While I was waiting for green/black belts clarify my thoughts, I discussed this with another BHPian. He wondered why I assumed Range/6 = σ, and what is the meaning of mean shift by ±1.5σ.

So I am further

spit-balling.

In the walking stick example, I had mentioned that the lengths 991mm-1009mm are limits of the tolerance, and that the shortest stick is 991mm and the longest stick is 1009mm for this sample. This is either perfect zero defect or near zero defect scenario. But taking the worst case scenario, what process comes closest?

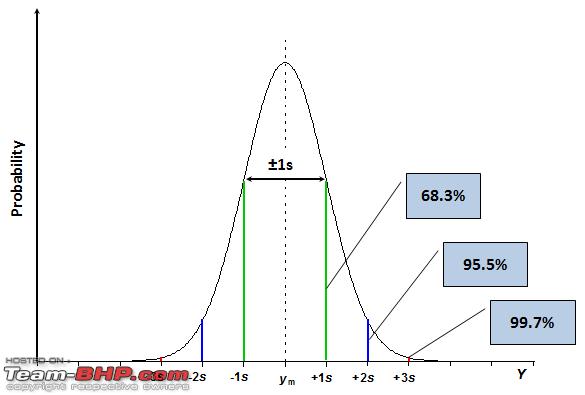

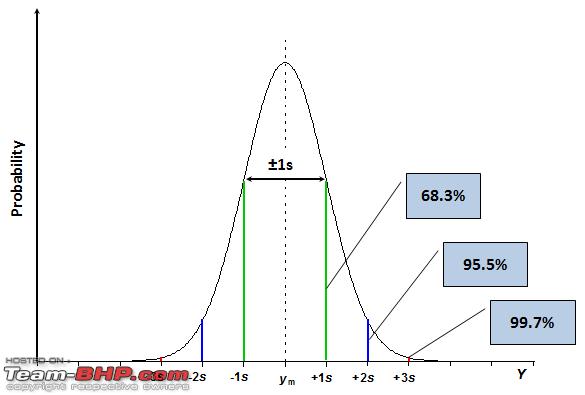

1σ Process: At least 31% walking sticks will be outside of 991-1009mm range. So this can't be it.

2σ Process: At least 4.5% walking sticks will be outside of 991-1009mm range. So this can't be it either.

3σ Process: Only 0.27% walking sticks will be outside of 991-1009mm. So this could be the worst σ value we could consider.

That is why I assumed 3σ process, and got σ = Range/6, or 18/6 = 3mm.

But there is one major problem with 3σ process, it has no tolerance for mean shift. As long as the mean is at 1000mm, everything is fine. However, after some wear and tear, the machine might shift the mean away from 1000mm. What if it starts making sticks of mean length of 1002mm, while the σ remains at 3mm. The ±3σ range now shifts to 993mm-1011mm. The 3σ deviation on the higher end is now outside of specified tolerance.

The six sigma allows for ±1.5σ deviation in the mean value itself. That means the machine can shift the mean from 1.5 times σ in either direction. But that is not possible while keeping σ at 3mm. At 3mm, the mean can shift from 995.5mm to 1004.5mm, if you add another 9mm (3x3mm) for 3σ deviation, we are looking at 986.5mm to 1013.5mm. Too many rejections.

If the machine is replaced or improvised to provide σ = 2mm, then the ±1.5σ mean shift will be between 997mm-1003mm. The 3σ deviation will be 6mm (3x2mm) in either direction, restricting the extremes to 991mm-1009mm. While the range has remained same, due to decreased σ, the probability of sticks falling outside of tolerance range would have gone from 0.27% to 0.00034%.

PS: What happens if distribution is not normal? Is six sigma still applicable?

) and give you the certified certificate. This process is same for all institutions.

) and give you the certified certificate. This process is same for all institutions.

This is an hypothetical scenario, I can't measure each hypothetical walking stick and calculate the actual standard deviation using the formula. Hence the approximate method.

This is an hypothetical scenario, I can't measure each hypothetical walking stick and calculate the actual standard deviation using the formula. Hence the approximate method.