Team-BHP

(

https://www.team-bhp.com/forum/)

-

Motorbikes

(

https://www.team-bhp.com/forum/motorbikes/)

A few days back, Vespa Scooters were launched at Rs. 66,000/- in India.

Link to report

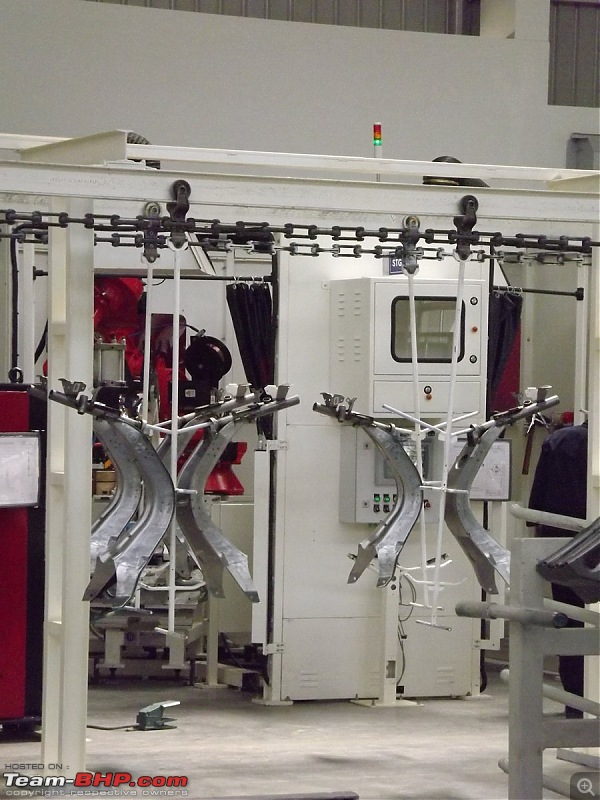

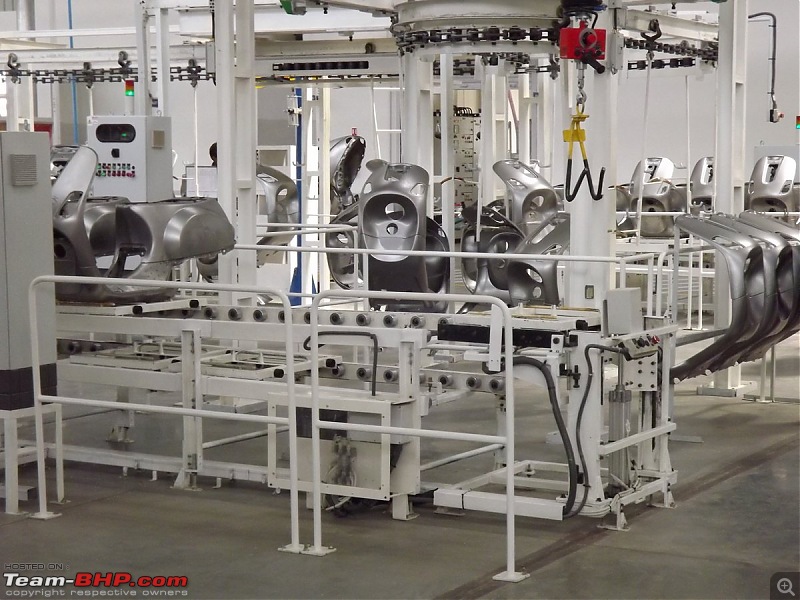

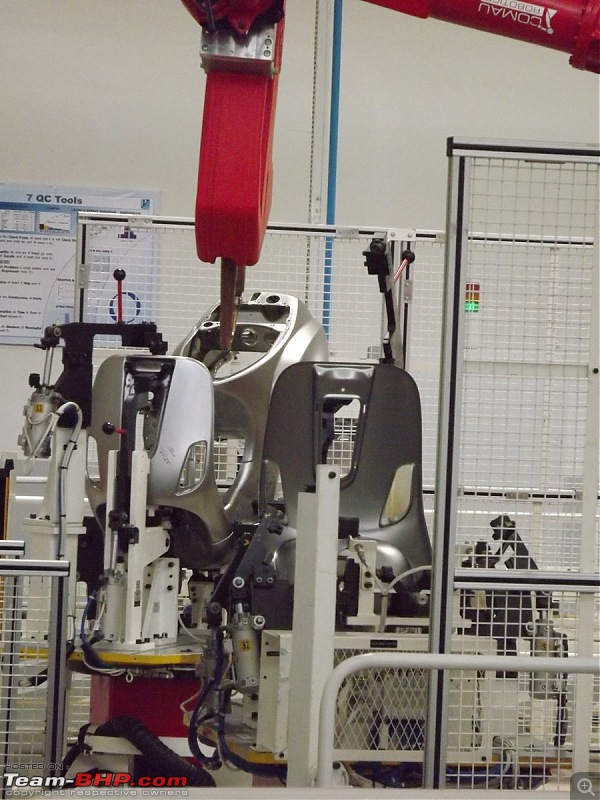

On 28/4/2012, Piaggio Vehicles inaugurated their manufacturing facility :

High Points:

High Points:- As of December 2011, over INR 100 crore has already been invested.

- Initial production capacity is of 150,000 units per year, which is to be doubled to 300,000 units by mid-2013.

- The plant has been set up in 12 months.

- 100% localisation of components.

- In 1999, Piaggio set up a facility for the production of 3 & 4 wheeled commercial vehicles; this production capacity has grown from 20 vehicles a day to the current capacity of 1000 vehicles a day.

- Piaggio provides employment to over 3000 people in Baramati.

- Currently working only in 1 shift with a daily target of 70 scooters.

Plant Inauguration:

The plant inauguration ceremony was attended by Mr. Sharad Pawar, Mr. Praful Patel, Mr. Ajit Pawar, Mrs. Supriya Sule along with Mr. Roberto Colaninno - Group Chairman & CEO for Piaggio.

As of now, the plant is humongous considering only one scooter model is going to be produced; it can also mean that Piaggio group has more in store for the Indian 2-wheeler segment.

All the dignitaries on the dais.

Lighting the lamp for auspicious reasons.

Mr. Ravi Chopra - Chairman & MD for Piaggio Vehicles Pvt. Ltd.

Mr. Roberto Colaninno.

Mr. Praful Patel also mentioned that as per the last fiscal year, the nation benefits almost 23-25% of GDP from the automobile sector.

Mr Sharad Pawar discussing the development of Baramati and other related aspects.

The ribbon cutting ceremony.

Thread moved from the Assembly Line to the Motorbikes Section. Thanks for sharing!

Great pictures and details. It seems this time Piaggio is making a calculated move. Company has done massive investment (considering a two wheeler plant).

The vehicle parts are similar to first generation Honda Activa (I meant full metallic body). Overall the scooter looks great and brings Vespa's heritage. But we should wait and see how the product going to fare commercially. Though Piaggio has placed Vespa XL125 as a lifestyle product, I feel it could be tough for the company to run a plant of this scale for such low volumes. There would have more buyers if company managed to price it below Rs.50K...

I think Piaggio may utilize this plant for making their small car (?) MT03 and Aprilia series motorcycles.

I never quiet understood why after tasting success with their LML brand of scooters they fizzled out in between. Most probably the emission norms killed them. We used to own a LML T5, the scooter would beat some of the bikes with the kind of pickup it had.

Glad to see them enter again to bring some good quality and fun to drive scooters.

Wonderful pics. Good to see the iconic brand getting shaped in India now. Also the political bigwigs ensured that Piaggio got the right coverage.

One thing which surpirsed me was the lack of safety awareness amongst the employees. None of them had the hard hats, hand gloves on which is vital in the manufacturing process. I hope Piaggio takes notice of this.

Hope the scooters start rolling and are seen at the dealership fast enough.

@Parrys,

Thanks for the detailed pics. Not often you get to see the assembly line pictures.

Looks pretty decent setup by Piaggio, but the numbers seem a little ambitious, both in production capacity and sales.

Quote:

Originally Posted by ghodlur

(Post 2761859)

One thing which surpirsed me was the lack of safety awareness amongst the employees. None of them had the hard hats, hand gloves on which is vital in the manufacturing process. I hope Piaggio takes notice of this.

|

Hard hats are mandatory for working under suspended loads. Did not see any overhead loads. Hard hats not usual in motorcycle assembly lines.

But the poor practice of putting gloves in pocket and working is rampant. Usually the gloves are to be blamed for the lack of dexterity and feel they offer. Most better outfits have switched to expensive nitrile gloves. Dont expect to see a change in that soon.

Cheers

Ride Safe.

Quote:

Originally Posted by MaxTorque

(Post 2761805)

I think Piaggio may utilize this plant for making their small car (?) MT03 and Aprilia series motorcycles.

|

I did have a word with a few Piaggio Top Management guys and got to know the following:

- As of now, no plans of localising the Aprilia series. This plant as of date is ddicated only to the Vespa.

- They will not help service the old Vespa customers. This would actually have been a good move to create some goodwill for the company.

- Will not compete with other scooter manufacturers for volumes.

- No plans of bringing in the Aprilia RS125 to compete with the R15 & CBR150R.

Quote:

Originally Posted by gthang

(Post 2761891)

Hard hats are mandatory for working under suspended loads. Did not see any overhead loads. Hard hats not usual in motorcycle assembly lines.

But the poor practice of putting gloves in pocket and working is rampant. Usually the gloves are to be blamed for the lack of dexterity and feel they offer. Most better outfits have switched to expensive nitrile gloves. Dont expect to see a change in that soon.

|

As per Factory Act any manufacturing unit should have the basic safety practices in place and employees wearing the hard hats is one of them. Following the safety practices defines an organization and automibile sector is no exception be it a 2 wheeler or 4 wheeler.

@parrys - Where are the scooters tested? Is it in the same vicinity or elsewhere?

Quote:

Originally Posted by ghodlur

(Post 2761899)

As per Factory Act any manufacturing unit should have the basic safety practices in place and employees wearing the hard hats is one of them. Following the safety practices defines an organization and automibile sector is no exception be it a 2 wheeler or 4 wheeler.

|

Even though most Govt Acts are odd and without logic, and interpretations even stranger, I would think that some hazard specific PPE norms are practiced. It might seem really strange to see workers in a watch "Factory" wearing hard hats.

Cheers

Ride Safe.

Quote:

Originally Posted by ghodlur

(Post 2761899)

As per Factory Act any manufacturing unit should have the basic safety practices in place and employees wearing the hard hats is one of them. Following the safety practices defines an organization and automibile sector is no exception be it a 2 wheeler or 4 wheeler.

@parrys - Where are the scooters tested? Is it in the same vicinity or elsewhere?

|

I doubt there is a Factory Act provision which makes hard hats mandatory for all shop floor workers. Normally hard hats are used when a person works under suspended load or there is a chance of hit injury for the operator.

What we see here is much better compared other plants. There are some stations where operator is wearing glove on only one hand (eg: where front fork and shock absorber are being assembled). That could be due to method problem. Some times operator has to apply grease on parts. So usage of cotton gloves is not possible. Nitrile gloves are recommended where the operator is handling chemicals. But they are ergonomically very bad..

Quote:

Originally Posted by MaxTorque

(Post 2762197)

Nitrile gloves are recommended where the operator is handling chemicals. But they are ergonomically very bad..

|

Nitrile gloves have come a long way since the kitchen sink types.

There are nitrile coated foam, polyurethane coated foam, etc., that offer dexterity as well as protection.

Example:

HyFlex® 11-624

Cheers

Ride Safe.

| All times are GMT +5.5. The time now is 08:36. | |