Team-BHP

(

https://www.team-bhp.com/forum/)

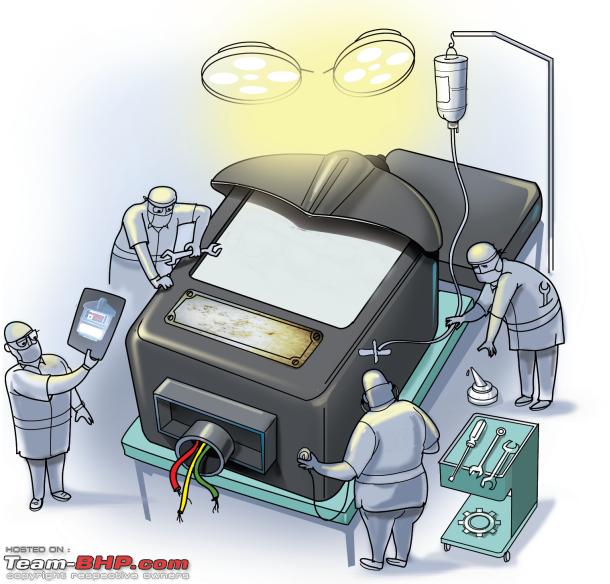

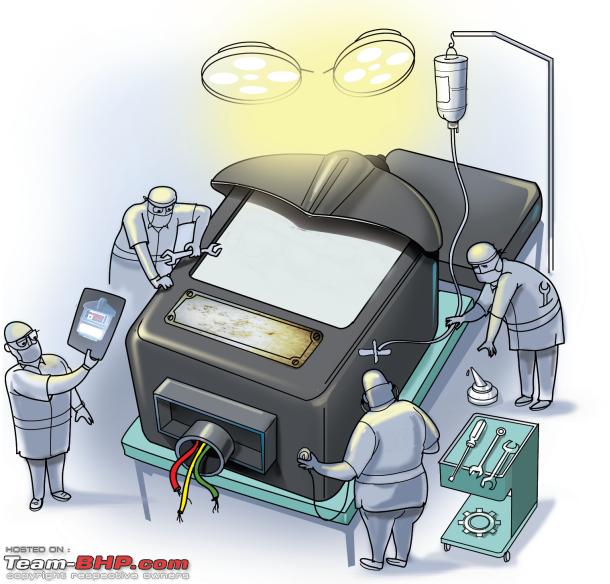

With modern cars, we've seen that authorised workshops & service advisors are rarely inclined to repair any part. Rather, they just push for replacement. It's simpler for them + higher invoice value too.

But it's not good for the environment. While the below points are for appliances, we could apply them to automotive spare parts as well. Pasting from the

Times Of India daily newsletter (strongly recommend you subscribe to it):

Quote:

An EU rule: The European Union last week adopted new regulations to make household appliances more sustainable. These measures include requirements for repairability and recyclability, "contributing to circular economy objectives by improving the life span, maintenance, re-use, upgrade, recyclability and waste handling of appliances," the European Commission, the EU's lawmaking body, said.

Why this matters? While the main objective is to make appliances more sustainable, a supplementary benefit is that consumers get to repair their malfunctioning appliances rather than abandon them. That's because when one buys a new refrigerator, the old malfunctioning one gets discarded — becoming an electronic waste. Hence, the law is being termed the "Right to repair", and could influence similar laws across the world — as EU laws of privacy, human rights and the like have. The "right to repair" is also gaining traction in the US; 2020 Presidential candidate Elizabeth Warren has proposed a law on this.

About Earth: The demand for the right to repair grew as consumers began observing their appliances were malfunctioning as soon as the warranty period is over. Some are calling it "planned obsolescence", though manufacturers vehemently oppose they deliberately act to limit the age of their devices. Nevertheless, electronic waste is piling up. According to the EU, 10.1 million tonnes of e-waste was accounted for in 2016, and household appliances make up 55.6% of it. India generates 2 million tonnes of e-waste annually, according to the Global E-Waste Monitor 2017, less than only the US, China, Japan and Germany.

Also about the future: The "right to repair" is also about securing consumer rights as appliances become high-tech. The Open Repair Alliance, an advocacy group, says with the advent of the internet of things (IoT), software support of appliances are becoming essential. If manufacturers do not provide software support, the device, say a smart refrigerator, may become obsolete even if its mechanics are in good condition. The EU's new law though does not yet consider this aspect. In the US, the demand has also grown among car owners — Tesla, for instance, does not allow owners to repair their cars by themselves.

But... manufacturers have pushed back against a broader "right to repair" as that would hurt their ability to sell new products more frequently, and would push them to become a service provider rather than a product maker. They also say allowing the consumer to repair high-technology products is a risk — think of lithium-ion batteries in cars. A lobbying group in the US also argues it will put consumer data on smart devices at risk. That theory is, however, rejected by Securepairs.org, which represents prominent security experts, including Harvard University's Bruce Schneier.

|

An extremely relevant thread! But there needs to be a paradigm shift in customer mentality as well and not just just the manufacturers and service centres. Customers including me have been very happy when service centres have replaced parts, specially under warranty, instead of repairing them.

With regard to Automobiles Mechanics who can repair instead of replacing is a dying breed . I have witnessed and benefited in 2 cases where i saved almost 80% of cost mentioned by Authorised Service Centers and in both cases the part replaced were small yet critical items .

1) My Alternator went kaput , A$$ quoted 12k for replacement + labour . All that was required to be replaced was a small Cutoff Circuit board costing Rs.680 ,overall i was charged Rs. 2100 only and whole work was completed in about 1.5 hours .

2) Driverside power window went kaput , A$$ quoted 14k which includes motor , track etc . The gentleman who did the work changed a set of Plastic gear set inside the motor and everything was working smooth ,earlier it used to make lot of noise moving up and down . Now it is super silent . I paid Rs.1400 only for this repair .

Old wisdom revisited.

Can someone tell the Indian government that replacing cars instead of repairing them, especially without a formal scrappage policy and infrastructure in place, is

really, really bad for the environment? :D

"It can be frustrating to repair something when it costs the same amount to replace it. But that’s how planned obsolescence works. Companies create poor quality products, so you are forced to pay to replace it. This trend has taken over the modern consumer’s life."

Excellent topic! yes, a lot of stuff gets replaced rather than repaired. Obviously, these days not just on cars, in many ways we have become a throw away society.

Sticking to cars: When looking at the economics of replacing versus repairing we do need to take into consideration the local cost or repair versus local cost of a part.

In the western world, hourly wages are significant. Labour cost is often a much larger part of a service / maintenance / repair bill than the actual parts.

I looked into getting my Alfa Romeo brake callipers properly overhauled. I had it done some 20 years ago. Today it is cheaper just to buy a new set of callipers! Takes about 3 hours to overhaul a set (pair). That involves dismantling, cleaning, honing, new seals, assembly and test. Costs around Euro 300,-- . A complete new pair of callipers costs Euro 185!

Another aspect is what people expect and what you might get; it is very often possible to repair an individual car part. But that does not necessarily mean the repaired part is as good a a replaced new part. Many companies that do repair job will guarantee their level of workmanship. But what they can and will not guarantee is anything else going amiss.

So, yes if the diode bridge on an alternator fails it can be replaced. In most cases very easily actually. But it is no guarantee the alternator will not fail again, due another reason (e.g. bearing problem, insulation problem etc)

So to some extent simply replacing parts gives “piece of mind” for the car owners as well as the mechanic.

But we all have seen and heard of the ridiculous replace versus repair examples.

My most extreme was years ago when we still lived in the UK. A good friend of ours drove a second hand, pretty beat up Fiat X19 with pop up headlights. One of these failed, would not pop up. So she really could not drive the car anymore, the MOT was due, that would have been a definite failure. The Fiat dealer quoted something like UKP 5-700 to replace the headlight pop up mechanism. She was in tears, she could hardly afford to fill up her little car, let along foot such a huge bill.

I offered to take a look at it. Quickly found the problem was a burned out diode. Went down to the local electronic store and bought a replacement diode for 50 pence and soldered it back in. All was fine again. Took me about 2-3 hours and obviously I did not charge for those. (her dad, a real wine connoisseur, gave me an excellent bottle of wine for helping his daughter :))

But it does illustrate a different angle to the replacement versus repair. In order to trouble shoot and repair this way requires different skills, expertise and sometimes different tools beyond what is available. Any mechanic can replace a headlight pop up mechanism. Pretty straightforward spanner job. Opening up the unit, and finding which electronic part has gone kaput and fixing it, is beyond quite a few car mechanics.

To my earlier point about a repair giving a different result from replacement. Yes, I got the headlight to pop again, for the price of 50 pence. Pretty amazing against the UKP700 the dealer quoted for a replacement. But I had to cut into an electronic box that was factory sealed and never designed to be opened up in the first place. I just did so. And I put it together and weather sealed it as good as I could. But of course, that is not the same as factory weather sealed. Luckily our friend did sell her Fiat, because at some point in time it is very likely water ingress would have caused substantially more damage than just one diode.

So obviously replacing parts rather then repairing them is likely to be less environmental friendly. Of course, all these replaced broken parts tend to get recycled these days here in the West. Not quite sure how big the burden on the environment is, beyond of course producing a new part

Whether it is more advantageous for other reason is not that easy to answer. I can not compare my handy DIY repair work, with a professional workshop, that needs to guarantee its workmanship and it formally (legally) liable if they did not do a good enough job.

Jeroen

Just like quite a few manufacturers nowadays have a recycle/ scrappage system in place, manufacturers/ OEs need to implement a recondition or recondition exchange program. The reconditioned part being reconditioned/ repaired to the manufacturers standards using the manufacturers setup.

Regards

Sutripta

To add to that, we must also look at something miniscule when compared to cars and get rid of them left right and centre for something that can be repaired....Yes, I am talking about our Smartphones.

I have seen people discard their devices for reasons as ridiculous as slowing down a tiny bit, which should get resolved by a complete factory reset.

But these phone companies keep on coming up with new devices bi or yearly to make customers "Upgrade".

And no-one played this game better than Apple. They made their devices so complex and requiring so many specialised tools, that it was financially more viable to just buy a new one, with the latest one, especially for something like a cracked screen.

However, now they have started using recycled Aluminium for their laptops and rare Earth materials for their phone which is a great step.

So hold on to your phones as much as you would hold onto your cars. Their costs are relatively low, but in large quantities, they cause equal damage to the environment.

Quote:

Originally Posted by Sutripta

(Post 4672097)

Just like quite a few manufacturers nowadays have a recycle/ scrappage system in place, manufacturers/ OEs need to implement a recondition or recondition exchange program. The reconditioned part being reconditioned/ repaired to the manufacturers standards using the manufacturers setup.

|

Not sure if the economics of such a model are viable for more or less the same reasons I pointed out earlier. Refurbishing parts requires a very different kind of organisation than producing new parts. There are some economy of scale aspect by keeping it within the same company, e.g. volume-procurement power, competence to a certain extent. But you need a very different set up for re-furbishing compared to producing. Essentially the later requires a product orientated approach, the former a service orientated approach.

In the west we do see specialised companies refurbishing certain car parts at very high standards. But that is always for parts that have become unavailable. So it tends to cater for the classic car scene.

My Alfa Spider has refurbished trailing arms and steering box. You buy a refurbished part from a refurbishment specialist. You get a refund when you hand in your original parts after you swapped the old for the new bits.

This appears to be a viable model on mostly relative expensive parts such as steering boxes, gear boxes, differentials etc. I have only seen independent shops do this, not the OEMs.

Sometimes original parts could still be available, but really expensive. An example; I can still buy a new steering box for my Mercedes W123, original supplied through the MB dealer. Will cost a whopping Euro 3000! (Most of the cars I have owned cost less)

A good fully reconditioned steering box for a W123 can be had for less than Euro 900 from independent repair/re-conditioning shops.

Similar story for my Jaguar gear box.

I recall in the past certain shocks were often refurbished, but I have not seen or heard about any of that lately.

So the traditional car manufacturers and associated part OEMs do not appear to be interested in this at all. To them it is about a viable business model that supports and adds to their current business model. It doesn’t seem to add up for them. In fact, if refurbishing is cheaper than a new part, it does not help develop their business model.

Jeroen

More than planned obsolescence, another rage has struck these days, the modding rage.

This is not in disrespect for modders (many of them in this forum, and they give some of us many useful tips to enhance our cars as midlife makeovers) but with the tonnes of metal and plastic garbage already being generated by the planned obsolescence/wilful replacement of whole parts, the modding scene also result in parts that would otherwise have a useful working life to be scrapped/shelved, thus gradually becoming trash that would require scrappage.

Think steel wheels, alloys wheels, head units, plastic housings, speakers, springs, stock seat covers etc. Some owners also facelift their cars with newer bumpers, led with drl headlight housings etc leaving the older parts to be wasted (even if old parts are sold, we must consider that the other too, in some way is scrapping one part for another). The only zero waste calculation that can work is when the vehicle is truly stock (apart from wear & tear parts) and remains so till the last mile.

Workshops count on sales, not repair to make money. That is their bottomline. It goes without saying that cars have been the most wasteful, polluting material possession since its inception, nothing comes close when you think of the amount of water, oils, glass, metal, fibre, leather etc that this industry has consumed either at production or susequent repairs (accidental or otherwise).

Excellent topic. Terms such as "use and throw" and "disposables" have become a norm in the last two decades.

I work for a petrochemical industry that produces plastics. So far the whole objective has been to produce as much virgin plastic as possible. But now a days, the scene is changing rapidly, driven by regulations. There is a paradigm shift towards sustainable processes and circular economy. Whole plastic business and compounding will be redesigned to maximize recyclability.

So, the whole process of designing needs a complete revamp. Certainly "design to fail" and "designed to replace" are more attractive business models than "design to repair/recycle". But regulations are regulations and only regulations can force business models to adopt less attractive options. For example, if there are no regulations for industrial effluent, NO industry would spend in effluent treatment plant.

Having said that, the regulation could definitely benefit consumers. Today, repairing a phone costs more than buying a new one. The boards are designed to replace not repair. Repairing a LED-TV would cost a bomb, the boards are again designed to replace, not repair. Gone are the days of Cathode Ray Tube TVs that lasted decades.

Quote:

Originally Posted by Jeroen

(Post 4672059)

...My most extreme was years ago when we still lived in the UK. A good friend of ours drove a second hand, pretty beat up Fiat X19 with pop up headlights. One of these failed, would not pop up. So she really could not drive the car anymore, the MOT was due, that would have been a definite failure. The Fiat dealer quoted something like UKP 5-700 to replace the headlight pop up mechanism...

|

I too, have experienced it first hand in Europe. Few years back, newly landed in UK, one fine day our fridge breathed its last. Called up the landlady (it was provided by her), and her statement was 'send it to the recycle facility, I'll order a new one' !! I was a bit confused, asked her if I should look for a mechanic around first (in India, refrigerators live for decades , with repairs :) ) ! Pat comes the reply 'Nope, it'll be cheaper to buy a new one'.

So yes, in developed countries, its the manpower cost, which often takes the repairs out of equation (a neighbor was quoted ~600 pounds for a broken ignition switch for her Honda, which she bought for 2000 pounds a year back lol:).

Quote:

Originally Posted by Jeroen

(Post 4672363)

Refurbishing parts requires a very different kind of organisation than producing new parts. There are some economy of scale aspect by keeping it within the same company, e.g. volume-procurement power, competence to a certain extent. But you need a very different set up for re-furbishing compared to producing. Essentially the later requires a product orientated approach, the former a service orientated approach.

|

Very true. I also think this whole 'throwing parts at a problem' arises from mechanics increasingly being not trained to diagnose root causes, coupled with the fact that some units can be tech intensive and opening up such units is practically impossible. You will know that this is particularly true in aviation. However the good thing about aviation is that removed parts do undergo repair wherever possible and become available as serviceable units, with certification and warranty. In fact sometimes readily available refurbished spares can cost more than those which will be produced only on order and have a very long lead time!

Of course this whole system works because of the large ticket size of spares and decent margins even on refurbished parts, and the fact that OEMs themselves participate in it (either directly or through authorized shops). I doubt such a model will work in the automobile industry.

Quote:

Originally Posted by Jeroen

(Post 4672363)

Not sure if the economics of such a model are viable for more or less the same reasons I pointed out earlier. Refurbishing parts requires a very different kind of organisation than producing new parts.

|

By itself in the same organisation structure - unlikely to be viable. But maybe can be made viable.

But mandated? Extention of 'right to repair'.

Regards

Sutripta

Few years back, i drove in to a road side ditch trying to avoid collision with oncoming bus while over taking a huge 18 wheeler truck. This was on Chitradurga-Hospet highway.

While the local's helped to lift the car from the ditch and get me going on my way, the car (Fiat Palio 1.3) had taken a nice beating and had a big dent on the front right door. The ORVM was also broken.

When i took the car to Tata ASC, they immediately asked me to get the front door replaced under insurance. But since the co-pay amount itself was coming to around 12K for this option, i decided to take the car to a local garage near my home.

He got the dent fixed in couple of days, made the door look like brand new and ensured the color matched to the rest of the car. All for 12K! with insurance co-pay i paid around 2K only.

So yes, the authorized service centers can put more efforts to repair the issue than replace.

| All times are GMT +5.5. The time now is 18:13. | |