Team-BHP

(

https://www.team-bhp.com/forum/)

Interesting, we could not run in parallel with the aux engines. We synchronised the shat generator with the aux generator and the shaft generator would take the full load from the aux engines. RPM of the main engine was fixed as we had CPP.

Nice to hear about these developments!

Jeroen

Things have changed a lot in the industry and now we are looking at engines running purely on gas in future, MEGI series from MAN B&W. Even conventional ships will be running on gas, which means we are looking at a change in how we take bunkers, from coal in ship's bunkers in olden times to oil at present and natural gas in future:).

It'll probably be a special sort of filthy, thick, unrefined gas!

rl:

Got this forward from a shippie friend.

About the Jahre Viking - the biggest moving man made object on the planet whilst it travels around the Cape of Good.

Shows you a peek into the engine room too.

She was commanded by an Indian Master during the BBC Top Gear Shoot.

https://www.youtube.com/watch?v=WX2HFVHbo18

For additional reading, The Jahre Viking went through many name changes. This is the wiki page for when she was known as "Seawise Giant"

She was scrapped at Alang Shipyard in 2009.

https://en.wikipedia.org/wiki/Seawise_Giant

The largest vessel I sailed on was a VLCC which was 328 m long and could carry 290,000 MT of crude oil.

Questions, if any, would be appreciated. Answers would take some time though.

Ithaca, thank you for sharing. The size and immenseness boggles the mind. Very proud to see how Indian merchant navy officers now dominate the officer cadre of the world's shipping and carry a reputation for thorough professionalism which has replaced the hard drinking hard swearing old sea dog culture of 60 years ago. Give us some two liners on unusual things involved in sailing such ships. The video talks of stopping & turning. Tell us about fuel burn, weight & size of the propeller, engine size, how many on the bridge at a time, does the ship bend and warp, how do you navigate inside the ship-getting lost can be a problem, is the shaft ever removed for maintenance or does it stay in place through the life of the ship. etc.

Quote:

Originally Posted by Ithaca

(Post 4327864)

Got this forward from a shippie friend.

About the Jahre Viking - the biggest moving man made object on the planet whilst it travels around the Cape of Good.

Shows you a peek into the engine room too.

She was commanded by an Indian Master during the BBC Top Gear Shoot

The largest vessel I sailed on was a VLCC which was 328 m long and could carry 290,000 MT of crude oil.

Questions, if any, would be appreciated. Answers would take some time though.

|

Quote:

Originally Posted by Ithaca

(Post 4327864)

Shows you a peek into the engine room too.

She was commanded by an Indian Master during the BBC Top Gear Shoot.

|

Comparing navigating on seas with driving on Mumbai traffic, The way Jeremy was asking questions to the captain, seemed a bit racist to me to be honest. I am sure it takes immense skill and expertise to captain this ship.

This ship was managed by Wallems at one point of time right?

Well I had priviledge of sailing on ship similar 'Jahre Viking' as a cadet, Indeed she was a real BHPIAN, consuming 200 Mt of Heavy fuel oil per day.

Now a Captain such a behemoth and indeed its a pleasure. Now a days owners prefer mid size ships as they are more fuel efficient and can trade in more flexible ways.

Quote:

Originally Posted by aspire

(Post 4328069)

Comparing navigating on seas with driving on Mumbai traffic, The way Jeremy was asking questions to the captain, seemed a bit racist to me to be honest. I am sure it takes immense skill and expertise to captain this ship.

This ship was managed by Wallems at one point of time right?

|

@ aspire, while watching the video it seemed that Jeremy was surprised that the Indian Captain could navigate a vessel of this size at sea and does make a snide comment about driving in India.

With regard to Wallems managing this vessel, I am sorry I do not know this answer.

Quote:

Originally Posted by V.Narayan

(Post 4327964)

Ithaca, thank you for sharing. The size and immenseness boggles the mind.

|

@ V.Narayan sir, I will answer your queries below in separate sections.

The Jahre Viking is a ULCC - Ultra Large Crude Carrier.

Most vessels of that size are currently a tad smaller and called VLCC - Very Large Crude Carrier.

SCI has a few ULCC - Desh Ujala, Desh Vaibhav, Desh Viraat & Desh Vishal.

Tell us about fuel burn

Most VLCCs will consume roughly 100 ~ 120 MT of Heavy Fuel oil a day doing a sailing speed of 12 - 14 knots per hour at 70~75 rpm . (1 nautical mile = 1.852 kilometers). This translates into a sailing distance of 288 to 330 nautical miles per day.

This consumption will vary on whether the vessel is in ballast or fully laden. Weather conditions also can lead to increased consumption.

Typically Total Fuel Tank (called Bunker Tanks) Capacity would be roughly 6000 to 8000 MT for Heavy Fuel Oil spread out over four tanks.

Marine Diesel will have her own separate bunker tanks.

weight & size of the propeller

Will find out this answer and get back.

The attached sheet has made a mistake on the propeller size though.

Cannot be 1000 meters diameter, should be 100 meters instead.

engine size

Typical engine sizes for a VLCC would range from 6 to 12 cylinder engine with a bore diameter of 800 mm to 1200 mm.

Engine in the attached sheet - Hyundai – B&W 6S90MC - is a 6 cylinder, Super long stroked engine having a cylinder bore of 90 cm or 900 mm.

The power output would be in the range of 32000 bhp and above.

The pdf I have attached to this post shows the engine power as kW and not BHP.

BHP = 1.36 x kW (Approx)

how many on the bridge at a time

During the sea watches, it is mandatory to have two watch keepers at all times on bridge whose only duty is to keep watch to ensure vessel is following her course and there is no traffic to attend to.

This will include the watch keeping officer and his lookout who is a certified Able Bodied Seaman. At no time is the Bridge allowed to be unmanned.

Modern vessels have an bridge alarm system. Motion Sensors are fitted at various parts of the bridge and lead to a command box which has a timer unit. Timer is set by master - usually 15 minutes - and the watchkeepers on bridge during watch have to activate any sensor to reset it to 0.00 sec.

If not an alarm is sounded in the Captain's cabin and deck officers cabins, smoke rooms and dining rooms to alert staff that the bridge is unmanned.

The chief officer who keeps the 0400 to 0800 & 1600 - 2000 watch will always have a cadet with him along with his own AB. The cadet uses this time to learn from chief officer.

During passages in congested waters, shallow patches or in heavy traffic areas like the English Channel, Hormuz Straits or Singapore straits, the Captain is always on bridge and he is assisted by his duty officers and duty lookouts as per the watch schedule at that time.

does the ship bend and warp

Hogging and sagging are typical for vessels this long. The structure also gets affected due to variations in temperature that the vessel has to endure during its life cycle. It could be up at Alaska in the winters today and two months later could be steaming down the Persian Gulf. Design of ships take into account expansion of plates and piping to counter hogging and sagging.

how do you navigate inside the ship-getting lost can be a problem

The area we live in is called the accommodation and is the superstructure in the aft of the vessel.

Consider it like an apartment that is typically 4 to 6 stories high.

This houses the bridge, Officer & Crew accommodations, dining areas, recreation areas, gym, the cooking area - galley, stores for provisions + deck spares + electrical spares + engine stores, Ships office, Master's Office, Chief Engineer's Office, Radio Room.

Most ships that I have sailed on if they had more than 4 floors above, they would have an elevator going from the Engine Control room to the Bridge since climbing a total of 8 to 9 floors is not an easy task day in day out.

Entrance to each floor (Deck in naval speak) has the layout of that particular floor & ranks of the occupants or name of the various cabins that occupy that floor so navigating within the deck is easy.

From the accommodation superstructure we access the engine room from within the accommodation.

Typical engine rooms too will be 4 to 6 floors deep.

Within the first day, most seafarers get the general layout of their vessel since it is usually a repetition of their previous vessels.

First timers / Non Ship staff tend to get confused so are usually always accompanied by ship staff.

is the shaft ever removed for maintenance or does it stay in place through the life of the ship. etc.

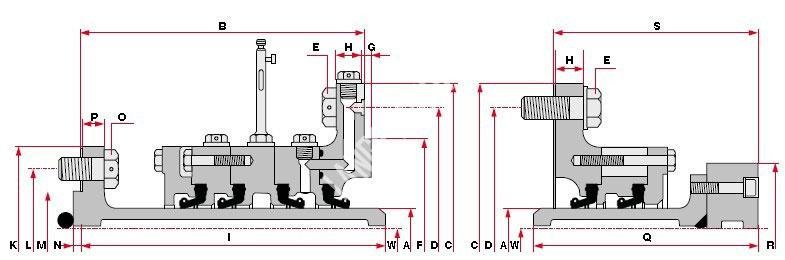

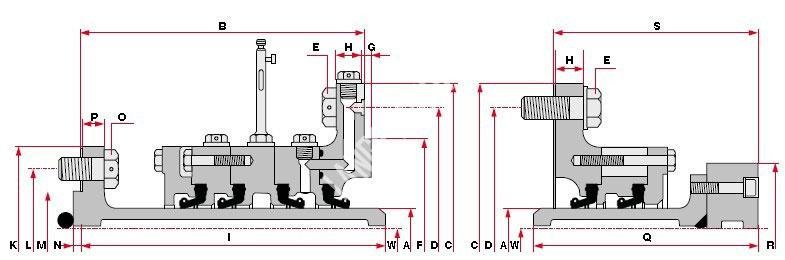

The main engine is connected to the propeller via shafting that would typically consist of one or more intermediate shafts.

Each intermediate shaft is balanced by its own Intermediate Shaft bearing.

It exits the engine room via the stern tube and is connected to the propeller on the outside.

Stern Tube is an oil filled tube that is seated in a water chamber with oil seals on either end to prevent oil from leaking into the sea or allowing salty sea water enter the stern tube. These seals harden over time and need replacement. Hence the shafting has to be extracted once in 5 years for inspection and seal renewal.

Typically a vessel has to enter dry dock twice every 5 years. The 5 year cycle is the major drydock and the 2.5 year interval drydock is the intermediate drydock. Nowadays due to cost cutting the vessel stays inside a drydock for the most minimal time to get her hull cleaned and painted. It is during its stay at the drydock that the shafting is removed.

Attached:

1. specs.pfd (VLCC NEW BROCHURE)

Propeller Shafting - Typical Layout

Oil Seals

"weight & size of the propeller

Will find out this answer and get back.

The attached sheet has made a mistake on the propeller size though.

Cannot be 1000 meters diameter, should be 100 meters instead."

The propeller will be around 8-12 metres in diameter, no ship (as of now) has a draft of more than100 metres to accommodate a 100 metre dia propeller.

Regarding removal of shaft, as mentioned, every 5 years its mandatory to inspect the shaft seals, bearings (stern tube and intermediate), and the shaft itself. At an interval of 2.5-3 years it is mandatory to check the stern tube bearing wear, by measuring the drop of the propeller shaft against set marks and a standard gauge which is specific for the ship. These readings are recorded and maintained throughout the life of the ship.

The shaft is inspected for any cracks, external or internal through magnetic particle test. The shaft is always withdrawn into the engine room after removing the propeller. The propeller is hydraulically fitted on to the shaft with a graph providing details of the linear movement of the propeller against the applied pressure (at various temperatures usually between 20-40 degrees C). This graph is provided by the maker and is to be adhered to always for fitting of the propeller. All these jobs are witnessed by the ship's chief engineer with the class surveyor. Hope that explains enough to understand this aspect. Cheers.

The whole world is moving towards efficient designs and redundancy, so are the ships. Now a days the usual trend is to equip large ships with two propellers and/or diesel electric propulsion system.

Two propellers significantly reduce losses and in most of the cases at least one propulsion system will always be available to move the ship to a nearest safe port in case circumstances warrant for.

Diesel electric propulsion provides the most economic propulsion without having the side effects of slow steaming (moving at slow speeds). Slow steaming is known to result with reduced intervals for maintenance schedules and hence extra work for the people on board and shorter life of the engine components.

With the emission norms in place the ships using large slow speed 2-stroke diesel engines use residual fuels with less than 3.5% sulphur by mass and in specific regions classed as ECA (emission control areas) the sulphur content is limited to less than 0.1% sulphur.

Fuel consumption varies from ship to ship but depends only on the size of the engines on board. Large container ships are the fastest and usually have highest fuel consumptions going upto more than 200 tonnes per day. These ships are capable of going upto 25 knots or more and can carry upto 15000 or more containers of twenty feet (TEU-twenty equivalent units). The half ahead speed of a container ship is more than the full ahead speed of most of the large bulk carriers or oil tankers. The main engines are rated at anything between 10000bhp to 100000bhp depending on the size. The container ships vary in size from as low as around 700 TEU to 15000 TEU or even more.

The subject is vast and covering here in detail will be difficult. Just trying to help you understand in short.

Please feel free to ask questions and I will try to answer. Though I am no expert, but in this profession for quite some time now. Seafarers usually suit the saying "Jack of all trades, Master of none":)

Cheers.

- It takes max a week for a new seaman to get used to his new home, then the skill remain for life, from one fire door to another, or one ship to another. Every seaman is given a safety book in first few hours on joining ship (includes ship plan & assembly point for emergency)

- Photoluminescents direct route during emergency.

- Everything from a nail is governed by SOLAS ( Safety of life at Sea), even the 20'/40' containers are manufactured are as per SOLAS.

- Cruise ship Dry Dock after every two-year.

- On Cruise lines all TV have a channel which is bridge view, pure uninterrupted live video feed.

- All ships use Heavy Fuel oil, but EPA laws are very strict, wish any ship environment official can help with hard numbers regarding Exhaust gas purification. If a seaman throws a tissue, even in International water, can lead to straight warning,Three warnings and kicked off.

- Oil to gas as a fuel is like crude carrier to VLCC. Gas is cheaper now, just like VLCC we're in thing, with oil at $100 per barrel.

- Attached are pics of harbor master climbing the ship before channel to port to assist in navigation

Quote:

Originally Posted by V.Narayan

(Post 4327964)

Ithaca, thank you for sharing. The size and immenseness boggles the mind. Very proud to see how Indian merchant navy officers now dominate the officer cadre of the world's shipping and carry a reputation for thorough professionalism which has replaced the hard drinking hard swearing old sea dog culture of 60 years ago. Give us some two liners on unusual things involved in sailing such ships. The video talks of stopping & turning. Tell us about fuel burn, weight & size of the propeller, engine size, how many on the bridge at a time, does the ship bend and warp, how do you navigate inside the ship-getting lost can be a problem, is the shaft ever removed for maintenance or does it stay in place through the life of the ship. etc.

|

Apologies for multiple posts here but got hold of a document from my archives regarding the requirements of power, speed, propeller size and weight for container ships. Hope it helps. It might be a little over the top because of terminology used but you can google everything to understand.

Its been quite some time since I last sailed on container ships, but yes my first ship was a big 5000TEU container with 66120 BHP Sulzer engine. Presently the container ships of around 18-20K TEU are either already at sea or under construction.

Hope you will get most of the answers for your technical queries.

Regards.

To the Aquatics from an Avian - Ithaca, Brumby, Jeroen, ritz3645, aspire, Behaln, thank you very much for the effort and time to pen your answers and sharing your knowledge. Most interesting and informative. I am absolutely amazed when you say diesel producing 100,000 bhp; and to think this is a reciprocating engine and not a turbine.

Q. When you say container ship doing 25 knots is that the maximum speed or the sustained steaming speed. Either way it is a lot.

Q. I can understand that the big oil carriers cruise at 13 knots with the direct connect engine turning at 75 to 80 RPM. What about the container ship? Are they also direct drive or geared. Are its engines slow revving or more medium speed is 700RPm with a gear box.

Quote:

Originally Posted by Jeroen

(Post 4327997)

Here is another interesting marine engine video: This is medium speed engine on a Cruise ship where they swap the crankshaft.

|

Thanks.

Quote:

Originally Posted by aspire

(Post 4328069)

Comparing navigating on seas with driving on Mumbai traffic, The way Jeremy was asking questions to the captain, seemed a bit racist to me to be honest. I am sure it takes immense skill and expertise to captain this ship.

|

Navigating that ship certainly needs a lot more wisdom and maturity, amongst other attributes, than what Mr J possess.

Quote:

Originally Posted by Ithaca

(Post 4328129)

Most VLCCs will consume roughly 100 ~ 120 MT of Heavy Fuel oil a day

|

The oil the ship consumes in a day is greater than the all up weight of a medium sized airliner like the Boeing 737!

Quote:

Originally Posted by Ithaca

(Post 4328129)

Timer is set by master - usually 15 minutes - and the watchkeepers on bridge during watch have to activate any sensor to reset it to 0.00 sec.

|

Now that is something we could use in an aircraft cockpit. On long flights some pilots have been known to doze off, literally.

Quote:

Originally Posted by Brumby

(Post 4328145)

The propeller will be around 8-12 metres in diameter

|

The physical forces on such a large propeller operating in a non-compressible fluid is quite astounding.

Quote:

Originally Posted by Brumby

(Post 4328180)

Diesel electric propulsion provides the most economic propulsion without having the side effects of slow steaming (moving at slow speeds). Slow steaming is known to result with reduced intervals for maintenance schedules and hence extra work for the people on board and shorter life of the engine components.

|

I can understand why diesel electric is more efficient - by running the diesel at a constant optimum RPM I assume. But what is the piece about inefficiency at slow speeds. I assume it is that fuel consumption shoots.

Quote:

Though I am no expert, but in this profession for quite some time now. Seafarers usually suit the saying "Jack of all trades, Master of none":)

|

Master of the shipclap:

Quote:

Originally Posted by Brumby

(Post 4328145)

"weight & size of the propeller

Will find out this answer and get back.

The attached sheet has made a mistake on the propeller size though.

Cannot be 1000 meters diameter, should be 100 meters instead."

The propeller will be around 8-12 metres in diameter, no ship (as of now) has a draft of more than100 metres to accommodate a 100 metre dia propeller.

Regarding removal of shaft, as mentioned, every 5 years its mandatory to inspect the shaft seals, bearings

|

The propeller dia mentioned by me is a mistake - should have said 10 meters. stupid:

@ Brumby, thank you for succinctly explaining the tail shaft inspection & withdrawal procedure.

| All times are GMT +5.5. The time now is 08:11. | |