| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  44,740 views |

| | #46 | |||

| Distinguished - BHPian  | Re: Wheel nut stuck! Tyre shop messes up threaded bolt Quote:

Usually torque specification come with a minimum and maximum value. If you do want to put something on the thread I suggest using the minimum value. The biggest problems when it comes to seizing is not the wheel nuts but the rim sticking to the hub. There are many theories and practices what and whether you should use anything. I just make sure that the mating surfaces are really really clean (which usually means taking a pneumatic wire brush to it). I tend to use vaseline rather than anti seize paste. Especially on light alloy rims. Because the hub is always metal and some of the anti seize pastes will increase the risk of electrical corrosion. Quote:

Quote:

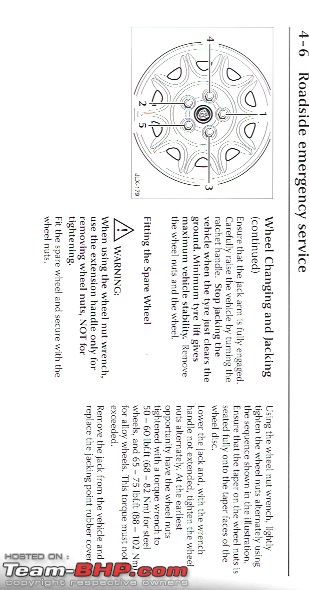

Being a good competent car mechanic, takes time, continuous training and having the right tools. Without wanting to offend anybody, but my general impression is still that any manual type of labor is simply not taken seriously in India. I had the same issues in my profession where we relied heavily on well trained and well equipped technicians. Very few were, even my management team did not see the need, because they considered it very simple work. We introduced a bunch of training, personalised tools, procedures, wages related to certification/workmanship etc. The level of quality went up considerably and that actually reduced our total cost considerable as well. We had a lot less recurring problems, fewer accidents, problems got solved in one visit rather than multiple visits etc. But I will tell you one thing; even with a mountain of concrete evidence and data that this new approach was very beneficial to our customers, to us and to the involved employees, it was still frowned upon by many. I think the flip side of such an approach to other peoples work is that these kind of technician don’t feel much appreciated and it also makes it difficult to them to have some sort of professional pride. They are paid a pittance, might feel looked down on. Quick and cheap is not necessarily a good combination when quality matters. When you change your tires, or rotate them, the mechanic should also check and adjust the pressure of each tire. Most cars have different pressure for front and rear wheels and they also have different tire pressures for full loads/high speed driving. So yes, you need to look it up in a simple table that should be available in the workshop. Some with a torque wrench: every car has different specifications. I have this little table hanging in my garage.  Different tire pressure, different torque settings for all our cars!! Most people don’t carry a torque wrench with them, so what do you do if you have a flat and have to change it yourself by the roadside. Well, obviously you put the spare on and tighten it by hand. But check you car owner manual. It might well tell you to get the lug nuts torqued properly at the first available opportunity.  Especially on light alloy it is advisable to re-torque them after a little while. I am attaching an invoice from Sears, when I lived in the USA. They have a tire/wheel alignment outfit. And yes, they make sure they know the applicable pressure for the tires of your car and yes the also check the torque and advise you to re-torque after 25 miles and they put all of that on the invoice.  With a car on a lift, looking up the torque spec and torquing the nuts will not take more than 2 minutes. But a torque wrench is an expensive and delicate tool. It needs to be recalibrated now and then. It needs to be handled with care. You drop it, it might be damaged beyond recalibration. Again, all of the above (tire pressure / torque specification and procedures tends to be listed in the car owners manual. But as we know, as we have a dedicated thread on it, a lot of people never ever read their car manual. I am an engineer at heart. So no matter what the job is, I will always try to understand what the proper procedure is and why. I do admire the Indian approach to many things. If it works, it is ok. That can be fine, as long as you really understand what you are doing. I have sat down with quite a few mechanics working on my Royal Enfield bullet. I was amazed by their skill and ingenuity. But I was also appalled by their working conditions, lack of proper tooling and disdain for proper procedure. Including their own safety! If someone believe that somebody who gets his hand dirty is doing a very simple, menial, job, and therefor the task at hand, can never ever cost a lot, I think there is mismatch between that person’s perception and reality. Jeroen Last edited by Jeroen : 16th February 2023 at 17:07. | |||

| |  (6)

Thanks (6)

Thanks

|

| The following 6 BHPians Thank Jeroen for this useful post: | dailydriver, R2D2, s4ch, shankar.balan, Thad E Ginathom, vaasu |

| |

|