Recently i came across this interesting article on Engine Oil Cooler from Mocal oil coolers. I'm uploading the entire stuff from their web page

http://www.mocal.co.uk/FAQ.html WHY DO WE NEED AN ENGINE OIL COOLER?

The design of any car, with the exception of the many that are fitted with an oil cooler as standard, will ensure that just sufficient cooling by airflow across the sump takes place under normal conditions of use to keep the oil of a chosen viscosity at its design temperature, without for reasons we will discuss later, overcooling. It follows that changes to the specification or usage of the vehicle can cause the oil to exceed its design temperature. The changes most likely to cause an increase in oil temperature are:

- Increase in rpm, the oil cooling requirement of an engine will increase up to threefold for an increase of 1000rpm, making this the most common cause of engine oil overheating. German specification cars are always designed with extra oil cooling because of possible high speed running on unrestricted autobahns. On the track the almost constant use of high rpm makes an oil cooler mandatory, even in an unmodified engine.

- Obstruction of airflow to the sump, caused by fitting sump guards, spoilers etc.

- Oil circulation through a turbo charger not only lubricates but also removes a large amount of heat which will add to the overall cooling requirement.

- Increasing the power output of the engine will increase combustion temperatures but except in the cases where oil is used to cool the piston crowns, most of the excess heat will be taken away by the water coolant system.

IS OVERHEATED OIL A PROBLEM?

Oil as it gets hotter becomes thinner (less viscous), losing its film strength, this film strength supported by oil pressure is what keeps bearing surfaces from touching, once bearing surfaces touch, metal is removed, clearances widen, oil pressure drops, the contact surfaces are further worn away and immediate engine failure takes place.

It is also worth considering that, in the modern engine, oil is used as a coolant of pistons crowns, if the top of the piston becomes too hot detonation takes place causing loss of power or even piston/gasket failure.

Some oils are advertised as being able to cope with higher temperatures, this is easily achieved by supplying a more viscous oil that will have greater film strength for a given temperature, the down side is that at lower temperatures there will be higher friction/pumping losses.

The oils recommended for everyday motoring will have a viscosity sufficient to cope with the warmest extremes of expected motoring conditions, by fitting an oil cooler and oilstat a very low viscosity oil, giving increased power and decreased fuel consumption during relaxed motoring can be used.

It will be appreciated from the foregoing that there is no optimum engine oil temperature, modern oils will not be damaged by high temperatures although some may leave varnish deposits which can block oil ways. Every engine will have a different oil temperature requirement but, as a general rule temperatures in excess of 110oC should be avoided.

WHAT KIND OF OIL COOLERS ARE THERE?

OIL TO AIR COOLERS

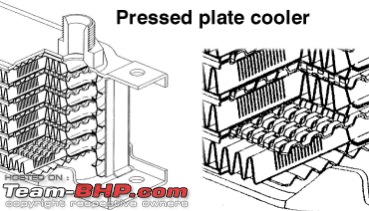

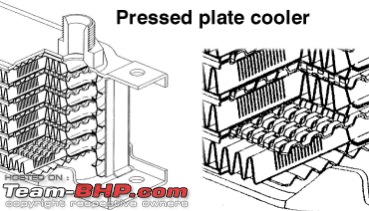

Pressed plate type:

The most popular oil to air coolers are the pressed or stacked plate range of coolers which were first made in the late 50’s, These coolers built to our specification since 1965 must rate as the single most commonly used component on racing cars world wide.

The cooler consists of a variable number of aluminium pressed plates forming oil ways and end tanks, the oil ways contain turbulators which not only break down boundary layer effect in the flow to obtain maximum heat dissipation without undue pressure drop but also because they are brazed to both surfaces of the plates hold them together under pressure. The oil ways are interspersed with aluminium strip louvered and formed into corrugations to provide airways.

The design is beautifully simple and efficient and most suitable for mass production, but being made from expensive press tooling it is restricted in thickness and length but not height.

Tube & Fin type:

Making a comeback is the tube and fin cooler consisting of a number of preformed flattened tubes surrounding turbulators and separated by corrugated airways, this is a more flexible design allowing infinite lengths, depths can be in multiples of the tube width, however end tanks have to be made separately resulting in a more expensive and heavier assembly. The finned tube type of oil cooler is an anachronism only suitable where space is unlimited.

Plate & bar type:

The current money is no object attitude prevailing in the top echelons of motor racing has resulted in a couple of aerospace heat exchanger manufacturers becoming interested in supplying their plate and bar coolers to the racing car industry they are fabricated from strip, and can be made to the exact size to suit the customers packaging requirements.

OIL TO WATER COOLERS

Laminova Cooler

The most common the tube and fin in a shell type cooler, popular in marine usage is too heavy and cumbersome. Up to recently the ubiquitous pressed plate type of oil to air cooler but in a fabricated water jacket has been the answer, now the amazing Laminova laminar flow cooler has opened the automotive market to oil to water coolers. The main components are two aluminium extrusions, one forming the outer shell, the other the core which by some magical process has been machined to provide fins 0.2 mm ( 7 thou) thick and 3mm high and spaced 0.3mm (11 thou) apart through which the oil flows, such restrictive finning would normally cause a huge pressure drop, but by introducing channels in the finning, the oil flow is kept laminar as opposed to turbulent as in other cooler designs and the pressure drop remains low. The water flows through extruded channels in the outer core, removable plugs/restrictors control water pressure drop This construction is pretty versatile the shell and core being made in 4 different diameters with, in theory, infinitely variable lengths. For very compact installations, cores may be slotted into each other. The secret to obtaining the best performance is to tailor the removeable plugs to obtain the best oil temperature drop without compromising the water temperature.

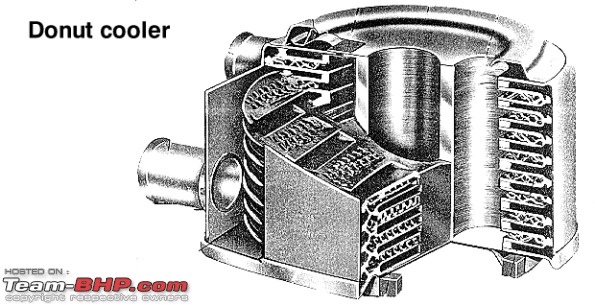

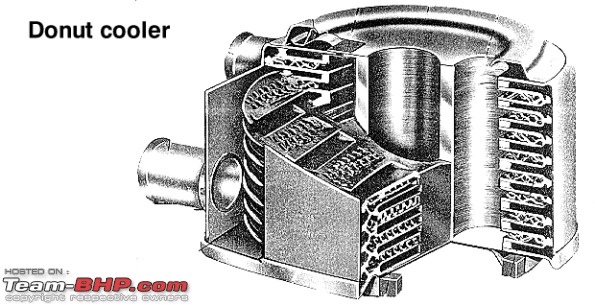

Donut Cooler

The donut cooler has a variable number of pressed plates forming oil and water ways, the oil ways containing turbulators. A pressure relief valve is incorporated to allow oil to bypass the oil ways during cold starts, excessive oil flows or blockage. Pressure drops through this type of cooler are high.

WHICH ARE THE BEST OIL COOLERS?

All the coolers discussed here, except the finned tube and the Laminova are as efficient as each other in so far as greater heat rejection can only be obtained at the expense of oil pressure drop or air pressure drop, On the oil side the performance is controlled by the design of the turbulators, if you increase the amount of turbulence and make the oil follow a more tortuous path so as to bring it into greater contact with the cooling surface area to obtain greater heat dissipation you will increase the oil pressure drop, often the very problem you are fitting an oil cooler to avoid.

On the air side if you increase the pitch of the corrugations or increase the depth (front to back measurement) you will increase the air pressure drop, thus requiring higher vehicle speed or sophisticated ducting to obtain better results.

The fluid to fluid cooler becomes viable when packaging constraints do not allow for mounting a cooler in the airstream and where there is enough thermal capacity in the water radiator to cope with the extra loads, because engine coolant warms more quickly than the oil, the oil warm up is quicker which can show benefits in engine wear and economy. The Laminova cooler is able to achieve a high degree of efficiency within a slim envelope because the unique finning provides an enormous cooling surface area in contact with the oil Although not as cost effective as the pressed plate cooler, there are bonuses in that it is very strong and unlikely to be damaged in any but the biggest crash and it may be stripped for cleaning purposes, invaluable after an engine blow up.

The donut cooler is designed for ease of installation, fitting between filter head and filter and using a bypass water flow (in a similar fashion to a car heater) , as it cannot use the full water flow performance cannot match the Laminova, it is made of stainless steel thus incurring a weight penalty compared to all others.

The bar and plate coolers are not, in their construction, any more efficient than the pressed plate, tube type or Laminova coolers, their value lies in their being able to be made to exactly match the vehicle requirements where all relevant parameters, oil flow, air flow, temperatures, acceptable oil pressure drop, and air pressure at varying speeds are known. These hand made coolers are priced in thousands of pounds.

We think that the design of the pressed plate cooler is the best compromise to cover all types of motoring and motor sport, irrespective of price, the best of the competitors offer very similar performance because their design closely follows our product. However there are now a number of Chinese made copies on the market which due to lack of investment in proper tooling are heavier but worse are inadequately brazed resulting in early failure when subjected to pressure cycling tests. Unless a cooler has genuine Mocal, Setrab or PWR labels we suggest you avoid. In the literature of one of the many sellers they claim "these coolers have been developed from years of practical experience in the Motorsport field".We very much doubt that anyone in the Chinese factories has ever heard of a racing car much less have ever seen one.

Heat dissipated is not necessarily the sole reason for choosing a cooler, A larger cooler may be chosen to avoid excessive oil pressure drop, be aware that the more rows/tubes and the shorter their length the smaller will be the pressure drop or in the case of the Laminova the longer the cooler the smaller the oil pressure drop although the water pressure drop is greater.

--

Addendum: The donut oil coolers are used where the filter used is of the metal canister type, i.e., spin on fitment. The Oil cooler mentioned in this thread is similar to the donut cooler in operation but not the same because filter is a cartridge type.

(6)

Thanks

(6)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

Now have to see if it fits, else return it. Well it should but i'm worried about a pipe going into the AC compressor which looks kind of positioned in front of the cooler assy so need to check the clearance between it and the cooler box.

Now have to see if it fits, else return it. Well it should but i'm worried about a pipe going into the AC compressor which looks kind of positioned in front of the cooler assy so need to check the clearance between it and the cooler box.