Team-BHP

(

https://www.team-bhp.com/forum/)

"

The Most Beautiful Car Ever Built" - Enzo Ferrari.

When Sir Williams Lyons, Jaguar's founder, unveiled the Jaguar E-type at the '61 Geneva Motor Show, its sculpted form wowed everyone present, including the great Enzo Ferrari.

Pic Source:

Jaguar Heritage

A brief history of Jaguar:

1922 - Jaguar Cars Limited is founded as the Swallow Sidecar Company by two motorcycle enthusiasts

1945 - Swallow Sidecars changes its name to Jaguar

1961 - The Jaguar E-type is launched

1968 - Jaguar merges with British Motor Corporation, subsequently taken over by Leyland, which itself was eventually nationalised as British Leyland

1984 - Jaguar is split off from British Leyland

1989 - Jaguar is acquired by Ford

2008 - Ford sells Jaguar Land Rover to Tata Motors for $2.3 billion. Ford never made a profit from Jaguar. In recent years, Tata made over 3/4th of its group profits from JLR.

After the Jaguar X-Type's production ended, a big hole in the portfolio is absence in the entry-level premium segment, that is the C Class / 3 Series / A4 category. I expect this to be corrected in the coming years.

For those of you interested in the manufacturing of automobiles, be sure to read GTO's detailed report on Ford's Chennai factory

at this link.

We are in Day II of the

Jaguar Land Rover Engineering and Drive programme, and are visiting the manufacturing facility where the Jaguar XJ, XF and XK are built.

You can read about Day 1 of the programme

here.

This factory has had a chequered history. In the late 30s, it used to be the facility where the legendary Spitfires & Avro Lancaster aircraft were manufactured. Just before the factory, at the roundabout, there is an art piece that celebrates the association of Spitfires with this town. The roundabout is called the Spitfire circle.

Here is a picture showing the assembly of aircraft at this facility. The exact figures are not known, but it is believed that about 305 Lancasters & 11,780 Spitfires were manufactured here between 1940 & 1946.

Pic source:

Battle of Britain - The Beacon - Royal Air Force Museum

Now of course, it is a far cry from those days. We are told that the factory employs about 2500 people today.

Notice the "F-Type" marking in the picture above? Yes, that's the spiritual successor to the E-type that Jaguar is building to take on the Porsche & Mercedes roadsters. The F-type, which is the production version of the C-X16 concept, marks the return of Jaguar to its sports cars, after decades of focus on luxury sedans. The company is betting big on the F-type which will be launched in the early part of 2013.

The XJ XFR & the XKR in the lobby area:

We are then handed over fluorescent safety jackets:

And a wireless earphone for 2 purposes; One, to protect our ears from the high decibel sounds in the factory and second, to hear our guide's running commentary on the tour:

The first structure we see upon entering the production line are the 6 HUGE stamping machines. These are almost a storey & half tall, and all of the six are connected at the top. The operation is entirely computer controlled & handled by robots. Human role is only to do with observation, and implement any changes to the stamping dies:

The 6 rigs stamp a panel in stages, out of aluminium sheets. All Jaguars are made almost entirely of aluminium (there is no steel used in the body). Trivia : 50% of the XJ body structure is made from recycled aluminium. Quantity? Aluminium worth 12,000 soft drink cans:

The robot picks up a sheet of aluminium using suction cups, and precisely places it on the rollers. From the rollers, another robot lifts the aluminium sheet and puts it in the first of the 6 stamping machines. We were told that a typical stamping operation cycle produces 9 days of production stock:

The machine does the stamping, after which a robot passes the panel onto the next stamping station. The process is progressively repeated six times before a panel is considered complete:

Here is an example: See what happens between press B1 & B3 for the same part. The die used in each step and the load set-up are different. In B1, the section is being formed and in B3, holes are being pierced:

The stamping operation is fast & the robots are kept really busy, moving their arms from left to right in clock-like precision. As the panels leave the final stamping station, they undergo quality checks by engineers who place them in specially designed bins. Almost all of the bins in the XJ line carry the

"Aluminium Only" tag. This is to ensure that no contamination with any other metal takes place. These bins are made of steel, but their inner side is coated with a special resin to prevent aluminium from coming in contact with the steel

The QA station for checking the stamped panels. We were told that the first panel, middle panel & last panel of each production run are taken as samples and thoroughly tested for tolerances:

The sample panels being setup on design spec panel rigs and carefully placed on a test bed. Notice the perforated floor area? These perforations are to accurately place the design spec rigs, which then proceed to laser beam tests for measurements. In the picture below, you can't see the laser equipment, but notice the 2 white / black stands at the end of the perforated floor. The laser machine is on top. You can see a hand in the top left corner of the picture pointing towards the laser:

The area is full of design spec panel rigs. They are neatly stored with the respective numbering and codes:

A die for the panel stamping. 45 minutes is what it takes to change a die in the stamping station:

Here is a die being moved, via the overhead crane line, to its stamping station. Just rewind to pictures of the stamping station above...you'll notice rails in front. The die is moved in / out of the stamping stations using these guide rails:

This part of the factory is just full of dies! They are seen everywhere, piled one on top of the other:

The one replaceable part of the die. See that vertical grooved spacer in the picture below? This part wears off after use. The rest of the die is practically bullet proof:

Talking of bullet proof, the atmospheric pressure inside the factory is kept higher than the pressure outside. This is to ensure that when factory doors open, the high pressure air from inside the factory goes out, and no air from outside comes in. The big pipes running on the roof line pump in high pressure air:

As we move across the factory, we are told that the technological investment & modernization done by Ford is paying off. We could also tell that the folks at Jaguar are really happy with the TATA management. The sentiment goes like "

Jaguar was a small fish in a big pond with Ford. With TATA, we are big fish in a big pond". It is also evident that TATA has given JLR a relatively free hand, without many significant changes. This has really gone down well with the JLR team.

Once we are through with the stamping section of the production line, we move on to the Body Construction area of the XJ. I have to say this :

God bless those wireless earphones, else our ears would have gone numb with the high decibel sound of the machines in the stamping section:

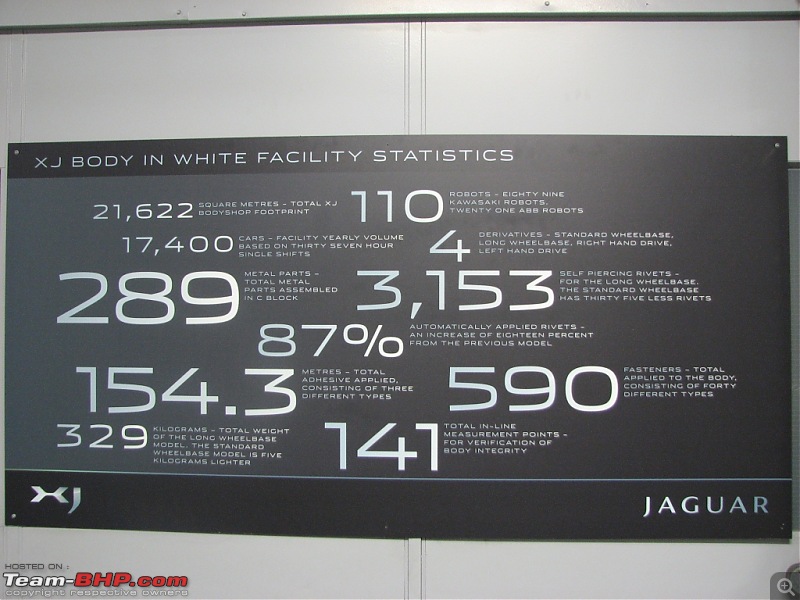

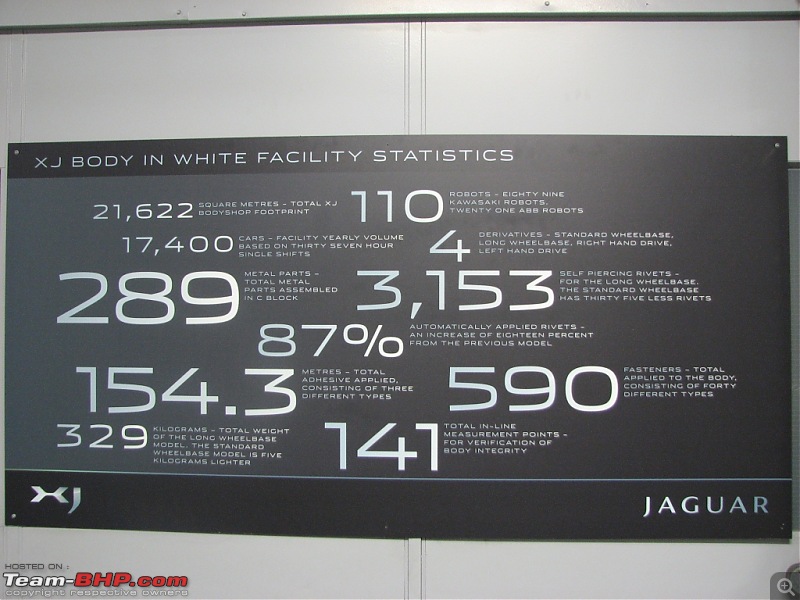

We are first taken to a large reception area where we see a cut section of the XJ body in polished aluminium, and an info-graphic of key figures for the XJ manufacturing process. The info-graphic below is self explanatory. Notice the absence of 'welding' in the manufacturing process. There is no mig/tig welding involved at this plant. Just rivets in combination with adhesive!

Cut section of the XJ body. Notice how shiny the aluminium is. We asked if a customer can order this finish, but the answer was in the negative. If someone from the Middle East sees this, he'd have probably placed an order for a dozen right then and there:

The cut section shows the various aluminium components involved. The manufacturing process of aluminium parts entails 3 types:

1. Stamping of body panels (covered in the post above).

2. Casting of aluminium parts. See the picture below. The upper portion of the door / window is a casting part. That can't be stamped, and one of the reasons is that the tolerances in some parts have to be perfect. For example, the screw-holes in the door near the B-pillar have to be absolutely perfect with no tolerance at all, hence casting is used.

3. Extrusion (explained later in this post).

The guide opens the door for us and we see rivets that are used to join the aluminium parts together. Some 3,153 rivets are used in the making of an XJ. The rivets are made of steel and are coated with a special alloy to ensure that no galvanic corrosion happens between steel & aluminium. Aluminium rivets can't be used as they will not be hard enough to pierce through the aluminium panel:

Here is a section of aluminium plates which shows the x-section of the rivet, once it has pierced through:

Below is the 3rd type of component used, that is the extruded ones. The front rectangular cross member is an aluminium part made from the extrusion process. This allows for fine-tuned localized strength. For instance, in the picture below, the bottom left corner of the x-member & the middle left portion are areas whose thickness is greater than the rest of the part. Why? Simply because additional strength is required only at these points. The practice saves quite a lot of overall weight from each part:

We then head to the

real area of action. The body construction line is a maze of robots & huge stacks of parts for assembly. I noticed that almost all the sections had wire-mesh to prevent any person from entering the assembly line area (where the robots are working). Each station has a computer terminal from where the robot could be controlled & data sets loaded. The station below is an example of the same. Here you see Kawasaki robots riveting the underbody chassis; notice the black colour spool & blue colour belt with the rivet in the center of the picture:

Not everything is done by robots though. Many of the part sub-assemblies requires human intervention. Here are screws being embedded in the part (you'll see 3 screws on the left side). This person is wearing earphones to protect his ears from the high decibel noise:

The same production line manufactures the XJ & the XJ-L (LWB version). BTW, only the XJ-L is sold in India. A panel is simply added to the XJ frame to make it an XJ-L version; the right end of the section is an extension made for the XJ-L:

This station is where the side panels are being riveted to the underbody frame, thus giving first semblance to the individual parts of a car that will eventually become an XJ. The side panels are the biggest parts that are stamped. The robots lift the side panel from the stack and then, in a split second of acrobatic moves, place it for riveting. There is a bit of human intervention required to place the clamps:

After the first layer of side panels are riveted, the outer side panel is called up. The person in charge carefully aligns the outer panel, after which robots complete riveting the side body panels:

One can see the contours of the vehicle taking shape. It now begins to look like a car, rather than just individual pieces of aluminium parts:

The line now moves on, and we come across a station where strips of these tapes are applied. Notice the different black colour tapes / strips in the picture below. These are applied to different parts of the frame. The hammer? Well, no factory can ever be complete without a hammer. There is always one nearby:

Tape being applied:

The line moves on to stations where the bonnet is attached:

And then to the boot area assembly:

The sub-assembly of the hood & the LCD (Luggage Compartment Door, a formal term for the boot lid) is a small factory in itself. They have a separate area for the ABB robots:

The ABB robots are used for parts where there is NO tolerance level permitted, and 100% precision is needed. The Kawasaki robots would have some tolerance levels. Here, the robots are performing the roller operation of fusing the edges of the LCD tub:

The ABB robot control screen shows the various operations being performed:

One can also see robots applying the aircraft-grade adhesive. The adhesive is used wherever parts are joined together. Surprise fact : It is actually the adhesive that provides the core strength in holding the joints together...the rivets are only there to provide supplementary strength. Remember the info-graphic in the posts above? Some 154.3 meters of 3 different types of adhesive are used in an XJ. In total, that isn't even 1/2 kg of adhesive per car:

The view of a line from one of the stations. Notice how parts are stacked near a station and the sub-assembly is underway. The sequence can be summarized as : Individual Panel -> Sub-Assembly -> Assembly (one or more times) -> Main Production Line -> Part on frame for body construction:

Door panels and side fenders are now attached to the frame. It moves to a line where there are no robots, but only sheet metal experts. These are long timers and their expertise is just that -- sheet metal. They can look at the body frame, pick the area that doesn't seem right and then, hammer it back in shape :)

They ensure that the overall body frame is within tight specs. No robots, just them and their trusted hammer. They do take measurements of the body panel gaps using feeler gauges:

After this, the body frame moves on to the fitment of other critical parts. You can see magnesium components in the body frame (the black coloured part):

The body frame moves on to its final stages of the journey which is called the "customer acceptance line". There are hundreds of fluorescent lights above:

Experts go over the body frame with a microscopic eye and mark out any imperfections:

A marking on the hood:

The frame goes through a wash. Water is sourced from an underground borewell:

The absence of welding machines makes the plant use very less water. The mini water-plant at the line:

Finally, after 110 robots working on 289 individual parts, some 3153 rivets & 590 fasteners, 154.3 mts of adhesive and 141 inline quality checks, 329 kilos of the finished body frame is ready and comes out like this. Can you see the Jaguar in here?

After an amazing experience at the body construction block, we move on to the XJ trim & final assembly block. This is where we will get to see an XJ roll out of the plant, ready for the stockyard. The production line caters to 4 variants of the XJ; the XJ & XJ-L in both, RHD & LHD combinations:

An info-graphic of all that goes into the trim & final assembly line. 92 stations and 946 parts used:

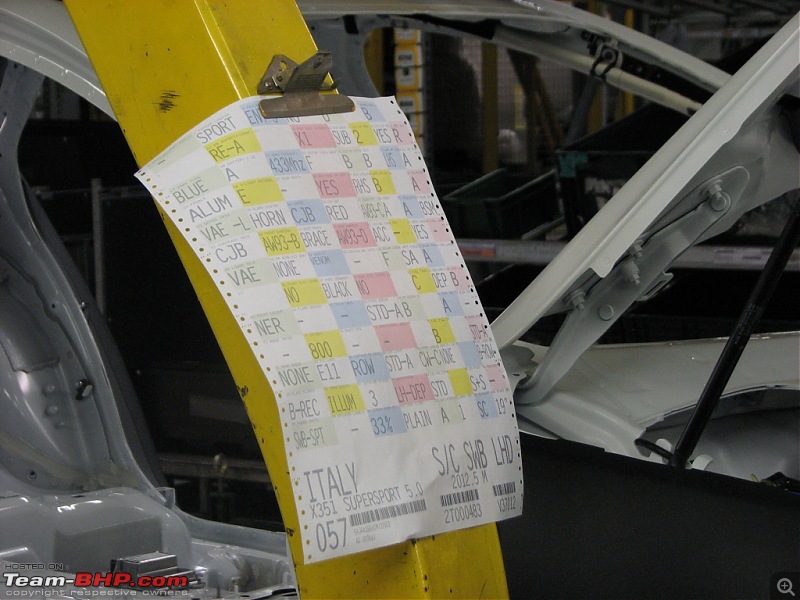

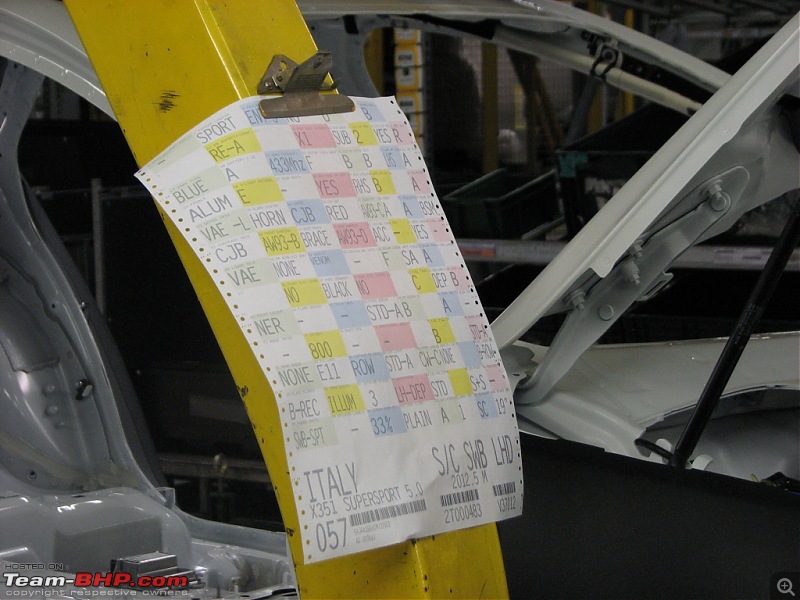

Displaying the block layout and process flow. In this block, each part that goes into the XJs is for a specific vehicle, and is numbered (computer controlled) for exact identification in the supply / production chain:

The only robot in the trim & final assembly block. Used for some processing on the windshield:

The first to go in are the various wiring harnesses. Here, you see the wiring of the engine bay area being completed. Notice the paper on the LHS:

That paper is the master identity document that will be referred to at each station in the line. It contains important data such as the country this vehicle is being built for (location is important for fine-tuning of various parameters for local laws, LHD / RHD, engine options et al). Also note how the inside of the car is completely bare:

The different wiring harnesses being put into the XJ. Notice the first layer of carpets & firewall cladding being placed:

The rear seat area:

The seat belt assembly:

Next in line is the dashboard. There is a pile of dashboards nearby. These are the LHD versions:

Lights being fitted:

The car moves on to the next station:

Fuel tanks are installed. The production line has moved up, the car lifted and then a U-turn to arrive at the next station. Notice the line lifts at the end for a U-turn:

The line comes down again for the mating of the body & engine to happen. The most interesting part of the process, if you ask me. It's like watching a wedding :)...the unison, the coming together of 2 critical parts that will live together forever:

The engines aren't made in the Jaguar factory. Instead, they are manufactured at a Ford facility where Jaguar has a "

plant-in-a-plant" structure. The entire area in that Ford factory is as per Jaguar's specifications and is painted in Jaguar colours. Even the controls are from Jaguar. We were told that Jaguar is planning their own engine manufacturing facility. Currently, their production capacity is limited due to the dependency on Ford for engines:

The engine drive-train assembly is positioned below the body frame and then, carefully lifted up:

Mating done!

I could see the propeller shaft that drives the rear wheels of the XJ. Must say that it looked very robust, and fully capable of handing / transferring the enormous power & torque:

Once the engine / drivetrain are mated, a lot of tests are performed to ensure that all is in order. In each of the pictures above, you'll see the master identity document on the vehicle:

The bumpers are fitted next:

Followed by the exhaust system:

Its time for the XJ to wear a nice pair of shoes. Fat tyres from the nearby station are used. Each tyre is marked to indicate what goes on which side:

With shoes on, it's time for the XJ to come closer to the ground and move on to the next stage:

| All times are GMT +5.5. The time now is 08:57. | |