News

Replacing a few parts on my used Jeep Cherokee to get it back in shape

Everything looks easy on paper. I was confident that I could replace the stabiliser bushes in a day but I was wrong.

BHPian Jeroen recently shared this with other enthusiasts.

With a new car, different brand from my current cars, there is also the need to build up my network of people that can help out with parts, jobs and general advice and support.

The Jeep Cherokee is to date a very popular 4x4 car in the USA. There are several excellent forums. I became a member of one of them in 2009 when we bought our Cherokee in Kansas City. After we sold it and left the USA, I never re-visited it, but my account was still active after all those years! Nice to be back on that forum too.

I find that by and large, if you need specific information on a particular car, the American forums are by far the best. Always lots of sensible advice, lots of folks that are happy to help you out. Americans have a unique way of dealing with cars. Lots of Americans, irrespective of status, job, background etc, work on their own cars. Some out of necessity to cut cost, but many just for fun, as a hobby.

Americans are a very upbeat lot. There are never problems and challenges, only fantastic opportunities. Always very refreshing to deal with them. Say, you put out on the forum you need to change the front lights. (As I did too). Somebody will immediately reply: Awesome! When you take the grill off to get access to the frame that holds the light reflectors, you might as well rip out the engine too. Replace front and rear seals. Taking an engine out on a Sunday morning before the traditional family breakfast is a small change for the average American car enthusiast.

There are literally hundreds of YouTube forums on Jeep Cherokee out there too. Type Jeep Cherokee XJ steering box replacement and you will be presented with several dozens of videos. I have watched many of these. Some of them are very good and I will be referring to these, whilst describing the various jobs I undertook, will be undertaking.

I also found a Dutch Jeep Cherokee forum. Very handy too. They helped me find some parts suppliers. Would you believe it, Jeepparts.nl is a 10-minute drive from us. Literally the next village.

I called them and spoke to the owner, Edwin. Very nice chap, very knowledgeable. I have since visited him many times. Essentially he runs a huge Jeep online parts store. But as I live so close to him, I can just phone him and pop over to pick up my parts.

I found parts availability in the Netherlands pretty good and pretty decent prices. Also, you can still get a lot of parts in the USA. Parts prices in the USA are really, really cheap. Of course, they need to be shipped, imported (4% import duty) and VAT (21%). The other thing, apart from the prices, the number of different parts is staggering in the USA compared to anywhere else. We will come to that during some of the jobs I undertook.

Edwin also hooked me up with another local business. Brinkman garage.

Same village as Jeepparts. They are basically an independent general garage. But they specialise in, among others, Jeeps! Again, all 10 minutes from where we lived. I rocked up, in my Jeep obviously, to have a chat with them. Met up with the owner Martin. Very pleasant, very professional and very knowledgeable about my Jeep. Martin will be doing some of the odd jobs I don’t want to do myself or can’t do. Also, he will help out by doing a sort of Pre-MOT inspection, to see what I might have missed.

Lastly, when working on cars, you need all the documentation you can get. The previous owner had given me his Haynes manual:

The Haynes manuals are always tremendously handy to have. I still have quite the collection of them. I had this one in Kansas City too. I also gave it to the guy who bought the Jeep from me when we left KC. But Haynes simply does not have enough details when you really need to dig in. So I always try to get the original Manufacturer Workshop manual. I have them on all my current cars.

You can find a lot of stuff online. I have found these guys very useful.

Yes, you tend to pay $15-25 for what is essentially a PDF file. But it is an excellent quality file. You can print individual pages, and they tend to be indexed as well, which makes looking up stuff a whole lot easier. They give pretty good service too. I had some problems with the file they sent to me. It all got sorted quickly and efficiently.

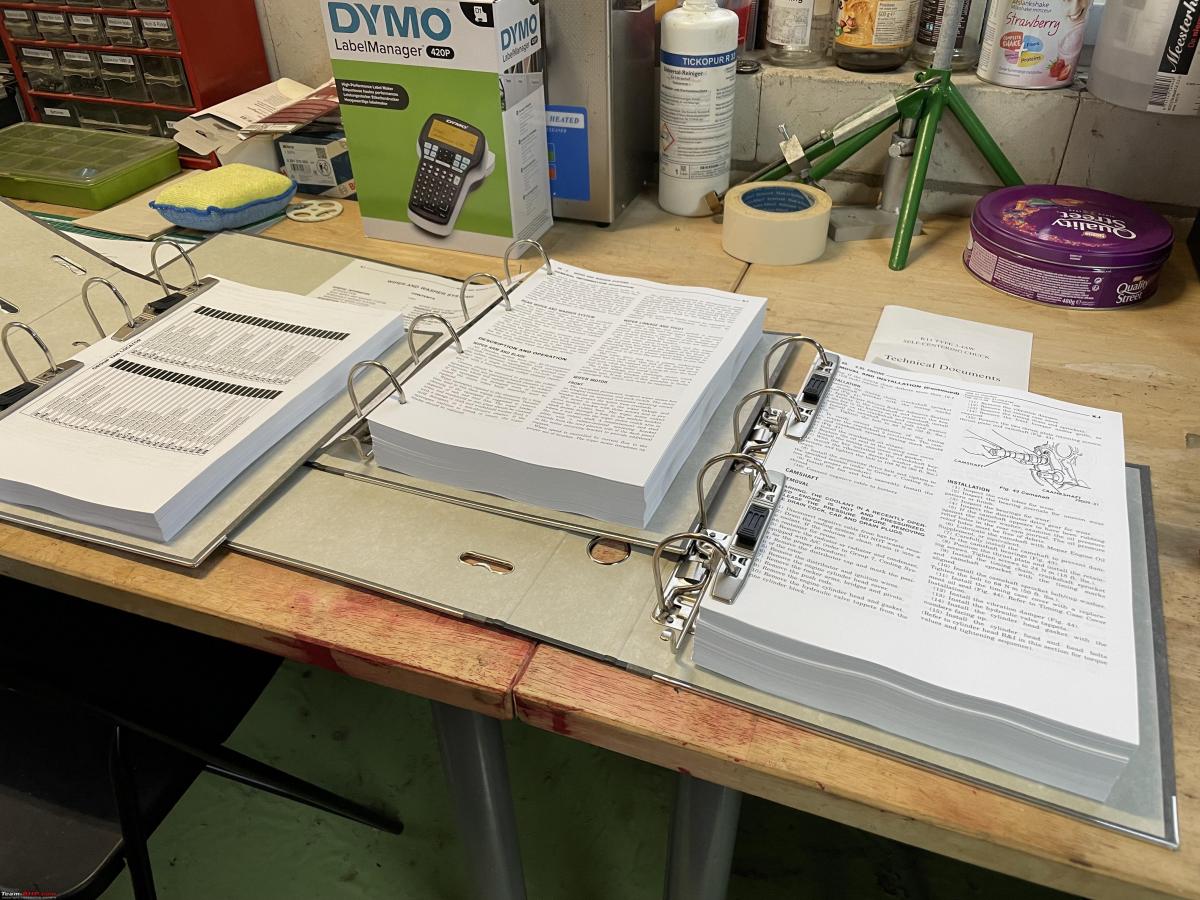

I mailed the PDF file to my local printing shop. I don’t like to sit behind computers for very long these days. I prefer printed material any day.

The Cherokee workshop manual is a whopping 2300 double-sided pages. The print shop printed them and put them in three binders.

I am very pleased with the workshop manual. It is excellent. Probably the best manual I have ever seen. Very detailed, very well laid out, excellent drawings. Very happy with it.

When it comes to jobs on a new car, I always start with everything that affects the safety. So that tends to be tyres (the current ones are fine), brakes, suspension, steering and checking the fuel lines.

It became very obvious, very quickly that the brakes needed major work. Fuel lines are fine. Suspension and steering are all fine, but all the bushes in both stabiliser bars, front and rear, were gone. So I ordered all the brake and rubber components for the stabilisers from Edwin first. Some of the parts were on backorder, so I had to wait a few days. But I did pick up a door hinge repair kit.

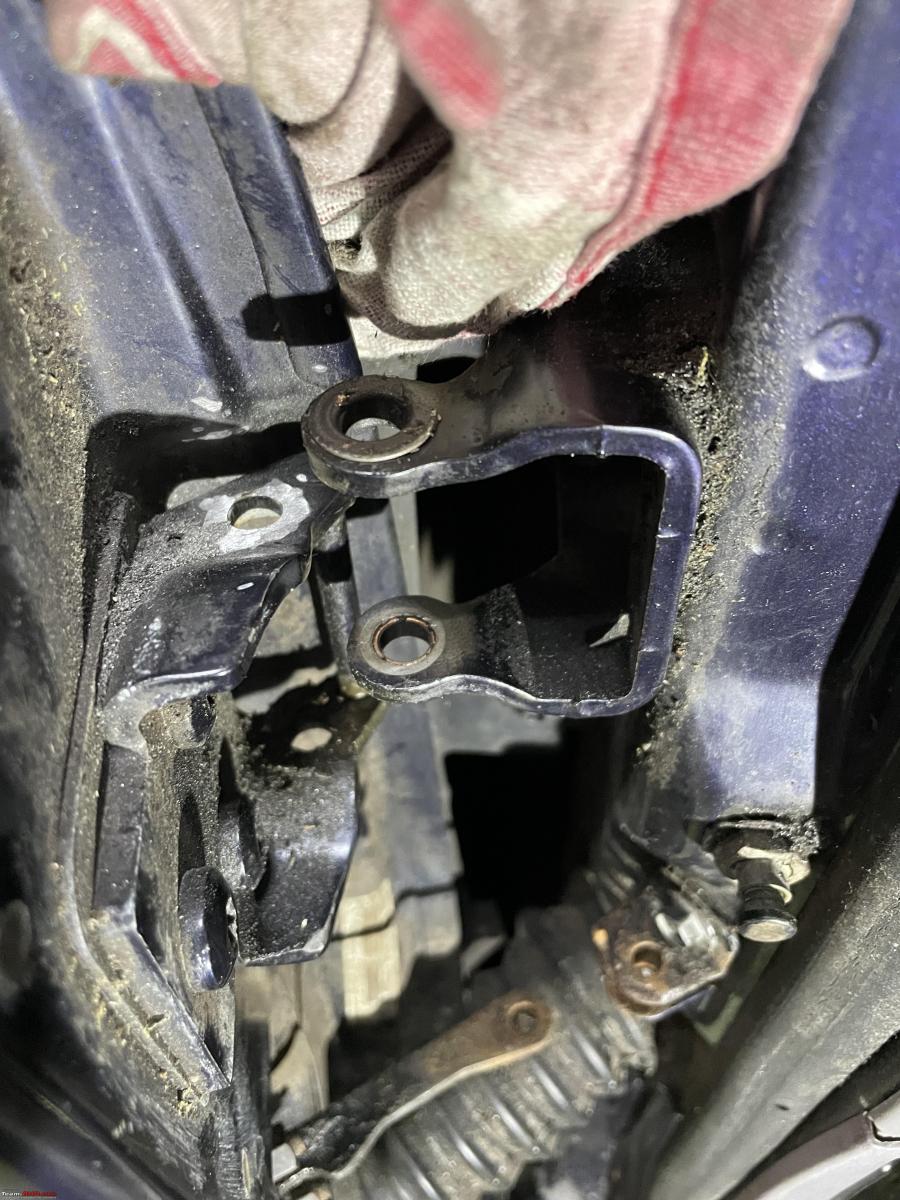

The hinges of the door of a Cherokee are welded to the chassis. The actual hinge mechanism is a very simple pin that holds the two parts of the hinge (chassis/door) together. The pin sits inside two bushes in the hinge. These bushes wear and thus the door starts to sag. They all do. I had the same problem with my Jeep in the USA as well.

So time to rig up a little door hinge pin and bushing replacement set up.

Here you can see the bushes on the hinge part still attached to the chassis.

Getting the two pins out is a bear of a job. You have very limited access to get in there with a punch. I ended up grinding off the tops of the old pins with my little dremel.

Here the bushes are removed as well.

Replacing the two pins and four bushes on the driver’s door took me the whole afternoon. But as a result, the door is completely straight now. No sagging, which means it also closes easier.

Next job - Stabiliser bar

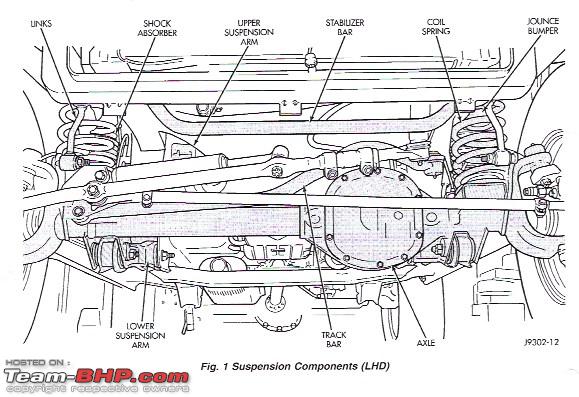

The set-up of the stabiliser bars on the Jeep is very simple, very traditional. Stabiliser bars minimise body roll. Well, that is at least the idea, and of course, they do, but even with perfect stabilisers, some cars will still do quite a bit of body roll into corners. The Jeep being one of them. Still, without them, or with worn parts, it will be a lot worse. Apart from it being uncomfortable it also does affect the handling, so it is a safety aspect too. In addition, stabiliser bars, small as they are, tend to add to the overall structural integrity of the suspension set-up.

In most cars, replacing the bushes on the stabiliser bar tends to be pretty straightforward. There are at least two caveats; rust and tension. As these parts don’t get replaced very often, everything tends to be rusted solid. Mounting the bar might require putting a bit of tension on it, which can be a real PITA for DIY mechanics such as myself. Especially if you, as I was on this job, all by yourself.

Lastly, as we will see, if they have been replaced before, you might have to put up with mistakes made by the previous mechanic.

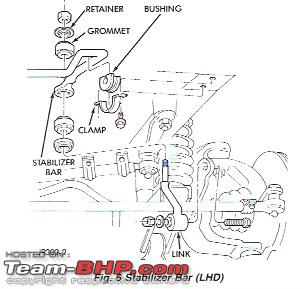

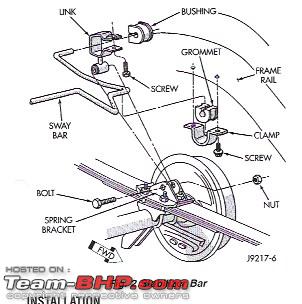

The set-up on the Jeep is very simple:

As you will have noticed, my garage, roomy as it is, will only keep three cars at a time. I could cram four cars in, but the floor will collapse, it is not strong enough.

I made a special deal with the insurance company, this being a YoungTimer, it is supposed to stay in a garage, but mine can live outside 24/7. So when I work on the Jeep I need to shuffle my cars around. If on a project of more than a day, the Jaguar gets moved to a mate of mine, further up the dike. He has ample storage space, so I leave my Jaguar with him, whilst I can take apart the Jeep.

I was confident I could replace the stabiliser bushes in a day, so I just drove the Jaguar in and put it on some axle stands. Of course, I was wrong!

On paper, it is all very easy!

It is literally undoing some bolts and nuts and that’s it. I always spray penetrating oil on all bolts and nuts the night before. Really soak them. Works really well.

On the front, everything came off real easy. As you will see, definitely worn out:

As the bar and the brackets were all very rusty, I decided to clean them with my pneumatic driven wire brush and give them three coats of Hammerite paint.

It took me about 25 minutes to get the stabiliser removed. It took me about 3 hours to put it back in place. Just because it slightly tensioned when mounted in place. Lots of swearing.

Next day I tackle the rear ones, so reversed in to have easy access:

Again, removal looks very easy on paper:

But immediately it became apparent that there was a problem: I could not remove the bolt holding the bracket in place.

If you refer to the drawing you will notice that the bolt should have been inserted from the other side. I suspect that they had the complete rear axle off and mounted these brackets first, before installing the leaf springs. Taking the springs off, was too big of a job, so I decided to just cut the bolt and get a new one.

You might also have noticed that the end of the stabiliser bar is badly corroded and worn thin.

New bushes would not be enough. And of course, the old bushes were really worn:

So I called Edwin of Jeepparts.nl. He did not have a new bar, but he had a decent second hand one. So I decided to pick that up. Cleaned everything and resprayed it. Installing it went pretty smoothly.

If anything, it all looks a lot smarter! Newly freshly painted second-hand bar, new bushes, new bold, new link as well! We are good to go. But in order to stop you need good, safe brakes. Boy, did mine need some serious seeing too!

Check out BHPian comments for more insights and information.