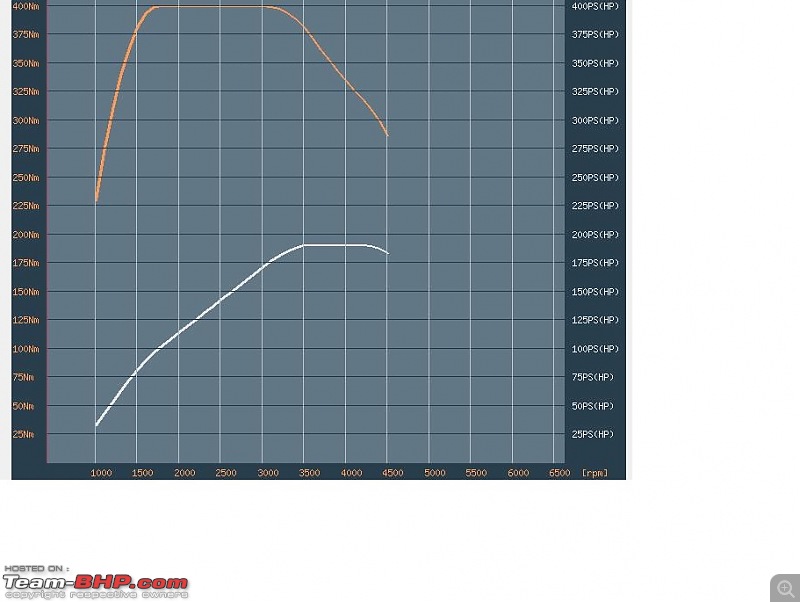

| Re: VW 2.0 TDI: Different Power & Torque outputs - How & why? I think what is generally not understood very well is the concept of an engine producing different power levels at the same RPM, and the impact that it has on operating efficiency. These are measured by BSFC curves. As can be seen from these, at a given RPM level, as you change the absolute torque (and hence, power) developed by the engine, the efficiency of the engine changes. In most cases, the highest efficiency is obtained when operating near the peak torque characteristics of the engine. Obviously the designers try to make the peak torque line intersect with the peak efficiency zone. Remaps just pick that line up and throw it above the peak efficiency zone. And if manufacturers want to extract greater power, they have to throw more air (turbo boost) at the problem, which will lift the region of max efficiency in this BFSC curve. Check out a bunch of BSFC curves here: http://ecomodder.com/wiki/index.php/...on_(BSFC)_Maps About the 190 PS engine producing 140PS of power more efficiently than a 140PS engine producing 140 PS of power - I hope that these curves make things more clear. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank d3mon for this useful post: | i74js, R2D2, SmartCat |

|