Quote:

|

Hope the attached schematic helps.

|

It did the job well but with a difference. Here is the complete picture of the Duel.

My plains are to get three Tachos. One will be used on my M800, second & third will be used to fine tune my carbs of HH S. Splendor, K.Nova 135 (4 Stroke Engine) & NV Spl. (2 Stroke Engine).

I positively feel that I will be able to accomplish this task with the help from Big brothers like you.

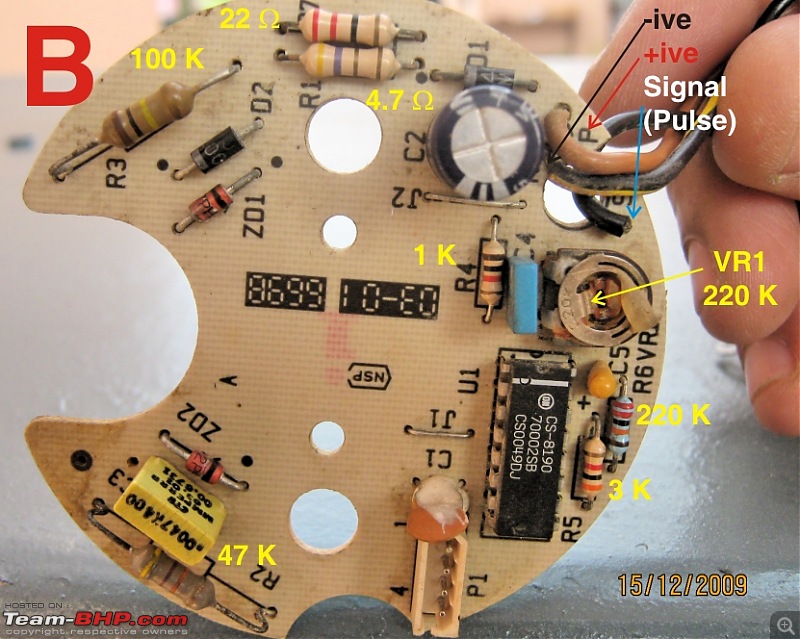

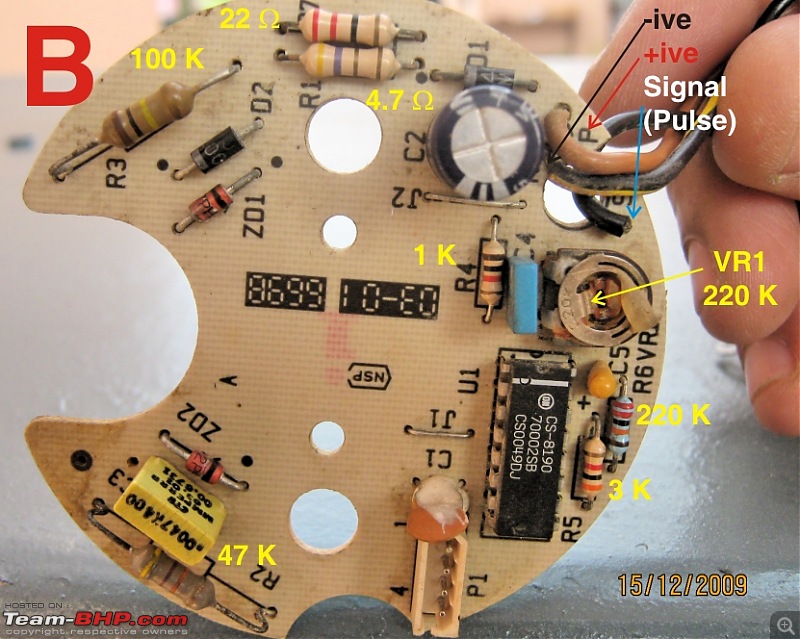

At present I have 2 Tachos (A & B) both are from Baja Bikes (’A’ is definitely from a old Bajaj Pulsar and

the other ‘B’, having the Old Bajaj Logo, no idea.)

Now, I have successfully checked ‘B’ with the circuit given by you and also by connecting it to my HH. S. Splendor. But ‘A’ was again stubborn to towards the given circuit & bike as well.

I made one experimental observation, though. I slowly lifted the tip of the armature needle, over the small pin (near 0) and let it go. Naturally the spring action (the snake like coil under the printed dial) tried to bring back the needle to the 0 but the needle stopped in between say number 8. When I powered the tacho, first, the needle came to zero & then when I signaled the pulse wire according to your circuit, It showed movement (1500 RPM). When I removed all the power the needle again went to 8.

Though, after this small experiment I placed the needle again to its original position (i.e. 0)

Now what is your ideas on this. Is there is the something wrong with the Spring Coil ? Its Placement etc.

Quote:

|

If possible please post a picture of the rear side of the tacho also.

|

Very much possible. Here is the front & back side of the PCBs

Quote:

|

Hope you have gone through the data sheet

|

Although, the Data Sheet is complex thing to under for a average like me, I am going through it

again & again and started to get hold of the things a little.

Quote:

|

post the values of the components Ct & Rt

|

As you can see in the picture I have 2 Cap(C4, C6) as Ct . I can identify the ceramic (Pale Orange one) but the other is having hard to remove white glue all over it. For Rt, if it is R6 + VR1 I suppose, then it is very much conspicuous. (360 K + 100 K) and I also de-sealed the pot (VR1 was set to 83.5 Ohm before I changed it for trial as you asked for)

With regards

Zmint

(1)

Thanks

(1)

Thanks

), but managed to caught hold of one, from the scrap yard.

), but managed to caught hold of one, from the scrap yard.

What do you suggest ?

What do you suggest ?

. But it was that signaling schematic that was helping me all the time. Without it, I still would be looming in dark.

. But it was that signaling schematic that was helping me all the time. Without it, I still would be looming in dark.