| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  961,437 views |

| | #781 | ||

| BHPian Join Date: Sep 2013 Location: Bangalore

Posts: 732

Thanked: 1,369 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Modern cars have diagonal split brakes, which are safer because locked up wheels along the diagonals corners are less likely to cause a loss of vehicle control. Quote:

1. To act as an insulator to prevent galvanic corrosion between dissimilar metals. 2. To prevent entry of water into the joint and causing corrosion. This type of paste is available from Loctite, Kluber, Weicon, and others. I use this paste in my work to prevent seizing of stainless steel fasteners due to galling and, in the assembly of shafts in gearboxes to prevent them from seizing to each other. | ||

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks Motard_Blr for this useful post: | Thad E Ginathom |

| |

| | #782 | ||

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Brake bleeding sequence is also affected by which system is used. So on the Spider you can bleed per axle. Technically there is no reason to starts at the rear or even find the longest brake line. Because the reservoir is split as well. Although, some manufacturer specify very whacky bleeding sequences which do not make sense. (E.g. my Jaguar for instance. Nobody has been able to explain the sequence on my XJR, even the Jaguar specialist have no clue. They had no clue to start with, as they were not aware until I showed them the Jaguar workshop manual. This is an aluminium wheel on a steel hub. So there is going to be galvanic corrosion. If you add copper to that mix it is going to be a whole lot worse!! Never use copper paste on aluminium wheels!! The vaseline works as an insulator to some extent. These are machined flanges, so a very thin coat, evenly spread is required. Any water ingress is only capillary effect and the vaseline blocks that effectively. The vaseline stays surprisingly long in place. Wheels come off regularly . Thanks for mentioning the ceramic based assembly pastes. I have some, but I rarely use them. I work mostly on old cars and most workshop manuals will mention copper paste, because that is the stuff in use when these cars where new. It did fine then, and it still does. I know the limitation of copper grease (e.g. see above) but I am les familiar with assembly paste. There are a lot of them about advertised as general assembly paste. But I have a health distaste of stuff being advertised as “general" or worse “universal". Because it usually means it is average at best, mediocre at worse. So unless I see it specifically mentioned by the respective manufacturer I stick to what I know will work best. Quote:

Did a few more odd jobs on the Spider. Getting everything ready for when the paravan comes back from Johan. Although I had test my overhauled wiper motor and linkage, I had not run it with wipers on it yet. So I decided I better try that. I don’t want to have to remove the paravan again!! So put the wipers back on and fastened them properly:  Got my wife’s plant mister to simulate rain in my garage. Wipers working fine.  Even did a little video: So the problem with the interval is completely gone and it runs superb on normal and fast speed too! I go the air intake ready to be mounted onto the paravan. Cleaned the edges:  As you see I made a very carefully little bed for the air intake. It is face down, so with the paint down! I don’t want any scratches. So there is a blanket, a paper and some workshop paper towels. Note: When using news paper underneath (painted) car parts make sure you take the stables out!! They can scratch badly!!  Cleaned all the little bolts and washers. Also, fastened the little hose for the window spray system with some tie-wraps.  All done. I also touched up a few tiny spots of paint along the edge of the paravan and on the car. Like I mentioned, I do not want to have to take this paravan off again, ever! Jeroen Last edited by Jeroen : 5th January 2021 at 23:19. | ||

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank Jeroen for this useful post: | digitalnirvana, QuadraticAmoeba, Thad E Ginathom, VivekCherian |

| | #783 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,005

Thanked: 26,445 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp I'm surprised that you use paper as protection against scratches. When I first made jewellery, I thought I could wipe silver with paper tissue. Oh no! It is quite abrasive and one has to back a stage in the polishing and do it again. Didn't make that mistake again: used nothing but pure cotton from worn-out vests. Now, I would probably use microfibre. Car paint always seems to me to be ridiculously fragile and ill-suited to its demanding task. I'd expect it to be scratch-able with paper towel? |

| |  ()

Thanks ()

Thanks

|

| | #784 | ||||

| BHPian Join Date: Sep 2013 Location: Bangalore

Posts: 732

Thanked: 1,369 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

A sports car from the 80s with leaf springs?! It looks like Alfa just reused some surplus chassis from the 60s to make this car. For a country with their engineering heritage they sometimes make surprising decisions. Quote:

Quote:

Quote:

The stainless steel fasteners are used on one machine that's built entirely from stainless steel because it's in continuous contact with water. Stainless steel fasteners can suffer from galling, where metal objects under pressure, such as between a screw and a nut, stick to each other and form a chemical bond. This bond is permanent and is generally a maintenance nightmare. The shaft I mentioned is a for a heat transfer roller and it is make from steel. The shaft is hollow and chilled water circulates inside the roller to cool it. The problem is that the cold causes condensation. The shaft is assembled into a hollow shaft of a gearbox, which is also made of steel. Over time, the shafts seize together because of corrosion from moisture and fretting. We end up having to destroy the gearbox to remove the roller. The gearbox is much cheaper to replace than the roller! All purpose grease doesn't work in this case and we now use a non-metallic paste to protect the parts and allow for easy disassembly. Generally, shaft and hub assemblies with sliding fits should be lubricated with a suitable paste. Here are a couple of links to the types of paste that I use: https://www.weicon.de/en/products/we...assembly-paste https://www.klueber.com/in/en/produc...cating-pastes/ For you, in Europe, they should be easily available. Even a small quantity should last you long time. | ||||

| |  ()

Thanks ()

Thanks

|

| | #785 | |||||

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

I even use them to to polish parts of the car, get grease marks of and so on. Quote:

The Spider did have all round disc brakes which at the time was quite revolutionary. Heck, even today many cars still have drum brakes at the rear! We have a whole thread dedicated to that phenomena. Quote:

As with anything, technology moves on. I am a great believer in sticking to what the manufacturer recommends when it comes to liquids and greases! Which is a very controversial point of view on the internet and specifically on car forums. Each car forums comes with endless discussion on what oil/grease/fluids to use. Whereas all you need to do, is look in the car owner manual. The problem starts when what you manual specifies is not available anymore. Quote:

Quote:

It’s very expensive and usually strength, compared to steel, becomes a problem too. Anorak fact: All the shiny bits on the Spider are not chrome, but polished stainless steel. Very Italian to shell out big time on the flashy, shiny bits!! These cars suffer from rust badly, but no matter what they will retain their bling-factor! Jeroen Last edited by Jeroen : 6th January 2021 at 14:37. | |||||

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Jeroen for this useful post: | Jaggu, Motard_Blr, Thad E Ginathom |

| | #786 | |

| BHPian Join Date: Sep 2013 Location: Bangalore

Posts: 732

Thanked: 1,369 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

These days, trailing arm suspension well generally use stoppers within the dampers themselves to limit travel to prevent the springs from dislodging from their seats. | |

| |  ()

Thanks ()

Thanks

|

| | #787 | |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,005

Thanked: 26,445 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

I wonder if your superior workshop towels are made from cotton fibres, or some other material, and not wood pulp? When I say scratch, by the way, I am using it in the literal way. As in, use a paper towel on polished silver, and you now have hazy silver. I don't mean big scratches. I'm very impressed that the spider's shiny bits are polished stainless steel! Being a lazy man when it comes to car care and cleaning, I hate chrome, which takes a bit of love and care to keep looking good. Here in India, it seems particularly subject to attack by atmospheric pollutants. Last edited by Thad E Ginathom : 6th January 2021 at 17:56. | |

| |  ()

Thanks ()

Thanks

|

| | #788 | ||

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Quote:

Quote:

You might recall I had those headlight rings re-chromed. And that was the second time I had to have them re-chromed too! I also replaced the doorhandles once, because of the chrome looking very poorly. Chrome is actually perfectly capable of withstanding just about anything. However, it comes in many different formats. Getting the base material right, the cleaning and what kind of chrome and dips are used is very important. Cheap chrome won’t last, but really good quality chrome parts are worth their weight in gold, not kidding! So it is a bit of a balancing act between your wallet and how long/short the chrome will last! Jeroen | ||

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank Jeroen for this useful post: | digitalnirvana, Thad E Ginathom |

| | #789 |

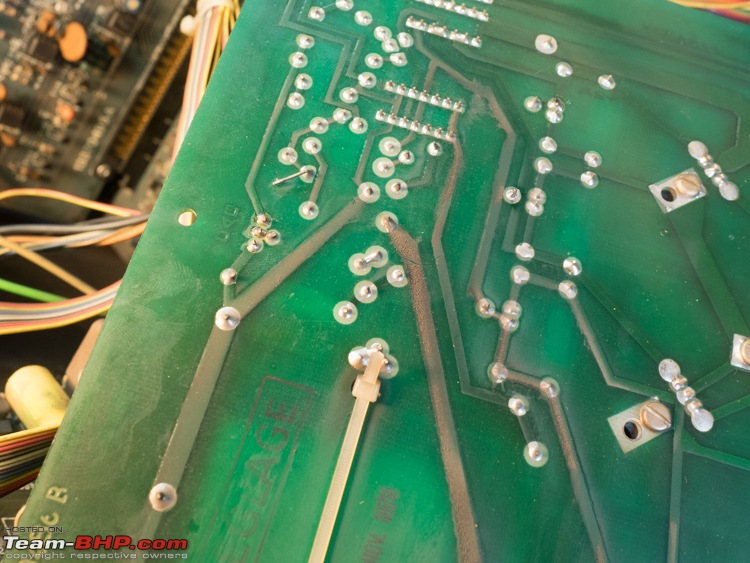

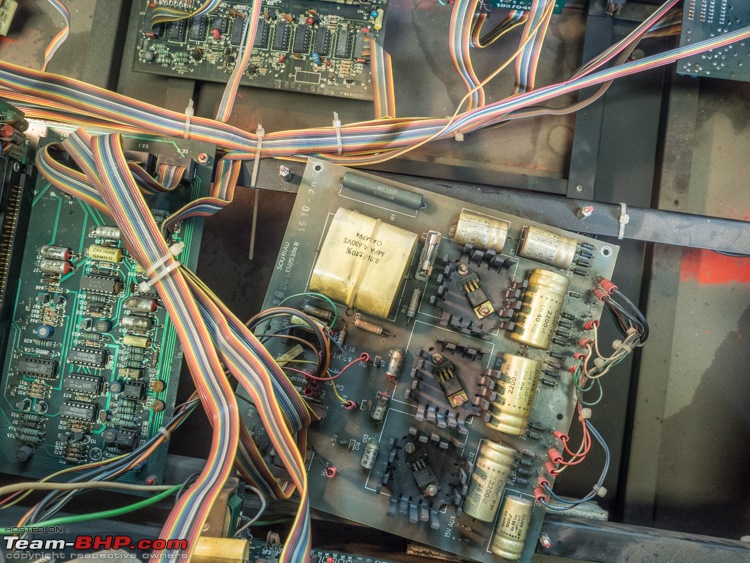

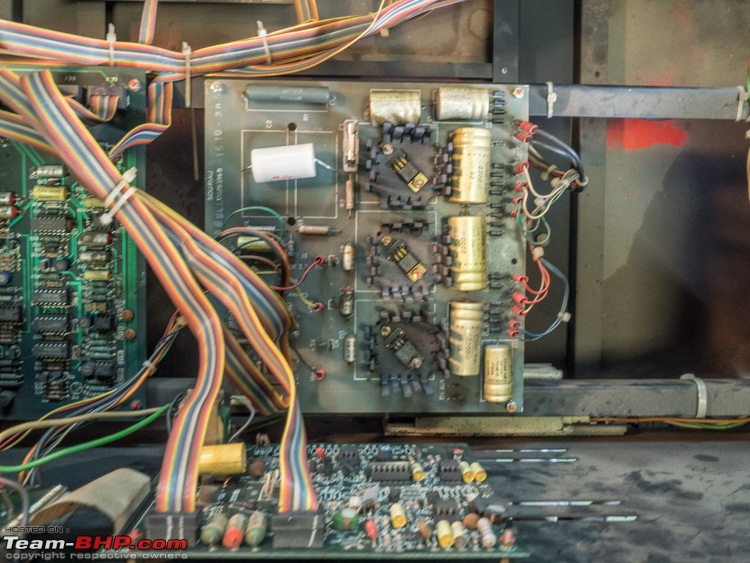

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Yesterday I decided to spend a bit more time on my still not fully functioning car analysers. So the usual set up. I have to keep the garage doors and the windows open, when I run the Mercedes engine. It’s only 4oC here at the moment, so it is not exactly a pleasant job.  I found some more problems on some of the PCBs. I re-soldered about half a dozen connections.  It certainly made a difference, because some of the functions are beginning to come alive again! However, there was also a very peculiar noise coming from somewhere deep within the bowls of all these electronics. Initially I thought it was just a relais clicking and sparking. But there is only one of those and it was that one. Tried to identify the culprit. Turned of all the lights, see if I saw any sparking. In the end I decided to use my old trusted stethoscope.  Sure enough, within minutes I had identified the component causing this peculiar noise. It was one of the very large capacitors. And it is related to the stroboscopic timing light which is not working properly. I have ordered a new capacitor, fingers crossed. Whilst I was busy with my electronics, Johan arrived! He brought back my Jaguar and the Spider Paravan. I am very pleased with the repair on the Jaguar. There was some nasty rust in the corner of the rear window, both on the right and left hand side.  Johan managed to restore and respray it, without having to take the window out. (which is a PITA on this Jaguar). I am very pleased, there is absolutely nothing that shows some respray work has been done here! Also, the Spider Paravan was done very well, perfect colour match!!  This morning I set about re-installing the paravan. Which is a very finicky job. Primarily due to very poor design by the Italians. First thing was to bolt the air intake back on. Sounds simple enough, but it took me almost two hours.  Next re-attaching the window washing tubes and making sure it actually sprays water and doesn’t leak anywhere.  I put everything back on, but I was not happy with the end result, somehow it just did not line up properly. Also, the rubbers on both ends of the paravan, newly bought, did not fit properly. So I took everything apart, cut the rubbers to proper size and re-installed everything again. Much better:   Finally the stainless steel bottom strip locks up everything. Looks nice, but is a real bear to install. Very fiddly.   All the rubber grommet on the window wiper mechanism are new as well. Just for good measure, I filled them up with Lithium grease.    Cleaned of all the grease and muck, put on a bit of wax and put the Spider back in its pyjama. All ready to roll as from the 1st of March onwards!  Last edited by ajmat : 8th January 2021 at 19:34. Reason: One picture did not get inserted...added |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Jeroen for this useful post: | digitalnirvana, vaasu, VivekCherian |

| | #790 |

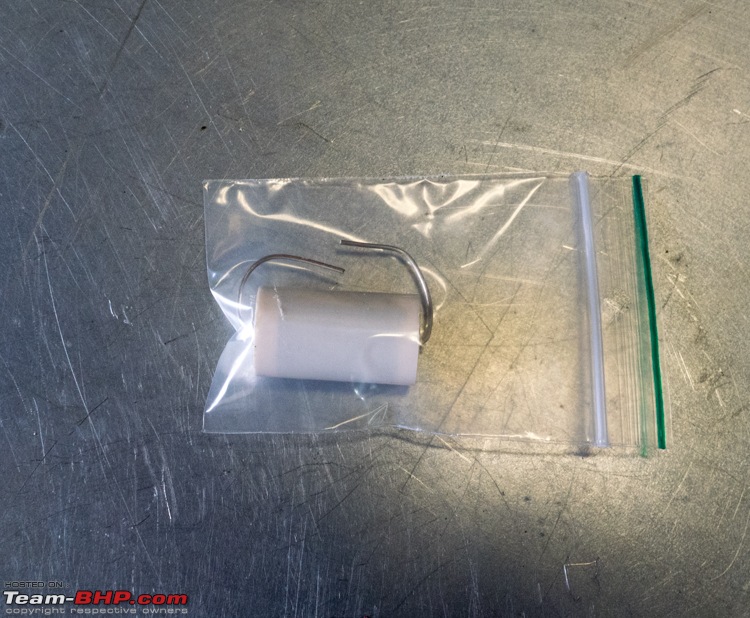

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Last Saturday the new capacitor arrived.  So I took the PCB out one more time, to replace the one that was making all these peculiar noises:  Here you can see the old one still mounted:  And now replaced with a new, more modern one (and thus smaller too)  The good news: The noises are gone! The bad news: the stroboscopic timing light still does not work properly! Back to the drawing board as they say! I cut open the old capacitor. I am still puzzled on what makes that ticking sound. I have searched on the internet and all kinds of noises have been reported from capacitors on their way out.    I could not find a thing, that would suggest it makes these noises. But it definitely did and at least that is sorted. So one potential problem eliminated. Many more to go! Jeroen |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank Jeroen for this useful post: | digitalnirvana, Thad E Ginathom, VivekCherian |

| | #791 |

| Newbie Join Date: Aug 2018 Location: Delhi

Posts: 15

Thanked: 19 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Thoroughly liked this thread. It's always interesting to see the life of a motoring man in some other part of the planet. With the semi-lockdown nature of the pandemic, there's more free time than before and I have been tinkering with some of my old cars. And restoring an old Fiat Palio of mine. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank SamDrive for this useful post: | digitalnirvana, Jeroen, Thad E Ginathom |

| |

| | #792 |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp |

| |  ()

Thanks ()

Thanks

|

| | #793 |

| Newbie Join Date: Aug 2018 Location: Delhi

Posts: 15

Thanked: 19 Times

| Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp The rusty old Fiat named, well, Rusty. It's the Palio 1.6. Flop in India, but loved by petrolheads. Almost 6 years in the making. Punctuated by ‘abandoned, but not forgotten’ timelines, working in other cities, my travels and then the Coronavirus pandemic. Engine and major body work. Oversized pistons, hi-lift camshafts, headers. Semi-roll cage. Tried to enhance the mechanical feel.    |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank SamDrive for this useful post: | digitalnirvana, Jeroen, Thad E Ginathom |

| | #794 |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Not much happening on this thread. My classic Spider and W123 are off the road for another two weeks. All maintenance has been done and since we are still in the midst of this pandemic no car shows or events to visit. But even so, did a little job on our Ford Fiesta. Rotated the tires. As you might recall some time ago I had to get new tires due to cupping. To avoid cupping I will now rotate the tires once a year. In this case back to front, these tires can not be swapped left/right as they are directional tires, so can only be mounted on one specific side of the car. Not a particular huge job. Two jacks, pneumatic wrench and a torque wrench is all it takes  These are steel rims. Still, the smallest, lightest, least powerful car in our little fleet has, by far the biggest specified torque for the lug nuts: 135 Nm  A bit of an unusual maintenance job too: Whilst rummaging through the loft in my garage, I can upon this Radio Controlled Helicopter. It belongs to our son Thomas. We bought it for him, when we lived in Kansas City and he used to fly it when he came to visit us. Has not flow for almost 10 years. So a quick check of all the wires, connectors, soldering, new batteries, a charge and lets see what happens:   |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank Jeroen for this useful post: | digitalnirvana, QuadraticAmoeba, R2D2, Thad E Ginathom, vb-saan |

| | #795 |

| Distinguished - BHPian  | Re: My Car Hobby: A lot of fiddling, and some driving too! Jaguar XJR, Mercedes W123 & Alfa Romeo Sp Got a nice surprise yesterday; If you have been following this thread, you might recall I had a bit on accident with the Jaguar in September 2019. https://www.team-bhp.com/forum/diy-d...ml#post4660270 It happened as I was waiting at the Stena Terminal at Harwich UK. The damage was repaired almost immediately. This car is insured under a “classic car full coverage” policy. So the insurance company paid for the damage, but minus my own risk. But they did go after the guy who did this damage. I did not say much about this at the time, but the guy who pulled his trailer against my door, was not cooperative at all. He and his son became very abusive and did not want to exchange contact deals. So I was left by taking a picture of their car, registration and them. Which really upset them. Luckily at that time we had to board and they had to get into their car. So I was not hopeful about the chances of the insurance company being able to recover. However, I received a letter from my insurance company informing me that they have managed to claim the full amount, including interest! Remember, I have a full comprehensive insurance, so I was only out of pocket for my own risk. (euro 150). As this is now fully settles, I received on the very same day Euro 165, the own risk plus interest. It also means that as far as this particular accident is concerned it will be on record as not my fault. Which is always good too. So very happy with the final outcome, even though it took almost a year and a half to be settled. This coming Monday is March 1st. Which means I can take the Spider and the W123 back onto the road. Weather looks good, I will give both cars a good look over this weekend, adjust tyre pressure etc. I hope to take them out on Monday late afternoon after work. Jeroen Jeroen |

| |  (6)

Thanks (6)

Thanks

|

| The following 6 BHPians Thank Jeroen for this useful post: | digitalnirvana, QuadraticAmoeba, R2D2, Thad E Ginathom, vaasu, vb-saan |

|