News

Detailed process: Sound insulation of my Maruti XL6

I also had to ensure proper waterproofing and making sure the damping sheets or insulation stuff doesn't come in contact/hold water at any location.

BHPian Leoshashi recently shared this with other enthusiasts.

Finally, the much awaited post on Sound Insulation of my XL6. This post got delayed due to multiple reasons. Firstly my Phone got damaged and barely managed to recover the pics. Secondly, it was done in two stages. Stage I involved insulating the Doors, A Pillars and Roof. This was done last year, in August 2020 I guess. Stage II took care of Floor and Rear Quarter panels which was done in October 2021. Thus I'll be posting two back to back posts, one for each stage.

Stage I: Insulating the doors and roof:

Objectives and problem areas:

- The Damping part will arrest the vibrations of panels, plus help in preventing dings which Maruti cars are infamous for since they provide mechanical rigidity to the panels from behind. This is why it was in first priority.

- Arresting vibrations at high volumes even with stock speakers.

- The irritating Tabla on roof during rains.

Process: Now this wasn't just going to be a mindless application of damping sheets and feeling smug about it. I also had to ensure proper waterproofing and making sure the damping sheets or insulation stuff doesn't come in contact/hold water at any location. Also, use of different materials at different places ensured optimum absorbtion of frequencies/noise/rattles. A friend who is a NVH Simulation engineer with a leading OEM was my guide, and anything done was after detailed discussion with him.

Materials used for insulation:

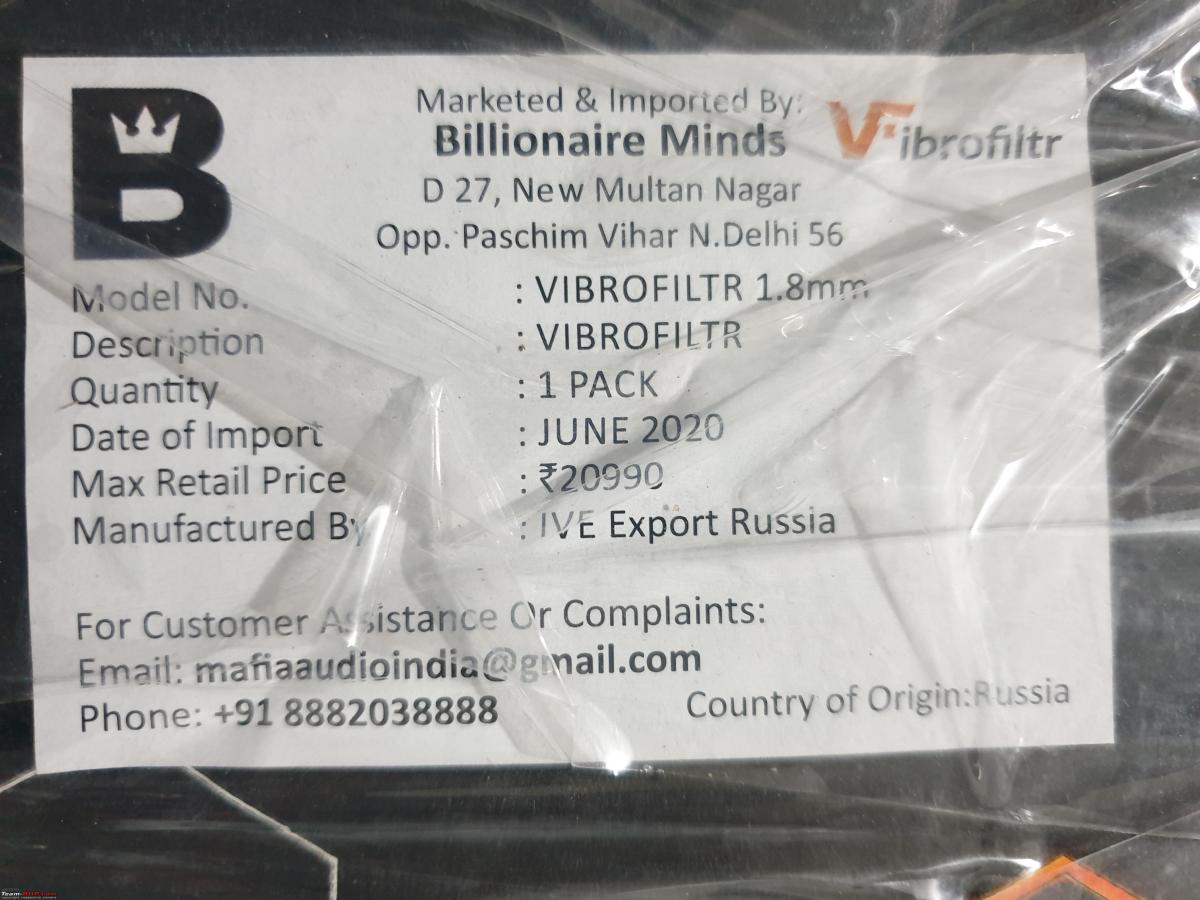

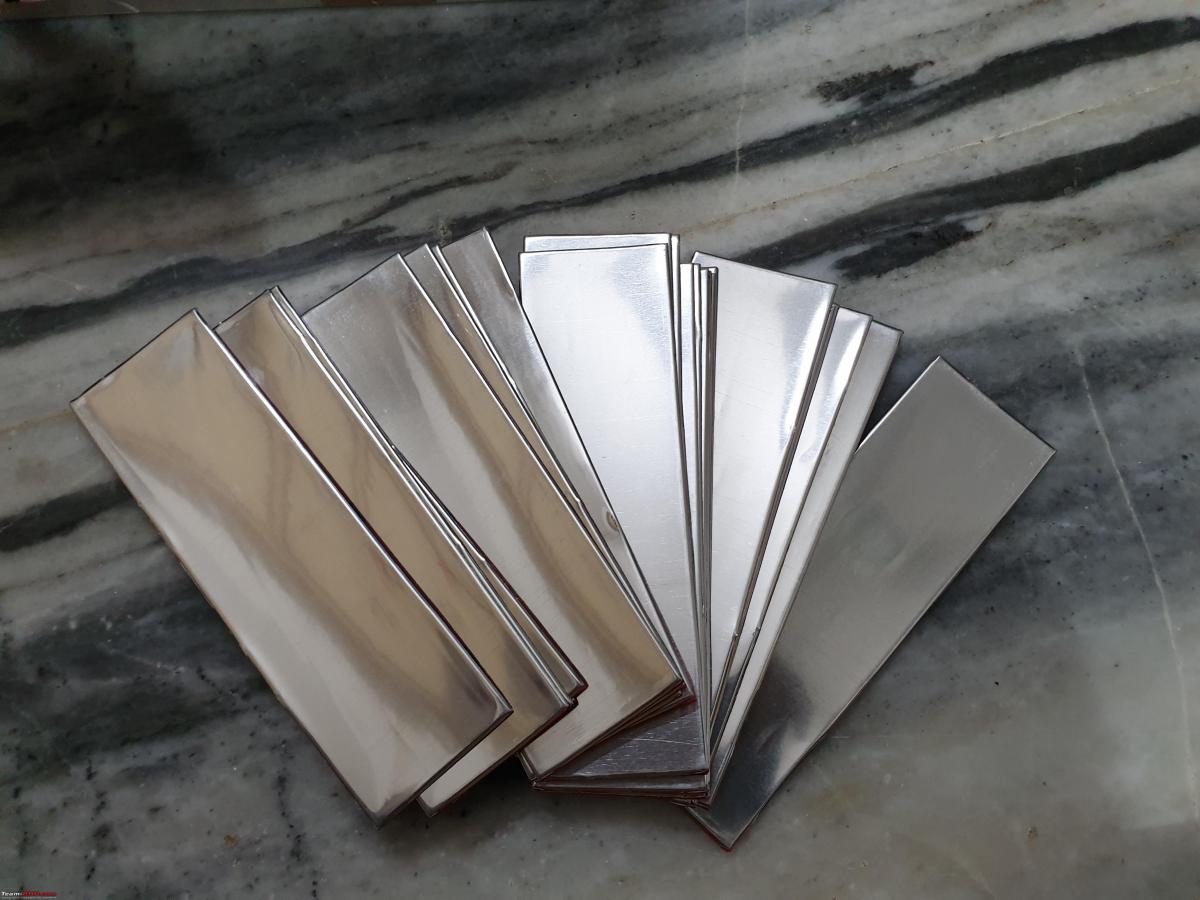

- Alubutyl Sheets(S1): 1.8mm, Vibrofiltr Brand. I am a fan of STP and CTK brands, but this first stage was done during lockdown last year, so those brands weren't available. Vibrofiltr is also quite reputed, so opted for this. A pack was ordered which came with 15 sheets:

- Closed cell foam loaded Alubutyl Sheets(S2): This provides weight of Alubutyl, plus has a closed cell dense foam layering on top, for excellent noise absorption. iCopper was a brand available on Amazon, ordered a pack of 5 sheets:

- Dr. Artex Lace(S3): This is a sound absorbing open cell foam, which can be easily compressed and being flexible, can be used on any type of contoured surface. Ordered 10 sheets:

- Dr. Artex Baffle Plus(S4): While this is a good sound insulator, it excels in heat insulation too. Ordered 4 sheets:

- A friend who owns a 3M store, sent in a kit of 3M's damping kit, from which I used only the stiffener(S5). This is an excellent option if one needs only panel stiffness with minimal weight addition. Thanks mate!

Chaps Involved: My trusted mechanic Arjun and yours truly. I gave the ideas, while he simply followed them to the T. I don't trust any random chap for these things. Thus it had to be Arjun, plus the job was leisurely done at my place since I have enough space for dismantling the car and tools.

Time taken: We used to work from 7pm to 11pm after our work hours, straight for 5 days. Basically 1 panel was done per day. Since we worked till so late in the night, I ensured Arjun got his dinner at my place, so that he doesn't have to worry about cooking after a long day.

Tackling the doors: We divide the door into three parts. 1. Inner part of outer skin. 2. Outer part of Inner skin 3. Door pad

Inner part of outer skin:

We first cleaned the door's inner section with IPA to remove any dust and wax/oil.

Pasted the 3M stiffeners(S5) at regular intervals.

Video: [Mega Soundproofing of the XL6] Adding 3M Stiffeners to the outer skin of door

Pasted strips of Alubutyl Sheet S1, ensuring zero overlap or pocket formation where water can sit. Do note that water flows from inside, so there shouldn't be any hindrance to that movement. This was rolled down aggressively with a roller to ensure maximum adhesion:

Video: [Mega Soundproofing of the XL6] Adding VibroFiltr Alubutyl to the door's outer skin

Sprayed Hinge Wax all around the lip of these sheets. This makes the surroundings water proof, once the wax solidifies. This becomes equal to the hot wax which is applied from factory:

Outer part of inner skin:

Once the harness, nuts and bolts were removed, the panel received a wipedown with IPA to remove any oil/dirt/wax.

Foam Loaded iCopper Alubutyl sheets were then used to seal off the cavity. This served 3 uses, first made a enclosure for speakers, increased rigidity of this skin and the closed cell foam ensured proper blocking of noise frequencies too. Also closed cell foam is used here because this area may come in contact with water/moisture, the closed cell structure ensures water isn't absorbed into this material. This sheet is quite thick at 2mm, but still was diligently pressed with the roller. For difficult contours, rear part of screwdriver is used to press the adhesive in.

Care was taken to ensure that this sheet work is done within the adhesive limit of OE vapour barrier. The plastic sheet is needed to ensure water/humidity doesn't reach the door pad which houses electronics.

Vapour barrier was put back, and adhesive was rolled:

Door pad:

I took this opportunity to install MGA's interior styling kit on the PW console.

The doorpad was wiped down with IPA:

Alubutyl sheet S1 was selectively pasted over all the flat areas which were susceptible to flexing:

Dr. Artex Lace(S3) was then pasted over the Alubutyl and this provides excellent sound insulation. We tried to cover edge to edge to eliminate all noises. This also eliminates any kind of rattles which may come up in later years, quite common in Marutis:

I also ensured no old Clip is reused, and I also switched to foam laden clips used in Kizashi which eliminates clip related noise. Part number: 09409-10318. New Clips fit tight and give factory finish. Difference between Clips of normal Marutis and premium imports like Kizashi:

Continue reading on the sound insulation process of Leoshashi's Maruti XL6 for BHPian comments, insights and more information.