Team-BHP

(

https://www.team-bhp.com/forum/)

Dunno if anyone has started a thread on this, but michelin has demonstrated a new technology in wheels.

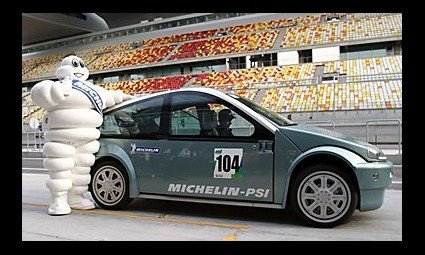

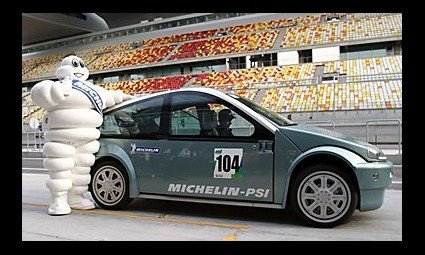

They have put suspension/brakes/electric motor inside the wheel, here is a pic

The vehicle

Each motor makes around 250nm of torque so in total car has 1000nm of torque.

and there is no motor in the car so better space utilisation and also less lose of energy.

and you can convert any 2 wheel drive to 4 wheel drive by just changing the wheels lol .

Wow Micheline seems to be inventing car inside the wheel :p

By having more mechanical parts near wheels the losses will be less.

Rahulkool could you please provide link to the article?

As for cost while changing tyres,

- Because of car being electric normal running saving will be very much, comparitively changing entire assembly will be cheaper

- Although entire wheel assembly is changed, other parts than tyres can be refurbished and re-used thus lowering cost impact to end consumer

- By targetting volume the total cost can be lowered.

Quote:

Originally Posted by karlosdeville

(Post 728969)

|

Porsche had experimented with gasoline electric hybrids during the war, but his projects were not successful due to shortages of copper, maintainability and reliability issues.

It only seems to be a mechanical realignment to get the motor, suspension and brake into the rim internal space, nothing more. That way, a car designer (well, a few of them, really) will be able to select an off-the-shelf component from one manufacturer instead of 3, thus cutting down on design and manufacturing time (car, not the component) and a few design headaches. Upside: perfectly flat chassis - without the suspension intruding into the cabin space >> more space to keep batteries.

In practical terms, even Toyota is doing the same in their hybrids, the only difference being it is not utilizing fully utilizing the rim internal space (only the motor and brake go in there).

There is more to it than meets the eye, for it to be practically adopted:

* This is not a productionized component but a concept to prove some ideas

* Designers who have to look at performance (cornering, off/bad road, etc.) would tend not to consider it. Conversely, any company trying to make mass-market hybrid/electric econoboxes will find it attractive

* Companies like Honda, who prefer a single central electric motor mounted on the engine crank-shaft, will not be able to use it

* Serviceability concerns will need a long time (and a lot of on-road testing effort) to get over

* Suspension travel would be limited, so God save your coccyx

Surely they must have thought about bald tyres and punctures - being a French company they couldn't have missed the public awareness advertising on highways in France: "Please change your tyres if they are bald - it is dangerous on highways". One can be sure that tyre changing will not involve disconnecting the whole unit from the chassis!:p

Doesn't the concept of unsprung mass apply here as well ? Now wouldn't the weight of the tyre wheel combo increase with the addition of the motor requiring the motor to put more effort in spinning the wheel ?

Quote:

Originally Posted by revvedup

(Post 729573)

Doesn't the concept of unsprung mass apply here as well ? Now wouldn't the weight of the tyre wheel combo increase with the addition of the motor requiring the motor to put more effort in spinning the wheel ?

|

Unsprung mass = correct.

Motor to put more effort/torque (for rotating mass) = incorrect.

Unsprung mass on a typical car is the wheels, tyres, brakes, suspension (and anything else on the "road side" of the suspension).

In this case, the unsprung mass will also probably include the motors (unless the motors do

not move up and down when the suspension does -- but that is hard to tell from that picture).

Would this setup require the motors to make more of an effort to rotate the wheel, as opposed to if the motors were sprung mass? -- no.

Given the fact that the motors and suspension, do not rotate with the wheel, there is still only the same amount of mass rotating (wheel + tyre + brake disc(if there is one)). Hence no more effort is needed due to the motor/suspension being in the wheel.

Is there a brake disc in there or is it only the motor that does the braking?

cya

R

PS - Thanks Adya, i didnt know the term "potting"...

Quote:

Originally Posted by Rehaan

(Post 731350)

Is there a brake disc in there or is it only the motor that does the braking?

|

It would be difficult to implement an electric motor system that would act as the brake that can bring a vehicle to a dead stop (elevators have such a system, but their speed is essentially infinitely controllable, including near zero either side of zero speed).

Instead, one can expect a combination of dynamic regenerative braking (energy recovery), coupled with a disc brake system. IMHO no authority will allow a vehicle without a safe dead-stop braking system on the road.

Absolutely agree with you about the motor-braking Der Alte, however, i feel like since this is still not a production peice yet, they might have skipped fitting the brake disc in there?

cya

R

So i guess there will be no spare wheel...

It might cost 1/4 the cost of the car.

Quote:

Originally Posted by Rehaan

(Post 731350)

......

In this case, the unsprung mass will also probably include the motors (unless the motors do not move up and down when the suspension does -- but that is hard to tell from that picture).

...

|

One simple doubt, unless the motor is mounted rigidly on the chasis, how will it manage to turn the wheels? I mean, you can pack it within the wheel, but the motor has to be mounted on the Vehicle frame right?

In that case, The motor will contribute to the sprung mass only, as the entire spaceframe is.And there has to be some linkage/mechanism to transfer the torque.

This is just a logical deduction only, as nothing could be inferred from that pic. Dudes pls correct me if I'm wrong here.

No, @aravind, why does the motor have to be on the chassis? It is only required to provide motive force the wheel. Even in a FWD car, the front wheel keeps turning on it's own axis (axle) - the steering mechanism just moves THAT axis in the direction of the turn (CW when looking from top for turning right, CCW for left).

Anyhow, by the time this concept wheel is productionized, we will have true drive-by-wire: Joystick instead of steering mechanism - no conventional mechanical linkage to turn the wheel axis. Since there are motors on all wheels, it will only be a matter of regulating what speed each wheel should be rotating to achieve the turn.

The precursor to this - servo-based positioning of the steering linkage - is already a reality is some experimental vehicles for physically challenged.

@rehaan, yes, the disc brake is not the most important piece in the concept proto - it is the suspension arrangement.

Motor has to be connected to some part in the car. Otherwise the reaction force from tyres will rotate the motor in opposite direction. Which means the car remains in the same place (due to friction of road) and motor keeps on turning.

One advantage will be - you can select different combination of motors (all parallels / series or parallel-series to get different torques with a flick of switch.

Quote:

Originally Posted by DerAlte

(Post 733195)

No, @aravind, why does the motor have to be on the chassis? It is only required to provide motive force the wheel. Even in a FWD car, the front wheel keeps turning on it's own axis (axle) - the steering mechanism just moves THAT axis in the direction of the turn (CW when looking from top for turning right, CCW for left).

.

|

Already answered by jat:

Quote:

Originally Posted by jat

(Post 733273)

Motor has to be connected to some part in the car. Otherwise the reaction force from tyres will rotate the motor in opposite direction. Which means the car remains in the same place (due to friction of road) and motor keeps on turning.

|

:OT

Basically all sort of relative motion(except the ones due to attractive/repulsive forces) Depends on Action-Reaction pair of forces.

So, If you want to walk, You exert force on the ground,and ground in turn exerts the reactive force on you making you move forward.In loose sand/slush you will have less/no reaction making your movement difficult/impossible.

In a similar vein, the torque at the wheel exerts the force on the ground and the reaction provided by the ground makes the car move forward. Now if the Motor is mounted inside the wheel, without mounting it on to the frame, then that would result in futile spinning , as the weight of the motor is no match to the torque produced by it.

Guess I have made it far too complex:Frustrati........ Sorry Guys , I always falls for it!

Jat and Aravindwarrier,

As Der Alte said, the motor does not have to be

on the chassis.

But, Ofcourse the motor will be fixed!!! :eek:

Take a look at the picture again.

Suppose the pentagon/coffin shaped peice with the 5 bolts was attached to the chassis, and also attached to the motor (the two black cylinders on the extreme right). That would solve your query right?

cya

R

| All times are GMT +5.5. The time now is 09:42. | |