Team-BHP

(

https://www.team-bhp.com/forum/)

Quote:

Originally Posted by Jeroen

(Post 4098564)

I’ll see if I can dig up some of my (very) old photographs on these engines.

|

Look forward to the photos. Thank you for sharing your experiences.

I would love it if a BHPian could write a similar thread/post on marine steam turbines.

Fascinating thread. Thank you Sail, for sharing this. And thanks to all others who pitched in with their experiences. When you think about it, these engines would be quite inefficient ( as compared to modern engines or turbines) since it is an open cycle.

I am presently working as Chief Engineer onboard VLCCs.

Have worked my way through ranks on motor and steam ships.

Would be happy to contribute my 2 cents if I know what it is aboutstupid:

To add to the info that "sail" wrote earlier,

Fuel injectors:

The set pressure of 380 - 400 Bars are for setting the opening pressure for these slide valve type injectors.

The new common rail engines have a fuel pressure of 800 - 1000 bars in the rail. So the injection happens at that pressure.

Turning Gear:

In addition to the internal inspection purposes, its an integral part of maintenance as well.

For eg. The removal of various bearings & piston etc. will need the crankshaft at certain positions for the tools to be attached/ used.

Turning gear is the only means to bring the crankshaft to the desired position in a controlled manner.

Usually used with the indicator valves open on the cyl. heads. to avoid any pressure/ vacuum inside the unit which is bound to overload the turning gear as it is usually a small electrical motor with a reduction gear to multiply the torque required to turn the flywheel while engaged.

Quote:

Originally Posted by earthian

(Post 4098643)

Fascinating thread. Thank you Sail, for sharing this. And thanks to all others who pitched in with their experiences. When you think about it, these engines would be quite inefficient ( as compared to modern engines or turbines) since it is an open cycle.

|

A specific fuel consumption of 170 g/(kW·h) would be common.

They are 2 stroke engines.

These engines are unique because of the ultra long stroke that they use.

Typical Bore : 960 mm. : Stroke : 2,500 mm.

Power density would be typically 30 to 35 kW per tonne

Quote:

Originally Posted by jfxavier

(Post 4098669)

A specific fuel consumption of 170 g/(kW·h) would be common.

|

That would translate into a Heat rate of ?

Absolute gem of an article with so much information. I was amazed by the sheer size of the Marine Diesel engine. Never knew about it and never thought that engine can be of such a big size with such a huge/complex control system to run and manage it.

Thanks for sharing !

Quote:

Originally Posted by earthian

(Post 4098675)

That would translate into a Heat rate of ?

|

Heat rate is a term used in US and in turbine based installations.

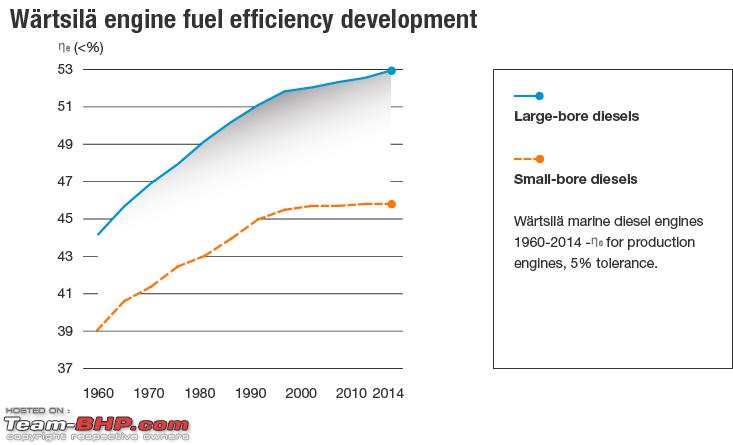

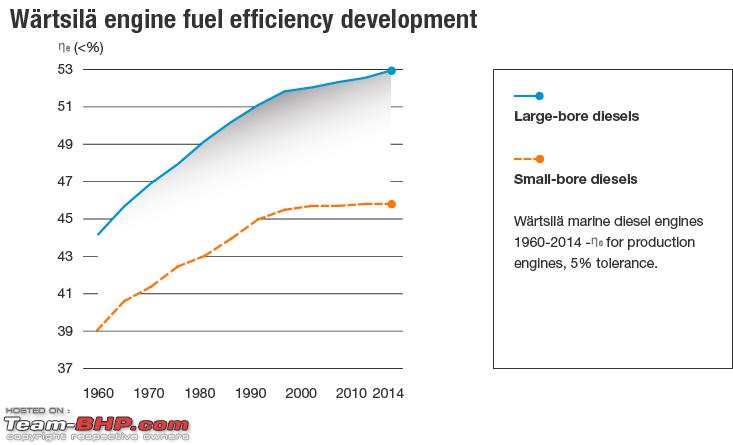

However, when we talk about efficiency, a marine 2 stroke slow speed engine is one of the most efficient prime movers out there.

Here is something that will give you an idea.

Typical fuel used in Marine applications will be having 40 MJ/Kg.

The engine would give a consumption figure of 170 g/kW.h. approx.

Hope that is clear enough.

Quote:

Originally Posted by SKavuri

(Post 4098288)

Are you in the engineering of the systems or in operation/maintenance?It would be interesting to know if there is any international standard for these engines other than from classification society (ABS) standards?

|

Hi

SKavuri,

I work as Captain on Oil Tankers.

You are right. Maker of these engines have to comply with various IMO’s MEPC (International Maritime Organization / Maritime Environmental Protection Committee) strict regulations. This is a vast subject, where each and every engine component is subjected to a specific design / safety / quality / emission requirement.

Regarding classification of these engines, it is mainly decided by owner that which class they want their ships to be classified. Class can’t over-rule any IMO guidelines, they add more stringent regulations on top of IMO’s requirements in term of inspection, maintenance etc. So it means, each engine maker needs to design their engines in line with IMO & IACS (International Association of Classification Society) recommendation. Hence owner can opt for any classification society.

Hi

Jeroen,

Thank you very much for your valuable feed-back. Few points to share:

1. On my last vessel, maneuvering full rpm was ‘46’ & at rpm ‘53’ we used get 13 kts speed on a fully laden VLCC. Just imagine how powerful these engines are. Massive propeller size of 10.60 mtrs diameter has helped a lot. While slowing down, at the end of one hour notice, just put the telegraph from 53 to 46 rpm at one go, electronics will take care of everything. It means with-in few minutes you are ready to maneuver her. Rightly you said, earlier days it used to take close to one hour for slowing her down from Nav Full to maneuvering rpm.

2. Steam boilers are very much in use now a day, especially on tankers. All cargo pumps run on steam turbine. EGB (Exhaust Gas Boiler) takes care of all steam requirements while at sea. Even main boilers are also controlled electronically. It will work on its own as per steam requirements. Principal of cargo/bunker heating remains same. Simple heating coils, designed to carry super heated steam & heat exchange process. Some machinery component uses heated water coils for warming up. VLCC does not have cargo heating system, due to huge amount of super heated steam requirements. It is not at all economical.

Quote:

Originally Posted by Sail

(Post 4098713)

Hi SKavuri,

Steam boilers are very much in use now a day, especially on tankers. All cargo pumps run on steam turbine. EGB (Exhaust Gas Boiler) takes care of all steam requirements while at sea. Even main boilers are also controlled electronically. It will work on its own as per steam requirements. Principal of cargo/bunker heating remains same. Simple heating coils, designed to carry super heated steam & heat exchange process. Some machinery component uses heated water coils for warming up. VLCC does not have cargo heating system, due to huge amount of super heated steam requirements. It is not at all economical.

|

All aux. heating steam is usually saturated steam or de-superheated steam in case of a super heater being used for supplying super heated steam to Main turbines. I have seen superheater in a motor ship supplying a turbine generator but it's not common. Usually all aux. steam is de-superheated or saturated, for obvious safety reasons and for initial cost as well.

Thanks you Sail and Jeroen for all the information you've shared.

I just want to know whether Pony Engines were ever used for starting?

Quote:

Originally Posted by landcruiser123

(Post 4099188)

Thanks you Sail and Jeroen for all the information you've shared.

I just want to know whether Pony Engines were ever used for starting?

|

Anything over a certain size is always started by air. Even smaller auxiliary engines of only a few hundred horsepower were air started on the ships I have sailed on. Maybe it's different on ships these days, but I don't think I have ever started a diesel on a merchant ship other then with air! Well, to be completely honest: the engines in the lifeboats were hand cranked! We had to start them every month as part of maintenance.

Jeroen

Quote:

Originally Posted by Jeroen

(Post 4099249)

Anything over a certain size is always started by air. Even smaller auxiliary engines of only a few hundred horsepower were air started on the ships I have sailed on. Maybe it's different on ships these days, but I don't think I have ever started a diesel on a merchant ship other then with air! Well, to be completely honest: the engines in the lifeboats were hand cranked! We had to start them every month as part of maintenance.

Jeroen

|

The generators use Air motors for starting, in some designs.

Makes the cyl. head have one less component.

Main Engines always use air starting valves.

Compressed air of 30 bar pressure is let into the appropriate units to turn the engine in the desired direction till it picks up on fuel.

Quote:

Originally Posted by Jeroen

(Post 4099249)

We had to start them every month as part of maintenance.

Jeroen

|

Its a weekly routine now a days unless things have changed in the last three-four years.

@Sail.. Captain Saab welcome aboard! An ex-sailor myself here. Quit sailing in 2012. Would have been a Chief Engineer now had I continued. Now a days I try selling services to the Marine Industry.

That's a good Paanch Saab you have there!! clap: And a nice thread too. Stirred up quite a few memories. Keep going will try to share some pics myself here.

Quote:

Originally Posted by Jeroen

(Post 4099249)

Well, to be completely honest: the engines in the lifeboats were hand cranked! We had to start them every month as part of maintenance.

|

Dismally failed to hand crank a yacht engine once. We wore skin off our hands trying.

On the other hand, on another, actually larger boat, the single-cylinder engine was designed to be hand started: get the flywheel going, close the compression valve and Chug! Chug ... chug ... chug ... chug.

Quote:

Originally Posted by Thad E Ginathom

(Post 4099421)

Dismally failed to hand crank a yacht engine once. We wore skin off our hands trying.

On the other hand, on another, actually larger boat, the single-cylinder engine was designed to be hand started: get the flywheel going, close the compression valve and Chug! Chug ... chug ... chug ... chug.

|

The engines in Lifeboats are designed with easy starting even in cold climate in mind.

Now a days it's common to find Lifeboat engines without hand cranking mechanism.

Two sets of batteries would do.

Quote:

Originally Posted by jfxavier

(Post 4099467)

The engines in Lifeboats are designed with easy starting even in cold climate in mind.

Now a days it's common to find Lifeboat engines without hand cranking mechanism.

Two sets of batteries would do.

|

One could argue what is better and more reliable. Batteries need maintenance too. Starter, switches etc.

Jeroen

| All times are GMT +5.5. The time now is 19:24. | |