| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  108,782 views |

| | #31 | |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

| Re: 124's DAWG | My 2021 Force Gurkha 4x4 Quote:

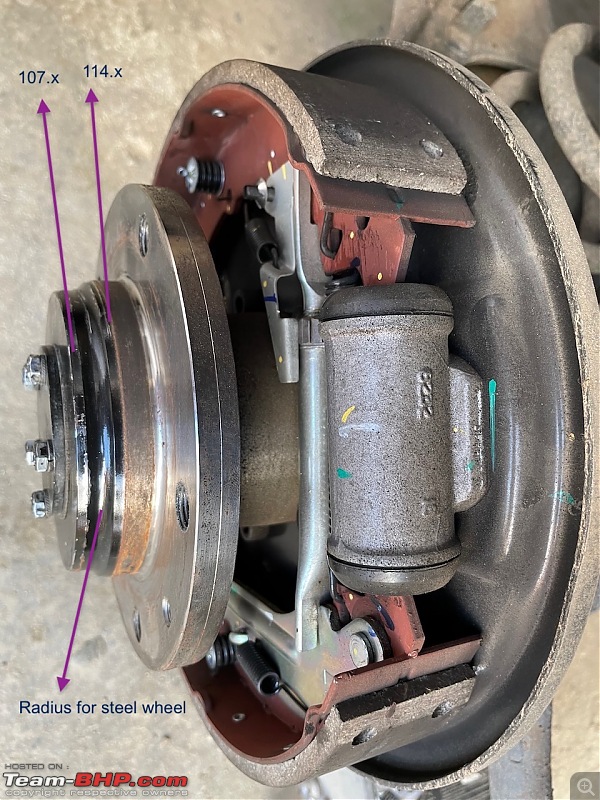

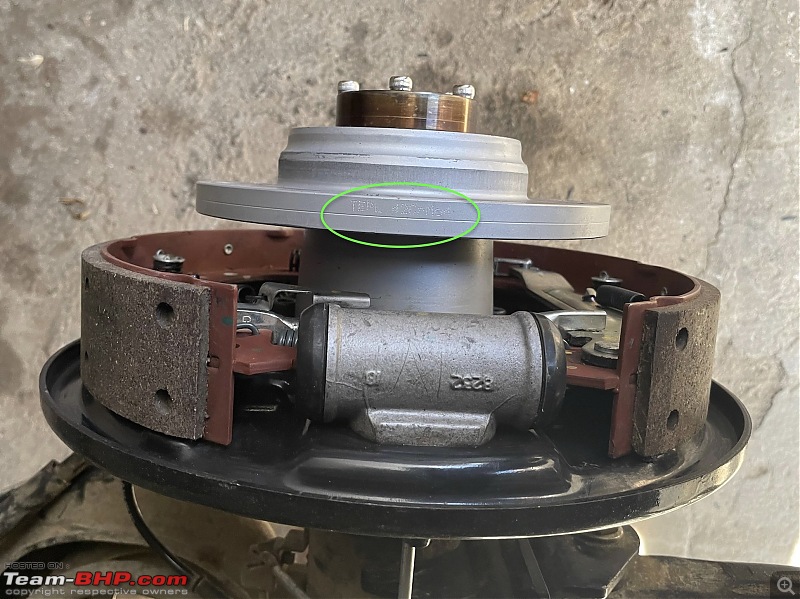

Since I am re-designing my rear hub mod, I had closer look, rear hub center bore is basically a taper, see below.  So actually FM choice of CB 115 is ideal/safe as it clears the top the circle, but it still mostly lug centric since this 114.x mm is just about 1mm which will not touch alloy due to alloy center bore bevel.  Now coming to your alloy with CB 110mm check if its touching brake drum, it could be if bevel in alloy CB is large else you might have a gap. You can verify this by putting a paper sheet in between alloy and brake drum and check if wheel mark is even. | |

| |  (6)

Thanks (6)

Thanks

|

| The following 6 BHPians Thank PhantomLord for this useful post: | 2himanshu, AdityaDeane, digitalnirvana, Manuuj, Rigid Rotor, theexperthand |

| |

| | #32 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

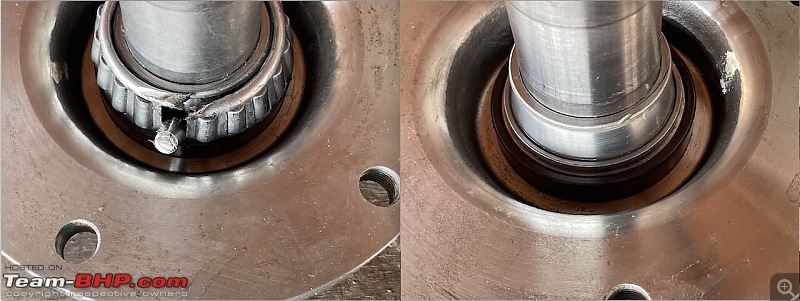

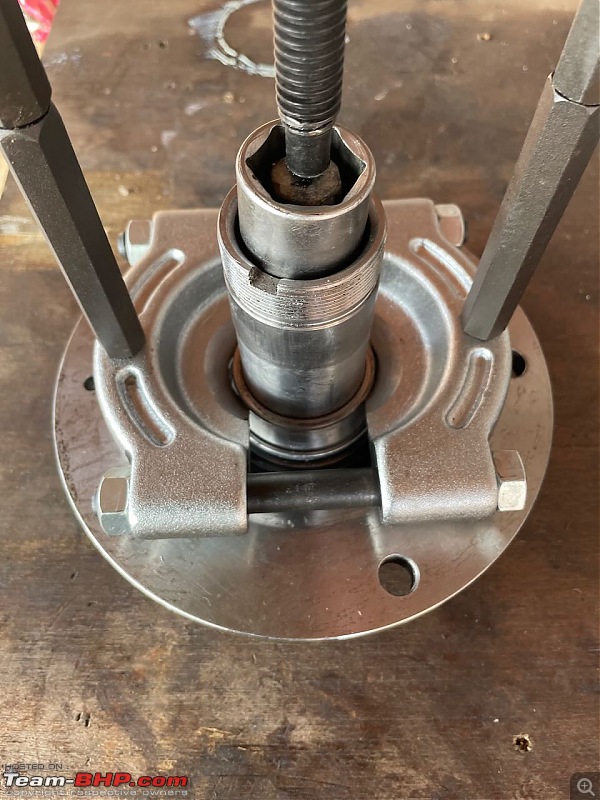

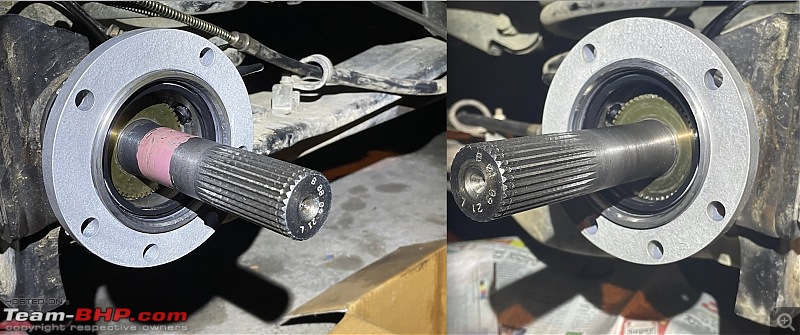

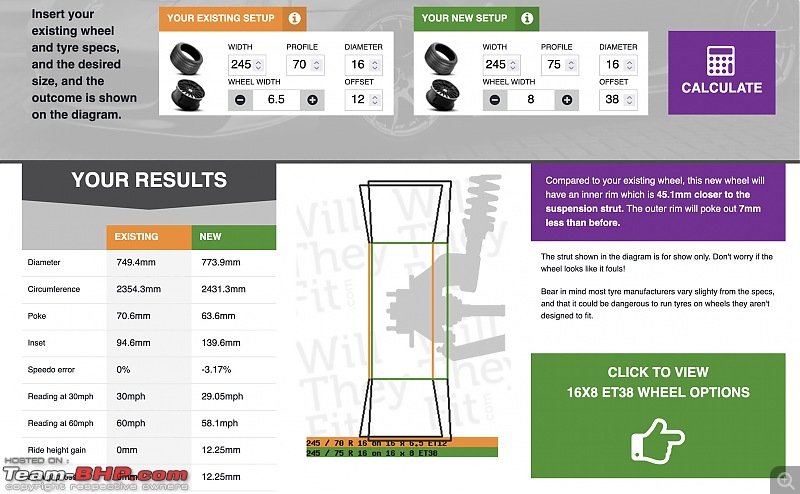

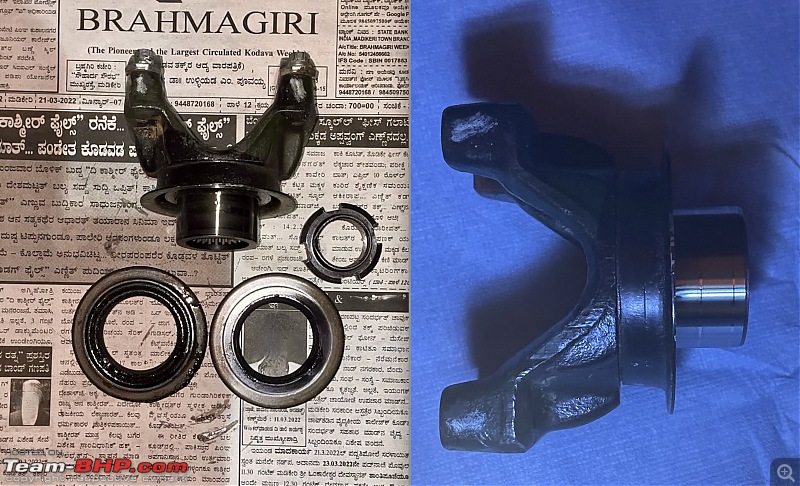

| Hub Mod Take Two Rear hub modification had an issue, while planning this modification I just analyzed front hub and planned the modification, on the day of the cut I just asked Mukhtar to match front hub cut depth. Rear hub in Gurkha is of unconventional design, unlike the common bell like design seen in front or other 4x4's, bolt plate is pulled in(towards chassis) leaving and gap behind(see pic below), so metal removal from front weakens the hub.  Plan: Keep the rear hub stock and add wheel mount ring + washer for wheel bolts. Planned to convert 5 M6 bolt oil seal plate into wheel mount ring and cut a tapered washer for brake drum and wheel gap. Had Timascus billet in stock just the cut the thing   Cage Cut Rear wheel bearing is pressed into recess so pulling it is pain, just cut the cage and pulled it with old school bearing puller.  Bearing Puller  Take Two: Refinished the factory hub  Hub Mount Refinished the hub mount with caliper paint, leaves hammerite like finish.  Wheel Mount Wheel Mount Ring Test mount, if you zoom in you can see 42CrMo4 hub material stamping  Washer & Ring Both washer and ring mounted. Note, wheel mount pin is absolute must when center bore clearance is tight, specially heavy wheel without spokes to hold on. Hard alloy wheel mount ring and bolt will gouge your alloy wheel while you kill yourself to mount it.  Wheel Bolt Ordered bolts with correct taper for proper seating and fit. BR wheel has V taper, factory bolt I was using had ball seating. Arrow shows old contact ring, bolts on left shows new contact ring. Had to use different length bolts for front and rear, rear with washer needs 50mm bolt, front needs 36mm. Bolts are M14x1.5 - 17Hex made by Bimecc for VW cars.  Ready To Roll Timascus ?  Ok, was just joking about Timascus, I just planned to use old modified hub to mint parts. Hub wheel bolt portion became washer and center shaft the wheel mount ring Slay It Mukhtar slaying old hub  Taking to me ? Planned to cut the Center Shaft by 16mm to create wheel mount ring.  Wheel Check Alloy wheel to washer contact patch  Test Fit brake drum bolt needs to be longer  Match ? My current measured track width is approximately 1540 both front and back. Factory track width is 1490 at front and 1480 at rear, I am not sure where exactly this is measured, I am guessing at wheel bolt flange based on my measurement. Below is the comparison with factory wheels, BR was sitting 7mm inside in old setup, now it is moved out 12mm so +5mm increase in rear.  New Setup  Tropy I asked Mukhtar to cut a tropy for me, with left over hub, he said "You can't win such detailed tropy ever, You have to make it" We started at 5:00PM that day and it was around 12:30AM and he still wanted to debur the edges.  |

| |  (13)

Thanks (13)

Thanks

|

| The following 13 BHPians Thank PhantomLord for this useful post: | 2himanshu, AdityaDeane, Alpha Defender, digitalnirvana, howler, katoom, Rigid Rotor, RijuC, saviouravenger, Siva Prakash, Tgo, theexperthand, vaasu |

| | #33 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

| Spare Wheel Mount My Gurkha came with steel wheels, spare steel wheel is mounted with 3 bolt bracket like below  Plan: Buy factory alloy wheel mount and modify it to mount BR wheel. I planned to use steel wheel bolt bracket and weld a 65.1mm shaft and mount it on factory alloy bracket. Factory Alloy Bracket Factory bracket comes with 115mm centering ring.  Test Fit  Modification cutting shaft to exact 65.1mm in local lathe was problematic, I was lucky to find SKF LM48548/Q locally which has diameter of 65.088 mm. Just outer race is what we need, but planned to use a shaft + bearing to create mount ring with 30mm depth. This makes its easy to keep the wheel in position without bolt and tapered bearing provides some wiggle for easy mount.  Bracket Done belted it matt black.  Wheel Mounted  |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank PhantomLord for this useful post: | 2himanshu, AdityaDeane, Alpha Defender, bamaboy, digitalnirvana, dr_TJ, FloatingCanvas, howler, Meph1st0, Rigid Rotor, saviouravenger, Siva Prakash, theexperthand, ysjoy |

| | #34 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

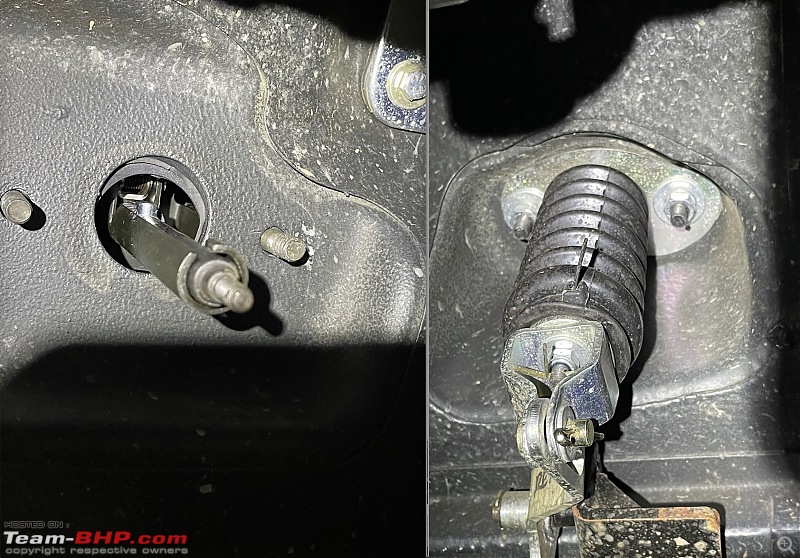

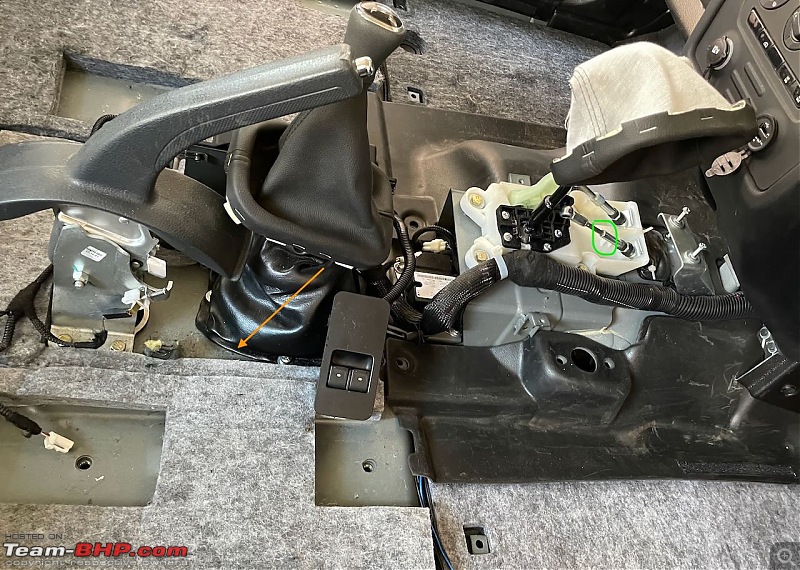

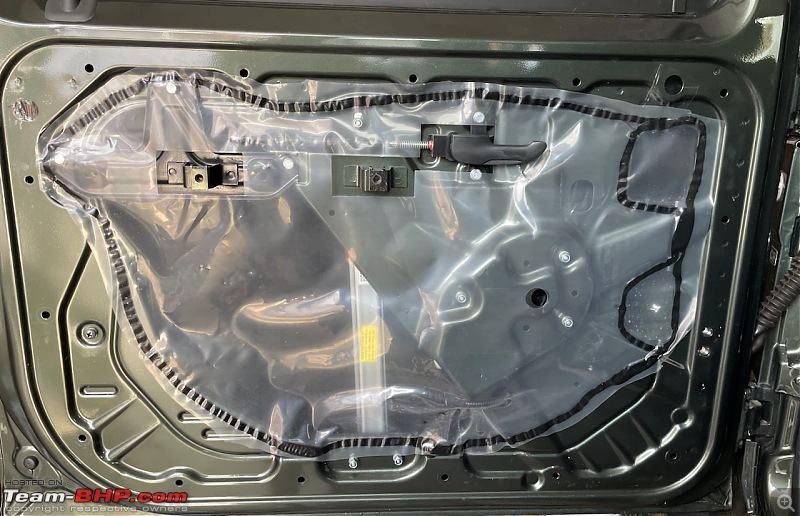

| Force Gurkha internal discoveries While waiting for wheel bolts I thought of completing Audio setup and internal rust proofing, below are notes and pictures from inspection. Gurkha sheet metal quality is excellent, has e-coat and is dip coated, but rust proofing, sealant for joints looks poor for an off-roader, it is a project in itself to do proper rust protection. Dash Crossbar: Dash Crossbar is not painted but has some oil coat on the exterior, but inside tube is dry, my initial plan was to pull the dash and paint the cross bar. I did do a dry run, but crossbar is fully integrated unit carrying complete A/C unit, instrument cluster and steering, only way to get to it was full disassembly. Luckily there was no rust on inside of the bar, used 3M cavity wax to quote the inside.  Centre Console has two piece, rear piece is held by 4 screws, front piece needs diff lock circuit disconnection. Houses AirBag control module and BCM under it.  Removal of diff lock lever from underneath  Note the edges are crude flaring and sharp.  Factory Centre Console trim damping  Since trim was out just belted it matt black to match the dash  Rear cabin, wheel well sheet metal is well formed and has thick gauge.  Left and right plastic trims have foam attached, with already padded shell, this may not have much affect.  Left and right shell cavity collects dust from rear wheel fender, rear speaker was fully covered with dust.  Dust enters from rear wheel well through these holes into cabin, looks like these are mounting holes for fender of different type(not used). These can be closed with sealant or rubber caps, you can also use foam to block dust through fuel cap slot.  Pressure washed the area, later wiped and kept it ready for cavity wax.  Left side of the shell, opportunity for large boom box ? Note the forced ventilation flap next speaker mount as well, more on that later.  Left side of the shell, wheel well joint is missing sealant, you will see dust here via micro pores, I planned to seal it from outside.  Forced ventilation exit is same as G, from shell it goes via breather pipe to area under rear bumper.  More here Rear wheel well trim is damped as well, I would have preferred outside wheel well cover like front instead (outside cover is open at top, increasing chances of stone chip, noise and rust).  Roof has good support and is well damped.  Full cabin as seen from rear door  Gear shifter is slick, handle with care, internals does not look abuse friendly.  Shift area houses AirBag control module and Body control module  Shift cable actuator is missing boot ? Also note the 4 wheel lever boot assembly.  4 wheel shift boot is damped, you can see that retaining ring is assembled wrong it should have been on top.  Transmission tunnel damping, it uses same damping material as dash, even though damping material is good, its loose and not pinned like it should be, just held by center console trim.  MB(G55) transmission tunnel damping uses thermo-plastic, typically these weight around 4kg on 124, this one should be around 5-6KG.  Front door is well formed and stamped, I did not find the cross crash bar/rod though. Outer Sheet metal is damped with black foam as seen on roof, I felt it needed heavier damping, din't want to pull the dust barrier and pull the foam so let it be :-). Front doors get double rubber seal for better noise insulation.  Door card, simple and robust.  Rear door does not have the dust barrier mostly due to wiper washer, mine had lot of dust. Rear door does not get the double rubber seal like front as well.  Added dust barrier for rear door with a cut out for rear wiper reservoir.  Front and rear seat, front is well built, rear minimal under support.  There is no way to remove these plastics without disassembling the seat.  Interior lights used are same old school bulb like 124, here is compare, OSRAM is 124's  |

| |  (24)

Thanks (24)

Thanks

|

| The following 24 BHPians Thank PhantomLord for this useful post: | 1000bhp, 2himanshu, AdityaDeane, dailydriver, deepfusion, digitalnirvana, dkaile, FloatingCanvas, Fuldagap, GTO, gunin, howler, InControl, mazealot, ph03n!x, redohabitat, Reinhard, Rigid Rotor, saviouravenger, sierrabravo98, Tgo, theexperthand, ysjoy, Yuvuz |

| | #35 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

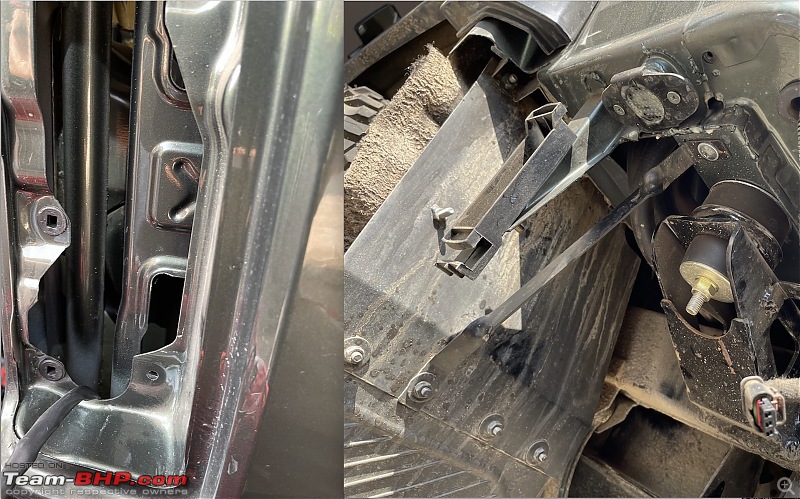

| Jugaad Some Jugaads seen, slipping this in between  Glove box has two caps for passenger Air bag bolt access.  Looks like some hacksaw cutting was done when caps din't fit and then cap became loose and as expected quick fix glue was used. This is common practice in MB garages when service personal breaks a clip, magically quick fix or super glue appears from pocket for the fix :-)  Forced vent fixing has some design issue, vent and its cover is well made, but the vent is fixed to shell and it can't be adjusted. Cover is fixed after fixing shell plastic trim which makes fixing cover impossible due thickness and alignment, in comes the double sided tape.  Body sealant at front B pillar seat belt mount area. Body sealant application is missing for most part, I could see it properly applied at some absolutely necessary places though, rest of the places it is missing or applied for sake of it.  |

| |  (19)

Thanks (19)

Thanks

|

| The following 19 BHPians Thank PhantomLord for this useful post: | 2himanshu, AdityaDeane, Alpha Defender, arjunsatheesh, CEF_Beasts, deepfusion, digitalnirvana, Doge, FloatingCanvas, Fuldagap, mazealot, ph03n!x, redohabitat, Reinhard, Rigid Rotor, sierrabravo98, Tgo, theexperthand, theflyingguy |

| | #36 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

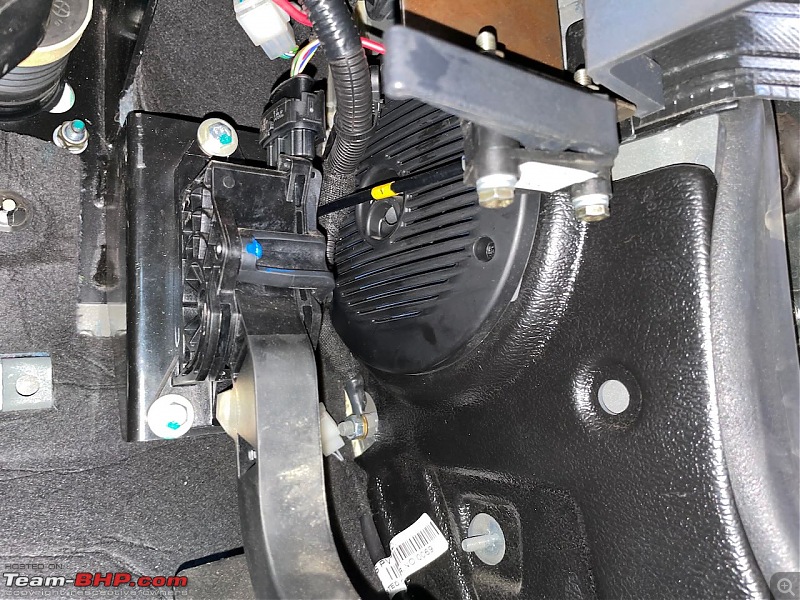

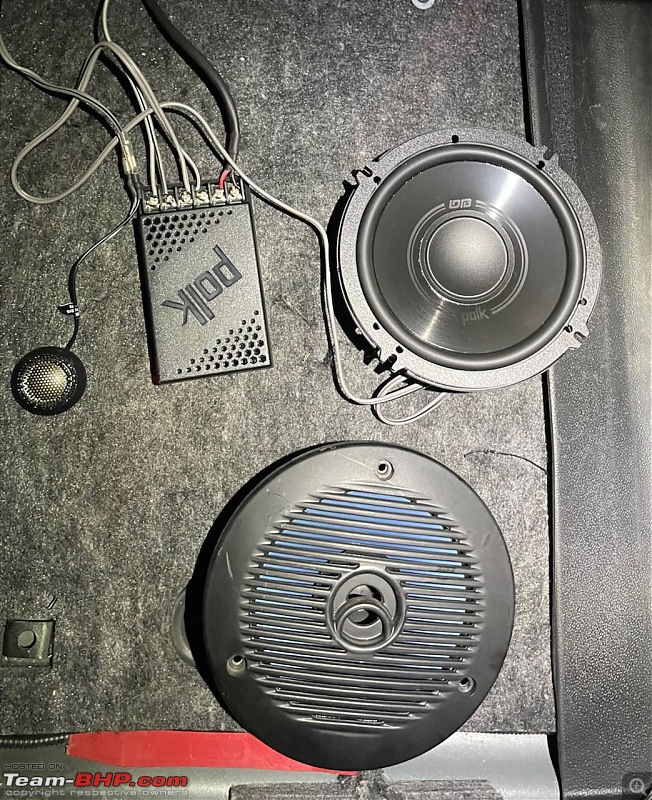

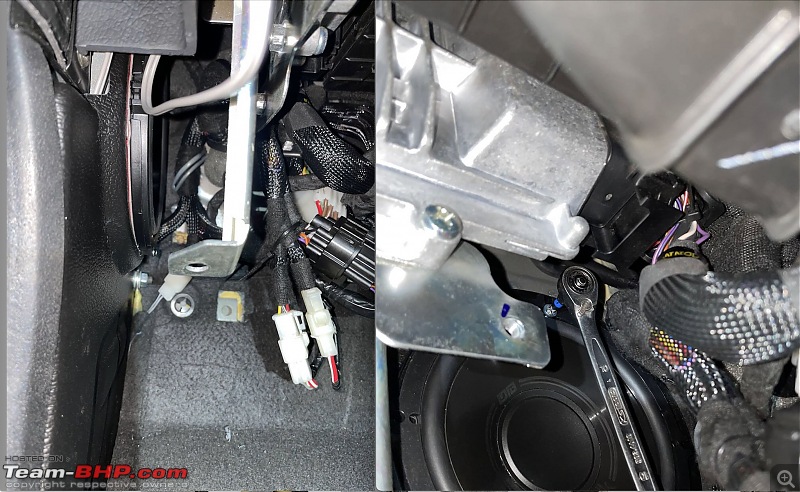

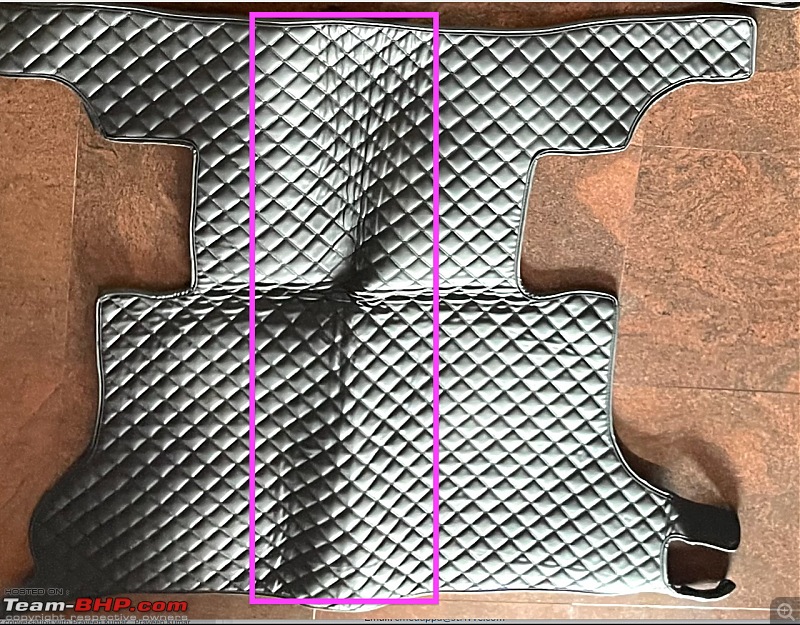

| DAWG's Audio Setup I think Gurkha makes a good vehicle for Audio setup for both SQ and Bass heads. It is hard to find heavy, rigid chassis with excellent shell(see my later post) sheet metal thickness for the size these days. To boot stock speaker sizes are 6.5" Setup: 1) Front Speaker - POLK DB6502 DB+ 2) Rear Speaker - JBL STADIUMGTO620 3) Woofer - Infinity BASSLINK SM2 8" UNDERSEAT (Under driver seat) 4) Amplifier - JBL CLUB704 4-Channel Amplifier (Under passenger seat) 5) Wiring only - Only added Power and RCA, for speaker used stock wiring. Infinity BASSLINK is press fit for driver seat, its about 1mm larger than seat support, you can just press it in.  Speaker at front are very busy, I am glad Force did not exclude it. To remove left speaker ideally you need to pull the ECU and may be blower assembly.  Right side speaker area too is very busy, you need to pull the pedal assembly for proper acces.  Front speaker, Stock vs Polk  Front Speaker slot is in foot-well, even though access is pain, the slot is well made. It's shallow, can't use deep speaker like STADIUMGTO620, but DB6502 fits like glove. There is even slot which looks just made for component crossover module. Speaker slot actually tunnels and vents into A pillar, sound play is good considering speaker is near the foot. Attachment 2310026 Front Speaker installation you can't use normal screw driver unless you dismantle the dash, looks like speaker is the first part to be assembled in dash :-). There is about 1" gap to get the screws in and out + stock screws can be used for aftermarket speakers due to different mount points. I planned to use only 2 screws and use double sided tape for sealing, used one stock screw and had to cross drill hole for another.  Rear Speaker is walk in the park, STADIUMGTO620 is press fit (rarely I get this lucky), but stock screws can't be used. Also made improved fitting for forced ventilation vent, still using double sided tape since tabs are broken from factory.  Tweeter: I planned to cover the coin hole and mount tweeter into it, but it sounded fine in current location and mostly is closer to recommended 12" from woofer.  Damping: Damping plan was to inspect existing damping and damp wherever needed, just converted all 1 KG plastics to 10 KG. Gurkha plastic trims have good clearance unlike 124, so made it heavy and tight. Lead jacket for transmission tunnel, for damping I used Texsa Tecsound MLV, 5.2mm thick sheet gives ~1kg per square feet and extremely flexible.  Dash area is well damped inside out from factory, only weak point is cable entry hole from engine bay, its just thin rubber sheet, lead wrap is the fix.  Audio work done ready for assembly.  Center trim fixed, added edge binding to mask sharp edges and blend with carpet.  Music play for this setup is brilliant even with windows rolled down, unless you rev it to the limit. Got a set of matt from CoverWell Nexus, it is well made, but needs improvement. Noodle overlay is press fit and removable for cleaning.  Passenger side fits well and I could tuck it under console trim.  Driver side, noodle patch needs to extend till under pedal to properly collect dust and easy cleaning. Also it kinks with foot when releasing clutch  Rear needs noodle patch for walking area.  |

| |  (42)

Thanks (42)

Thanks

|

| The following 42 BHPians Thank PhantomLord for this useful post: | 2himanshu, AdityaDeane, AjayJoshuaN, Alpha Defender, arjithin, arjunsatheesh, AROO7, brownkaiser, Chandrahas, Cool-Shine, deepfusion, digitalnirvana, dkaile, Doge, Excommunicado, FloatingCanvas, Fuldagap, GTO, howler, ike, Manjib, mazealot, Meph1st0, Nair.V8, Nature&Me, rakesh_r, Reinhard, Rigid Rotor, RijuC, ron82x3, saviouravenger, somspaple, SS80, Sudeep Lakhotia, Tgo, theexperthand, Thekalacoatwala, Trojan, vishy76, wadewilson, wbd8779, Yuvuz |

| | #37 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

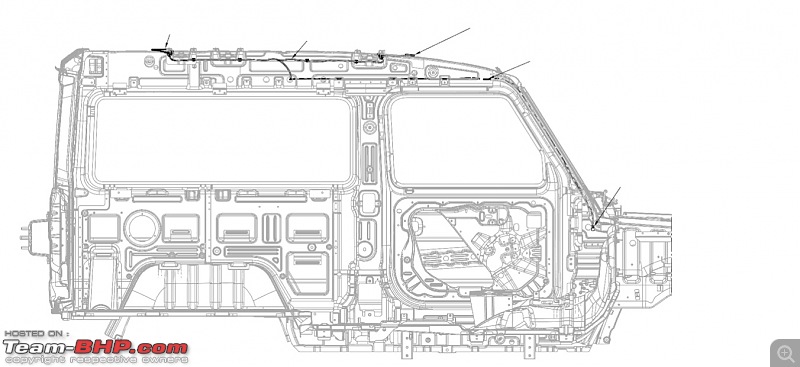

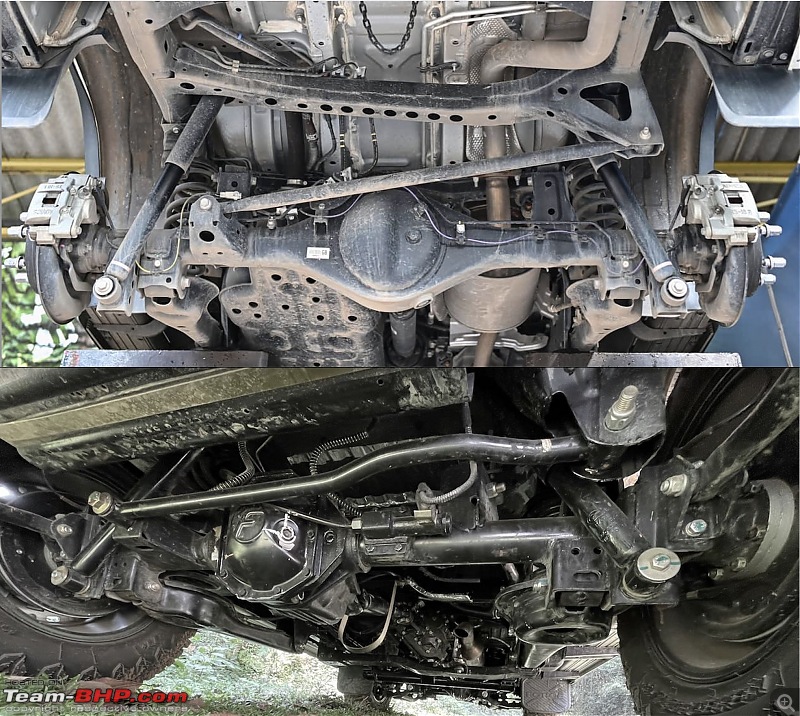

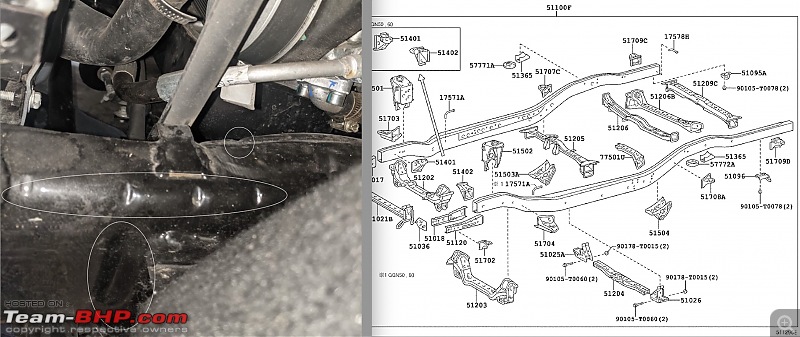

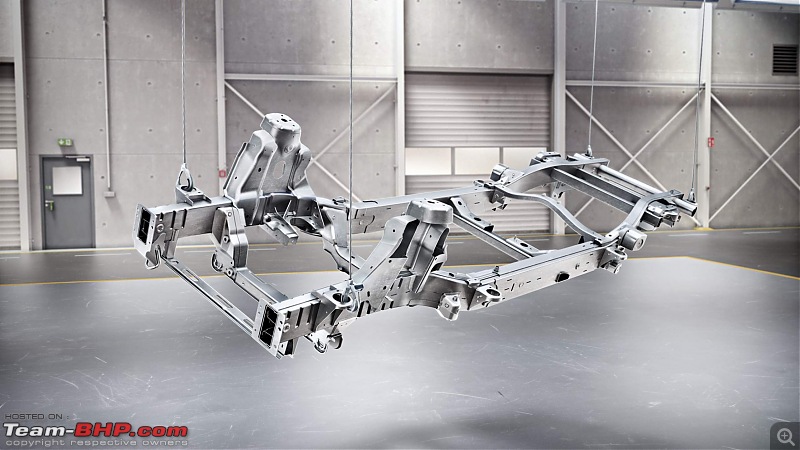

| Shell, Frame, Suspension and Steering Gurkha's body shell is very well made, resembles modern G or Discovery, paint protection could have been better though. Component placements are similar to MB.  Older discovery and G shell  Newer discovery and G shell  Gurkha's shell is covered with foam everywhere except for rear, so you have do with poor quality pic.  Frame and suspension of BS6 Gurkha is close to Toyota than MB. Suspension setup is very similar to Fortuner, which coincides with similar ground clearance and braking(Drum brakes) issues. Except for front and rear sway bars which are mounted similar to Land cruiser or other Toyota trucks. Lower ball joints use similar bolt attachment, most of Toyota suspension mods should be transferable ? FortGurkha ? Lower control arm, shocks, pan rod and mounts look very similar to Toyota trucks.  Gurkha looks to have similar design and length of front crumple(51120) member, it tapers down in width and height like Toyota, but it is not separate part like in Toyota. Crumple indents end at about 12" and member continues till rear of LCA. Fortuner chassis for comparison.  MB G class frame for comparison, it has larger and longer crumple member, note the C-IN-C within C-IN-C and internal spacer(Gurkha has same style internal spacer through out the Frame) and C-IN-C within C-IN-C can be found in rear axle area)  Gurkha's frame longitudinal member is 3 piece, font and rear pieces hold front and rear axles. At the end of center piece, transfer case is mounted. I guess 5 door chassis would only need swapping center piece. Center piece is C-IN-C within C-IN-C slotted into front and rear pieces with larger asymmetrical overlap and welded, yielding rigid and strong joints. I think Gurkha SWB could be one of stiffest chassis in the country. Sway bars are real thick adding to suspension stiffness, looks even thicker than ones used in Toyota KDSS systems. Rear outer wheel easily looses traction in tight corners, small mound can get rear wheel to spin freely without diff lock. Steering shaft system looks similar to Ford F150, but Gurkha has single long shaft with a joint at each ends. Steering is sharp and light for the size, its unforgiving in narrow twisty roads, rigid chassis makes it behave like brick even when rear hits an edge. If you have driven Gurkha in narrow roads with broken edges you don't need to second guess possible reason for Sandakphu incident. I think recirculating ball bearing steering would have been more relaxing and safe.  |

| |  (17)

Thanks (17)

Thanks

|

| The following 17 BHPians Thank PhantomLord for this useful post: | 2himanshu, Alpha Defender, amoi, brownkaiser, deepfusion, digitalnirvana, FloatingCanvas, Fuldagap, howler, Manjib, Manuuj, redohabitat, Rigid Rotor, sierrabravo98, WhiteSierra, ysjoy, Yuvuz |

| | #38 |

| Senior - BHPian | Re: 124's DAWG | My 2021 Force Gurkha 4x4 What grade steel did you use for the hubs? |

| |  ()

Thanks ()

Thanks

|

| | #39 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

| Re: 124's DAWG | My 2021 Force Gurkha 4x4

(Click to enlarge)  I just cut the stock hub, apart from metal being stock, did not have to deal with bolt alignments. Last edited by libranof1987 : 20th May 2022 at 20:26. Reason: As requested |

| |  (6)

Thanks (6)

Thanks

|

| The following 6 BHPians Thank PhantomLord for this useful post: | 2himanshu, amoi, digitalnirvana, FloatingCanvas, Fuldagap, saviouravenger |

| | #40 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

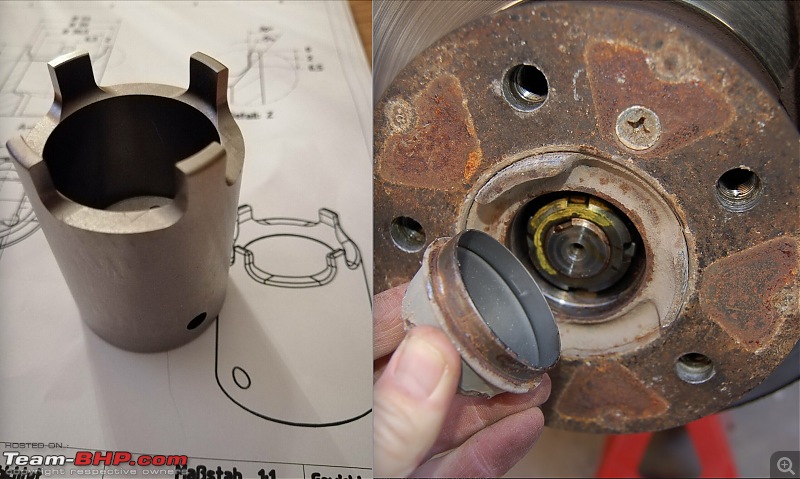

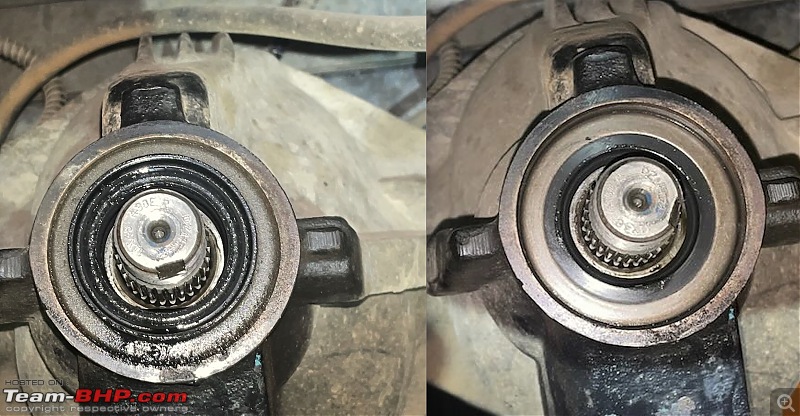

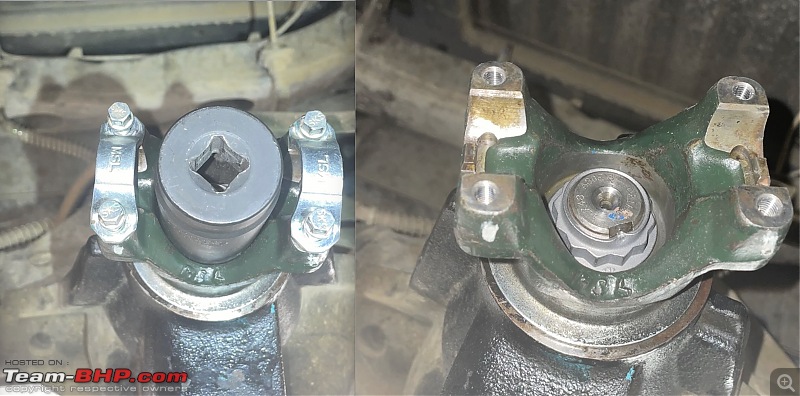

| Differential Seal and Steering Hose fix. Rear Differential oil seal was leaking from day one, but it was minor wetting just around the flange initially, it got worse over time so thought of replacing the seals.  Differential flange slotted nut is straight out of 1979 MB, so had to make a tool like I did for wheel bearing. There is not much leverage for removal,made a socket based tool to be used with impact wrench. Socket size is 30mm, just cut the fingers matching the nut slot and flame harden it.  MB W46x had this slotted nut for rear axle as well  124 differential nut uses same thread and size, since I had spare one and proper tool thought of using it for easier future maintenance. Both nuts are exactly 14mm height(in case you plan to use thread marking to set the friction torque). MB differential nut, 124 flange with Gurkha's seal and MB nut removal tool.  MB part number, MB nut on right side is rear axle nut which is same size but has larger contact surface.  You need puller to get flange out, mine was loose though.  There are two seals, oil was trapped between seal one and two, guessing inner seal gave up.  Flange surface was good, leak was due to damaged rubber seal. (Flange size is same as 124)  Cleaned and ready for assembly, it is recommended to use sealant on outside of the seal.  All done, friction torque setting has elaborate procedure to copy from exiting setting. But exiting setting on mine was loose, so just hand tightened + 1/8 turn (Overall goal here is to be as loose as possible without slack).  Shaft catcher protrudes a bit below rear differential, bent it to tuck in.  Greased all the 3 shafts while in there, just in case if it was missed from factory.  Steering Hose fouling radiator hose is known issue, I did not face the issue but mine was quite close. Primary issue looks like Adhoc design to accommodate routing of steering hose from pump to reservoir, to correct this issue reservoir mount is made adjustable in all direction. To increase gap, reservoir needs to be moved towards the engine but mounting clamp design limits this. However you can adjust it to create more gap.  Before and After, make sure to loosen all joints before adjusting reservoir position , else it will add tension to hose.  Last edited by PhantomLord : 20th May 2022 at 17:48. |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank PhantomLord for this useful post: | deepfusion, digitalnirvana, drsnt, FloatingCanvas, Fuldagap, howler, icar, Learner, Meph1st0, ph03n!x, Rigid Rotor, romeomidhun, saviouravenger, t3rm1n80r |

| | #41 |

| BHPian Join Date: Mar 2022 Location: Delhi

Posts: 27

Thanked: 58 Times

| Re: 124's DAWG | My 2021 Force Gurkha 4x4 Any idea how much increase in the Kerb weight of your ride? |

| |  ()

Thanks ()

Thanks

|

| |

| | #42 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

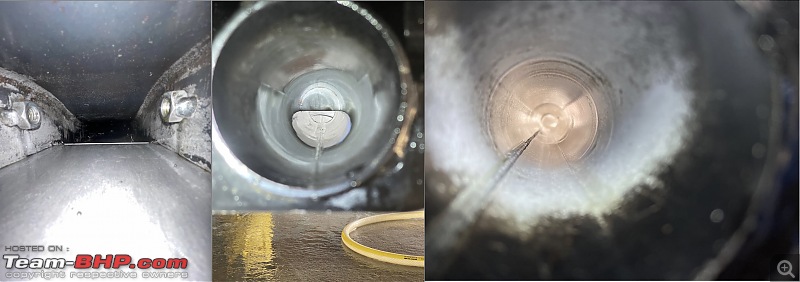

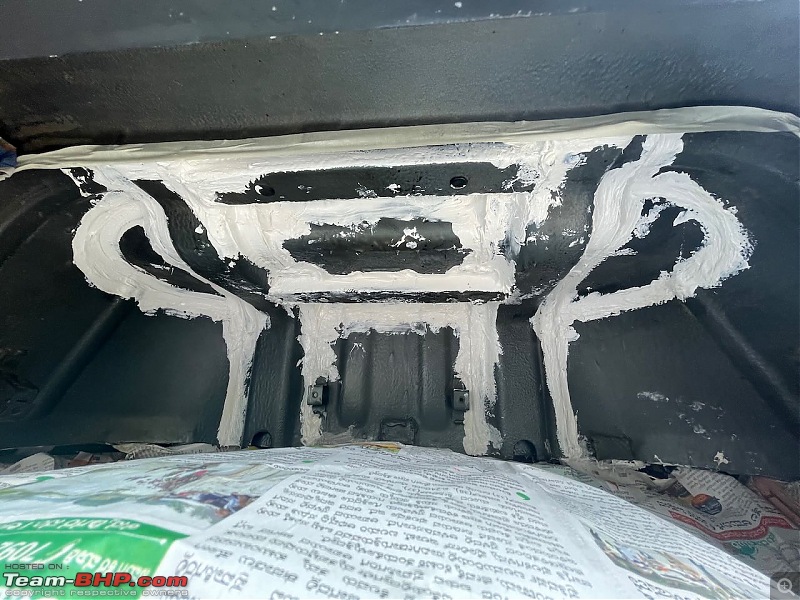

| Paint Protection Or Rust Proofing Cavity Wax Plan: Since I had already dismantled the interiors planned to cavity wax the entire body shell. 3M cavity wax and wand is good, though considerably expensive reach and coverage is unmatched. Waxed full shell including interior tunnels, side fenders, hood and all doors joints  Top picture: you can see factory waxing in tunnel between A pillars, coverage is sparse. Bottom is after applying cavity wax, ripple as seen via cable camera, coverage was excellent.  Factory waxing in tunnel between A and B pillar  Tunnel between rear pillars  Frame Rust Proofing: Gurkha's Frame has poor paint protection, unlike body shell, frame is not dip coated. It is simply painted from outside without primer, main member internals, cross member internals, under mount points etc do not have paint. It was real pain to do frame rust proofing. All cross members had rust, this is just sample, ignore the red color its due to phone camera being too close.  Cross member after rust removal, grey or white coating you see is coating left by rust removal acid, this will quickly start rusting if not painted.  Internal of the frames as seen via cable camera, you can see rust, MB like spacer and C-in-C overlap joint as well. Internal of one side of center frame piece was painted though.  Rear end, this C-in-C overlap extends till front of rear wheel arch, its painted just at the end.  I used RustOust(see previous hub post) in 50% concentration sprayed in throughout via various frame holes and kept it wet for a day, then used pressure washer with swivel head + zero deg attachment to clean up the rust. (If rust is thick just repeat, if you can reach and scrub that would be good too).  You can see one side of center piece has paint or coating, white/grey is bare metal, poor resolution of cable cable camera makes it look like paint.  I used 3M underseal with small quantity of slow curing thinner for better spray/flow inside the frame, 3M underseal has very good adhesion over rust.  Taking clear pic is hard with cable camera once internals are coated black, this one is phone shot through paint hole.  3M underseal inside pan-rod mount, those bubbles are weld splatter.  Moved antenna from glass to here, I like clean glass without any sticker or attachment, only registration sticker remain.  Waxed side chambers as well, see below.  You can see W463 waxing(yellow stain) in this picture.  Spare Wheel Mount: Looks like chassis is dip coated with wheel mount attached, so spare wheel mount joint has some bare metal, resulting in rust. Had to clean and paint this patch on both shell and wheel mount side.  |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank PhantomLord for this useful post: | 2himanshu, Alpha Defender, digitalnirvana, govigov, GreenerPlanet, howler, k0p, lemedico, NICHE, redohabitat, Rigid Rotor, somspaple, SS80, t3rm1n80r |

| | #43 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

| Re: 124's DAWG | My 2021 Force Gurkha 4x4 |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank PhantomLord for this useful post: | digitalnirvana, redohabitat |

| | #44 |

| BANNED | Re: Project Infotainment |

| |  ()

Thanks ()

Thanks

|

| | #45 |

| BHPian Join Date: Nov 2007 Location: Bangalore

Posts: 114

Thanked: 1,132 Times

| Underchassis Protection Underchassis coat used by Force Motors is good, but coating is missing from some corners, it would be ideal to get the coating material from Force Motors if possible and use it to re-coat. Also paint holes are not closed + cross tunnels not sealed (which I guess most manufactures skip these days) Sample undercoat missing in some areas  Process * Use cavity wax coating in all under-body cross tunnels via paint holes. Not my Gurkha(I did not take pictures) process is essentially same, insert cavity wax wand through each paint hole and lay the ripple. Long cross tunnel near transmission did not have paint hole so had to drill one.  * Close the paint holes with rubber caps and seal tunnels as shown in G assembly video below  Skip to 3:30 for sealing, closing ports and under chassis protection * Overcoat with Force undercoat if you can source it or 3M underseal should do. G500 under chassis, you can see under chassis is fully sealed.  This G went Full Monty  Check here for more of Wax Em All, it mostly covers what you need to do. Note: TimMAX 300 Wax resembles tuf-kote® 3852 PENETRANT available locally, this could have been good alternative to 3M cavity wax, even 3M cavity wax wand is direct fit on tuf-kote aerosol CAN, but it does not generate enough pressure resulting in poor coverage/reachability. 3852 is available in paint cans, best/economical way would be to spay 3852 to cover major area and then use 3M for un-reachable area else you will need at least 10 3M CANS. Since I do not have under chassis picture, you can take this rear fender area as example, unlike front, rear fender cover in Gurkha is skirt only(open at the top), dirt, salt etc can collect in these cross tunnels increasing chances of corrosion.  No pits + No holes = No dirt, rear fender sealing to keep dirt and corrosion out, this was repeated under chassis.  |

| |  (14)

Thanks (14)

Thanks

|

| The following 14 BHPians Thank PhantomLord for this useful post: | 2himanshu, Alpha Defender, amoi, ashpalio, Ashtoncastelino, dailydriver, digitalnirvana, govigov, highwaypatrol, howler, ObsessedByFIAT, ph03n!x, Rigid Rotor, somspaple |

|