Winch: A winch is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust the "tension" of a rope or wire rope (also called "cable" or "wire cable"). In its simplest form it consists of a spool and attached hand crank. In larger forms, winches stand at the heart of machines as diverse as tow trucks, steam shovels and elevators. The spool can also be called the winch drum. More elaborate designs have gear assemblies and can be powered by electric, hydraulic, pneumatic or internal combustion drives. Some may include a solenoid brake and/or a mechanical brake or ratchet and pawl device that prevents it from unwinding unless the pawl is retracted.

Source:

Winch - Wikipedia, the free encyclopedia

Recommended Reading:

ATV Winch Cleaning and Maintenance Guide, Part 1 « ProMark Offroad Blog ATV Winch Cleaning and Maintenance Guide, Part 2 « ProMark Offroad Blog CDMFabrication.com • View topic - Winch Maintenance / Rebuild http://www.macquarie4x4.com.au/cmsdo...hMaintTech.pdf http://pirate4x4.com/tech/billavista/8274/ http://www.warn.com/fire_rescue/imag...Techniques.pdf

Winches are expensive equipment and need to be maintained so that they serve you when you are stuck without breaking down.

A quote i liked from (

http://4x4winches.com/): Quote:

|

A WINCH IS RATHER LIKE A FIRE EXTINGUISHER, absolutely useless if it doesn't work when you really need it and just as useless if it only puts out half the fire. If you are going to the expense and trouble of fitting a winch to your 4x4, it needs to work every single time, whether it is recovering you from a small ditch, or a 200 metre long mud hole

|

The following points i have gathered from forums and websites and am compiling them from everyone's ease:

- Run the winch cable out about 10 feet and then back in at least once a month if it’s not been used. This keeps the solenoids’ contacts from corroding.

- Never pressure-wash the winch. This forces water into the solenoid pack and motor causing serious problems down the road.

- Don’t silcone the winch to seal everything. The little weep hole on the motor is there to let water and moisture from condensation escape,

- If you work in a high-humidity region, leave the winch cover off or else the cover will keep the winch from drying out.

- If the winch can’t make the pull, don’t crank up the vehicle and use the winch/cable as a snatch strap. If you do it’ll destroy the internal brake assembly or explode the planetary gear set.

- Don’t use the winch cable as a choker with the cable hook placed back over the cable. Doing this will snap the cable every time.

- Spool the winch so the cable comes off the bottom of the drum — not the top. The internal brake is a one-way setup and it only works when the drum spools cable off the bottom.

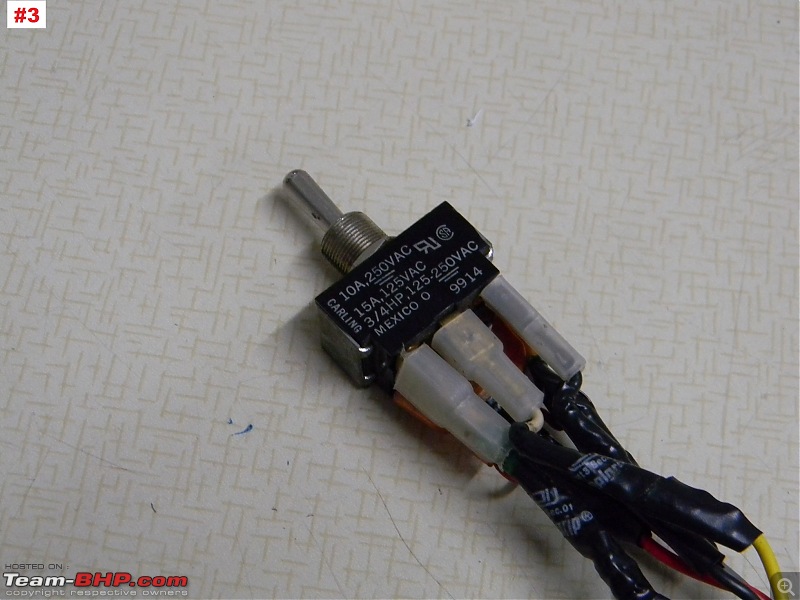

- If a solenoid goes bad, replace both in the pair; two for in, two for out.

- Never let the winch remote-control cable get sucked into the drum. If the remote gets smashed it instantly short-circuits the control panel, destroying it.

- A straight line from the winch to the object being pulled is critical. (This minimizes wire rope collection off-siding on the drum which can damage rope.) If you don’t have a straight line to the vehicle you’re winching, you can effectively change pulling direction with the help of a snatch block. Secure the snatch block to a point directly in front of the vehicle. This lets you maintain proper drum spooling and achieve extra winching power.

- To achieve extra power, a snatch block provides mechanical advantage. The snatch block is an amazingly efficient tool to utilize, easily doubling your winch capacity. At the same time, using a snatch block also cuts your line speed in half, making it easier to stabilize objects.

- Using a snatch block is particularly useful in situations where your vehicle is closer to the winching situation. A fuller winch drum means less power. Power you can regain, and increase, by using a snatch block.

- Wire Rope: Inspecting your wire rope before and after each winching operation goes a long way towards safe, reliable operation. You’re checking for kinking or fraying. Either situation warrants rope replacement. Also, inspect the winch hook and hook pin for signs of wear or damage, and replace if necessary.

- Synthetic Rope: If you have synthetic rope, the outer line filaments may “fuzz up” with mild abrasion. Typically, this won’t affect the performance of the winch line. When fibers become melted or fused from excessive loads the winch line needs to be replaced. Also check for:

• Inconsistent diameter (or reduction by 25%)

• Exposure to hard chemicals

• Exposed core strands (the grey synthetic cover is worn through)

• Cuts, melting or glazing of internal core strands (these are tan colored)

- Cleaning: Improve the life of your winch by keeping winch, rope and switch control clean. Use a clean rag or towel to remove dirt and debris. If necessary, unwind the winch (leaving at least five wraps on spooling drum), wipe it clean, and rewind properly before storage. Light oil on the wire rope and winch hook can prevent rust and corrosion.

- Vehicle Battery: Operating an electric winch for long periods places a burden on your vehicle’s battery. Check and maintain battery and cables according to manufacturer guidelines.

- Remote: Inspect remote for damage. Cap the remote socket to keep dirt and debris out.

- Lube: No lubrication required for the life of the winch. (debatable point in many other forums).

- When you take the winch for a swim you should ALWAYS at the end of the day run out 20 ft or wire rope, then wind it back in. This will disapate the water that has gotten into the motor area. If you do water submersion often then yes, you will have to take it apart and "service" the unit via the dealer or yourself if you are confident about it. The DIY is explained in one of the links above.

Another take from pirate4x4 regarding lubrication:

Quote:

Very few if any electric winches are fully sealed. Electric motors gas while in operation and that gas needs a place to go. So if you want to play submarine with you winch, you will need to do a few mods to it. First is to tap the motor for a barbed fitting and run a breather hose. Then you can seal the motor end cap and the field case to the winch frame (liquid electrical tape works good for this). The next thing is make sure the gear box gaskets are in good shape as well as any other seals (clutch, ect). Most planetary winches do not have seals on the drum (Warns 9.5ti and XP do) so I pack a fair amount of grease between the drum flanges and the drum supports. Warns use Aeroshell 17 which has a decent washout rate so it works good for this.

Now for the control pack. I prefer the non I series winches so that the pack can be relocated. The I series winches solenoid housing is not sealed so it will fill with water if submerged for extended periods. The solenoids themselves are not sealed so keeping them out of harms way is a good idea. The control pack is where dielectric grease and spray corrosion guard are your friend. Liberally cover all connections (dont forget the motor posts too) and you will be good to go. (Waterproof winch? [Archive] - Pirate4x4.Com Bulletin Board)

|

I think greasing the wire is a catch 22 situation: if you grease it then it will pick up every bit of dirt and sand and jam up the winch. if you don't then the cable may rust. Best is to wipe the cable down with a slightly oily rag to try and keep most of the crud off after first scraping it with a brush to remove most of the muck.

Other important points i picked up from some forums regarding lubrication of the wire:

- The lubricant applied should be of the type that does not hinder visual inspection.

- The surface of some ropes may become covered with dirt, rock dust or other material during their operation. This can prevent field-applied lubricants from properly penetrating into the rope, so it's a good practice to clean these ropes before you lubricate them.

- The lubricant you apply should be light-bodied enough to penetrate to the rope's core. You can normally apply lubricant by using one of three methods: drip it on rope, spray it on or brush it on. In all cases, you should apply it at a place where the rope is bending, such as around a sheave ( Pulley Block ). We recommend you apply it at the top of the bend because that's where the rope's strands are spread by bending and are more easily penetrated.

- Your rope's service life will be directly proportional to the effectiveness of the method you use and the amount of lubricant that reaches the rope's working parts. A proper lubricant must reduce friction, protect against corrosion and adhere to every wire. It should also be pliable, and not crack or separate when cold, yet not drip when warm. Never apply heavy grease to the rope because it can trap excessive grit, which can damage the rope. Nor should you apply used "engine oil" because it contains materials that can damage the rope .

- It is also a good practice to oil down any hardware Fairleads / Chrome on your Winch to give it a coating to keep corrosion from pitting / rusting these areas. At the same time you can check the motor terminals to make sure they have Vaseline /Lithium grease etc as the Rubber boots over the terminals are notorious for trapping mud moisture in them.

(11)

Thanks

(11)

Thanks

(5)

Thanks

(5)

Thanks

(5)

Thanks

(5)

Thanks

(9)

Thanks

(9)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(3)

Thanks

(3)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(3)

Thanks

(3)

Thanks