This forum being one which is frequented most by Car enthusiasts and containing loads of info on cars, I felt, maybe I should try to contribute in a little way by starting a thread on the Car Manufacturing process. (In ways there is a lot of similarities with the Commercial Vehicle Manufacturing process as well as the Two Wheeler manufacturing process and I'll try to have some insights to be given on them too.

@FellowBHPians: Anyone with knowledge on the Manufacturing process, please contribute to make this thread rich!

@Mods: In case there is a thread already on the topic, please merge it (apologies if I would have missed finding one)

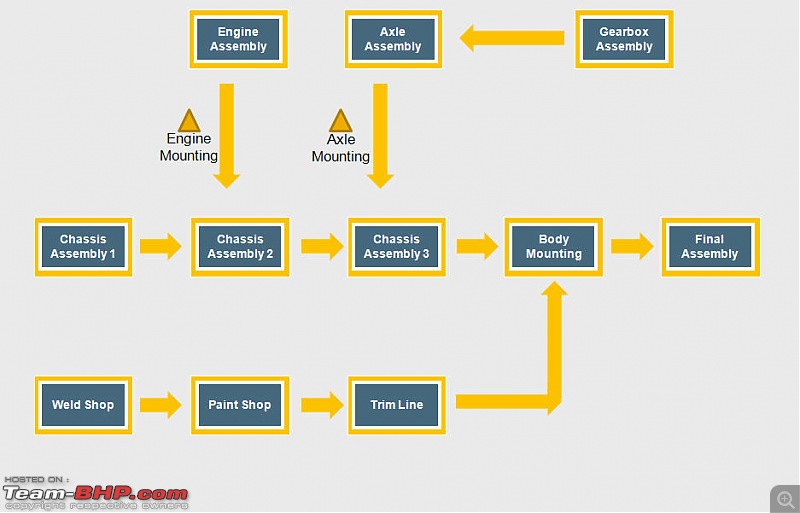

A car manufacturing process is one of the most interesting and technologically advanced. Probably one of the most advanced in terms of the use of technology as well as execution of complex logic. To appreciate the Manufacturing process one needs to know that an automobile comes together with 3000 - 4000 parts and a typical manufacturer churns out anywhere between 700 - 2000 vehicles (There are some though with a production capacity of about 250). The synchronization of the Auto Manufacturers with the Tier 1 Suppliers have to be spot on as delays or large quality rejects can cause a big dent to the production volumes (which would mean enthusiasts like us would need to wait more for our new cars). Lot of interesting production techniques are used in todays manufacturing and it has evolved a lot from the Mass Production system of Henry Ford and then the Japanese manufacturers (Toyota specifically) bringing in the Lean Production Concepts. Today it is one of the most agile and adaptive and the concepts of production methodologies are so strong that now we find most discrete manufacturing processes following Lean to even some IT companies... anyways.. not to digress too much from the "core" topic, let me try to talk about the life of a car inside the plant :-)

Press Shop : This is where the production process starts, with most of the Metal parts getting pressed out of Steel Sheets. The door panels, Roof, Bonnet, Boot Lid etc are typically pressed in to form the basic structure of the automobile. The pressing process is a multi-step process where the sheets are pressed into shape in stages.

Weld Shop : The Weld shop is typically the place where the automobile is born. The point of birth for most monoque design cars are where the Underbody takes shape from the Pressed parts. It can be the marriage of the Underbody front & rear or in some cases the the entire underbody can be a single pressed unit. In stages, the Side panels, the roof are then welded to the underbody and the automobile begins to take its shape. The welding process is typically

Tungsten Inert Gas (TIG) welding, mostly done by Robots and is a treat to watch, wherin you have all these multi axis robotic arms work in unison and utmost precision.

Paint Shop :

Paint Shop : The output of the Weld Shop is called as a BIW or a Body In White. These are the cabs that enter into the Paint Shop. The painting process is one of the most complex and cleanest of process. The Paint booths for example have to be completely dust free. The various sub-process in the Paint Shop include

(a) Pre-treatment where the BIW is dipped into an electrolyte solution which would help in better paint deposition on the Metal.

(b) Sealant : Prior to the application of paint, the BIWs enter the sealant area where the sealant is applied.

(c) Paint Booths: The BIWs enter the paint booths, for the final painting process. This is typically an area where it is mostly robots again which do the job, or you would need highly skilled human workforce. A highly clean environment is maintained and access is limited and if at all, it has to be with wearing the right kind of overalls.

(d) Oven: The painted bodys are then passed through the oven where the final baking process of the Paint takes place.

(e) Wax Booths: Where application of a fine layer of wax takes place. This is sometimes skipped for some local market vehicles or the lower variants.

(f) Polishing : One of the most laborious processes and the most time consuming one as well. Each of the cars are polished to give the right shine and gleam. A simple rule of thumb, the longer and more elaborate the Polishing process, the better is the shine. So the costlier the car, the longer would have been the polishing done on it.

Engine Shop and TransAxle

Engine Shop and TransAxle: There would be no point talking about the Automotive Production without talking about the Heart of the Vehicle, i.e. the Engine and along with it the TransAxle. The reason I brought it in here after the Paint Shop Processes is because the birth of the Engine for a car, typically happens when the Vehicle is in the paint shop. The birth or identity of an engine is given when the Engine Block gets machined and the the EIN (Engine Identification Number) is punched into the Engine Block. The assembly process of the Engine is again precision controlled with various stages of machining the Pistons, fitment of the Piston rings and then lowering the assembly into the Engine Block. Finally the Engine Head comes and then the engine undergoes a series of tests. One of the most significant being the Leak Test and pressure tests. The engines are then "pre-run" in some cases before getting mated to the TransAxle. The TransAxle, consisting of the Gear Box assembly is typically made ready and made available at the marriage point. The Sequence of production of the Engine closely follows the Production of the Vehicle Body and that of the TransAxle closely follows the sequence of engine production.

Trim/Final Fitment

Trim/Final Fitment This is the last and final stop for the automobile in the production process. When out of it, the vehicle is roadworthy with all its parts working in unison providing locomotion!!!

This part of the production process is where most of the fitment is actually done by human hands. The complicity lies in making the right parts available in the right sequence of production at the fitment area. (Right Place, Right Time, and Right Sequence is the key to it all). Most of the components of the car like the windshields, trims, Steering Column, electronics and the engine - vehicle marriage happens here. Finally after the wheels come in, the vehicle becomes capable of moving by its own power. Before getting dispatched out of production, the Vehicle undergoes stringent quality tests as well as the various important component information of the vehicle is captured and stored into the production databases. Following the drive test, the vehicle reaches the yard from where they are dispatched to the dealership and finally to waiting customers

Note from Team-BHP Support : Please note that it is imperative for you to upload pictures directly to the Team-BHP Server. Click here (Uploading photographs directly to Team-BHP) to view our simple help article on uploading pictures. Thanks.

Note from Team-BHP Support : Please note that it is imperative for you to upload pictures directly to the Team-BHP Server. Click here (Uploading photographs directly to Team-BHP) to view our simple help article on uploading pictures. Thanks. (6)

Thanks

(6)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

is how the test drivers may drive our future cars.

is how the test drivers may drive our future cars.

. But yes, you can say the cars are tested!!!!

. But yes, you can say the cars are tested!!!!