Team-BHP

(

https://www.team-bhp.com/forum/)

The DEFINITION

Parentage German. Name:

Direkt-Schalt-Getriebe /

Dual Shift Gearbox, commonly abbreviated as DSG.

Perhaps this widely viewed YouTube video on its functioning is a good way to start off the proceedings:

http://www.youtube.com/watch?v=mj1Vk7SE-TI

Albeit, VW also has a video on 'Knowing your DSG' but it doesn’t “shift” much, if you get what I mean:-

https://youtu.be/s4wsyrdZyhI

Needless to say, there are tons of videos out there which explain the concept vividly.

The most elementary definition of the DSG is perhaps that it is an electronically controlled dual-clutch, multiple-shaft manual gearbox i.e. it comprises two separate manual gearboxes (and clutches) contained within one housing and working as one unit.

Back to index

The LAUNCH and INITIAL SUCCESS - The dual-clutch transmission (DCT) may have debuted on a production car as late as 2003, yet it was initially conceived many decades prior, just before the onset of World War II- by a French military engineer by the name of Adolphe Kégresse (wiki page). He called it Autoserve and it operated on the same principle as modern DCTs, using two clutches - one for even gears and one for odd sprockets. Since torque converter automatics were rising in popularity at the time (and were cheaper), the DCT idea lay buried for decades.

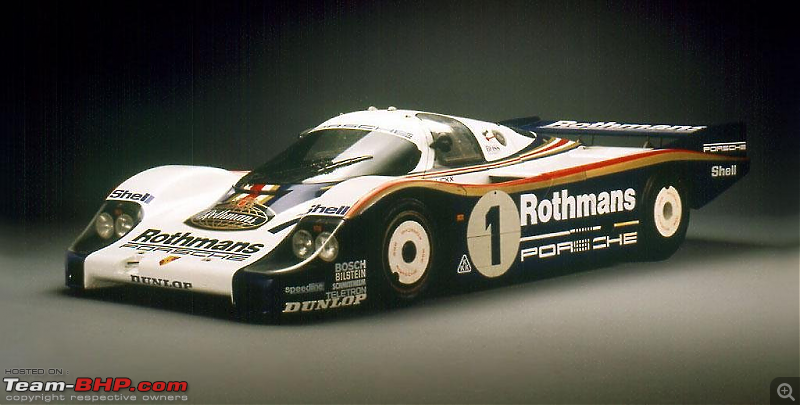

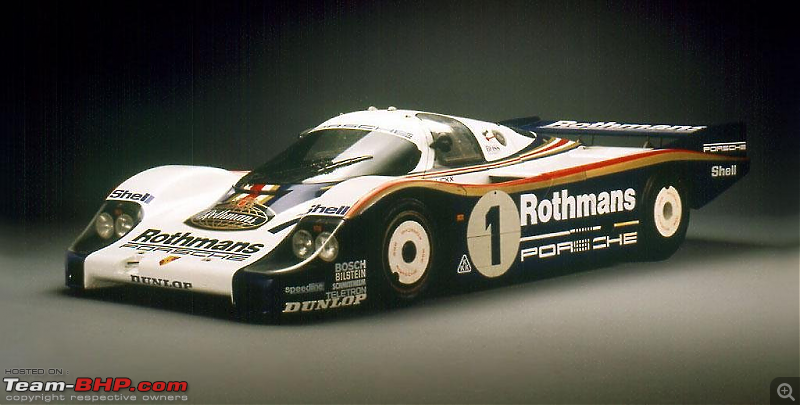

- It took another half-century before the DCT was looked at again, this time by Porsche which used it in two 1980s race cars: the 956 and 962 - the German company dubbed the transmission Porsche Doppelkupplungsgetriebe which was shortened to PDK, the name which has stuck until the present day.

The beautiful Porsche 962:-

- Next up it was used on another racer, this time the Audi Quattro S1 which actually used a PDK straight from Porsche, instead of making its own. Its first outing was in November 1985 at the Semperit Rally Austria. It was claimed that with the five-speed dual-clutch installed, the Quattro could crack sixty in under three seconds (claimed 2.6 ticks) and allow shifting of gears without lifting off the throttle.

The blazingly fast Audi Quattro S1:-

- In 2001, BorgWarner reported that "DualTronic" transmission technology selected for production by VW

- In 2002, VW announced the 6-speed, wet clutch DSG to the world

Quote:

Volkswagen presents a world-wide technical innovation: the sporty and economical direct-shifting 6-speed automatic gearbox "DSG”. This especially dynamic form of power transmission with integrated dual clutch will be used for the first time in the Golf R32 in the first quarter of next year. Its use will be extended to other production series in the course of the year 2003.

The direct-shifting automatic gearbox has been designed to fulfil the demands of European customers for sporty driving as well as fuel economy.

|

Link to press release

- Again in 2002, Volkswagen produced the Golf R32 in Europe. It was the world's first production car with a dual-clutch gearbox (DSG) — available for the German market.Due to unexpected popularity, Volkswagen decided to sell the car in the United States and Australia as the 2004 model year Volkswagen R32. The R32 was capable of 0-100 kilometres per hour (62.1 mph) in 6.6 seconds, reduced to 6.4 seconds with the dual clutch gearbox

The super hot Golf R32:-

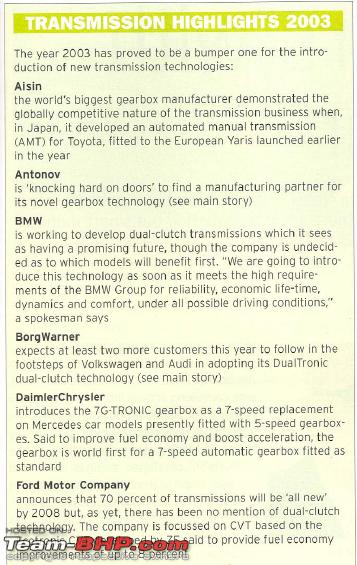

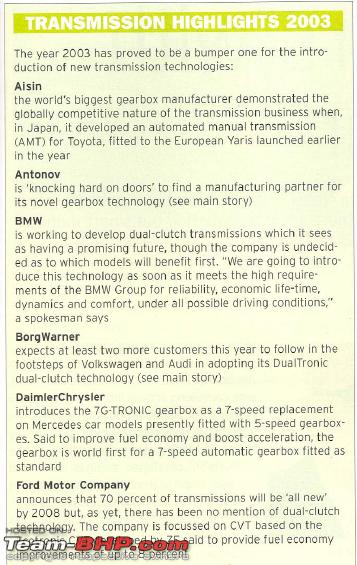

- 2003 – hailed as year for introduction of new transmission technologies by companies like Aisin, BorgWarner, Getrag etc.

Extract 1:

Extract 2:

Magazine PDF file source, published in 2003:Magaine_transmissions.pdf

- Between 2003 and 2008 - Over 1 million 6-speed DSGs sold by VW

- Jan 2008 – VW announces the 7-speed, dry clutch DSG to the world

Quote:

The new 7-speed DSG makes the revolutionary transmission technology available for smaller engines too

|

Quote:

In comparison to the 6-speed DSG, there is no “wet” clutch in the new transmission – that is a clutch immersed in an oil bath – rather a “dry” clutch. That too is a world first for DSG technology. This and other engineering modifications led to significant improvements to the DSG’s efficiency. The result: Further reduced fuel consumption and emissions values, even greater convenience and driving fun.

|

LInk to press release

- In 2010, VW announces DQ500

Quote:

Building on the experiences afforded by the proven DQ200 and DQ250 gearboxes, the new DQ500 now makes dual clutch technology available to customers with larger and high-performance vehicles. The DQ500 is currently the world’s only seven-speed transverse-mounted gearbox for high torques that is in large-scale series production. The clutch is designed for an engine torque of up to 600 Nm, and yet 8 mm smaller than in the DQ250. It can be used for a range of applications from sporty passenger cars to commercial vehicles.

|

Link to press release

Back to index

The WORKS

For the uninitiated, this section really gives you a ringside view of the design and what/how VW came up with such mind-blowing technological innovations.

For reasons attributed to sales volumes, intend to focus on the two most popular gearboxes – the

DQ250 and the

DQ200.

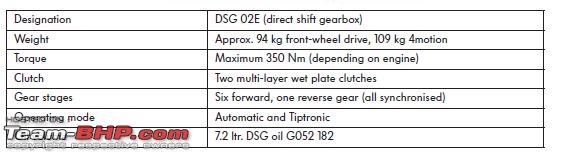

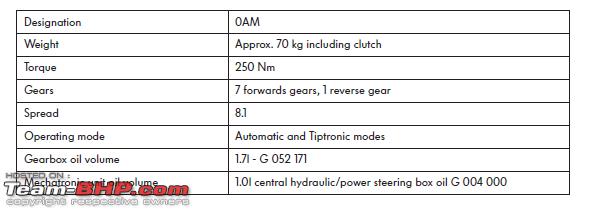

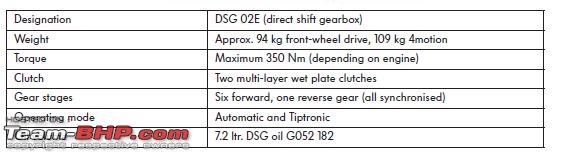

Introductory data for the

DQ250:

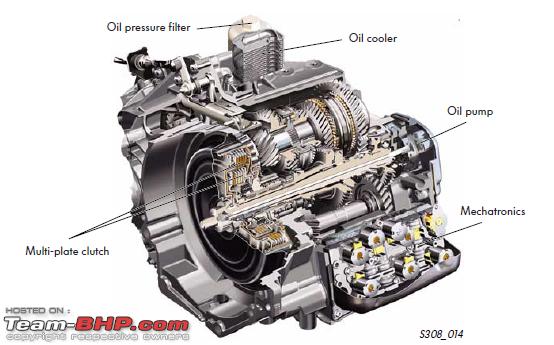

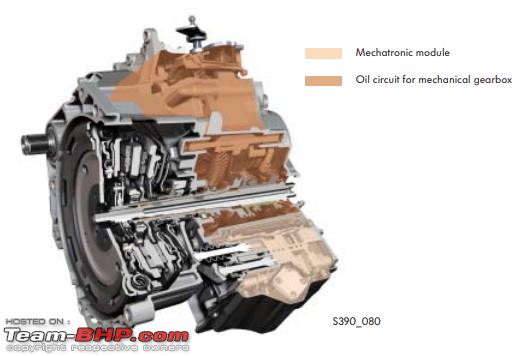

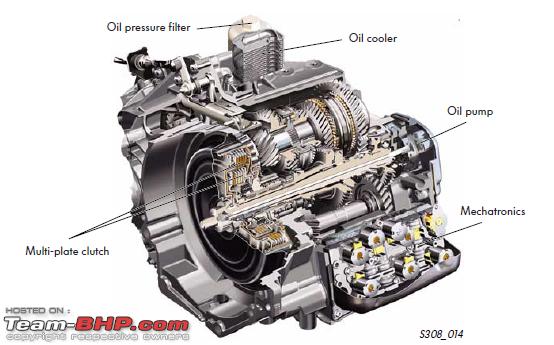

With the section-wise image of the gearbox unit with the multi-plate clutch:

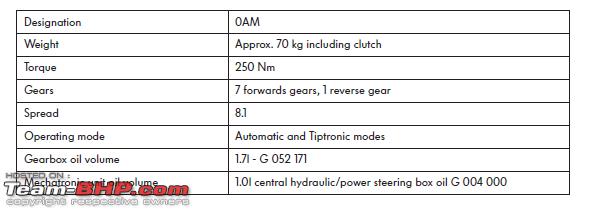

And similar info for the

DQ200:

Along with the section-wise image with the double clutch:

The

source of the extra weight for the DQ250 can be clearly attributed to the

~5 times the amount of gearbox

oil, along with the

number of clutch plates.

This also

clarifies the wrongly-held view that the DQ200 is a totally "dry" unit.

Also explains the rationale

why VW wanted to have the lighter, 7-speed gearbox - mainly

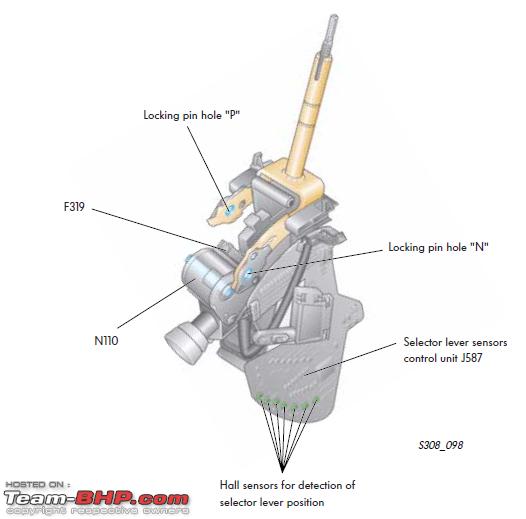

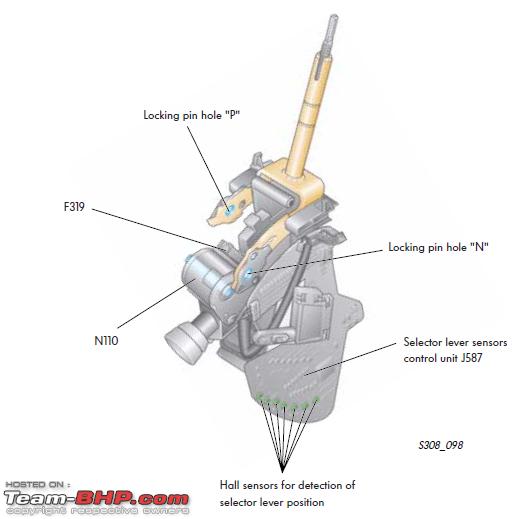

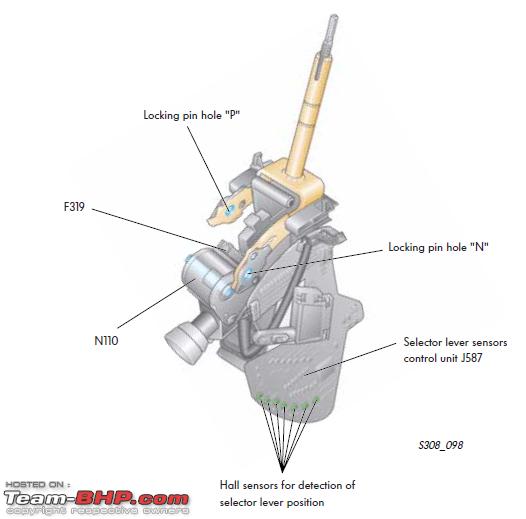

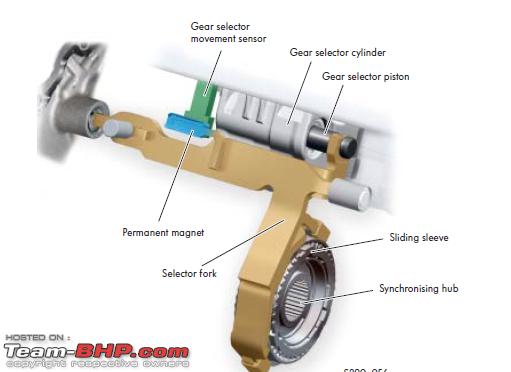

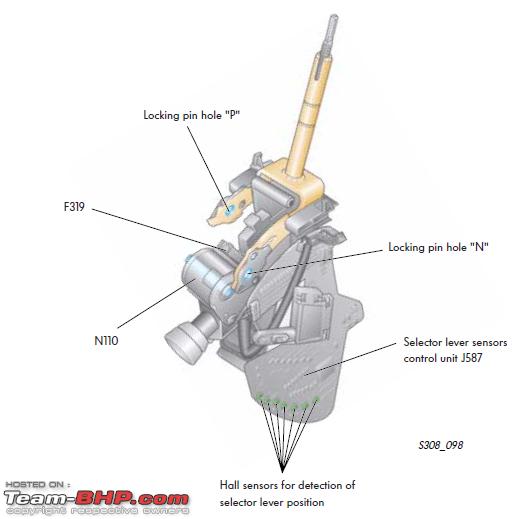

to cater to smaller engine/relatively higher volume cars. Selector level design is common to both gearboxes:

In the above selector design, the "

hall sensors" play a very critical role since they act as the

primary feed in case of any failures for the gearbox. More on that later.

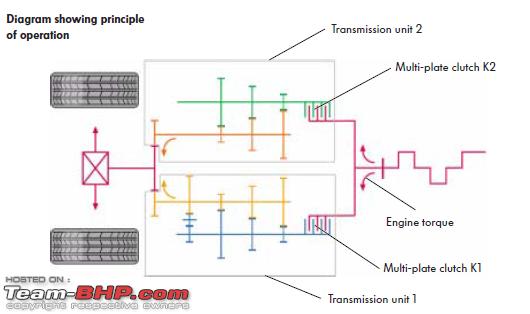

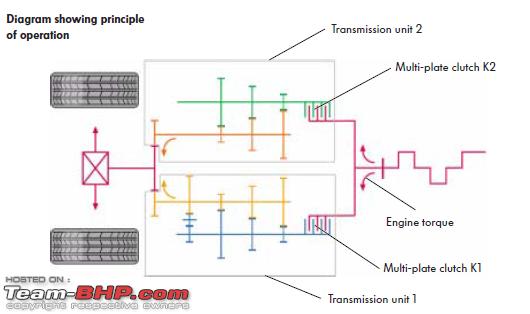

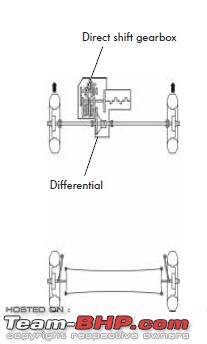

Principle diagram for the DQ250:

1st, 3rd, 5th and reverse gear are selected via multi-plate clutch K1.

2nd, 4th and 6th gear are selected via multiplate clutch K2.

Both the multiplate clutches are submerged in oil.

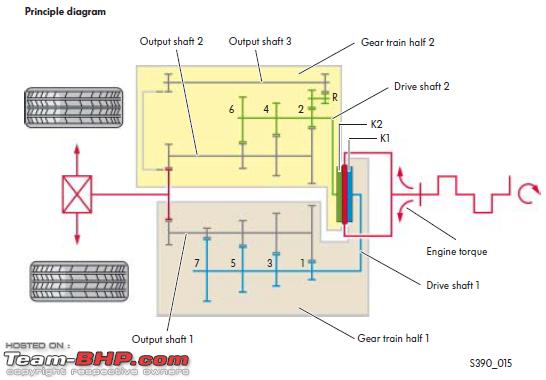

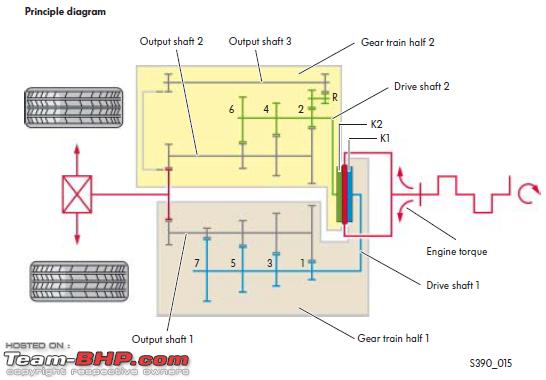

And for the DQ200:

Gears 1,3,5 and 7 are shifted via clutch K1 whereas gears 2, 4, 6 and reverse are shifted via K2.

Note how the

DQ200 clutches are arranged concentrically, to aid in

compact gearbox design.

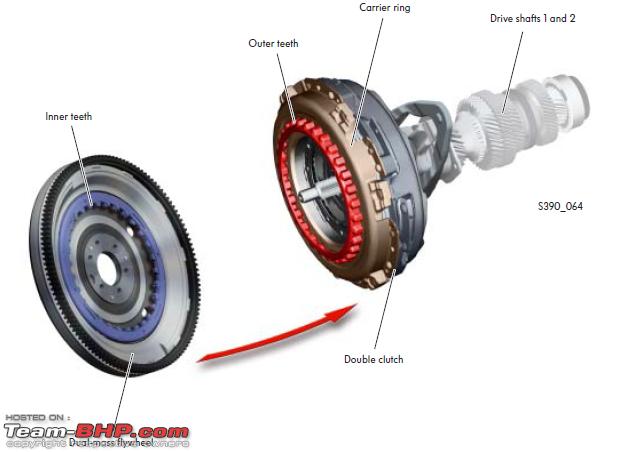

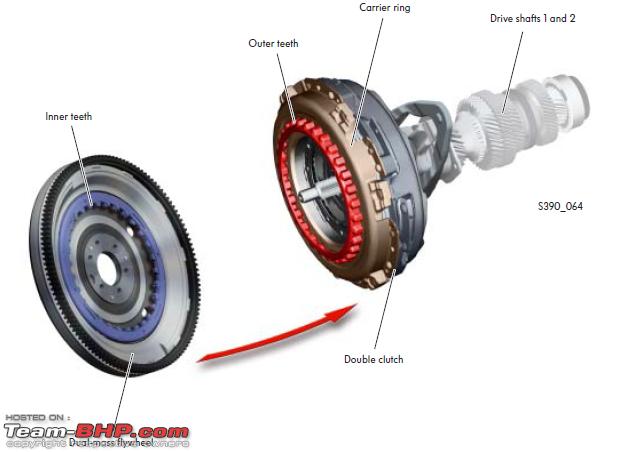

When it comes to the very important activity of

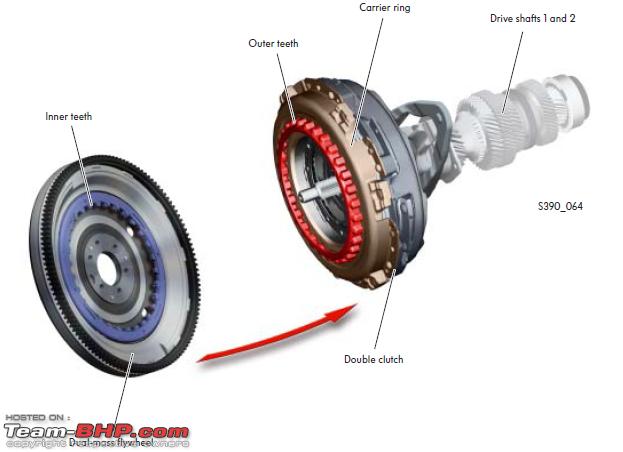

torque transmission inside the gearbox, this diagram probably explains it quite nicely:-

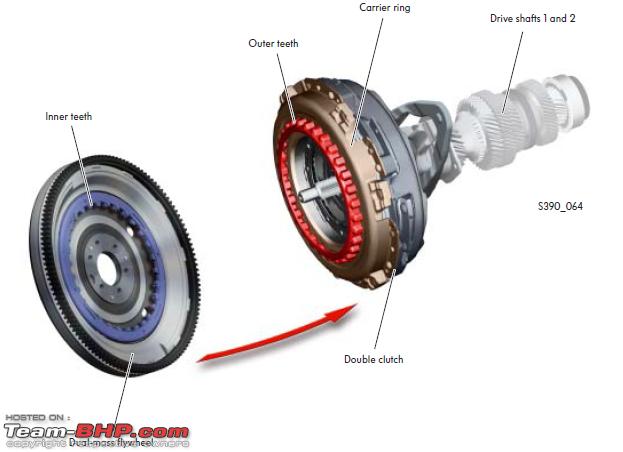

The torque is transferred from the dual mass flywheel, which is secured to the crankshaft, to the clutch plates.

The above diagram is for the DQ200 but the mechanism remains the same in the DQ250 also.

Some cases of

shuddering in the DSG gearboxes have been also attributed to the

improper torque transfer by the dual mass flywheel.

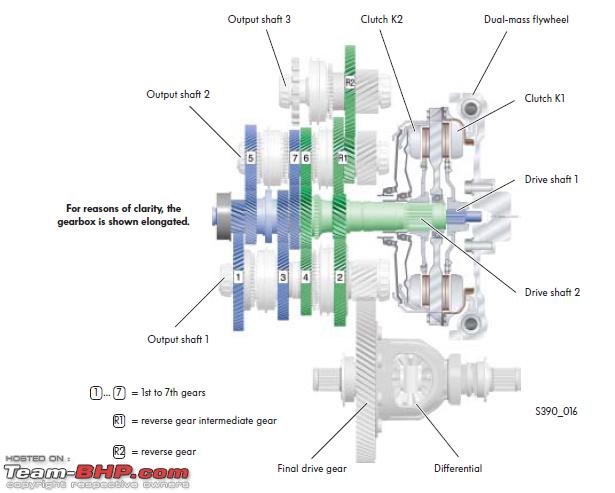

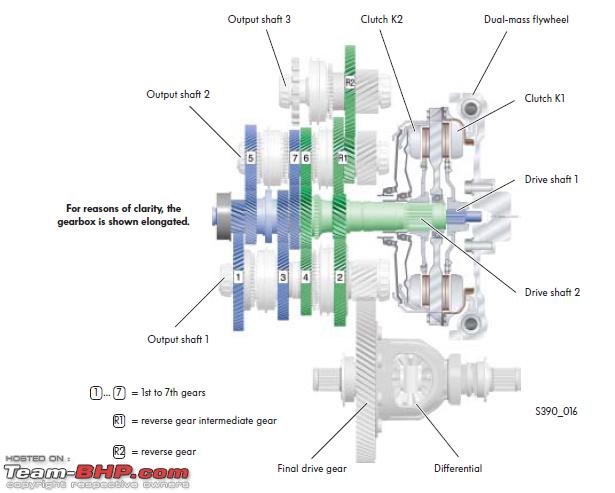

And the below diagram explains the end to end view of the entire torque transfer, per se:-

This diagram is again depicted for the DQ200 dual clutch gearbox.

After "receiving" the torque from the mass flywheel, the clutch K1 transfers the torque further to drive shaft 1 (marked in

blue color). From drive shaft 1, the torque for gears 1 and 3 is transferred to output shaft 1 and that for gears 5 and 7 to output shaft 2.

And the other clutch K2 transfers the torque to drive shaft 2 (marked in

green color). It transfers the torque for gears 2 and 4 to output shaft 1 and the torque for 6th and reverse gear to output shaft 2. Via intermediate reverse gear R1, the torque is then passed to reverse gear R2 on output shaft 3.

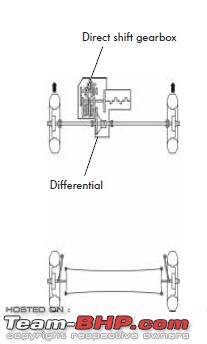

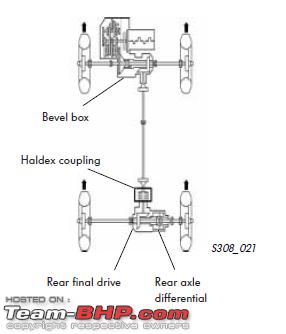

And now for the

torque transmission outside the gearbox, the below diagram mentions that on front-wheel drive vehicles, the drive shafts transmit the torque to the front wheels.

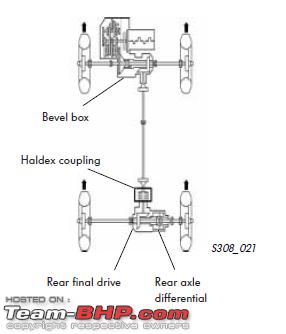

And for 4-wheel drive vehicles, in addition to the front wheels, the torque is transmitted to the rear wheels via a bevel box, wherein a propshaft transmits the torque to a Haldex coupling. Integrated in this rear final drive is a differential for the rear axle.

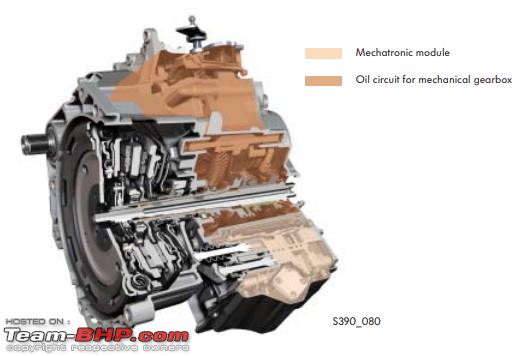

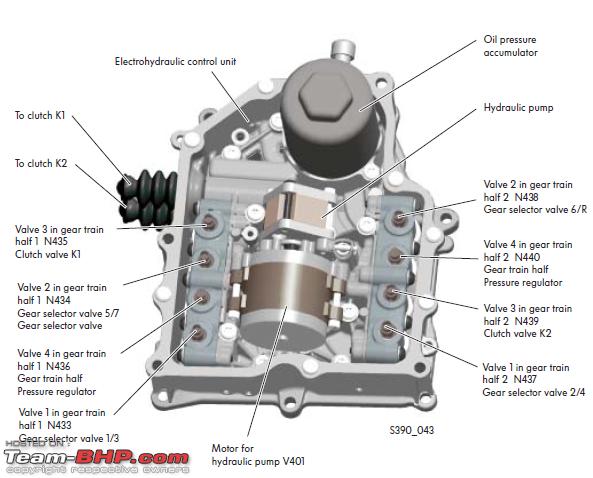

Next, is an important part of the gearbox, referring to what is termed as the brain of the DSG -

Mechatronics:-

In the DQ250, the mechatronics is housed

inside the gearbox, surrounded by DSG oil, whereas in the DQ200, it is flanged

onto the gearbox. This means that, in the DQ200, the mechatronics has a separate oil circuit, independent of the gearbox oil circuit.

The mechatronics comprises of an electronic control unit and an electrohydraulic control unit. The electronic unit is where the

learning or the adaptation regarding the position of the clutches, positions of the gear actuators and the pressure characteristics - get

developed or imprinted due to a particular driving style over a period of time. Now you know the source of the

DSG's "intelligence"!

The salient features of this autonomous, compact unit are:-

- Except for 1 sensor, all other sensors are contained in the mechatronics

- There is only 1 vehicle side connector required, reducing the amount of wiring, thus resulting in lower weight and greater electrical efficiency

- In the DQ200, due to the separate oil circuit, no foreign material from the gearbox can enter the mechatronics unit

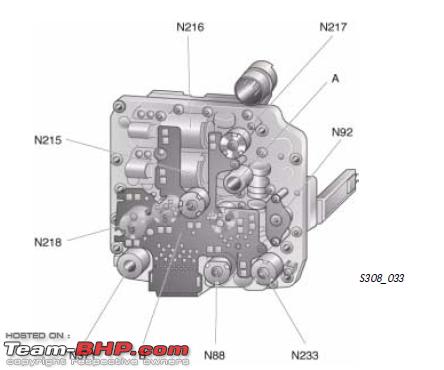

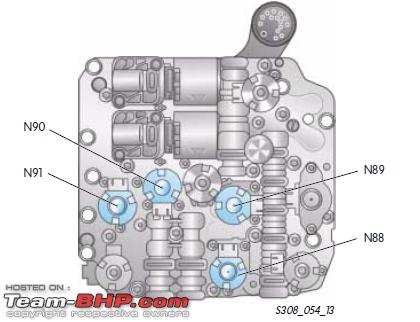

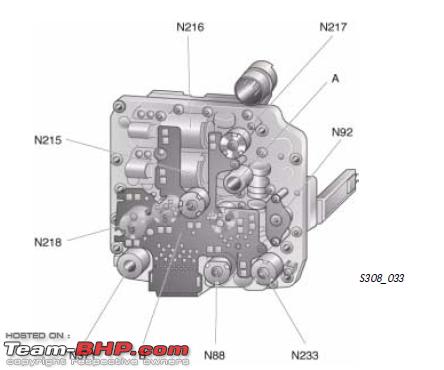

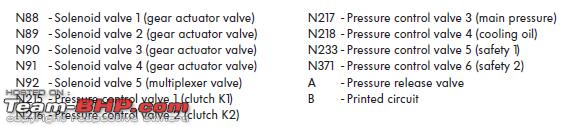

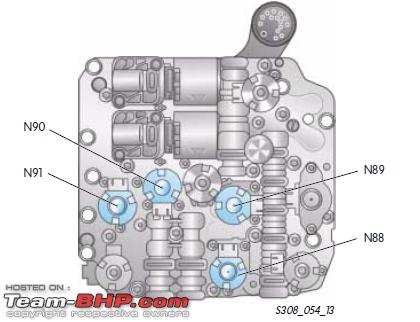

For the DQ250, the electro-hydraulic control unit houses all the solenoid valves, pressure control valves and hydraulic selectors alongwith the multiplexer, as shown in the below diagram:-

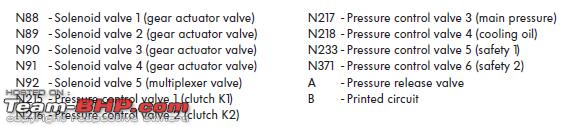

Since this gearbox has the common lubrication circuit for all units, the oil has the task of lubricating/ cooling the clutch plates, gear wheels, shafts and also actuation of the plates and plungers.

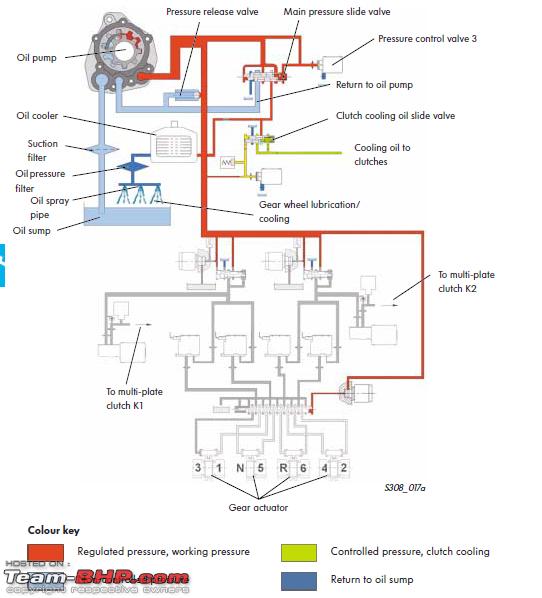

Here is the

oil circuit diagram for the DQ250:-

Even though the above diagram is self-explanatory, however just to give it a perspective - it starts with the oil pump drawing oil from the sump and and supplying it to the pressure valve. The pressure generated by this valve is then used to actuate the multi-plate clutches and final selection of the gears.

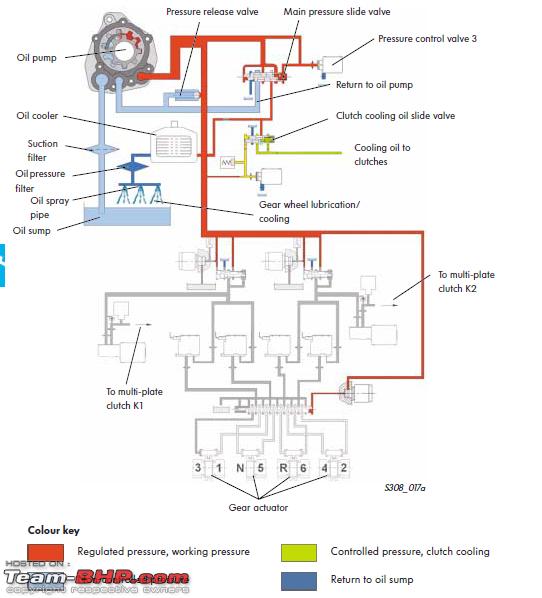

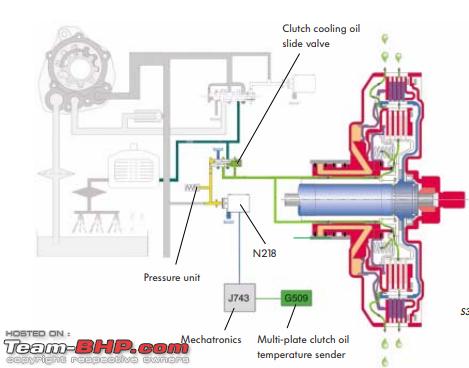

Since the DQ250 has multiple clutch plates, the

heat produced by the mechanical friction of the plates is cooled by a

separate cooling oil circuit, as shown in the below diagram:-

The pressure control valve increases/decreases the oil pressure at the slide valve depending upon the temperature generated.

Point to note, however obviously, that the

DQ200 does not have this separate clutch cooling oil circuit due to absence of the multiple plates.

Now coming to the

biggest misconception for the DQ200 - as can be seen in the below diagram, there are not 1 but 2 separate oil circuits:-

As is evident from the above, the 2 circuits run on independent oil supplies.

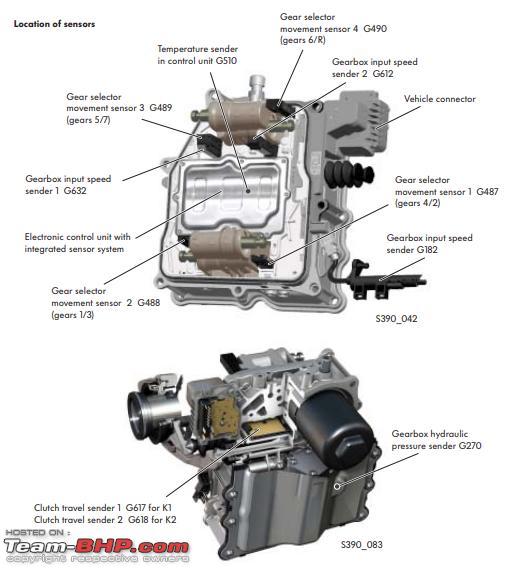

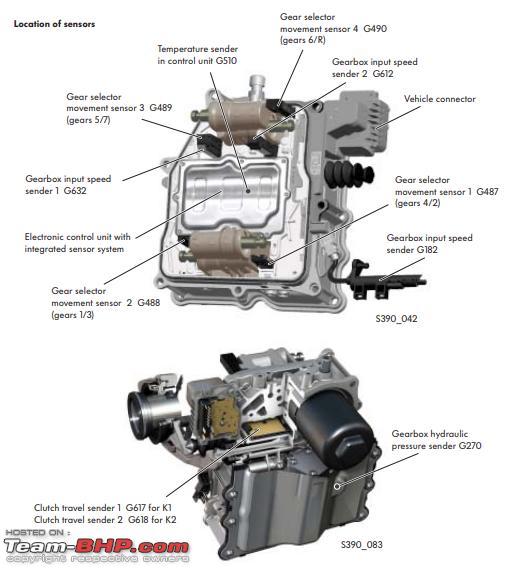

When it comes to the various sensors for the mechatronics's electronic control unit, all actions are analysed and directed from this unit.

Below diagram showing the sensor locations:-

The sensor G182 is the only sensor located outside of the mechatronic unit. In the event of signal failure due to this sender, the control unit uses he engine speed signal from the ECU.

The input senders G632 and G612 help in calculating the speed of drive shafts 1 and 2. In the event of signal failure of G632, the vehicle can be driven only in gears 2,4,6 and R. And for failure of G612 signal failure, the vehicle can be driven only in gears 1,3,5, and 7.

The temperature sensor G510 is used to check the mechatronic unit's temperature. In the event of signal failure, the control unit uses an interally available substitute valve.

The hydraulic pressure sender G270 is used to control the motor for the hydraulic pump. In the event of hydraulic pressure reaching approx 60 bar, the motor is shut off according to the signal and switched on again at 40 bar pressure.

For the gear selector movement sensors 1 to 4, G487 to G490 - on combination with the solenoids, they generate a signal from which the control unit recognises the precise position of the gear selectors. In the event of a signal failure, the control unit is unable to recognise whether or not a gear is changed and the failed gearbox path is shut off in this case.

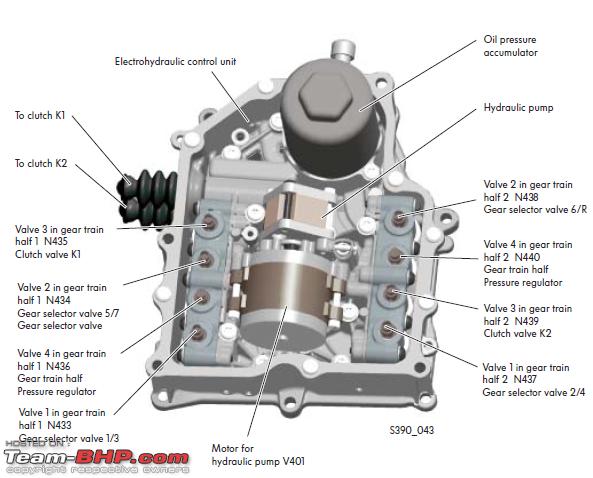

Now for the electro-hydraulic unit of the DQ200:-

The hydraulic pump pushes the oil through the filter towards the pressure limiting valve, the accumulator and the hydraulic pressure sender.

The pressure accumulator provides the system with oil pressure when the hydraulic pump is switched off.

As for the valve setup, this comprises of the clutch actuator solenoid valves (N435, N439), gear train half pressure control valves (N436, N440), gear selector solenoid valves (N433, N434, N437,N438). In the event of one of the solenoid valve failing, the corresponding gear train half is shut off.

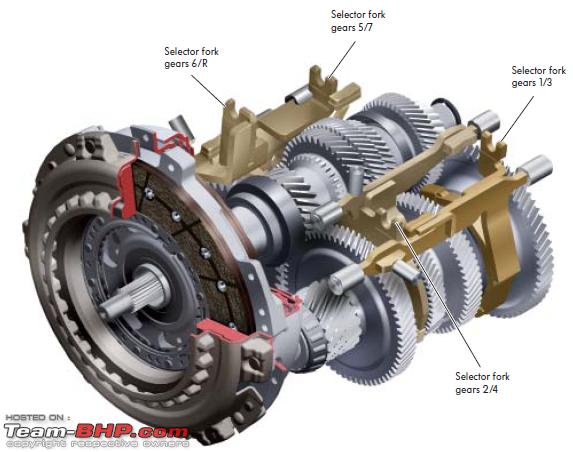

Now moving to another important section for the gearbox, related to

shifting the gears..

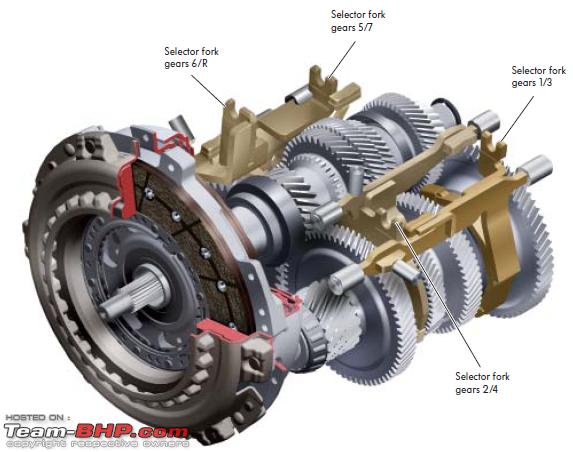

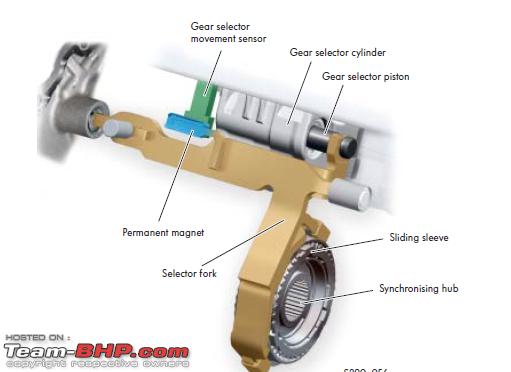

As in the case of conventional gearboxes, the gears are shifted using selector forks. Each fork shifts two gears. The below diagram depicts the housing:-

When changing gears, the forks are moved via gear selectors integrated into the mechatronic unit.

The way it works is that the gear selector piston is connected to the selector fork. To change gears, oil pressure is applied to the gear selector piston, thereby moving it. When it moves, it also moves the selector fork and the sliding sleeve. The sliding sleeve then actuates the synchronising hub and the right gear is engaged, as shown in the below setup:-

To end this section, here is a sample video showing an equivalent of an "Unboxing" DQ200 gearbox:-

http://youtu.be/xyp96e1p16Q Back to index

THE OWNERSHIPS

So, by now I hope that you would have got a very good understanding of how the various valves, sensors, actuators and the gear assembly come together to produce that beautiful motion when engaged correctly!

After having understood the fundamentals (at at certain places, something more than that!), this section will now attempt to capture -

at one place - various ownership threads posted on TBHP, so that we can

browse through them and compare, learn and understand the various owner perspectives.

I know by looking at the list here, some of you may argue that we could just search up the various forums with specific keywords etc. and not required to have a list as such but my view is to have everything sorted out and assembled together, so that we can navigate easily and even add to the list here in the future so that this evolves over time immemorial!

While browsing through some of the reports, I was amazed to find so many nuggets of valuable info related to DSG ownerships - obviously both good and bad experiences.

As I mentioned in my opening post, the emotions have ranged from extreme delight to shock!

These ownership links are arranged in no particular order (either in buying timelines or duration of ownership as such). However, what I have attempted is to cover both the categories of DSG ownerships - "Initial" ownership reports and the really "Long-Term" ownership reports by taking into consideration

Skoda and

VW car owners.

This list may not be 100% complete to start with (have

75 ownership reports listed for now), and it is possible that I may have not been able to include some ownership references. However, as I mentioned earlier, will keep on updating this thread and would also request folks to let me know of instances which need to be included in this DSG story.

Looking at the

Skoda list firstly.

Superb owners:-

Swanand Inamdar -

report | ivar1951 -

report | sahil -

report | Hayek -

report | holysmoke -

report | BoringProf -

report |

Octavia owners:-

Joethomasv -

report | Sandeepsarma -

report | Starrysky -

report | abhinav.gupta88 -

report | karvel -

report | nikhilb2008 (vRS) -

report | sivadas (vRS) -

report | imidnightmare -

report | sawnilrules -

report | suhaas307 -

report | adi_petrolhead -

report |

Laura owners:-

.anshuman -

report | Vignesh.cv -

report | newtonMeter -

report | luky_13 -

report | goutham_r -

report | .cArMaNiA -

report | amit2kin -

report | danc -

report | razor4077 -

report | seacat -

report | hvishwanathan -

report | | Insane Devil -

report | kiranjoshy -

report | lamborghini -

report | nitinbose -

report | akki_5 -

report | ACM -

report | deepakvrao -

report |

Karoq owners:-

Starrysky -

report |

Rapid owners:-

Laddz1121 -

report | MadAbtCars -

report | charansuki -

report | rohanjf -

report | shubhu3112 -

report |

And this is followed by the

VW list.

Passat owners:-

fordfreak -

report | kimianks -

report | ev06 -

report |

Jetta owners:-

Iliketurtles -

report | Amarendranath -

report | Graaja -

report | sunsbhp -

report | abhilashgp -

report | aseem -

report | ayedongivadam -

report | Aurum -

report | althaaf -

report | akhilesh51 -

report | cls_55_AMG -

report |

Vento owners:-

Execve -

report | rejeen -

report | Rajeevraj -

report | amitg79 -

report | Joshmachine (yours truly :D) -

report |

Polo owners:-

frankmehta -

report | diffsoft -

report | Nevgin -

report | graaja -

report | chase_nt -

report | Santoshbhat (Polo

GTI) -

report | abhilashnanda (Polo GTI) -

report | hemanth.anand -

report | robimahanta -

report |nishcal316 -

report | pilot77in -

report | GTPower -

report | prateekswarup -

report | suhaas307 -

report |

Back to index

My 2 cents on the DSG ownership and experience

When I put up the ownership report of my Vento last year (the car had close to 35k km on the odo), I had outlined some initial experiences of the DSG at

this post.

As of today, when the odo reads approx 60k km on the Vento, just to give a perspective of my driving patterns and usage based on which I have derived my DSG experiences, here is a break-up of the same:-

- Weekday driving to office and back almost 60 km - out of this, almost 15 km is slow-moving/crawling, bumper to bumper traffic and the rest is highway-like road condition

- Road trips in the last 3+ years: Pune - Bhopal - Pune (2 times), Pune - Nagpur - Pune (once), Pune - Gujarat - Pune (2 times), Pune - Mumbai - Pune (approx 10 times), Pune - Panchgani/Mahabaleshwar - Pune (3 times), Weekend getaways around Pune (6-7 times)

- Pune city driving on weekends

So, looking back in hindsight, I feel that I have been involved in a reasonable mix of highway and city driving scenarios, based on which I have inferred my own experiences of the gearbox behavior.

Am glad to reiterate that almost all of the advantages /observations from my ownership post hold true even today.

Just re-quoting from the original post herewith:-

Quote:

- Hardly any gear shift shock as compared to a manual transmission (about 6-8 millsec for upshifts and about 600 millisec for downshifts. A human hand on a minimum average takes about 1.1 - 2.0 sec to do the same, data point sourced to various forums). This is one of the primary reason for that "fun to drive" factor in these super machines

- Almost, continuous power flow of power is maintained as compared to a continuous variable tranny

- Very high levels of comfort for the driver

- Ability to execute a kickass kick-down with much more precision as compared to other auto-trannies

- Sports mode - more engine power available at disposal, more engine braking if used smartly

- No rubber band effect, no excessive grunt unlike the traditional torque converters

|

And to extend some of these points mentioned in this list and also extending those mentioned in my ownership post, here are some additional observations/experiences that I can list down:-

- The DSG behavior or response is at its "predictable best" if driven in a linear fashion, i.e. it works smoothly when you accelerate or decelerate gradually without any major speed shocks.

- From my experience, the DSG won't let the needle go beyond 3500 rpm under most conditions (climbing an incline with/without loads, trying to kick-down on a flat highway, trying to speed down a descent etc.). Please note however that the max calibration is done for 6000 rpm in the Vento

- When in bumper to bumper traffic or very slow moving traffic or going downhill, I immediately shift to manual /tiptronic mode to avoid potential over-heating of the dual clutch plates. When possible, I then try to drive at a speed greater than the car idling speed of about 7-10 km/h so that the mechatronics sensors do not have to continuously send a signal to engage the gear selector forks and keep the clutch plates on standby position for the next pre-selected gear.

- The upshifts will happen faster as compared to the downshifts. When I accelerate linearly from say 1st to the 7th gear, the car moves into its own zone of highly optimized state of efficiency. However, when I downshift in a sudden or non-linear or unnatural fashion, I can "feel" the overspin on the flywheel is still holding the gears that much longer and that's when you realize the downshift takes a wee bit longer to take place.

For those who are uninitiated with respect to the DSG world yet, here is a high-level summary view of the various driving modes:-

- As briefly explained in the WORKS section, the design of the gearbox lever along with the drive shafts and the plates (PLUS the VW philosophy of keeping things unambiguous for the end-customer) enables it to operate in a straight "fore and aft" motion. Therefore, the various modes like P, R, N, D, S are in a linear manner, one below the other - unlike the gated gear box or rotary or joystick patterns seen in other brands. Selection or design of the gearbox patterns is perhaps a conscious decision by different manufacturers, which depends primarily on what they want the customers to feel or what they want the customers to do.

- "P" or Parking mode: In this mode, everything is disengaged - i.e. the gear selector forks, clutch plates. The parking lock pin is engaged purely mechanically via what is known as a Bowden cable between the selector lever and the lock lever on the gearbox. Point to note is that the ignition key can be withdrawn only when the P mode is actuated.

- "R" or Reverse gear: functions like a "normal" gear, just that the output shaft gets driven in the reverse direction

- "N" or neutral gear: in this mode, the gears are disengaged and the gear selector piston is held in that position via the oil pressure controlled by solenoid valves.

- "D" or driving mode: the gearbox won't allow to shift from 'Neutral' to 'Drive' mode unless the brake pedal is pressed. The 'D" mode is where the DSG is meant to show its full array of automatic gear selection and the adaptive nature of the mechatronics unit. As was mentioned in the above WORKS post, the mechatronics sensors will pre-select the next set of gear changes with the assumption that there will be steady and linear acceleration by the driver. Since I am personally in favor of such a driving style and have been doing so for a large portion out of the 60k km covered so far, I can vouch for the view that the DSG has probably adapted to my driving style.

This is so because I have seen significant consistency in the tachometer and the engine throttle combination to result in a gear change.

On the contrary, when I apply throttle pressure which is far greater than the resistance offered by the normal operation of the dual clutch plates, then the sensors literally send an immediate instruction to downshift. In layman terms, this is termed as kick-down and will result in an almost instantaneous needle shift on the tacho, indicating that the engine has received the 'order' to pump in more revs and it will do the needful.

Another point to mention is that of cruise control - when this scenario is selected (irrespective of the car being in 'D' or 'S' mode) - the sensors and the associated conundrum of forks and plates are forced to hold onto the selected gear.

- "S" or Sport mode: the functioning of the gearbox while in this mode is very much like the "D" mode, with the notable difference being the increased engine revs enabling usage of more engine power/braking at the driver's disposal. Needless to say, this will have an adverse effect on the fuel efficiency since the car will definitely guzzle more fuel if operated in this mode for longer duration.

In my 3+ years of ownership, I have very seldom realized the "technical need" to shift into this mode purely from lets say, an overtaking perspective. The "D" mode is sufficient enough to provide that thrust with some kick-down action.

In this "S" mode, the engine revs are about 15-20% or even higher as compared to the equivalent 'D' mode gear. What this means is that, if you are driving in let's say 'D7' gear at about 1400 rpm, and if you shift into "S" at that point of time - then the equivalent gear would most probably show 'S6' on the MID but with about 1500-1700 rpm on the tacho. One needs to be aware of the increased revs and need to take that into consideration while undertaking a kick-down action in this mode else there is a potential of traction control loss due to excessive wheel spin while fast acceleration.

On other note, the 'S' mode is famous for a reason :D - on an empty stretch of road with good visibility, nothing comes close to that rushed feeling of being thrown back in the seat when you execute a clean kick-down in this mode!

Back to index

The FAILURES

The year

2018 coincided with the

15th anniversary of DSG production (as noted in the "The Launch and Initial Success" post above).

The origins (and majority of the production) of the DSG is attributed to a German plant located in the town of Kassel.

Until the middle of 2018, more than 26 million drivers of Volkswagen Group models have opted for a dual clutch gearbox (mostly 6-speed and 7-speed). That's putting it to

approx. 20-22% as DSG-powered vehicles out of the total volume of passenger cars sold by VW Group in the last 15 years or so.

When it comes to individual car brands like the Golf, Polo, Passat etc. these percentages are even higher, going upto 40% or even 60% in some cars.

In 2018 - the annual production of the Kassel plant was 3.6 million gearboxes and in terms of passenger car sales, VW group sold close to 9.3+ million globally - thus it can be extrapolated that approx. 38% cars were powered by a DSG in 2018 from the Kassel plant (numbers for DSGs produced from other global locations not known).

However

with such a relatively good success rate for the famous gearbox, VW has been very infamous in its handling of the problems attributed to the same.

This section intends to bring out some of the most widely known issues and the most probable root causes for them, along with the solutions suggested / implemented by VW.

The basis of the research has comprised studying various forums, VW technical documents, 3rd party analyst reports and talking to service advisors, Master Technicians (from VW), colleagues from the automobile engineering fraternity and our very own TBHP chronicles.

Generally speaking, both sets of gearboxes i.e. DQ250 and the DQ200 have had customer complaints across the globe, but the latter has drawn more flak due to the sheer volume of 7-speed DSG-powered cars getting sold (especially in Asia-Pacific region).

In no particular order of appearance or severity, listing the various issues/complaints that have surfaced:-

- Violent or intermittent shuddering during shifts

- Sudden loss of forward propulsion (unanticipated/abrupt shifting to neutral while driving)

- Intermittent or continuous abnormal sound/noise during shifting

- Sudden/unanticipated acceleration during a gear shift

- Harsh/unanticipated vehicle jerking during shifting (pronounced at low speeds and mostly for downshifts, some for upshifts too)

- Gears staying stuck (mostly odd gears 1, 3, 5)

There have been some other complaint categories also but those have been some or the

variant of the above.

In terms of the geographies affected, here is the list:-

- Americas - complaints started percolating mostly in the year 2009.

The issues were attributed to the DQ250 gearbox. Folks complained about mostly issues pertaining to sudden loss of power while driving and the gearbox shifting to neutral with PRNDS lights flashing, and depress brake light flashing on the MID - this was for cars sold in year 2008 and 2009 namely Jetta, JettaSportWagen, GTI and EOS and some Audi A3s and TTs as well.

Here is a video sample:-

http://www.youtube.com/watch?time_co...&v=De4OG8uLuxA

Initially, when complaints were raised, based on the news reports, it looks like VW didn't pay much attention. However, after a flurry of complaints to the federal investigation agency - NHTSA i.e. National Highway Traffic Safety Administration - and after media pressure (mainly via the popular show "Good Morning America"), VW decided to address the issue along with NHTSA, specifically by the Office of Defects (ODI).

The initial notice sent by NHTSA to VW : Notice from NHTSA to VW.pdf

And the reply from VW to NHTSA as part of acknolwedgement: Reply from VW to NHTSA.pdf

Summary of the investigation as concluded by VW:-

Quote:

The wiring harness of a temperature sensor in the DSG may have connector wires that were insufficiently crimped. Due to this, the temperature sensor has the potential to falsely detect a high gearbox oil temperature, causing the transmission to abruptly shift to "neutral". If this happens, the selector lever position indicator within the instrument panel will flash. In addition, the 'depress brake pedal' indicator light will be illuminated, alerting the driver to apply the brakes.

|

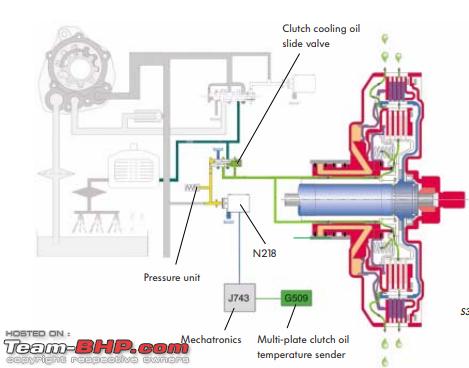

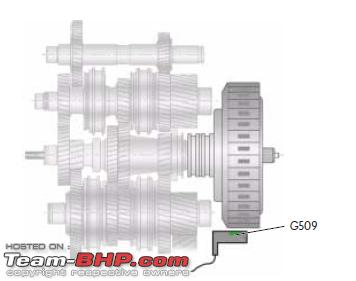

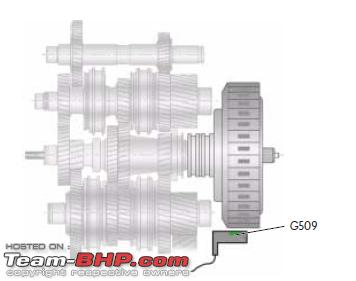

If we consider the clutch assembly of the DQ250, we can determine that the above temperature sensor is nothing but G509 as seen below:-

This sensor is found in the housing of the gearbox input speed sender. The sensor measures the temperature of the DSG oil at the outlet of the multi-clutch plates. Since the oil is placed under a large thermal stress, oil reaches the highest temperature at this point in the gearbox.

This sender is designed to measure temperatures very quickly and very accurately.

Goes without saying, that any indication of actual damage to this sensor will prompt the mechatronics to take action for protecting the gearbox.

And this is what seems to have happened in the above defects reported by customers. Since the wiring harness got corrupted, the sensor may have malfunctioned and the mechatronics would have immediately/ abruptly instructed the shift to "neutral".

While the action to protect the gearbox is not questionable, but the customers were at the receiving end of it, unfortunately. Specially those customers, who had to endure these problems bang in the middle of driving on a highway. And one gets scared to think of all the possible scenarios when your car suddenly shifts to neutral when driving on a highway!

One can question as to why did VW not issue a notification to its customers about this possibility.

In addition to the above issue, VW also identified complaints of harsh/jerky shifting in some DSG-powered cars.

Upon further investigation, VW attributed this condition, typically occurring at low speeds, to excessive wear and tear in the bushings of the solenoid valves that control clutch/gear actuation in the mechatronics unit.

However, VW pointed out this condition is not a safety defect because the changes in shift degradation happen over a period of time, do not cause a loss of motive power.

If we go back to the discussion in "The Works" section for the DQ250 mechatronics unit, the below diagram will help us understand the function of solenoid valves in detail and their linkage to the failure mentioned above.

All the 4 valves are present in electro-hydraulic unit. They control the oil pressure to the gear actuators. The valves are always in the closed position, unless energized, and oil pressure is thereby prevented from reaching the gear actuators.

N88 is for 1st and 5th gear, N89 is for 3rd and neutral gear, N90 is for 2nd and 6th gear, N91 is for 4th and reverse gear.

It can be thus determined or extrapolated that in the event of wear and tear or complete failure of these valves/bushings, the gear actuation can be greatly hampered resulting in potential jerks or even complete isolation may take place.

To provide a perspective on the wear & tear, here are some sample pictures showing the amount of metallic shavings that get dislodged and stuck on the magnetic sensors:-

As per news reports, the total number of vehicles recalled were about 53,500.

VW compensated the owners by replacement of the temperature sensor component and also offered a 10-year, 100,000-mile transferable warranty to the DSG transmissions.

- China - over here, the complaints started arising from year 2009 onwards for the DQ250 and peaked towards a build-up till 2012 for the DQ200.

The range of complaints for the DQ250 comprised intermittent or continuous abnormal sound/noise during shifting and inability to change gears, while that for the DQ200 comprised the excessive noise during shifts, abnormal increase in engine speed/revs and loss of power while driving. Major car models affected were Magotan (now Passat), Bora (rebadged Jetta), Sagitar (Jetta), Golf, LAng Yi namely.

Like the US market, here again, VW seems not to have paid any heed to the consumer complaints initially and was adamant that the issues were not a safety risk but simply required technical upgrades or modifications to the gearbox.

This naturally rubbed off the Chinese consumers since they were of the recall action undertaken in the US and demanded a similar action for China also.

However point to note, that the Chinese market saw a steady increase as far as sales were concerned for VW primarly driven by the DSG-TSi combination.

Going by the rate of increasing failures being reported across the country, the country's watchdog - General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) - urged VW to start looking into the issues more seriously. However, VW, failed to respond suitably to this initial request.

Subsequently, various media entities like the state-sponsored television house also aired customer surveys about the DSG problems.

Quoting an excerpt from a news article, probably sums up the mentality or the stand that VW seems to have adopted when dealing with this issue:-

Quote:

The case of VW’s refusal to recall its problematic vehicles and the practice of a double standard in China shows how a leading multinational carmaker has become growingly arrogant and snobbish in its most important overseas market.

In teaming up with China’s two largest automobile groups, FAW and SAIC, Volkswagen has succeeded in taking up the lion’s share of China’s growing auto market. And as FAW and SAIC are powerful state-owned companies, Volkswagen has been able to cultivate the best of relationship with local and central governments successfully lobbying for its interests. In addition, it has also created a bureaucratic corporate communications team in Beijing and working through a myriad of public relations firms to build a close relationship with the local media in an effort to prevent from negative press

|

.

The saga of ignorance by VW finally ended with AQSIQ issuing a statement in March 2013 that it had identified that the DSG transmission is defective and may cause loss of power resulting in potential safety problem. It also issued a notice to VW reminding it ofits legal responsibilities, else the body would force a restraining order on compliance.

As expected (and similar to the US market reaction), VW China announced on that it would recall its vehicles made at FAW (First Automobile Works)-VW and Shanghai-VW equipped with DSG automatic transmissions.

As per news reports dated Nov'13, the total number of vehicles recalled were about 1.02 million for the DQ200 gearbox. Exact figures for the DQ250 recall not known.

The recall treatment for the DQ200 included replacing the synthetic oil with the mineral oil since it was discovered that the usage of synthetic oil was likely to cause electric malfunctions leading to loss of power while shifting.

Alongwith this, VW also offered an extended warranty of 10 yrs/160,000 kms

- In early to mid 2013, while VW was busy fighting its battle in China - a country which was witnessing the maximum sales growth in terms of its cars, news reports of the DQ200 failures started pouring in from many other countries viz., namely Taiwan, Singapore, Malaysia, Australia, Japan and also France, Sweden and the UK.

The peculiar characteristic common to almost of all these gearbox failures was that they were attributed to the 7-speed, DQ200 variant. And the common or the most important root cause attributed to or investigated by VW to almost of these DQ200 failures was related to the synthetic oil, rather presence of sulphur compounds or additives in the synthetic gear oil being shipped in the gearbox directly from the factories.

Due to the barrage of the customer complaints for these gearboxes, and sensing that it had no option but to prevent further damage to its reputation, VW issued a voluntary recall in all the countries that were witnessing these failures.

As per news reports, here are the recall numbers for few countries - Singapore: 6000+, Taiwan: 1150+, Japan: 91000+, Malaysia: 4000+, Australia: 34000+.

The total worldwide recall, as per reports available then, crossed 1.6 milion units for the faulty gearboxes.

- In India too, there were a number of reported incidents, more so for the Skoda brand (including Superb, Laura, Octavia). Our TBHP chronicles are aplenty with many owners raising issues related to DSG failures, jerking, loss of power etc. A simple search on the TBHP forums will yield numerous results for the details. And one can even refer to the ownership report catalog posted above, as a starting point for the search.

And like the rest of the consumers globally who underwent the initial pain of not being acknowledged or catered to, the Indian lot also went through the same hassles. There are numerous threads even questioning the veracity of driving the DSGs in a certain fashion and owners starting to question their own driving styles!

Here are couple of references - link 1 | link 2

However, with harsh realities ruling the ground situation - VW didn't have any significant presence in the country back in those days meaning very few customers to warrant the business decision of a full-fledged recall, coupled with the fact there was not enough widepsread noise created via media and finally lack of a formal regulatory mechanism or watchdog to pull up the wrongdoers - there was no recall offered here.

However in the same breath, it must be noted that VW India did replace the faulty gearboxes for those customers who invoked the "goodwill" and put pressure on the company.

- Now, after having gone through the recall reports, let's take a slight deviation and have a look at some of the fundamentals to understand the issue of the 7-speed gearbox oil/additives.

As with any major move to a next-generation technology, the rise of this new transmission type brings with it new demands at other points in the automotive supply chain – most notably, in the lubricants which protect the inner workings of the transmissions and keep them running at peak efficiency for extended periods.

In developing fluids for the new generation of dual-clutch transmissions, lubricant engineers are faced with a whole new set of demands, several of which appear contradictory. In the case of wet-clutch DCTs the major difference is of course that the lubricant now has to cope with a set of clutches, as well as the normal gears, bearings, selectors and shafts. Thus the specific DCT fluid needs to provide:- Lubrication of the clutches, gears, shafts, bearings and synchronizers

- Heat dispersal for the entire system

- Hydraulic actuation of the clutches and gear changes

- Protection of the transmission against wear and corrosion

From these requirements it is evident that neither a conventional automatic transmission fluid (ATF), nor a standard manual transmission fluid (MTF) would be up to the task of protecting a DCT. It is clear that the new generation of DCT-specific lubricants (DCTFs) will require a specialized additive technology if these oils are to guarantee the DCT’s technical advantages and its durability in service.

The additive technology must be compatible with the clutches’ friction material, and the lubricant itself needs a carefully calculated viscosity profile to ensure smooth disengagement in low-temperature conditions as well as adequate protection of system components at high temperatures and under high load conditions.

Further considerations are thermal and oxidative stability – surface temperatures within the clutch system can reach several hundred degrees Celsius. Acidic by-products of thermal breakdown can generate lacquers and sludge which can in turn impair hydraulic and actuator function.

- Unfortunately, for VW, the usage of sulphur-laced additive synthetic gear oil led to the multiple failures for the DQ200 gearbox.

Offical VW statement corroborated the below observations:-Aggressive sulfur-containing additives in the used synthetic oil KP can react with copper conductive paths. Copper sulphide formed during the electrolysis process can be deposited between the tracks in the form of conductive particles, and thus lead to a short circuit and a gear box fuse. The emergence of a malfunction contributes to the impact of special climatic conditions characteristic of the countries of Southeast Asia (high temperature and humidity of the air while operating in hard mode with frequent stops and starting)

And the resulting malfunction meant that the blown fuse will turn off the power to the hydraulic pump or gearbox control unit. Because of this, the clutch opens, and the car is coasting. Now you know!!

An important point highlighted in the above statement is related to certain geographical/climatic conditions of South East Asia - which are tyically characterized by high humidity levels coupled with high ambient air temperatures.

If we consider the location of the gearbox as seen in the picture below - flanged to the underbody and exposed to possibly high humidity/high ambient temperatures on the underbody, the point related to outside climatic conditions impacting the performance , probably is relevant:-

So, what makes the observation interesting is that failure rates were higher if the climatic conditions were coupled with the additional point related to frequent stop/start traffic conditions.

In Sweden (where temperatures are single-digit degree Celsius or even below zero sometimes), the same gearboxes failed for a few taxi operators, as reported in some news articles. But then the instances were far and few.

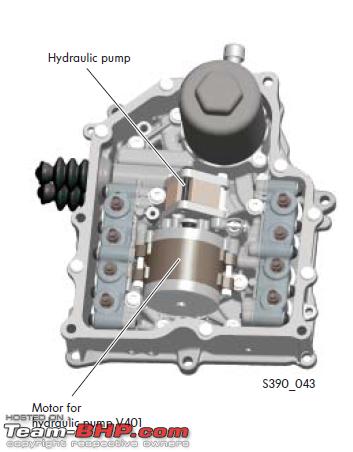

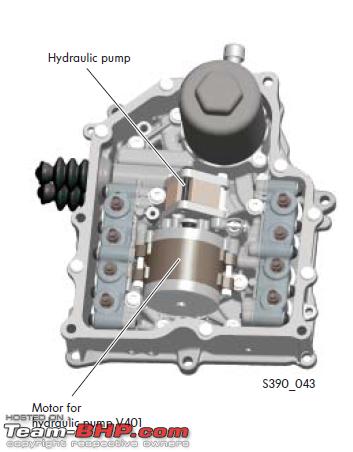

- Another potential failure point or area, which has not been talked/publicized about much is related to the hydraulic system of the DQ200.

As briefly explained in "The Works" section, the hydraulic system comprises of a hydraulic pump and an electric motor, as shown in the below diagram:-

The motor is actuated by the mechatronics control unit depending on pressure requirements. It drives the hydraulic pump via a coupling.

When the hydraulic oil pressure at the pressure limiting valve and the pressure sensor reaches approx. 70 bar, the control unit switches off both the motor and the pump.

The hydraulic system works in conjunction with the pressure accumulator when the hydraulic pump is switched off. Diagram below shows the location:-

The above explanation means that any malfunction in the pressure assembly will result in no/less oil being pumped to the circuit triggering a potential failsafe mode and leading to loss of power.

- Next up is a problem not directly to the mechatronics unit as such but something which lies outside of it.

This is about the dual mass flywheel shuddering and associated noises/jerking with it, which we briefly referred to in "The Works" post above.

Simply put, the dual mass flywheel is a key mechanical component which transfers one form of rotary energy or torque to the clutch plates. It does so by reducing or damping the unwanted vibrations or rotations and absorbing /storing the energy via its spring mechanism.

Reproducing the diagram shown earlier:-

And the below sample video explains this concept animatedly:-

http://www.youtube.com/watch?v=ckf5fWGi5TU

The point to be determined from the above explanation is pretty straightforward - anything which is mechanical, which uses rotary plates, which dampens heavy duty torque via mechanical springs - is very much likely to wear out or fail over a period of time provided it is not taken care of properly.

Over a period of time, various reports have pointed out to mainly two reasons why these flywheels fail:-- Driving Habits:- The cause of a failing dual mass flywheel may have something to do with the driving habits. Driving in too high a gear, uneven running caused by improper acceleration/deceleration, frequent kick-downs, towing heavy loads are typical sources of problems

- Performance Upgrades: One of the easiest ways to "kill" a dual mass flywheel is to increase engine torque. Engine tuners, water/methane injection kits, and other various performance upgrades all lead to greater engine torque. Since the damper springs are designed for a specific torque output, increased torque will eventually lead to a dual mass flywheel failure.

And here is a sample video showing core reasons dual mass flywheel failure:-

http://www.youtube.com/watch?v=TVcLGI0x5N0

Followed by an on-the-ground view of the same issue:-

http://www.youtube.com/watch?v=yrseA...ature=youtu.be

- To add, there has been another peculiar issue which lies outside of the gearbox but is a vital component of the entire ecosystem. This one's about the "selector lever assembly" error or failure.

Reproducing the diagram shown earlier for the lever:-

As mentioned earlier, the primary function is related to the Hall senders of the selector lever which register the position and make it available to the mechatronic unit via the CAN bus.

Based on the signals, the control unit implements the driver's D or R or S or Tiptronic command and to control starter release.

If the control unit detects no selector lever position due to a malfunction of the senders or the solenoid, then both the clutches are opened. The cause has been apparently attributed to the gear shifting wiring harness in the assembly.

The issue around this malfunction is noted by a transmission warning code "B116229".

The primary resolution offered has been to repair the harness else suggest a complete replacement of the shifter assembly.

- In summary, when we look at the reasons attributed to failures for the DSGs, it is evident that on one hand - VW has really gone to great lengths to focus on technological innovation marvels - but on the other hand, it has miserably failed to pre-empt the backlash associated with the failures. And on occasions, it has also been found guilty of ignoring the issues (probably deliberately) due to certain economic considerations.

The DQ200 failures seemed to be sitting on a very thin line as being classified as "Defective" or having "Wear and tear". Or maybe the swapping out of that additional cooling circuit to design for better efficiency may have resulted in those issues.

Surely, every product goes through an evolutionary life cycle and is bound to reach the peak of its expected designed performance at some time. In this case, it is apparent that VW did estimate and plan the product evolution to a certain extent BUT and a BIG one at that, it looks like, VW couldn't continue or foresee the same designed performance momentum when it launched the product in an entirely new geographical condition (SE Asia for e.g), which was quite distinct from the original conditions (Europe) in which it was primarily designed and tested.

By the way, here is an interesting video that showcases the story of DSG component improvements captured at a VW Fest:-

http://www.youtube.com/watch?v=vOEIptAJpyo&t=46s

Offering a voluntary recall and planning for it in terms of the associated labour and logistics costs is not an overnight or an easy corporate decision definitely, but VW surely could have managed the situation by resorting to more pro-active customer and dealer communication, holding customer roadshows etc.

Studying the various news reports highlight a particular pattern that the biggest problem perhaps, seemed to be a lack of a central, coordinated strategy to address the failures. This is evident from the fact that almost every country that was affected had to go through an entirely different process of customer complaint > VW acknowledgement > VW offering fixes > VW offering recall (if applicable) > VW offering extended warranty.

On that note, to conclude, here's hoping that the DSG ghosts are buried now for good and VW has smarted from the previous mishaps, ensuring that owners across the world continue to enjoy the beautiful technology that offers a combination of great comfort and fun.

Source:

Phoenix Friction Back to index

REFERENCES

Researching a topic as broad and controversial as this one entailed to look up myriad of news reports, scan through annual reports of VW, look up environmental reports, try to understand or rather go back to refreshing some concepts related to chemistry & physics and also talk to few folks related to the industry (colleagues in the automobile fraternity, Master Technicians). Ofcourse, one of the main sources was the service or technical manuals for the gearbox.

Few times, Google Translate was also invoked since some materials were Russian or German.

Here are some sources and artefacts that I could lay my hands on:-

p.s. The above are only some of the key sources at the top of my mind. There were other news articles which I have browsed but difficult to list all of them here.

Back to index

Thread moved from the Assembly Line to the Technical Section. Thanks for sharing!

Painstakingly researched and a delight to read the history, electro-mechanical operations, problems, failures and most importantly customer experience. Thanks for a delightful Saturday morning read. Rated 5 stars. :thumbs up

First of all, let me thank you for this wonderful post! It certainly made my day! Also, BHPians will definitely love it and this article will be most helpful for ownership experience as well as buying experience.

Oh man, I had thought DQ250, was trouble free. The sheer number of recall made by VW group is jaw dropping!

IMO, mechanical parts have certain efficiency which can not be increased after some limit. However, DSG contains lots of electronics which could have certainly helped to evolve the unit characteristics. In this case, it has gone into another side. I believe, electronics are major culprit here.

What could have done from VW side in this issue? Anybody, please share your views. This technology should have been improvised.

If VW had provided extended warranty around 10 years or DSG cover at least, it would have been really helpful to prospective buyers.

Cheers and happy revving!

So much tech to get power to the wheels...

Cons:

- Reliability

- Complexity

- More wear and tear items (clutch and DMF)

Pros:

- A bit more efficiency

- Fun

The fun part is no longer exclusive to DSG/DCT as per Peter Quintus of BMW:

"It's more a question of how long has the DCT got to go, How long will it last? The DCT once had two advantages: it was light and its shift speeds were higher. Now, a lot of that shift-time advantage has disappeared as automatics get better and smarter." Andy Palmer of Aston Martin (previously Nissan) says:

“Ten years ago, it still looked like the transmission of the future. Now it is starting to look like the transmission of the past. A good conventional automatic gearbox like the ZF is cheaper, which is absurd when you think that the manual gearbox has survived because it is meant to be the less expensive option, but there’s so much technology loaded onto a (DCT) to make it work. It’s heavier as well, which is another disadvantage, but the real issue is the gearchange itself. It’s actually now faster in a (planetary) automatic, because you can control the torque. That means ultimately your 0-100 km/h times are quicker with an auto, which takes away all of the marketing puff for the dual-clutch,”

And this is old news, I saw it come up three years ago but still relevant today and in this thread. Reminds me of the decision by Ford to discontinue its DCT in India for torque converter auto in the Ecosport.

https://www.autonews.com/article/201...e-favor-in-u-s

Src:

https://www.drive.com.au/motor-news/...18-gvndyw.html https://www.bmwblog.com/2017/04/21/b...ons-soon-gone/ https://paultan.org/2018/05/16/the-f...-transmission/

I would never ever buy a car with a DSG as my main car, though I have been tempted by some VAG models. I simply cannot live the damascus sword hanging over my head worrying about a ! inside a cogwheel symbol popping up on the dashboard or the thought of would it ever will far away from home.

I said the same thing 4 years ago and i live by it, today I drive a 6 speed torque converter equipped diesel, but not a Verna.

Quote:

Originally Posted by Sankar

(Post 3558641)

I'm the only one voting for the Verna so far...

If i buy any of these three cars i would obviously go for a remap. With the DQ200 transmission i would not risk it with the VAG cars. I would have the Verna remapped and the suspension changed with something better like Bilsteins or Teins. Hope the Verna torque converter transmission can handle the additional torque, if it can it will be interesting to see how the torque converter lays down the power. I'm told that the Verna 1.6 crdi motor is capable of some really healthy power figures.

|

Amazing thread!Looks very painstakingly researched and written. Hats-off! This thread deserves a five star rating :)

This will help any prospective VW group car buyers. Looking at the sheer complexity (or simplicity, depends how you interpret it) of the DSG concept, there are bound to be cases of failure in the future as well. Just hope that these guys continue to offer an option for manual transmission as well in India. The simplicity and robustness of a manual can never be matched (my take here, so opinions can definitely differ)!

Quote:

Originally Posted by GTO

(Post 4526573)

Thread moved from the Assembly Line to the Technical Section. Thanks for sharing!

|

Thanks a lot, GTO!

Quote:

Originally Posted by R2D2

(Post 4526602)

Painstakingly researched and a delight to read the history, electro-mechanical operations, problems, failures and most importantly customer experience. Thanks for a delightful Saturday morning read. Rated 5 stars. :thumbs up

|

Thanks R2D2! Yes, it did take some effort to dig out and do some research. Hopefully, it did pay off.

Quote:

Originally Posted by RedStallion

(Post 4526620)

First of all, let me thank you for this wonderful post! It certainly made my day! Also, BHPians will definitely love it and this article will be most helpful for ownership experience as well as buying experience.

|

Thanks RedStallion for the comments.

Quote:

Oh man, I had thought DQ250, was trouble free.

|

The DQ250 did have its own share of problems, but it's inherent "wet" design probably was wee bit tolerant as compared to its sibling.

Quote:

IMO, mechanical parts have certain efficiency which can not be increased after some limit. However, DSG contains lots of electronics which could have certainly helped to evolve the unit characteristics. In this case, it has gone into another side. I believe, electronics are major culprit here.

|

Yes, your observation is quite valid. The design of the mechanical components have been complimented by the "electronics" so to speak, either ways.

Quote:

If VW had provided extended warranty around 10 years or DSG cover at least, it would have been really helpful to prospective buyers.

|

As you can note in the thread, VW has indeed dished out the 10 year warranty, but unfortunately it is not a global strategy.

Quote:

Originally Posted by Sankar

(Post 4526629)

I would never ever buy a car with a DSG as my main car, though I have been tempted by some VAG models. I simply cannot live the damascus sword hanging over my head worrying about a ! inside a cogwheel symbol popping up on the dashboard or the thought of would it ever will far away from home.

|

Well, that is certainly a general impressions in the market what with the very inconsistent approach adopted by VW to address problems. However, if we look at the last 4-5 years data, then VW seems to have smarted in terms of tweaking it every now and then. And it looks like, VW is not done yet - as per news reports, they seem to be supposedly developing the next version of the gearbox to make it more compatible with the "hybrids"

Quote:

Originally Posted by AdiSolEn

(Post 4526652)

Amazing thread!Looks very painstakingly researched and written. Hats-off! This thread deserves a five star rating :)

|

Thanks budddy!

Quote:

This will help any prospective VW group car buyers

|

Will be glad if it really does, have tried to showcase both sides of the coin to help current owners know more about what's inside and help potential buyers make an informed decision to adopt this wonder tech.

@JM- great post!

Does the DSG gearbox oil come in contact with ambient air?

Quote:

Originally Posted by Sankar

(Post 4526629)

The fun part is no longer exclusive to DSG/DCT as per Peter Quintus of BMW:

"It's more a question of how long has the DCT got to go, How long will it last? The DCT once had two advantages: it was light and its shift speeds were higher. Now, a lot of that shift-time advantage has disappeared as automatics get better and smarter."

Andy Palmer of Aston Martin (previously Nissan) says:

“Ten years ago, it still looked like the transmission of the future. Now it is starting to look like the transmission of the past. A good conventional automatic gearbox like the ZF is cheaper, which is absurd when you think that the manual gearbox has survived because it is meant to be the less expensive option, but there’s so much technology loaded onto a (DCT) to make it work. It’s heavier as well, which is another disadvantage, but the real issue is the gearchange itself. It’s actually now faster in a (planetary) automatic, because you can control the torque. That means ultimately your 0-100 km/h times are quicker with an auto, which takes away all of the marketing puff for the dual-clutch,”

...

I would never ever buy a car with a DSG as my main car, though I have been tempted by some VAG models. I simply cannot live the damascus sword hanging over my head worrying about a ! inside a cogwheel symbol popping up on the dashboard or the thought of would it ever will far away from home.

|

Essentially we think alike!

The ZF 9 speed, like the DSG, is building up a nice unreliability reputation!

Regards

Sutripta

| All times are GMT +5.5. The time now is 04:24. | |