News

Installing an OEM 288mm Big Brake Kit in my Volkswagen Polo

Leaving the air in the system aside, I wasn’t too happy with the stock brakes on my Polo and this is something more common for folks with the Automatic gearbox

BHPian fluidicjoy recently shared this with other enthusiasts.

Opening Thoughts

So whenever you get a new car, the brake system is usually not at its best when its brand new. The discs and pads need a while to bed in and gel into each other for a reliable braking performance. The pedal is also not at its best during this initial warmup period. However, on my car, I found the brake pedal to be quite spongy and soft even after crossing the 1500 km mark. This could have well been due to improper brake bleeding from the factory, something which should not have happened but seemed to be the case. This sentiment only accentuated when I drove a few other Polo TSIs and found the pedal a lot firmer and consistent. In fact, even the dealership folks were asking me if I found the brakes spongy. Truth is, they were working fine, but the pedal had a fair amount of softness, but it wasn’t sinking to the floor and there was no immediate reason to worry, so I thought I’d give it a while before considering a brake bleeding job on my car.

Leaving the air in the system aside, I wasn’t too happy with the stock brakes on my Polo and this is something more common for folks with the Automatic gearbox. This is because of how eager the 1.0 TSI + Torque Converter drivetrain is in general. It’s no secret that braking and reduction in engine speed has a lot to do with how the gearing downshifts and this 09G gearbox just keeps delivering power. It likes to rev hard in general, and even while coasting there’s not a lot of engine braking to help in reducing speed. Moreover, I’ve found the stock brakes to exhibit plenty of brake fade after a spirited driving session during the day. So for all of these reasons, I was looking at better brakes for this car.

Making a Choice

Here are a few options and combinations I had seen friends and fellow BHPians resort to in the past:

- Better Brake Pads - I would have had to consider performance brake pads like EBC Yellow Stuff or opt for higher quality stock replacement pads like EBC Ultimax, Brembo, ATE Brake Pads (Made in Czech), but I felt the gains would not be organic with this approach.

- Upgrading Discs - Using drilled, slotted rotors from Brembo etc.

- Aftermarket Performance Callipers with Dual Pistons etc.

- Full OEM Big Brake Kit

It is no secret that the TVS Girling Brake system is fairly commuter at best. The stock brake system by TVS Girling is referred to internally as the C54 caliper system, and although it is quite conventional, it isn’t as well engineered as high-end brake systems made by ATE brakes, which is one of the most reputed brake OEMs in the world. It has innate problems which only multiply in our driving conditions. Further, Volkswagen doesn’t grease the slider pin until it’s time for a carrier replacement, which is accompanied with a fresh satchel of silicone grease. To be honest, the Indian brake system can fare a lot better with some love and care, and regular greasing and cleaning of hardware like Caliper Slider pins, Brake shims etc. The Indian OE TVS Girling pads have lasted some drivers and inspirational BHPians like Gannu quite a lot, but they don’t offer users a supreme performance and reliability for most other dusty, Indian driving conditions. There are quite a lot of hardware related brake complaints, which simply cannot be improved by upgrading to better pads or discs. Moreover, quite a few performance pads have a reputation for eating into rotors (which users might argue as fairly cheap by Volkswagen standards). A quick side view shot I clicked against a nicely vandalised wall near a neighbouring badminton court. Notice the silver shine of the stock braking system.

I wanted a cohesive solution and opted to go for an OEM Big Brake Kit. This brake kit uses a common VW Group calliper made by ATE braking (1K0 615 123 and 1K0 615 124) and uses dry slider pins. This same calliper is found on the Jetta, Laura and few other cars from the VAG stable. The part number suffix at the end determines the paint code. If you look at the two calliper assemblies side by side, you’ll instantly notice how much more sophisticated this newer brake calliper is. The piston and seals too are quite a few notches above in quality compared to the TVS Girling Brake system. The insides of the TVS Girling Brake calliper piston in my 4k KM driven car were fairly rusted already.

The same piston in the ATE brake system seems to be properly coated with a textured material, which should be fairly resilient to rusting.

I found a set which had calipers and carriers that I needed and ordered it along with my friend Sarfraz. The kit I received had quite a lot of paint damage in transit, but the reason I got put-off was because I was sent an incorrect caliper. So the carriers on this brake system are same for both the sides, which is the case in many calliper carrier brake systems, but the left and right callipers are not alike. They are directional for a purpose. If you do end up installing them on the wrong side, expect a huge braking issue concerning the pedal feel due to air in the system. So long story short, the bleeder screw on the calliper should be pointed upwards. That is the correct orientation for installing this brake system. If you accidentally install a wrong calliper on the right side, then you’ll never be able to reliably purge all of the air out of the brake lines during bleeding. Many folks internationally have made similar mistakes on their brake systems and have changed entire brake systems to fix their pedal softness, ineffective braking problems and the fault was finally diagnosed to be a calliper with an incorrect fitment.

So after this instance, I began parts hunting to assemble the right 288mm Big Brake kit. The Brake Kit I have is essentially a Red Caliper Carrier which pairs to a larger disc. You can opt for either a 288mm or a 310mm Disc which featured on the GTI, but both have their share of pros and cons with respect to this PQ25 6R platform. To begin with, it should be noted that a Big Brake Kit adds mass at the front end since each brake disc, calliper and carrier are heavier than the stock brake component. The 310mm disc is also heavier than the 288mm counterpart. For cars with ESP, the coding also takes into account the brake sizes on the front and rear axle, and we’ll speak about it in a bit. If you buy a full kit all together, it turns out to be much cheaper, since you don't have to bother buying bits and bobs, but here is a list of all parts needed if you’re handpicking everything.

Parts

OE Numbers of Parts

- Brake Discs :- 6R0 615 301 A/D - 288x25, 5/100 - Zinc Coated

- Brake Pads :- 5K0 698 151 A

- Brake Calipers :- 1K0 615 123 and 1K0 615 124 (Made by ATE)

- Polo Vento Brake Calliper Carrier for 288mm :- 6R0 615 125

- Brake Calliper Slider Pins :- 251 615 219

- Brake Calliper Retainer Spring : 1K0 615 269

- Guide Sleeve Kit :- 8V0 698 647

- Self-Locking Calliper Carrier Bolts :- N 90708504

Other Optional/Miscellaneous Parts

- Dust Shields :- 6R0 615 311 A/D, 6R0 615312 A/D

- Caliper Piston Repair Kit :- 1K0 698 471 B

- Brake Dust Shield Bolts :- WHT005227

- Brake Bleeder Dust Cap :- 211611483

- Rotor Retaining Screw :- N 10648301

Some more scoop about parts

I purchased 288mm Zinc Coated brake discs by ATE, but frankly the OE Zinc coated Discs are a really good choice too. 6R0 615 301A is fairly well-priced and can be found under 6k a pair while the newer revised part 6R0 615 301D is about 9400 rupees a pair, since it is a newer offering and a supersession from 301A, but both are made in Germany. The ATE Discs I purchased come with two Rotor Retaining Torx bits, which have a really premium shiny finish to them. Brake Pads for the MK6 Jetta are a straight fit for this calliper carrier but they come with a Brake Wear Sensor which the Polo presently is not equipped with, but obviously something premium which is in the works soon. I don’t think I classify as a heavy braking guy, but I wanted to try ATE Ceramic Pads which ATE recommends to be used with its stock replacement rotors. This is what the box of the ATE Ceramic pads looks like and my dogs wanted to pose in the background.

The most attractive USP of going with ATE Ceramic Pads is lesser brake dust and I must say, it’s real. I only hope these pads last as long as the usual ATE pads last on this calliper system, since these don’t come cheap, especially if you import them from abroad.

Installation Stories

So I was initially going to install this brake kit at The Mechanix Automotive where I would be working on the car raised on a lift. I thought I’d also have the expertise and experience of Sushant from the Mechanix Automotive and this seemed like a sorted plan. A family friend of mine working at the VW dealership was very keen that I install the brake kit under their supervision at the dealership and so I had quite a few options to choose from. I was really keen on doing this installation myself, but the only weak link according to me was the brake bleeding. I could do this on my own at the Mechanix or at home, but I only had two jack stands and so it would have been really inconvenient to bleed all four wheels at home. So, I packed all of the parts in the boot and was off to the Mechanix Automotive, but midway, I realised I had forgotten Brake Pads and Dust Shields at home. So I took a U-turn and took this as a sign that I was meant to complete this installation at home. BHPian Sarfraz was chiefly instrumental in inspiring me to do this at home, and thanks to his motivation I managed to complete this task, and it turned out great.

Tools Used

- 11mm Wrench for Brake Bleeder, Brake Line,

- 12mm Wrench for Older Brake Calliper Slider Pins.

- 18mm Wrench for Calliper Carrier Bolts

- T30 Torx Bit for Brake Shield, Brake Rotor Retaining Screw

- T45 Torx Bit for Brake Calliper Slider pin - An Alley key might also be usable, but I've found that the OEM slider pin likes the T45.

- Stanley 1/2 Inch Drive Tool Kit

- Stanley 1/4 Inch Drive Tool Kit

- Pair of Jack Stands

- Wire Brushes for brushing off rusty surfaces

Chemicals Used

- PetrelPlus Anti-Seize for Bearing

- WURTH High Temperature Brake Paste

- WURTH Silicone Grease for priming new slider pins

- Brake Cleaning Sprays

Getting Started

So I began by freeing the wheel bolts using the included tool and then securely placed the vehicle on a pair of jack stands. My hydraulic jack was out of order and so I had to raise the car using the included screw wheel jack. Surprisingly, this was an effortless affair and I'm glad the Widow Maker is being eliminated for good.

Another huge advantage of raising and supporting both front wheels at the same time is the ability to turns the steering wheel and subsequently the rotor to allow maximum leverage for taking out the critical calliper carriers bolts. In this picture, I have turned the steering to the left to easily access the passenger side caliper.

So this is the stock brake system and notice the accumulated surface rust on the rotor. A big reason for the presence of this rust here is the non-application of anti-seize. I have seen quite a few high-end VWs like the Passat and Tiguan, Skoda Superb, Audis to have a generous coat of anti-seize from the factory itself, and true to that, those rotors do not have surface rust at these points. Volkswagen seems to have skimped on this part since the Polo is an entry level offering. Nevertheless, this is only a very minor thing, and here's a before and after only a minute of light brushing with a metal wire brush.

Next, using a 12mm wrench or a socket, we undo the two calliper slider pin bolts after which, we can wiggle the stock calliper out. If the calliper isn't free, then use a screw driver for slightly compressing the piston inwards to easily free-up the calliper. Here's a quick at the stock pads which have a clear INSIDE and OUTSIDE marking. Two holes on the pad backing plate are also a distinguishing factor for INSIDE and OUTSIDE pads.

Once the caliper is free, hang it from a bungee cord but since I don't have one, I'll use a tall box to place the caliper on it. The whole idea is to prevent hanging the caliper and avoid straining the rubber brake hose.

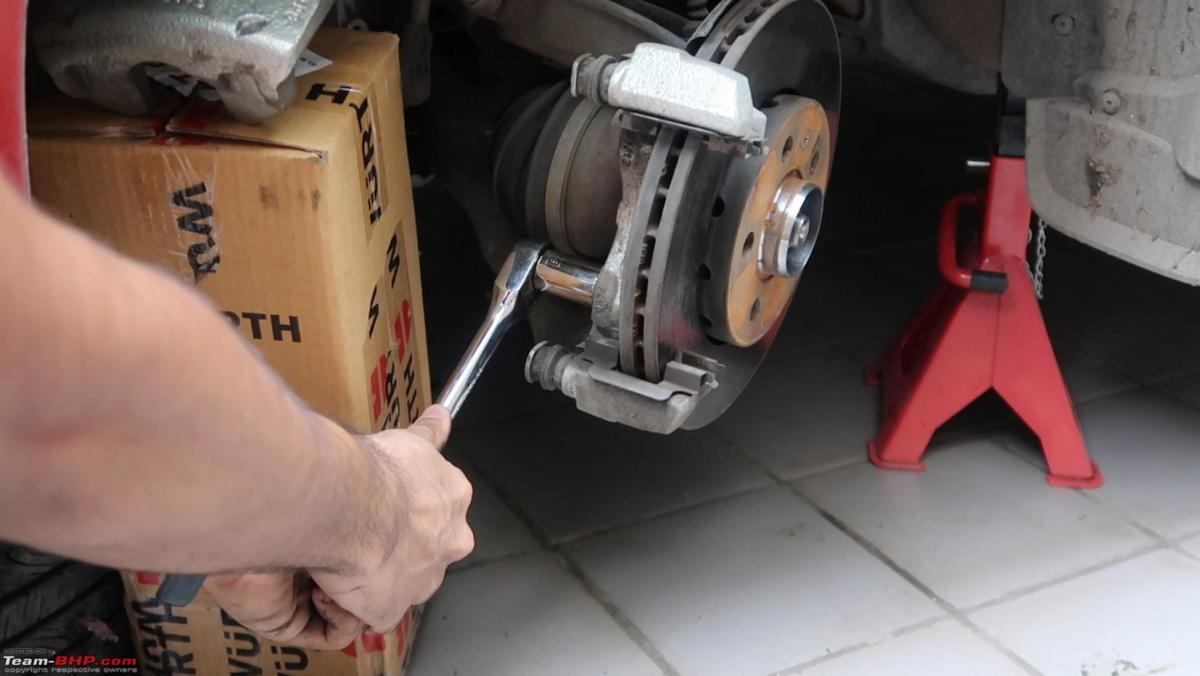

My strategy for this installation was to touch the brake line at the very end to try and lose as less brake fluid as possible to avoid running the master cylinder bone dry. So with this idea in mind, I proceeded to install everything else without still undoing the stock brake line from the stock caliper. With the old pads taken out of the way, it's now time to take out the stock caliper carrier which is held by two 18mm self locking bolts. I was expecting these to be really tight and since I don't have immense muscle power, I was mentally ready I'd need to use a long pipe slipped on a 1/2 inch extension. However, with the 1/2 inch Stanley Ratchet, I could free these bolts fairly easily. The factory torque spec for these bolts is 124 Nm.

Once the carrier is out of the way, we can now proceed to remove the stock 256mm brake disc rotor which is held by a T30 Rotor retaining screw. Using a wheel lug nut is a good tactic to prevent the rotor from falling on your foot or arms. A lug nut is also helpful in the event the brake rotor is tightly rusted onto the hub. We can whack it with a rubber mallet or spray penetrating fluid till it is free and thanks to the safety of the lug nut, the rotor won't fall off.

After the stock rotor is out of the way, we see the wheel hub, which is again rusted due to our natural elements. Using a combination of WD-40 and brake cleaners followed by some light to moderate brushing, we can successfully brush off this surface rust to reveal a nice and shiny wheel hub.

The 288mm and 310mm brake disc slightly interferes with the new brake dust shields 6R0 615 311 C, which is designed for the 256mm brake disc. So you can either slightly bend the dust shield or replace it to 6R0 615 311 A and 6R0 615 312 A which was initially sold on earlier Polos and Ventos. I believe replacing it to an appropriate sized dust shield is the way to go, since the objective of dust shields is to prevent stray dirt from contaminating the braking surfaces. 6R0 615 311/312 D would have been perfect, but these were never sold or natively available in India and would have been an unnecessary expensive, so the shield 311/312 A works just fine. This brake shield is made in Spain. Here's a side by side view of both the shields but this picture is not a perfect representation of the geometric differences between the two.

The dust shield is held on by three T30 screws, two of which are unobstructed while one is slightly recessed behind the wheel hub.

Taking the dust shield off gave me a chance to have a look at the notorious ABS Sensor which has troubled a lot of Polo Vento owners in India.

Here's the new dust shield along with the freshly polished wheel hub, waiting to receive the 288mm brake disc.

Next, I applied a thin coat of Anti-Seize to the wheel hub to reduce the rate of surface rust formation.

Now we're in a position to install the new brake rotor which should be lightly degreased before installation. This is more true in the case of non-zinc coated discs which have an oily protective film to keep them corrosion free in packaging. Zinc coated discs are usually advertised are ready for fitment. However, sometimes manufacturers apply stickers or some packing guides between rotors and they end up sticking or leaving light traces on the braking or non-braking surfaces. Notice the light blue tinge on the rotor face which mounts the alloy wheel. It is a remnant of the blue brake guide which came with the ATE Rotors. Using some more brake cleaner and wiping it off with a light rag or cloth would eliminate it.

Here's a closeup of the ATE Zinc coated ventilated brake disc. Notice the insides of the disc.

Ideally, this good zinc coat should prevent the rotor but accumulating rust in these crevices but after a rainy month with these discs, I've already found quite some surface rust in these fins, which isn't something I was expecting. The disc is held in place with the T30 rotor retaining screw and ATE supplies new brake rotor screws along with new rotors. There is no absolute need to replace this screw unless you ended up stripping it during its removal. The torque spec for the T30 rotor retaining screw is 4.5 Nm. Notice the light coat of anti-seize we applying during cleaning and greasing of the hub.

Before we proceed any further, let's have a quick visual comparison between the old and the new rotor.

Now that our shiny new rotor is in place, we can reinstall the caliper carrier. I hand threaded the new self-locking calliper carrier bolts to prevent any cross-threading.

The caliper carrier bolts are recommended to be replaced when the carrier is removed.

I have seen quite a lot of garages reuse these bolts, but I also happen to have heard a few horror stories which stem from reusing of these calliper carrier bolts and so I decided to replace them during this installation. These are to be torqued down to 124 Nm.

Continue reading fluidicjoy's experience for more insights, information and BHPian comments.

- Tags:

- Indian

- Member Content

- DIY

- Polo

- Volkswagen

- brakes