| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  70,757 views |

| | #1 |

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,918

Thanked: 10,064 Times

| PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery This report has been jointly written with Rehaan - Thanks to him for the expert observations, helping with the compilation and making the technical stuff easy to understand! Here's an interesting fact to start this report. Automotive battery sales rise by 15-20% in May and June. Why? Because a lot of people get their cars & bikes serviced before the monsoons. November too witnesses a demand spike, coinciding with the festive season when Indian car sales rise. This was just one of the small titbits of battery-related information we came across when visiting the SF Sonic factory at Taloja, Mumbai. Most people have heard of SF Sonic, but perhaps they don't know that it is an Exide-owned company (acquired back in 1998). For those having trouble placing the name, the 'SF' stands for 'Standard-Furukawa', which will probably ring a bell! Conversely, those who might think that Exide and SF Sonic batteries are just rebadged versions of each other (like the Vento and Rapid) are mistaken. Despite sharing some manufacturing facilities, both companies have different research & development centers, paste recipes, grid designs etc. Furukawa batteries in Japan brought in their technological expertise for SF Sonic; this plays a large part in the differentiation. Before we show you the detailed process of manufacturing a battery, it will help to know what the individual parts of a lead-acid battery are... The 3 essential components of a single lead-acid type cell:

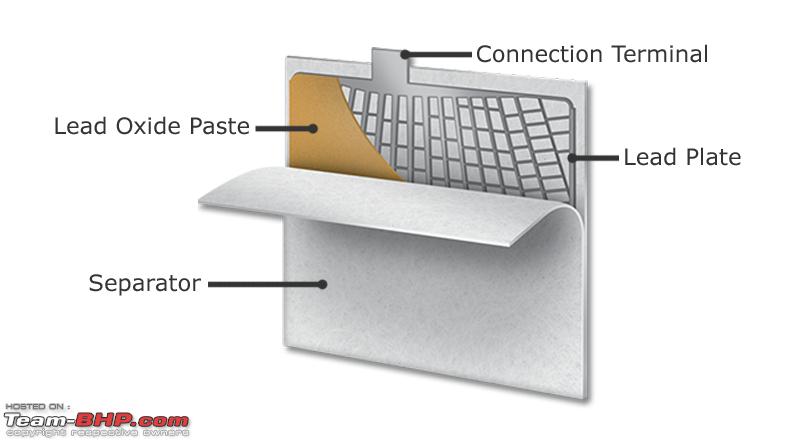

Looks simple enough, right? Not much has changed since Alessandro Volta developed the first battery in the 1800s:  image source If you want to see what a plate really looks like, they're actually lead grids like this. Each manufacturer has their own grid designs to help maximize battery performance:  The positive and negative grids have separators in between, to prevent them from touching or short circuiting. You should also know that lead-oxide is applied to the grids in paste form (shown in brown):  image source A pair of plates (1 positive and 1 negative, with separators in between) makes up a single cell. However, to increase the power output (Amps) & storage capacity (Amp-hours) of the cell, there are usually multiple alternating positive and negative plates in a single automotive cell:  image source Interestingly, a lead-acid cell always generates 2.10 Volts, regardless of the plate size or number of plates. Those familiar with electrical circuits will understand that plates of the same polarity are all connected together in parallel, and hence the output of a bank of cells will always be 2.10 V. Automobile batteries are roughly 12 volts, meaning each full battery has 6 banks of cells x 2.10 V each. In this cutaway, you can see the group of plates that are in the first bank. The banks in the plastic container are filled with acid (see the level markings on the side):  Fact: The number of charge and recharge cycles determine the life of a battery. Discharging a battery 50% twice is considered roughly the same as discharging it 25% four times. Last edited by GTO : 25th May 2015 at 20:23. |

| |  (25)

Thanks (25)

Thanks

|

| The following 25 BHPians Thank S2!!! for this useful post: | arnabchak, dreamliner17, Gannu_1, gpa, Grand Drive, GTO, Jaggu, Joe M, JoseVijay, manij, mrbaddy, Octane_Power, pankaj_sachdeva, R2D2, racer_m, Rehaan, rshanker, RSR, Simhi, The Rationalist, theexperthand, Turbanator, Tushar, Vid6639, Voodooblaster |

| |

| | #2 |

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,918

Thanked: 10,064 Times

| Now that you know what the components are, let's see how everything is manufactured. We'll start with the lead paste & grids. Oxide Making: Large blocks of lead, known as ingots are melted down to molten form:  They are then immediately cast as lead pigs. The thick lead blocks are converted to these smaller pigs because it's easier for these pieces to rub against each other to form the lead powder (used in paste-making):  Jump forth, little pigs! Your destiny awaits...  A closer look at 4 freshly made lead pigs, placed on a stack of hefty lead ingots (don't miss the mentioned weight!):  The lead pigs are transported via conveyor belts to their storage container:  Supervisors stand at these marked 'view points' in the factory to get the perfect view of machines & gauges (for observation):  Standing at the view point, you can look in the mirror to check the level of the lead pigs in their storage container:  The lead pigs are taken from storage and dumped into a large rotating cylinder which gives them the same treatment as your clothes would get in a tumble dryer. The tumbling action results in heat generation, because of which the lead pigs oxidize on the surface. The tumbling process also removes the surface layers of oxide when the pigs scrape against each other. This makes the cleaner lead (below the surface) available for continued oxidation. An air-stream then carries the lead powder to a chamber where it is collected. The lead powder from here on is used for several different applications. Paste Mixing: Making the paste is one of SF Sonic's trade secrets. The quantities and ingredients in recipes affect the battery's performance, and hence the formula is protected. We can tell you that the paste is usually made up of powdered Pb3O4 (Red Lead) or PbO (Litharge), or a mixture of the two. Diluted sulphuric acid and other additives are put in to create the paste. This paste is later applied to the grid and becomes the 'active material' (which actually participates in the electrochemical reactions of charging and discharging). This silo holds the powdered ingredients:  The powder (funnel on the left) and acid (tank on the right) are combined together in a motorized mixing tank:  Alloy Blending: This process is all about mixing the two or more metals that form the grid. In car terminology, a grid is like the chassis of a vehicle. Not only does it provide mechanical support for the 'active material', but it is also the main route for current flow. Just like a chassis, the grid is one of the most important components that determines the characteristic of a single cell. Interestingly, some additives are mixed with the lead, each of which performs a different role. They are:

Grid Creation: A typical grid must have the following:

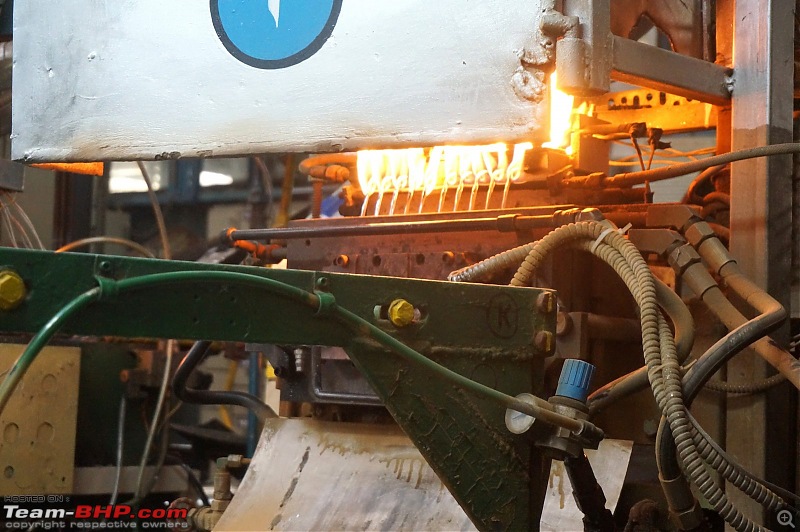

Grids are formed by 2 methods: Method #1, Gravity Casting - Molten lead + additives are poured into an empty cavity (mold) that is shaped like the grid. The lead cools down and solidifies to form the grid. Why is this method called 'gravity'? Simply because there is no external force pushing the molten lead into the mold, besides gravity. A long row of gravity casting machines for the grid/plate creation:  At 327.5 degrees centigrade, the melting point of lead is relatively low for a metal. For alloys (i.e. mixtures of other materials in the lead), it's a little higher. The molten lead is kept at 450-500 degrees (100+ degrees above the melting point) so that it doesn't solidify when it is being transported or while it is being poured into the mold. That is molten metal being poured out! A 'reducing flame' on top burns off the oxygen, so that the lead doesn't oxidize:  Once the lead has cooled down, the two halves of the mold split open, and the formed plate slides down:  The sliding plate goes through this facing machine (at the right) to shave off rough edges or excess material. The plates are then stacked:  This is what the end result of the gravity cast plates looks like. Note that they are manufactured as pairs of connected plates, just for convenience sake. They are split into two individual plates later on:  Grids then enter the pasting machine where the active material is pressed onto them. Thin sheets of paper are folded around each grid to prevent any loss of adhesion & bind together the active material, especially in the anode. Paper doesn't hamper the charge from passing through. A sample of a well-formed plate pair and a pasted plate pair:  Method #2, Expander Machine The newer expander technology is a superior method to gravity-casting when it comes to speed, cleanliness and even cost-effectiveness! The downside is this machine can only manufacture the negative plates, as there is a difference in alloy and thickness requirements for the negative and positive plates. The negative plates are thinner; this allows the expander machine to stamp and stretch narrow strips of metal to form the grids, instead of casting. Long rolled strips of lead are fed into the machine:  Lead is passed through rollers as the flattening and expanding process begins:  Here is where patterns are stamped (cut) out of the lead sheet to form a net-like pattern on the plate. The 'expander' name comes from the fact that it stretches (expands) a narrow punched strip to form a wider grid!  Notice how the original thin strip of lead has been stretched to something much wider, and the stamped out design has appeared:  Can you see how this strip is going to be cut into individual plates later on? We've drawn it out for you:  The entire expanded strip is fed in here for pasting. Yes, those are rolls of paper being used here as well:  The pasted strip is then cut to form individual pasted plates. The roller (in white) ensures they are flattened out completely:  A very cool robotic arm stacks these plates up neatly:  Here it is in action (animated image):  What the final pasted plates that come out of the expander process look like:  Curing: Next, the plates are transported to flash-drying ovens where moisture is removed from them:  For added strength and rigidity, the plates are then heated and undergo a chemical reaction in the curing chambers:  Before entering the process, the plates have over 11% moisture in them...they leave with only 0.5% when done. The curing process takes anywhere between a few hours to a couple of days, depending on the type of plate:  Last edited by Vid6639 : 26th May 2015 at 20:29. Reason: removed photo as requested |

| |  (27)

Thanks (27)

Thanks

|

| The following 27 BHPians Thank S2!!! for this useful post: | 1self, ampere, arunphilip, blahman, carrazy, dkaile, Gannu_1, GTO, Jaggu, jalsa777, JoseVijay, manij, mrbaddy, Octane_Power, Rehaan, rshanker, RSR, saket77, shipnil, Simhi, SmartCat, spdfreak, SS-Traveller, theexperthand, Tushar, utsav1303, Vid6639 |

| | #3 |

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,918

Thanked: 10,064 Times

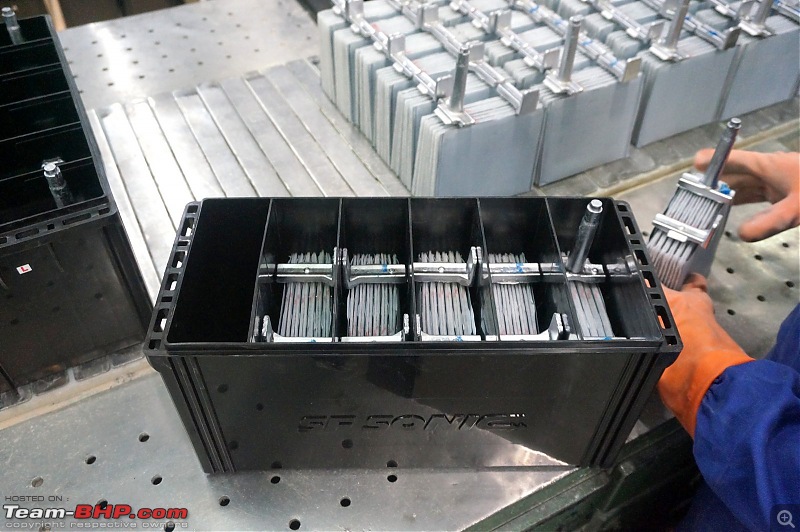

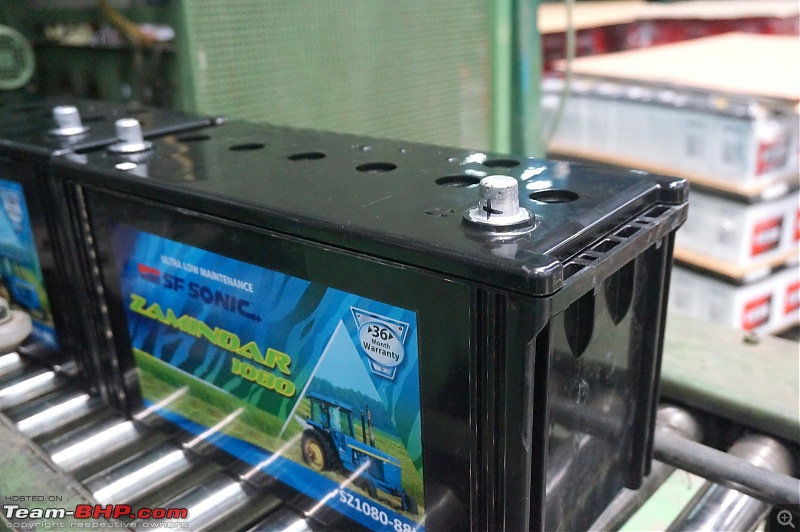

| Enveloping & Group Assembly: The pasted plates are now ready to be stacked in an alternating manner (positive, negative, positive, negative) to start to form the structure of the cell. However, each plate is covered with an envelope or separator, rather than being left bare. These separators/envelopes are made up of glass mat or polyvinyl chloride (PVC). Their role is as follows:

Glass mat ready to be placed between the plates and separators:  PVC separators are like envelopes sealed at the sides and bottom. They can have different designs that affect their properties:  This machine stacks the plates after they've been enveloped and have glass mat separators between them:  Notice how the positive and negative plates are positioned. The enveloped positive plates have their terminals (marked faintly in red) on the left, while the negative terminals are on the right:  Remember: Each cell can comprise of 'x' number of positive plates alternating with negative plates between them, all placed in a parallel layout, to produce 2V of power supply. Assembly: Group Building Now, groups of positive and negative grids are formed:  The group for the battery currently being made has 7 positive plates interleaved with 6 negative plates:  Interesting Fact: In industrial or inverter batteries, a long life is more important than the raw current output, whereas in the auto industry, high current output is a requirement for cranking. This leads to differences in the number of plates as well as chemical make-up of these batteries. It's not just a different sticker on the box! Cast on Strap This is the process that actually connects all the positive terminals in a cell together. Ditto for the negative ones. Yep, in parallel, like we keep saying: Here, the plate groups are held upside down, into a mold. Molten lead is then cast in a channel connecting all the like terminals (same polarity) together:  When the machine flips the plates back around, you can see the new straps (shiny bits at the top) that have been cast on the terminals:  A closer look. The cell groups are now well connected. The ones at the ends have long terminals - which is what sticks out at the top of your battery:  Boxing The tubs which hold the cells are made out of a tough plastic compound. Each tub has 6 individual compartments for each 2V cell group. The cells are placed in these tubs manually:  Short Circuit Testing Once all the cells are in, and before the groups are permanently connected to their neighbours, a short-circuit test is conducted to ensure no positive plate is in direct contact with a negative one:  Pinch Welding The tabs of neighbouring cell groups are pinch welded to each other (animated image):  There's a small hole in the plastic tub through which neighbouring tabs make contact:  Lid Sealing The plastic lid is manually placed on top of the tub, before a machine automatically heat-seals the whole shell together:  The machine removes the lid and temporarily slides a heating element between the two halves. Once they are heated up, the heating element is removed and the lid is pressed back onto the tub, sealing them together:  Terminal Building The terminals can be welded by a computer-controlled machine or be done manually. That's a rod of lead in the welder's left hand. He fills any gaps between the plastic shell and terminal with lead. It's amazing to see how fast the lead melts when it comes into contact with the welding torch:  That's the end of the long terminal poking out, sealed well to the plastic shell:  A serial number + bar code are added to the batteries at this stage. The filling-holes on top are temporarily covered with regular cello tape (so no dust goes in):  Filling The batteries are then transported to another section of the factory where they are filled with acid. We finally have a completely working battery! Charging The batteries are charged from 14-40 hours in charging tanks. To keep temperatures in check, the machines are filled with water, and the sensors ensure that power is cut off when the units become too hot. 99% of the gas produced at the time of charging recombines under normal conditions. The fume arresters (tubes with baffles in them) temporarily added to the top of the batteries keep the hydrogen gas from escaping; otherwise, it can cause explosions in the enclosed charging tanks:  Charging in these water-cooled bays is done at 15-30 amps:  These batteries are all OEM supply for VW, and hence they don't have any branding on them. After having been charged, the acid levels in the batteries have dropped a bit. Notice the unevenly filled cells:  The batteries are then topped up with acid. The acid used has a high specific gravity (~1.260), so that there is no drop in the cell's charge when this new acid is added:  Notice those red LEDs on the six pipes that are about to be inserted into the battery? Those are refractory optical sensors. They can accurately control the fill-level of each cell as it is being topped up:  A pressurized air hose is sprayed in tiny holes on the side to clear out any spilled acid / fumes:  Next, the batteries enter a unique battery wash. It's similar to an automatic car wash:  This cleans them of any spilled acid:  Can the finished battery take the stress of high discharge? This machine draws an extremely high 300-400 amps from the battery for a full 4 seconds. The voltage drop during this time is checked in order to see if the battery passes muster. Inverter batteries are tested at an even higher 700 amps:  Packing & Dispatch: A final check for leaks, irregularities and short circuits is conducted, after which the batteries are stacked in the warehouse:  All batteries are stored in batches and dispatched using the First-In-First-Out (FIFO) method, to ensure the stock is always fresh:  Lead is known to be one of the heaviest metals. Acid is pretty dense too. Combine them both in a large plastic container, and you'll understand why lead-acid batteries are extremely heavy! Battery weights for a small car start at 10 kgs, tractors at 25 kgs, and truck/inverter batteries are 40 kgs a piece. Don't miss the brand on the forklift machine - Maini, the same company that makes the all-electric Reva  : : Last edited by GTO : 25th May 2015 at 20:21. |

| |  (25)

Thanks (25)

Thanks

|

| The following 25 BHPians Thank S2!!! for this useful post: | Aficionados, ampere, blahman, carrazy, dkaile, Gannu_1, ghodlur, GTO, Jaggu, JoseVijay, Leoshashi, mrbaddy, Octane_Power, Rehaan, rshanker, RSR, saket77, shipnil, Simhi, spdfreak, SS-Traveller, theexperthand, TheTeacher, Vid6639, Voodooblaster |

| | #4 |

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,918

Thanked: 10,064 Times

| A bird's eye view of the factory floor:  Wrapped in plastic are stacks of batteries:  Some of the SF Sonic batteries ready to be shipped:  Furukawa influence = The 5S principles:  The factory has several charts indicating what could go wrong with each process. Symptoms as well as solutions are mentioned:  Right from the factory floor to the restrooms, you can tell that SF Sonic is serious about following systems (we were there on a Friday):  Here are some sample grids for training staff in identifying the various types of manufacturing defects:  Each factory worker is given prior training about the machine that he will be operating. This enables them to identify any possible irregularities and point out failed components:  We procured special permission to get you BHPians an inside look  ! ! Several electric forklifts silently went about their duties. Would have loved to drive one of these rear wheel steering machines:  Last edited by GTO : 25th May 2015 at 20:20. |

| |  (33)

Thanks (33)

Thanks

|

| The following 33 BHPians Thank S2!!! for this useful post: | --gKrish--, amit_purohit20, blahman, carrazy, dkaile, dreamliner17, Gannu_1, govigov, Grand Drive, GTO, Jaggu, JoseVijay, khan_sultan, Lalvaz, Leoshashi, MalluDude, manij, mrbaddy, Rehaan, rshanker, RSR, RYP, sajusherief, saket77, samsag12, Simhi, spdfreak, SS-Traveller, theexperthand, toothless, veerubhai, Vid6639, Voodooblaster |

| | #5 |

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,918

Thanked: 10,064 Times

| Other Points:  • About the Taloja Factory: Area: 82,845 square meters• While Exide is the OEM supplier to ALL car and two-wheeler brands in India, SF Sonic primarily supplies to the Volkswagen Group and Jaguar-Land Rover. • Exide has 9 plants across the country - Taloja, Chinchwad, Ahmednagar, Hosur, Haldia, Shyamnagar, Haridwar, Roorkee and Bawal. Out of these, Ahmednagar and Bawal manufacture only motorcycle batteries, while Roorkee and Haridwar manufacture only inverter batteries. • Exide has 2 smelting facilities in Pune and Hosur. Buybacks are done by SF Sonic and Exide dealers based on the weight of the old battery. • The highest demand for inverter batteries is in May & June. Sales rise by up to 40% in this period. SF Sonic had their facility stacked up with excess stock of inverter batteries, anticipating high demand. • While a typical car battery puts out 12.6V & has a capacity of roughly 60 Ah, in some trucks, 2x 12V batteries can be used to get the required 24V. • SF Sonic also manufactures batteries for Indian Navy Submarines which require 488V (i.e. 244 cells of 2V each). These have a storage capacity of 19,000 Ah, which is roughly 317 times the capacity of a car battery! The entire manufacturing wing was protected, hence we couldn't take a peek inside. • Lead-acid batteries are 88-90% recyclable (because of the low melting point of lead). However, it's important to do this correctly, as harmful by-products are released during the process. Last edited by GTO : 25th May 2015 at 20:18. |

| |  (61)

Thanks (61)

Thanks

|

| The following 61 BHPians Thank S2!!! for this useful post: | 1self, Aficionados, amitpunjani, amit_purohit20, arakhanna, blackwasp, blahman, budgam.boonyi, bullrun87, carrazy, Contrapunto, D4Drive, dhanushs, dkaile, DONZ, dreamliner17, fiat_tarun, Gannu_1, ghodlur, Grr7, GTO, iamswift, Jaggu, jalsa777, JoseVijay, khan_sultan, ksameer1234, Leoshashi, lurker, mallumowgli, manij, mishraak, mrbaddy, R2D2, Rahul Bhalgat, rakesh_r, redrage, Rehaan, rshanker, RSR, RYP, sai_ace, saket77, samsag12, scopriobharath, shipnil, spdfreak, SS-Traveller, tejas08, tharian, The Rationalist, theexperthand, TheTeacher, toothless, Turbanator, utsav1303, vhharan1, Vid6639, Viraat13, Voodooblaster, zavegur |

| | #6 |

| Team-BHP Support  | Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery Exceptional insight, guys! Thank you for sharing this with the community. It's apparent you had as much fun visiting the factory as we are in reading this report  . . For those interested in more, here's Vid6639's thread on how tyres are made: link. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank GTO for this useful post: | Aficionados, S2!!!, Vid6639 |

| | #7 |

| Senior - BHPian | Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery S2 & Rehaan, Great pics supported but equally interesting narration. Never knew the battery making process could be so complicated while we simply turn the key on to kick in the battery charge. Thanks for sharing this useful information. From the pics, we could see only the maintenance free batteries, what about the lead acid batteries which generally need distilled water top up? Looking at the nature of chemicals handled, I am not too impressed by the safety standards of the plant, it can be seen from some pics about people handling batteries with bare hands, no hard hat rules etc. Just my view. |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank ghodlur for this useful post: | Rehaan, S2!!! |

| | #8 |

| Senior - BHPian Join Date: Nov 2009 Location: Pune

Posts: 1,929

Thanked: 2,835 Times

| Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery S2 & Rehaan, Thanks for the wonderful and informative article. Batteries sadly are the most underrated and ignored component in a car.It's only when one suffers a breakdown we come to know it's importance. One question i always had a doubt.When we buy new batteries the old ones are taken back.Where do these old batteries end up?Do these companies use the old ones - recycle and reuse? |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank rakesh_r for this useful post: | lurker, S2!!! |

| | #9 |

| Distinguished - BHPian  Join Date: May 2010 Location: Bengaluru

Posts: 4,213

Thanked: 5,881 Times

| Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery Excellent information S2 and Rehaan! Thanks for the insight. Rated a well deserved 5 * SO SF is a sub brand of Exide is it? |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks sagarpadaki for this useful post: | S2!!! |

| | #10 |

| Senior - BHPian | Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery Exceptional report as I had done Risk Engineering survey for same unit couple of years back. Can see that there are few small changes in some areas. Kudos to you because even after being surveyors, we were not given photography permission. Our escort carried company camera and he took pictures of places we wanted recorded. Last but not least it was like watching that HOW ITS MADE? program on one of those Discovery channels. Regards-Sonu. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank ariesonu for this useful post: | GTO, Rehaan, S2!!! |

| | #11 |

| BHPian Join Date: Nov 2013 Location: BOM, AUH

Posts: 43

Thanked: 44 Times

| Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery It is really interesting to see how one of the most important parts is made. Thank you team. Last edited by GTO : 26th May 2015 at 12:38. Reason: Language |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks tejas.negandhi for this useful post: | S2!!! |

| |

| | #12 |

| Newbie Join Date: Oct 2007 Location: Bangalore

Posts: 15

Thanked: 15 Times

| Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery >> "Automotive battery sales rise by 15-20% in May and June. Why? Because a lot of people get their cars & bikes serviced before the monsoons. " I'm not sure about this statement, but I presume the sales of 'Batteries' (not only automotive, but homeuse) are high due to the peak summer and power cuts in the Indian homes. This would lead to installing/repair of Battery+Inverters at most of the homes. BTW, This summer I too ended up installing UPS in my home |

| |  ()

Thanks ()

Thanks

|

| | #13 | ||||

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,918

Thanked: 10,064 Times

| Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery Quote:

I believe your query is regarding the dry charge batteries where you need to pour acid for instant charge? These batteries are mainly manufactured for the export market; interestingly, for Bajaj 3-wheelers. We did not get a glimpse of these. The wet charged/green plate batteries are the ones which are the most commonly used - fully charged inside the plant. I hope I understood your question correctly.  When we speak about terminology like maintenance-free, here's something that might interest you. Depending on the alloy of the grid, automotive batteries are further classified into 3 types:

Quote:

Quote:

Quote:

Last edited by S2!!! : 26th May 2015 at 13:33. | ||||

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank S2!!! for this useful post: | GTO, R2D2, Rajeev1, rakesh_r, Rehaan |

| | #14 |

| BHPian Join Date: Oct 2012 Location: Bangalore

Posts: 189

Thanked: 381 Times

| Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery S2 & Rehaan Awesome report - thank you for taking the pains to publish this. Did you get some insights to how the old batteries are recycled ? Are the manufacturers involved in recycling or is it being done by a parallel recycling industry? |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Rajeev1 for this useful post: | S2!!! |

| | #15 | |

| Senior - BHPian | Re: PICS: SF Sonic Battery Factory. Detailed report on the making of a Car Battery Quote:

About 50 per cent of the lead in Exide batteries (SF, whose photographs are shown here, is a part of Exide) is recycled lead. Apart from the smelting process, breaking an old battery and taking care of the old acid is also an environmentally sensitive issue. It involves hi-tech machines and negligibly minimal human contact. The menace of unauthorised and illegal smelters is a threat to the environment. I think Exide is the only major battery manufacturer that has its own smelters with modern battery breaking capabilities. The other major battery manufacturers possibly operate through authorised smelters and don't have captive smelters of their own. Some large smelters are gradually getting into branded battery manufacture also but their market share is very small. | |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank Sudipto-S-Team for this useful post: | GTO, mallumowgli, Rajeev1, Rehaan, S2!!! |

|