| Automobile Technologies of the Past - A Revisit

This Thread is started to share knowledge of the automobile technologies used in the past. Some of these technologies have limited relevance but most have not survived as better technologies were developed.

With this thread one hopes that people will share technologies they have discovered in their vintage and classic cars (hopefully limited to 1960). This will help people with similar cars to appreciate their cars better. Many a times the originality of a car is compromised as many do not understand how a particular system works and in the absence of this understanding modifications happen.

One of the most interesting systems developed by Chrysler Corporation was the FLUID DRIVE technology which was introduced in the 1939. One may have seen a few DPCD cars with Fluid Drive on the horn ring, rear bumpers etc. Sadly getting a car with the fluid drive intact is quite difficult these days as lot of them got modified. Currently we are restoring a 1946 Chrysler Windsor which has a fluid drive system and I am sharing what I have seen and read.

Let us understand the system first which I googled  The Fluid Drive torque converter The Fluid Drive torque converter

The important part for understanding this system from the above link is as below Quote:

These moving parts are merely two bowl-shaped shells of steel almost identical in appearance, into which a series of evenly spaced blades or fins are welded. Imagine an orange cut into halves and you have the picture, except that the "halves" of Dodge Fluid Drive measure about thirteen inches in diameter. One 'of these halves is mounted at the end of the engine crankshaft, its open end facing toward the rear. This is called the driver or impeller. The second half, or runner, is mounted on the propeller shaft, its open end facing the impeller-almost, but not quite, touching it. A tightly sealed, close-fitting steel housing surrounds these two Fluid Drive parts. The interior is filled with two gallons of a special grade of oil with very low viscosity, so that the impeller and runner are completely submerged.

I have stated that a small gap exists between these two parts. Now picture what happens when the engine is running. The impeller naturally turns because it is fixed on the crankshaft. This rotating action throws the oil by centrifugal force against the fins of the runner, causing them to rotate in the same direction. It is exactly like one electric fan forcing a current of air against another idle fan and setting the latter in motion-just as a breeze turns a windmill. Only the medium of motion is oil in this case-NOT AIR.

After the engine has picked up speed, the car moves much as it would if this "fluid coupling" were mechanical. One important and very noticeable difference is that you experience no jarring or jerking. Not only in starting, but in driving and stopping, the motion is emphatically smoother.

Fluid drive advantages are:

1. The car can be driven by declutching and shifting in the normal fashion, starting in 1st, shifting to 2nd, and then to 3rd.

2. Downshifts from 3rd to 2nd are greatly reduced.

3. In stop-and-go traffic, the car may be left in 2nd gear with the driver starting and stopping merely by applying the foot brake and accelerator pedals, as is done in a car equipped with a modern automatic transmission.

4. Acceleration from 5 MPH up in 3rd gear is entirely acceptable under most level-road conditions.

5. Ascending moderately steep hills does not require downshifting.

6. Under light loads and relatively flat road conditions, the car may be started from rest in 2nd gear with entirely satisfactory acceleration results and without putting any strain on driveline/clutch parts.

7. Starting on hills is greatly facilitated. The car may be placed in 1st gear, the clutch engaged, and the car held motionless by application of the foot brake only. When it is time to start, the driver merely steps on the accelerator. There is no need to coordinate the clutch/brake/accelerator with the inevitable engine over-revving and clutch slipping that are the hallmark of manual-shift car hill starts.

8. Wear on clutch parts is greatly reduced because there is no need to “slip” the clutch for smooth starts from rest.

9. Fluid drive cars have a lower numerical rear axle ratio, thereby reducing constant speed engine RPMs.

There are also disadvantages:

1. When starting from rest in 1st gear, “off the line” acceleration suffers because of the “slipping” action of the fluid coupling. This is largely overcome at the point where the car attains a speed of 10-15 MPH, however.

2. Leaving the transmission in gear with the engine off does not lock the rear wheels. A fluid coupling car left in gear with the engine off will roll just as if it were left in neutral. Therefore, maintaining the emergency/parking brake is paramount, and care should be taken when parking the car when anything but absolutely level road conditions are encountered.

|

Here are the pictures from our car as we opened up the same for inspection

The most important part is the Fluid Fly Wheel which is known as the Torque Converter.

This is the rear part showing the clutch cover in place

In this picture one see the clutch plate exposed as the cover is removed

With the clutch plate removed one see the Runner clearly

Here one sees how big the Fluid Flywheel actually is. The size of this results in the housing to be larger than ususal

The drain plug for the 10 grade oil. The oil is supposed to be for life.

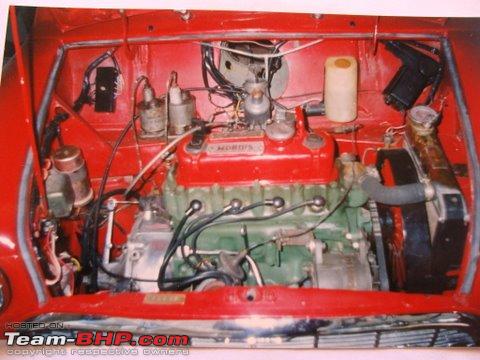

The front part which attached to the crank shaft and is called driver

I do hope that the stalwarts in the Forum will share their knowledge with pictures so that every one can understand better.

Cheers

KPS |

(8)

Thanks

(8)

Thanks

(2)

Thanks

(2)

Thanks

(5)

Thanks

(5)

Thanks

(4)

Thanks

(4)

Thanks

(2)

Thanks

(2)

Thanks

(5)

Thanks

(5)

Thanks

(2)

Thanks

(2)

Thanks

(3)

Thanks

(3)

Thanks

(1)

Thanks

(1)

Thanks