| BHPian

Join Date: Jan 2010 Location: Pune

Posts: 413

Thanked: 173 Times

| In search of material now..!

Quote:

Originally Posted by Psycho  Here are a few points that work against your idea:

1) you still need a metal casing for safety purposes My idea starts with,

"Method:

I suggest we have a expandible Poly-Ethylene (high grade Plastic) forming a baloon like structure inside our fuel tank...,

2) Plastic is not elastic in nature hence ruled out

3) Rubbers harden over a period of time ruled out I have not zeroed in on material yet!, Just mentioned what I require the material to do for it to work!

(the kind of technology we have here,, i dont think its going to be long before we find one.. and now I sure will !!

4) Well a good fuel tank with proper hoses and a decent tank cap does not allow the petrol to evaporate until it reaches a particular pressure, hence keeping the gaseous petrol inside the tank. Dear Psycho  , every fuel tank has breather arrangement. , every fuel tank has breather arrangement.

It will allow to maintain a atm. pressure inside the tank, by allowing controlled ingress of air!, If air can go in--fuel (vapours) can come out too! ..

5) A balloon kind of structure will not be centrally positioned hence will add to the de-stability of the car based on the fuel in it. Rather!, The Balloon kind of structure if sort-of-tied to the top of the tank and to the bottom will move the C.G. of the fuel volume as less as possible (definitely less than its free state.. )

Do tell me, If I need to explain more on this !!

6) you could run a fuel pump agree but what about fuel level only option is weighing, again wont work as the balloon can not be positioned in one place Thank you Sprucegoose for thinking upon that !

7) Again "The tendency of the balloon will be to empty its contents, hence keeping the fuel under slight positive pressure at all times." would mean flooded carbs if you park for a longer duration i don't think it will make a difference in case of an MPFI car Again, Not Many Carbs around in cars I think!

and, Sprucegoose, thinking about the cut off valve also was the first thought that came to me !  , thanks.. , thanks..

8) It cannot give you a long life as elasticity will reduce over a period of time. Will work more on that.. and get back with proper material..

9) Your statement "and I think it sure will add to the FE 10+percent.. depends on the running/filling patterns/standing time/ambiente' temperature !!" is so a guestimate that it does not even begin to make sense. Thank you for that!, I will try to come up with figures !

Hence I still believe in point 4 more than anything else. so stick to the original fuel tank. |

Thank you for your 'contructive' criticism !! Quote:

Originally Posted by Shan2nu  A tank needs to breath only when its rigid, since its volume remains the same irrespective of the amount of fuel inside. But a flexible material like a rubber balloon will expand and contract wth rise and fall in fuel level.

Thank you for that explanation Shan2nu!,

I think you understand what I want to say closely

....

.....

I think race/sports car are already using this to prevent fuel from flowing to one side of the tank when conering.

I rem Wolf having to abandon his track session midway due to the fuel moving away from the fuel pump inlet cutting off the fuel supply to the engine, everytime he cornered hard. I filled another 10ltrs of fuel in the car before my session and faced no issues.

Nice to know that bit !

Shan2nu | Quote:

Originally Posted by SamtheLeo  My 2 Cents :

The amount of money spent in the making & maintaining such a Elastic balloon (as it may have leaks & other issues) will certainly over run the price of the fuel which is lost due to eveporation currently. SO the first question is Does it make economic sense.

Thank you ! for your feed..

Lets calculate that after the quality and safety part is ensured!,

How much fuel do you think we loose due to evaporation normally. I dont think it is that a great amount.

For that, we can put a spoonful of petrol in a beaker, see how fast that evaporates! | Quote:

Originally Posted by BaCkSeAtDrIVeR  It was mentioned somewhere here that having a sort of "floating cover" on the fuel surface to prevent evaporation is compulsory as a part of Euro IV compliance.

I also remember reading that faintly though!, thank you backseatDriver!

that norm was in concern with safety I guess.. | Quote:

Originally Posted by n.devdath  +1 to that. The amount of fuel lost due to evaporation is very less if the vehicle is parked under shade and kept at a cool place.

Well, I have started off considering general usage, definitely I will consider the best case -worst case for further explanation..

though what you suggest still would result in considerable volume of evaporation!!

..There is no point in over researching the issue here.

Thank you for your opinion !

Take care.. | Quote:

Originally Posted by Sprucegoose  If the baloon has peizo electric strands in them then,

1> depending on the amount of strain they will out put a certain amoutn of electricity. that way the amount of fule can be checked.

2> if current is applied to the strands then they can be made to contract, hence negating the requirement of a fuel pump.

A cut of valve can be put to further restrict the amount of fuel flow.

Thank you Sprucegoose!

But the fuel could continue to evaporate inside the baloon, creating an vapor bubble which will throw off the fuel gauge.

About that.. I planned a vent, which is supposed to even feed in the air intake-- i.e. again resulting in burning the evaporated fuel too!! | Quote:

Originally Posted by rajeev k  This resembles an Accumulator used in Turbine governing systems. THe accumulator has a baloon inside, which is filled with NItrogen which in the event of a sudden pressure drop inflates and pushes the oil into the system.

The problem in car fuel tanks would be whether the fuel can press against the gas pressure of the baloon.

Any how try.

Yes, it does..

I think it more resembles Oil reservoir in a Station TRansformer / Generator Transformer!

wlll post the analogy later..

but the purpose there is to stritcly keep off H2O from Oil. | Quote:

Originally Posted by yogeshnaik  Idea is good. The suggested idea is implemented in Fighter planes. The fuel tank will have bladders which inflate after the fuel is filled. It is expensive too.

Thank you for your feed, But I think, we can go for a lesser graded 'bladder' than the one used in the jets.. and lesser requirements from the 'bladder' wrt jets..

But, I will surely put a calculation to that..

Lets see if it qualifies as a economy prod. or something else! (perhaps performance prod as its used in race cars/sports as mentioned by friends earlier.!! | Quote:

Originally Posted by Psycho  1) What if you had a flat surface as a fake roof that moves up and down in the tank and is settled on the liquid fuel wouldn't that reduce evaporation? So you are suggesting "moving surfaces" with "sliding (metal/nonmetal) contact" with "sealing requirements" in the tank filled with inflammable liquid

Nice!! No comments..

2) If you have a good gas tank cap and no leaks in your hoses, your evaporation will reach a particular point and stop. There is a breathing facility in every fuel tank..

you may agree on that, so there is provision for air to come in/equal opportunity for the formed vapors to escape out!!, no saturation of vapors, just more scope for vapors !!

3) If you had more fuel in the car tank in the first place your evaporation would again reduce as you have lesser space for the gases to occupy. Ok!, but we really cannot expect people to fill their tanks to fill to the brim & keep them that way all the while!!( and I am not asking anybody to do so!)

The cars will run, and the fuel level will go down !!

On the contrary if you do not use the vehicle for long time its even recommended to drain the fuel and store it safer!

but still I still feel non leaking hoses and a good tank cap is still a decent solution. Ok.. | Quote:

Originally Posted by Lalvaz  Brilliant idea Driverace, I'm sure there are lots of issues that will crop up during the implementation, but I like the kind of fresh thinking you have. Keep working on it, and I'm sure you'll learn a lot in the process, (even if your idea fails), BTW, I dont think its that difficult to overcome most of the obstacles pointed out by others. Thanks a lot for your support and your kind words!!

I appreciate it a lot, and I am even more motivated to work further..

For ex: for determining the volume of petrol left, I could use a sensor to weigh the balloon and calculate the volume of fuel left.

Also although the baloon will need to be replaced every so many years, it will also result in eliminating fuel tank cleaning. So, you change the rubber balloon every 3 years and come up with a brand new fuel tank. Now, I swear, I did not think of that!

That tank cleaning cost, I can consider in my calculations, I guess

As regards the volume of fuel being lost due to evaporation, well, no one knows how much is lost, cos no one measures it. Yes, But, I am sure, about the volume, since a visual idea is right in front.. as in splashing of oil that takes place, we can only imagine! with all the bumps, speedbreakers, and more!

I will try to come with figures to get a hold-support to what i propose!

Keep working on the original idea, you might just hit bullseye. Again thank you for the positive energy! | Quote:

Originally Posted by singh.amrit  Problems (as per my knowledge ):

1- Material of the tank, you will need a material with very high barrier properties ( to prevent vapors going through the rubber ), which are not usually elastic, an elastic material will have gaps in its structure to allow for coiling / uncoiling of polymer chains.

2- Petrol is an organic solvent ( a part of it is ) as we all know, hence , material will again prove to be a hinderance.

In short, if its expandable, it will have very high leakages.

what you can focus on instead, is the design of the fuel tank,

like :

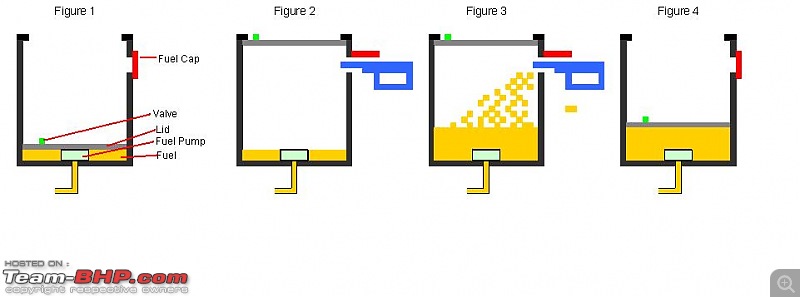

or something better, it should have different compartments, one used after the other, hence, lesser vapors at a given time in theory. I will surely study that more.. thank you too.. |

I wanted to say further more,

thank you for your feed and the kind words above.

I am studying more about the material and nature of material as expected.

How far can we justify it economically (since I am suggesting it as a FE improvement device to begin with!)

More to say,

I feel the astronomical averages that we see in the "Mileage Rallies" that we see and read, might just be the answers as to how much fuel "may be" lost in evaporation!!..

I am saying just may be !! since they dont at all waste any time after the fuel goes in, I think..

(Is that so? anyone?)

P.S. Sorry for the delay! had a 24 hr marathon at work on Monday!!

Care. Ace. |

, every fuel tank has breather arrangement.

, every fuel tank has breather arrangement.