| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  23,689 views |

| | #1 |

| Senior - BHPian Join Date: Feb 2004 Location: GTA

Posts: 14,765

Thanked: 2,705 Times

| A Guide On Technical Jargons Hi Guys, This is a compilation of tech jargons, which I have compiled from various sources on the Internet (most of it is from xBhp's members). Just thought I would share it here too. This compilation is generic in nature. There is a parked (sticky) thread with details on tech jargons related to bikes. A Guide On Technical Jargons - Motorbikes --------------------------------------------------------------------------------------------------- A Guide On Technical Jargons Carburetor : An apparatus that mixes fuel with air in the right proportions before feeding the mixture into the combustion chamber. Combustion Chamber : (Also called cylinder) A cylindrical chamber where air-fuel mixture fed by the carburetor is ignited using a spark plug to generate pressure high enough to push out a piston. Spark Plug : A device that uses electricity generated by an alternator to produce a spark that ignites the air-fuel mixture inside the cylinder. Power Stroke : The piston is at top dead center (we call this TDC), intake and exhaust valves are both closed and the spark plug has just fired (the CDI controls length/time of spark). The expansion of the ignited fuel/air mixture (which comes in from the carb.) forces the piston down. Before the piston reaches bottom dead center (BDC), the exhaust valve starts to open. Exhaust Stroke : The piston is at bottom dead center (BDC) and starts to come back up. The exhaust valve opens fully and starts to closed. Before the piston reaches TDC, the intake valve starts to open and the exhaust valve is still partially open. Intake Stroke : The piston is now at TDC. Both, the intake and exhaust valves are partially open. As the piston travels back down the cylinder, the exhaust valve is fully shut and the intake valve is fully open and starts to shut. Compression Stroke : The piston is at BDC and starts to travel up the cylinder. The exhaust valve is still shut and the intake valve is fully shut. Scavenging :After the fuel/air mixture is ignited, the expansion of the burning gases will be complete prior to the piston reaching BDC, but there will still be pressure contained in the cylinder. When the exhaust valve starts to open prior to the piston reaching BDC, some of the pressure in the cylinder will flow past the exhaust valve into the head’s exhaust port. As the piston starts its travel back up the cylinder, the piston forces the remaining gasses in the cylinder out through the exhaust port. The velocity of the exhaust gases flowing past the valve into the port creates a negative pressure (vacuum) in the combustion chamber. Prior to the piston reaching TDC (BTDC - before top dead center), the intake valve starts to open. The previously created vacuum in the combustion chamber will draw a fresh air/fuel mixture into the combustion chamber and some will even escape into the exhaust. This will ensure that all of the spent gases are removed from the combustion chamber (this is where everything takes place). This process is called "scavenging". Back Pressure : A better defintion for back pressure is the pressure within a system caused by fluid friction or an induced resistance to flow through the system. In any IC (Internal Combustion Engine), the burnt gases need to be either blown out (2-stroke) or pushed out (4-stroke). Now the gases don't happily travel through the maze of pipes we call the exhaust pipe. There is the basic fluid friction against the walls. The silencers or more technically, mufflers are sections, which are essentially restrictions intentionally built into the exhaust system to smoothen out the strong pulse of the exhaust (caused by the valve or port cracking open). So, you have opposition to the gas flow. Now, what do you think happens as the engine tries to stuff more and more burnt gases down the throat of this pipe? Obviously, the volume is not increasing. So, the pressure has to go up. Voila! Back pressure. The greater the back pressure, the more work the engine has to do to push the burnt gases out. Less usable power output at the crank. So what does a free-flow do? Reduce back pressure. How? Remove restrictions. Now the gases flow freely, but they don't flow continuously. There are strong pulses of high pressure gases followed by brief lulls. What is that in human equivalent? A very loud noise (although some people will beg to differ and call it music :-) ). About it being a mechanism for preventing air/fuel mixture from escaping through the exhaust valve, this is true, but misses the point. Alternator : A rotating device connected to the engine which when rotated by the engine, generates electricity to power the spark plugs and headlights and also to recharge batteries. Over Head Camshaft : OHC (Over head cam) layout was the solution to the problem of inertia of the venerable push-rod design. At high RPM, push rod engine valves don't shut (called valve float). So, to reduce the mass of the moving parts, they brought the cam closer to the valves, made the valves lighter (latest ones are ceramic and ultra-light). Valves are on the head, cam close to valves means OHC. Then they found the rockers, which are mandatory for Single OHC or SOHC, also too much mass. Hence, the advent of the Double OHC or DOHC. Performance improves simply because the engine can rev more freely and the efficiency improves as valve sealing improves. Types of Valves : There are only two type of valves in an internal combustion engine: a) Inlet Valve : The inlet valve as the name implies are the valves through which the fuel/air mixture is inducted into the cylinder. b) Exhaust Valve : The exhaust valves are the scavenging valves and open up after the power stroke to release the spent gases. What is the difference between an exhaust valve and an intake one? Answer : The perfection in the fulfillment of the cylinders in engines is never carried out absolutely. In spite of this inconvenience and in order to obtain a high thermical performance, we detail some solutions found by engine builders: With the adoption of accurate valves With a suitable “lift” of them With an advantageous valve arrangement With an optimum timing setting If we observe a cylinder head, we will note that the intake valves' diameter is bigger than the exhaust valves' (except for a multivalve engines) in general. The mixture entrance in the combustion chamber is limited by the action of atmospheric pressure (it changes according to height at sea level). On the other hand, the exit of the burnt gases is produced in very different conditions than the ones described before. The residual pressure of burnt gases (after their expansion) is bigger than the atmospheric pressure. The action produced by the piston rise favours the increase of speed of gas ejection. A) Head diameter of the intake valve is 20% or 25% bigger than the exhaust's, in order to make it easier to fill up cylinders. B) If the diameter of the exhaust valve is smaller, there will be less volume exposed to hot gases. So, the quantity of accumulated heat is reduced. C) Mixture temperatures before and after the ignition are very different. The exhaust valve is exposed to receive more heat (temperature = 1300º F). So, the structure, materials and heat treatments are not the same as the ones of the intake valve (temperature = 400º F). D) The seat contact of valve - insert is generally wider than in an intake valve. E) The exhaust stem guide clearance, because of reasons of different temperature, is also bigger than the intake one. Courtesy: BassoAssist - Basso SA - Valvulas Para Motor Engine Valves Soupapes Pour Moteur CC of an engine : CC is the swept volume. The formula for calculating the swept volume is the square of the radius of bore multiplied by the stroke multiplied by pie (i.e. 22/7) and if your bore/stroke measurements are in mm, then divide by 1000 to get swept volume in CC. eg. Zma bore = 65.5 mm stroke = 66.2 mm radius of bore = 65.5/2 = 32.75 mm so, swept volume = (32.75 * 32.75 * 66.2 * 22) divided by 7 * 1000 which = 223.154 cc Stroke Length : It is the distance the piston travels from Top Dead Center (TDC) to BDC (Bottom Dead Center). These 'centers' are those positions in which any force on the piston does not produce rotational motion. Hence, they are respectively the top-most and bottom-most positions. Rotary Engines : Rotary engines don't have regular pistons which go up and down along the cylinder. Instead, a triangular rotor rotates in one direction (so no reversing of direction) and forms 3 chambers in which the combustion, intake and exhaust process occur simultaneously. Generally, there is a single rotor (so 3 chambers), but I have heard of a twin-rotor rotary engine . Rotary engines rev very high, are smooth and relatively vibration-free. But earlier, they were more polluting, thirsty for fuel and complicated with difficulties in sealing the gas inside effectively. However, the Mazda RX-8 engine is very good having won the best engine award against rivals from other well known manufacturers. Normally aspirated engines are those which don't have any type of force-feeding as in turbocharged or supercharged engines. I guess the force-fed ones are not called 'abnormally aspirated engines'! Turbocharger and Supercharger: Both turbochargers and superchargers are called forced induction systems. They compress the air flowing into the engine (see How Car Engines Work for a description of airflow in a normal engine). The advantage of compressing the air is that it lets the engine stuff more air into a cylinder. More air means that more fuel can be stuffed in too. So, you get more power from each explosion in each cylinder. A turbocharged / supercharged engine produces more power overall than the same engine without the charging. The typical boost provided by either a turbocharger or a supercharger is 6 to 8 pounds per square inch (PSI). Since normal atmospheric pressure is 14.7 PSI at sea level, you can see that you are getting about 50 percent more air into the engine. Therefore, you would expect to get 50 percent more power. It's not perfectly efficient though, so you might get a 30 percent to 40 percent improvement instead. The key difference between a turbocharger and a supercharger is its power supply. Something has to supply the power to run the air compressor. In a supercharger, there is a belt that connects it directly to the engine. It gets its power the same way that the water pump or alternator does. A turbocharger, on the other hand, gets its power from the exhaust stream. The exhaust runs through a turbine, which in turn spins the compressor (see How Gas Turbine Engines Work for details). There are trade-offs in both systems. In theory, a turbocharger is more efficient because it is using the "wasted" energy in the exhaust stream for its power source. On the other hand, a turbocharger causes some amount of back pressure in the exhaust system and tends to provide less boost until the engine is running at higher RPMs. Superchargers are easier to install but tend to be more expensive. And as far as Indian bikes are concerned, they are all normally aspirated. Compression Ratio: Compression ratio if defined quite simply as the volume above the piston at bottom-dead-center (BDC), divided by the volume above the piston at top-dead-center (TDC). Just learnt that effective CR changes according to engine rpm, cam duration, etc. This explains why late closing of intake valve increases top end: Compression Ratio - Page 1 All you guys who want to know how much increase there will be in HP after increase in CR, check this site: Compression Ratio HP Determination Power Vs. Torque: There used to be 2 camps. The power freaks and the torque freaks. Now most people have begun to realise that one does not live in isolation of the other. So here goes. Torque first. Torque is the twisting force of the engine. How much force the engine can apply at rotating the rear wheel will define how fast your vehicle will pick up speed. Torque can be required in different ranges based on what the riding application is. Dirt Track : Most riding is done in the low-mid RPM range (unless you are really a pro and can keep the engine boiling). So, max torque should be available in that range SBK : Here you will notice that the stretches are nearly level and the engine can be kept boiling much more easily. Hence, here people look for torque higher up the rev range (there is another reason to look for it, explained below). Now about power. Power = work done in unit time. So, it is not enough if the engine develops lots of torque at the rear wheel. It should also spin up the wheel to good RPMs for you to travel fast. The faster you have to travel, the more power (BHP) you need. In rotary motion terms, Power = Torque * RPM. Here we go back to SBK (Super BiKing). Those bikes need to develop serious power. The maximum can be squeezed out of an engine (with no regard to reliability) if you can rev it to dizzying RPMs and also develop torque at those RPMs. How do these matter to each other? Torque without power implies low RPM limits. That obviously gets you nowhere. You cant get to any speed. So, the whole purpose is lost. Power without torque? Lotsa RPM, but it will take you forever to reach it. So you can even hit the speed of light, but you should live long enough. Wet & Dry Sump Engines Wet Sump engine: This is the most common kind of lubrication system for internal combustion engines. In these types of engines, oil is basically stored in a storage area or "sump" beneath the crankshaft. An oil pump then pumps oil all round the engine. Dry Sump engine: This is the second type of lubrication system in which, oil is stored in a separate tank. Here we have got 2 oil pumps, one to pump oil to all parts of the engine and another to pump the used oil (for want of a better term) back to the oil tank. Why use dry sump engines? During hard acceleration and cornering, in a wet sump engine, vital engine parts like the crank shaft can be left dry as the oil has sloshed to one side. You get the picture? Also, there is some BHP gain in a dry sump engine as the crank does not have to swim through the oil as in a wet sump engine. The down side to dry sump engines is that they are very complex and expensive to build because of all the intricate oil passage ways. Out of the bikes, I think only the Aprilia RSVR and the Dukes have got dry sump motors. Please share if you have such easy to understand articles on technical jargons related to automobiles. I will add them to this post. Most importantly, do not forget to mention source. Else, they will be deleted. Last edited by Aditya : 9th November 2018 at 09:34. Reason: Proofreading |

| |  ()

Thanks ()

Thanks

|

| |

| | #2 |

| BHPian Join Date: Feb 2006 Location: Bangalore

Posts: 30

Thanked: 0 Times

| Keep up the good work Technocrat. |

| |  ()

Thanks ()

Thanks

|

| | #3 |

| Senior - BHPian | OMG  Just what i've been loooking for Just what i've been loooking for Gr8 post |

| |  ()

Thanks ()

Thanks

|

| | #4 |

| Team-BHP Support  | missed missed this thread earlier but found it while searching for something. very informative indeed! |

| |  ()

Thanks ()

Thanks

|

| | #5 |

| BHPian Join Date: Feb 2006 Location: Melbourne

Posts: 542

Thanked: 9 Times

| excellent writeup bro. i m sure it wud have taken good research & time on the net but then its worth each word. kudos. |

| |  ()

Thanks ()

Thanks

|

| | #6 |

| BHPian | hey great work buddy....felt like i was in my auto eng classes...really great...keep it up!!! |

| |  ()

Thanks ()

Thanks

|

| | #7 |

| BHPian | Gasket & cotter pin Almost during every oil change for my car, I see they have replaced the "Gasket" and "Cotter pin", what the heck they are and how they look. Where does it go ? Can I have some pics ? |

| |  ()

Thanks ()

Thanks

|

| | #8 |

| Senior - BHPian | gasket woulod probably mean only the engine gasket, which is between the head (of the engine) & the rest of it. i dont think it has to be replaced everytime your car is serviced. only when it is worn out & you see splashes of oil , you need to replace the gasket. i dont know the cotter pin part, probably something to do with fixing the gasket. why dont you ask for the old parts & ask the guy to explain clearly where he has made the replacement ? |

| |  ()

Thanks ()

Thanks

|

| | #9 |

| Senior - BHPian Join Date: Feb 2004 Location: GTA

Posts: 14,765

Thanked: 2,705 Times

| *BUMP* Reviving this Old Thread. May be we can add more terms specifically related to Cars viz: - ECU - VTec - VVTi - CRDi\CRDe\DICOR - EPS\Motor Driven Steering wheel The list is long  |

| |  ()

Thanks ()

Thanks

|

| | #10 |

| Team-BHP Support  Join Date: Feb 2004 Location: Bombay

Posts: 24,198

Thanked: 36,140 Times

|

Thats not correct. There are several other gaskets used in the engine. The one you refer to is typically called the head gasket (between the head and the block). Gaskets are used to ensure a proper (watertight/airtight) seal between two parts. Gaskets are made of a softer material, so that when the two harder parts are tightened together the softer gasket (which is between them) can deform/ get compressed accordingly to fill in the gaps caused by any mating surface abnormalities/misalignments between the harder parts. Gaskets can be used to mate parts for the cooling(water) system, lubrication (oil) system etc etc. A cotter pin is quite simply a pin that is used to restrain another fastener. Wikipedia it for a better idea. cya R Pics - Head gasket. You can see the 4 big holes = 4 cylinders. The other holes are pathways for the coolant and oil to pass through (between the block and the head) as well as bolts.  Random oil filter housing gasket.  Vavle cover gasket (and a bit of the valve cover... this is the cover on top of your engines head)  Last edited by Rehaan : 31st December 2007 at 10:33. |

| |  ()

Thanks ()

Thanks

|

| | #11 |

| BHPian Join Date: Jan 2008 Location: Bangalore

Posts: 307

Thanked: 75 Times

| information in this thread is too good. one small comment on torque and power. Car makers tend to give data on engine specs and not on torque and power recieved on wheels and hence it is many times misleading. Acceleration is Torque/ mass and hence one should look at torque per ton not just torque. SUV can generate big torque but because of higher mass , acceleration may not be that good. Similarly power has to pull the mass of the car and hence power per ton gives a better indication of performance than just power. my 2 cents. avimal |

| |  ()

Thanks ()

Thanks

|

| |

| | #12 |

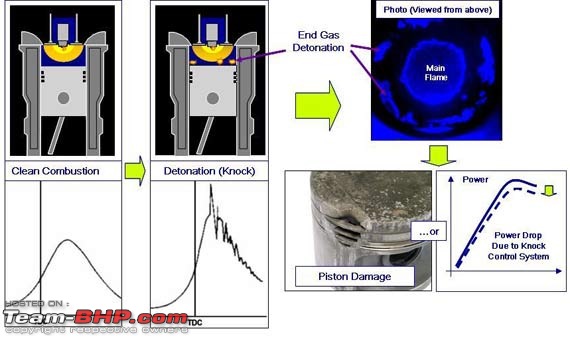

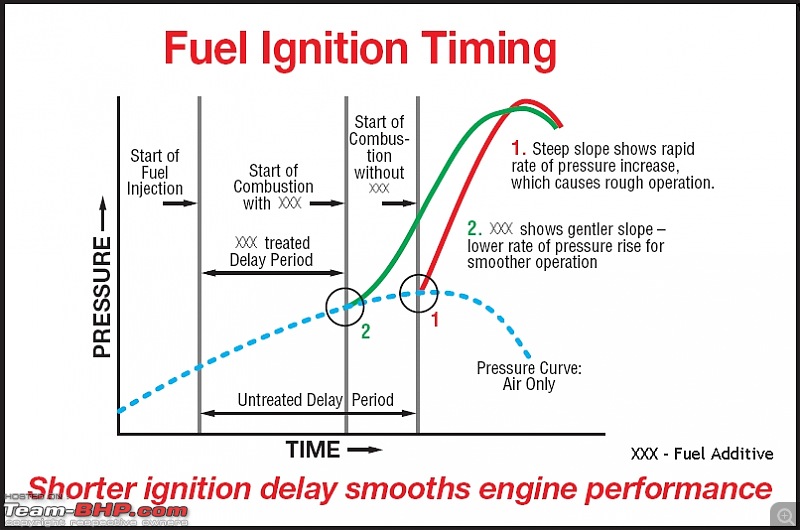

| Senior - BHPian | TechSpec® - When an Engine Knocks, you loose everything!! What is the "Engine Knock" ?? Abnormal combustion is more commonly known as knock or detonation, this has been the limiting factor in internal combustion engine power generation since the discovery of the otto cycle itself.  Abnormal combustion got the nickname knock from the noise that is transmitted from the colliding of the multiple flame fronts and the increased cylinder pressure that causes the piston, connecting rod and bearings to resonate. Abnormal combustion manifests in many different ways. To the typical enthusiast, all abnormalities are referred to as knock or detonation. Knock is evident by a high-pitched "pinging" noise, hence the common name "ping". Knocking can also be called “pinking”. Causes of "Knock" ?? Knock occurs near the end of the combustion process. It is the sound made when a small portion of the fuel/air mixture reaches a critical temperature and pressure, causing it to explode or detonate rather than burn smoothly. When knock occurs, there is uncontrolled combustion with multiple flame fronts, with only one of them being initiated by the Ignition. During knock, cylinder pressures experience an extremely rapid rise and spontaneous burning and release of the end gases energy. It is not uncommon to see a pressure rise of up to 8 bars per degree of crankshaft angle, or up to 50,000 bars per second. Anything that will either increase heat or retain heat in the combustion chamber will promote auto-ignition. Common problem areas are sharp edges of metal either on the piston or in the combustion chamber. For example, if the piston has a valve relief cut into it, there is usually a very defined edge that the cutting tool leaves. This sharp edge is greatly prone to super heating and will actually retain enough heat that it will start to glow. If the fuel should hit this glowing edge either prior to the lighting/ compression of fuel or even after ignition, it is very likely that another flame front will initiate. If this unintended ignition occurs very early in the compression stroke, then the piston will be forced up against the increased pressure of the burning gas and will result in a form of abnormal combustion referred to as preignition. When this happens, the end result, if severe enough, is that the connecting rods bend. Turbocharged engines are specifically prone to this. Carbon deposits that build up in the combustion chamber or on the piston top will have the same effect, along with the decreased volume, which in turn raises the compression ratio. Knock also occurs when the Octane/ Cetane requirement of the engine is greater than the Octane/ Cetane rating of the fuel it is using.The Octane/ Cetane rating of Petrol/ Diesel is a measure of its ability to resist knock in an engine. Octane/ Cetane NUMBER IS A MEASURE OF KNOCK RESISTANCE Octane/ Cetane ratings are determined using a single cylinder laboratory engine to compare the antiknock characteristic of the fuel with a known reference fuel. This laboratory method determines the research Octane/ Cetane number (RON) under mild conditions and motor Octane/ Cetane number (MON) under severe conditions. RON is more important under low speed, accelerating conditions, MON at high speed, cruising. ENGINE Octane/ Cetane REQUIREMENT IS BASICALLY SET BY ENGINE DESIGN Compression Ratio High ratios increase power and economy but also increase Octane/ Cetane requirement. Combustion Chamber Design The latest technology uses induction swirl and combustion turbulence to increase efficiency and reduce Octane/ Cetane requirement. Air/Fuel Ratio In general maximum Octane/ Cetane requirement will occur when the air/fuel ratio is near the chemically correct (stoichiometric) ratio. Enriching or leaning the air/fuel mixture will reduce the Octane/ Cetane requirement because peak combustion temperatures are lowered. Spark/ Ignition Timing Is normally set for best performance. In some engine designs timing is deliberately retarded during critical operation to avoid knock. Retarding ignition timing by two degrees will reduce Octane/ Cetane requirement by about one number. Engine Variations The manufacturing tolerance of components can result in variations between similar engines of 3 to 5 Octane/ Cetane numbers and sometimes more. Some engines therefore exhibit knock when new, although in reality only do so under specific driving conditions. OTHER FACTORS THAT INFLUENCE ENGINE Octane/ Cetane REQUIREMENT The engine Octane/ Cetane requirement also changes with operating conditions. Method of Driving Using full engine power will sometime cause knocking; it can be controlled by easing up on the accelerator. Temperature The higher the air temperature the greater the Octane/ Cetane requirement. Summer driving can require 4 more Octane/ Cetane numbers than winter driving. Engine water temperature also has a large influence on Octane/ Cetane requirement which highlights the need to maintain cooling systems in older vehicles. Altitude Higher altitude (lower air pressure) reduces Octane/ Cetane requirement; every 2000 metres means roughly 1 Octane/ Cetane number less. Humidity Increasing humidity decreases the engine Octane/ Cetane requirement. Going from 40% to 50% relative humidity at 30 deg C means the engine will require one less Octane/ Cetane number. Combustion Chamber Deposits Increase the engine's Octane/ Cetane requirement Carbon-like deposits gradually accumulate in the combustion chamber; up to about 4-6000 km from new. The amount of deposit then stabilises as excess deposit, flakes off. Highway driving produces less deposits than city driving and can reduce existing deposits.As stated earlier, anything that will raise temperatures in the cylinder will help promote detonation. This rise in temperature could occur many different ways: very lean air/fuel ratios, heating of the charge air prior to entering the combustion chamber, compression of the air molecules from forced induction, or poor heat dissipation through the cooling system. Increase of cylinder pressure will also prompt detonation. Camshaft profile, compression ratio and quench area all come into play. Design criteria as to combustion chamber shape and mixture motion, spark plug/ Injector location and piston design can all make an engine more or less inherently prone to abnormal combustion. Effects of this Knock/ Detonation Other than running an engine without oil, there is probably nothing that you can do that is more detrimental to an engine than detonating it. In an ideal combustion cycle there is a controlled burning of the compressed fuel and air, but during detonation there is an exploding of the mixture with a instantaneous release of all its energy, regardless of where the piston is in its stroke. The timing of the auto-ignition will have a direct effect on where the damage takes place. Detonation of very early in the compression stroke is usually the silent killer that goes unheard by the driver. This form of combustion usually results in rotating assembly failure by attacking the connecting rods and bearings. Detonation that comes nearer to Top dead center (TDC) or slightly after is usually heard as pinging and will likely result in the burning of the piston or the lifting of the ring land from the piston. The force from the colliding of the multiple flame fronts can be compared to the wake of two boats travelling in opposite directions on a lake. When the two wakes meet, they usually peak and absorb the energy of each other. The more dominant wake will still have some leftover energy and will proceed weakly in its original direction. The same holds true for colliding flame fronts in a cylinder. As the two flame fronts collide, the pressure in the cylinder rises from the compacting of the molecules. Historically, the normal flame front has enough energy to run over the abnormal one but uses a lot of its energy to do this. Add to this that the abnormal combustion has consumed a portion of the combustible mixture that filled the cylinder, and the least result is a loss of power, if not a damaged engine. Prevention of Knock/ Detonation Today's performance vehicles have a lot of technology and designs that make detonation less likely than it was years ago. As a matter of fact, I don't think we've ever heard modular engine's ping audibly. But the key word is "audibly." Even though you may not hear it, an engine can still be experiencing abnormal combustion. Inherently, small-bore engines are less prone to detonation than those with larger bores. The less distance the flame has to travel, the less likely there is for something to go wrong. By using reflective thermal barrier coatings on the top of the piston and the combustion chamber and quench area, you allow the flame to travel smoothly and keep the piston and head surface below the coating cooler. The actual temperature of the coating will be hotter but will reject that heat back into the combustion process to make power. Also engines with coated pistons need less timing than uncoated pistons that pull heat out of the combustion process. The least One can do is: - To use the correct specification of fuel as specified by the engine manufacturer - Use additives which improve combustion and have anti-knock agents. - Avoid adulterated fuels or fuel filling pumps.  An additive treated Fuel combustion Most modern engine management systems incorporate a knock sensor or two for closed loop timing control. These systems only have a limited amount of control and are designed to stop detonation in the normal operating range of the engine. What is Knock Sensor and what does it do? Mounted directly on to the side of the Rotor housing or cylinder block, they “listen” for engine knocking and send an oscillating voltage signal to the ECU. The ECU uses this information to control the ignition timing. The more advanced the ignition timing is set on an engine the higher the theoretical power, up to a limit. The limit is generally just before the point of knocking. It is the job of the Knock sensor, with the ECU, to keep the ignition timing at this peak setting.The ECU will advance the ignition timing until knocking is detected then retard it by, say 10 degrees, this process is repeated many times per second. Some ECU's have the capability of advancing and retarding the timing individually per cylinder. (A four-cylinder engine might therefore have four different ignition-advance settings.) In any case, the actual setting achieved is a variation on a “timing map” within the ECU, which takes into consideration parameters such as engine speed, load and temperature. The Knock sensor can also have a secondary role. The point at which knocking occurs is also the point at which peak emissions are generated. By accurately controlling the timing, the emissions of an engine can be reduced. How they work ?? When the sensor detects a “noise” within the frequency it is sensitive to, it generates a small electrical signal (a damped Sine wave signal of about plus and minus 2 volts). This signal is amplified and used by the engine management ECU accordingly.The sensor is located in a position on the engine where knock can be detected across all cylinders or chambers. One sensor is generally used per four cylinders, so an 8 cylinder engine will have 2 sensors and on a Rotary engine the knock sensor is mounted on the side of the front Rotor housing. The sensing element consists of a piezo-ceramic element and a seismic mass, which is clamped into place by the locating bolt. The sensor has a specific exciting frequency which is matched to the frequency vibration band within which knocking occurs.It's tuned to create an output voltage and is designed to bore and chamber geometries. When a given frequency of knock is detected, it in turn sends a signal back to the ECU identifying detonation, and the ECU retards the timings and inturn you loose power. Sources: A B C Last edited by dadu : 1st April 2008 at 13:06. |

| |  ()

Thanks ()

Thanks

|

| | #13 |

| Senior - BHPian | That was well compiled information buddie.Nice insight into the phenomenon called knocking. ram |

| |  ()

Thanks ()

Thanks

|

| | #14 |

| BHPian | excellent information - I am sure it will be useful for those who plan to turbo charge their engines  thanks for spreading the knowledge, keep it up  |

| |  ()

Thanks ()

Thanks

|

|