| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  1,130,255 views |

| | #76 |

| Senior - BHPian Join Date: Jun 2007 Location: Delhi

Posts: 4,902

Thanked: 8,348 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Excellent updates, shashi, on your golden goose. Subtle ideas and thoughts are all thats required to keep her running in the condition you have always desired for. Maintenance, time after time, will keep her looking timeless, time after time. |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank sidindica for this useful post: | baby_antu, Leoshashi, sumitsinha0280 |

| |

| | #77 | |

| Distinguished - BHPian  Join Date: Jul 2007 Location: MUMBAI

Posts: 3,060

Thanked: 5,406 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

1. Those are tooling holes, subsequently plugged. As you are taking good care of the floorboards, it's OK for you to use sealant in your car, for other cars, these holes are "supposed to be used" to drain out the water that the washing fraternity has a habit of spraying inside the car! 2. BLL850 is a 1987 model car. It has covered only 40300 kms in 29 years!  . You are correct for the bonnet, I wish I knew. It came like this. I'll ask the lady owner. . You are correct for the bonnet, I wish I knew. It came like this. I'll ask the lady owner.3. Correct, the side black strips are not there, though. 4. Hahaha, I mistook Ranchi for Raipur! 1600 kms from Mumbai is too long, maybe we can meet when I pass through from Ranchi airport to go to "you know where"! 5. Yes, I have two such grilles. One is brand new, which I will put only after completing the full restoration. The other one I picked up off a scrapped car just one month back. This is it's life story. It was there on an 800 which had the worst corrosion that I have ever seen, the doors had actually fallen off. The roof had holes in it. It was parked unused for many years in a building compound in Shivaji Park, exactly next to the seashore, directly getting the sea spray. I literally pleaded with the owner and got the grille 10 minutes before the scrappers came. The car was taken away on a handcart. The top screws did not open, the metallic cross member just fell away. I had to keep it immersed in a bucket full of surf water for 3 days, just to clean the grime. The four bottom locators are broken, I am drilling holes and putting two M5*0.8 size nuts and bolts in their place to locate it in the bottom panel. BLL850 is in safe hibernation now in my house in Pune due to the rainy season. I'll fit it when I take it out. I have ordered new bumpers. They look OK in the photograph, but all the mountings have deteriorated. Best regards, Behram Dhabhar Last edited by DHABHAR.BEHRAM : 6th June 2016 at 10:35. | |

| |  (11)

Thanks (11)

Thanks

|

| The following 11 BHPians Thank DHABHAR.BEHRAM for this useful post: | baby_antu, karuvally, Leoshashi, MAKMADDY17, rajvardhanraje, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000, Viju |

| | #78 | |||

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

1. Chrome wheel hub caps 2. Rear emblems-Hindi Maruti on the left side and Maruti suzuki emblem on the right. 3. Type 1 ORVMS Quote:

Quote:

Costs 3 rupees a piece if I remember correctly for my T2 bumper, so should be in that range for T1 also. Costs 3 rupees a piece if I remember correctly for my T2 bumper, so should be in that range for T1 also.Regards, Shashi | |||

| |  (8)

Thanks (8)

Thanks

|

| The following 8 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #79 | |

| Distinguished - BHPian  Join Date: Jul 2007 Location: MUMBAI

Posts: 3,060

Thanked: 5,406 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

Best regards, Behram Dhabhar | |

| |  (9)

Thanks (9)

Thanks

|

| The following 9 BHPians Thank DHABHAR.BEHRAM for this useful post: | baby_antu, karuvally, Leoshashi, MAKMADDY17, rajvardhanraje, Scarlet_Rider, sidindica, sumitsinha0280, tacho9000 |

| | #80 | |

| Senior - BHPian Join Date: Jun 2007 Location: Delhi

Posts: 4,902

Thanked: 8,348 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

My random search just landed me at this link which has amazing pics of that type of Sb308  http://www.team-bhp.com/forum/indian...80-dx-109.html | |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank sidindica for this useful post: | baby_antu, Leoshashi, sumitsinha0280 |

| | #81 | |||

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

Quote:

Quote:

This Maruti is one of the cleanest and the most original SB308 I have seen till date. It'll be infact our benchmark when we restore that white T1 next year. Regards, Shashi A Sad Update We are in the middle of a 2,500 km trip, and the speedo develops a fault, again!!. The needle is getting stuck randomly at 20 and 40 mark.  Last edited by Leoshashi : 6th June 2016 at 20:39. | |||

| |  (8)

Thanks (8)

Thanks

|

| The following 8 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #82 |

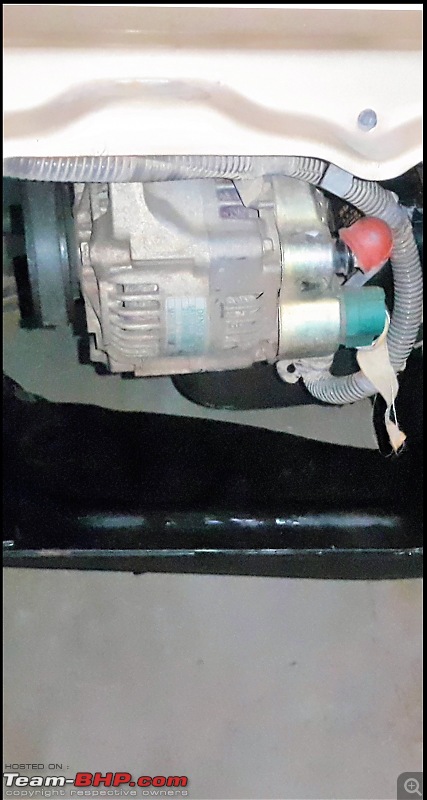

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Battery woes, this time Amaron goes down!!  After being extremely satisfied with Exide, I decided to try out something different this time. Went for Amaron based on recommendations, and also on my personal experience with my bike. Bought Amaron FLO 35Ah battery on 29th September, 2015 and today, it suddenly died on me, without showing any prior signs of weakness. The weird thing is, I was in the middle of a trip when this happened, and despite running the car for more than 450kms, the battery isn't storing the charge. After reaching Ranchi, got the alternator inspected by my MASS, and they too declared the battery to be the culprit. Have lodged a complaint, but I am pretty disappointed with the life of this battery. Does anyone have any experience regarding the warranty replacement procedure of Amaron?? Terminal voltage when battery is left idle  Used an inverter battery(12.8V) to start the car  Warranty card  Regards, Shashi |

| |  (8)

Thanks (8)

Thanks

|

| The following 8 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #83 | |

| Distinguished - BHPian  Join Date: Jul 2007 Location: MUMBAI

Posts: 3,060

Thanked: 5,406 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

. .Still if the battery is in any case dead due to its internal quality issue, you will have to replace it. Best regards, Behram Dhabhar | |

| |  (12)

Thanks (12)

Thanks

|

| The following 12 BHPians Thank DHABHAR.BEHRAM for this useful post: | baby_antu, glomus123, karuvally, Leoshashi, MAKMADDY17, Scarlet_Rider, Sheel, sidindica, Simat, sumitsinha0280, tacho9000, Viju |

| | #84 | |||

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

Quote:

Quote:

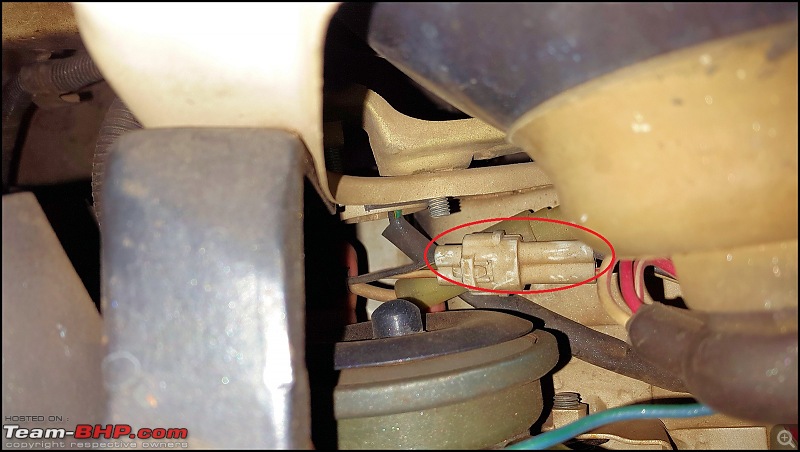

1. Output voltage at the terminals, at various rpm ranges. 2. My Fusible link was changed last year, so he ignored it. 3. He then asked a mechanic to remove the bumper, and fiddled with the alternator connector pins. I don't remember seeing any major dust or oxidation in it, still he blowed in it and applied WD40 and then some electrical grease in it. 4. After all these, he used a Bosch battery tester which measured some parameters of the battery, and the tester displayed result as weak. He checked these terminals.  I don't expect connectors to get oxidised in my car, as I have used electrical grease on almost all connectors I could find(including the indicator ones).  Earlier I have suffered bad connections due to rusting of terminals and oxidation(common in old cars), hence this precaution. Earlier I have suffered bad connections due to rusting of terminals and oxidation(common in old cars), hence this precaution.After all these things, he asked me to claim warranty for the battery. Based on your recommendation, I will take my car to him and get the fusible link checked again. Noticed a weird thing today- I measured the terminal voltage of the battery and it showed 11.4V. I thought the car won't start, still it started normally, as if nothing had happened. I thought that a normal battery should have more than 12V atleast for the car to start. Am I missing something here?? Regards, Shashi Last edited by Leoshashi : 9th June 2016 at 20:18. | |||

| |  (9)

Thanks (9)

Thanks

|

| The following 9 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, saket77, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #85 | |

| Distinguished - BHPian  Join Date: Jul 2007 Location: MUMBAI

Posts: 3,060

Thanked: 5,406 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

I have data on the Nippondenso alternator issues in the 800 (  ), I'll revert shortly on whether you should change to the SA15 or not, in your case the thing has run for 3 lakh kilometers. Be satisfied with the smiley for now! ), I'll revert shortly on whether you should change to the SA15 or not, in your case the thing has run for 3 lakh kilometers. Be satisfied with the smiley for now!Best regards, Behram Dhabhar | |

| |  (10)

Thanks (10)

Thanks

|

| The following 10 BHPians Thank DHABHAR.BEHRAM for this useful post: | baby_antu, karuvally, Leoshashi, MAKMADDY17, rajvardhanraje, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #86 | ||

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

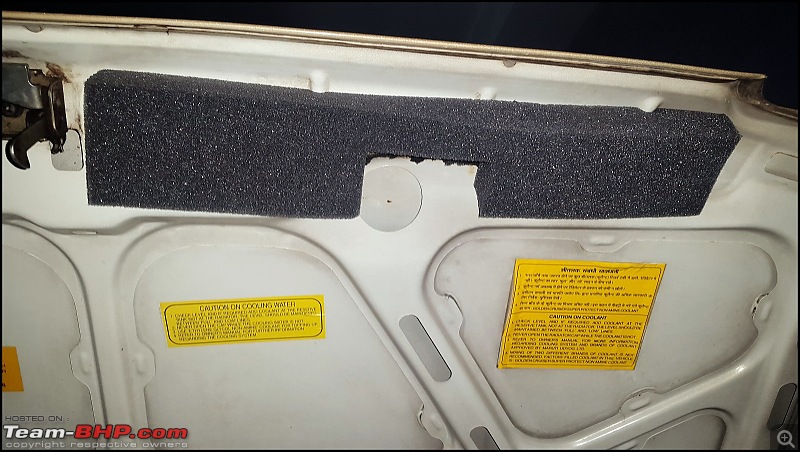

Thanks to Maruti, I got its part number, and was surprised that such an insignificant part(for aam junta) is still in production. No wonder they are trusted by millions in India.  Removed the remnants of the old foam completely, and pasted the new foam. Foam(packing) on the hood  Foam near the radiator  Part numbers  Update on the Alternator/Battery issue- I got my car inspected by MASS on all the points which you had recommended. They cleaned the alternator leads again, and although things improved after that, my SA wasn't satisfied with the results. He has asked me to visit again on Monday, when he will take the call whether an alternator overhaul/change is needed or not. He has declared the car fit for driving for the time being, and since I have an exam tomorrow, he asked me to postpone the extensive checkup/overhaul for Monday. Quote:

Update regarding child locks-As I have mentioned on page 1, that I have added Child locks on rear doors from the export model, a warning label was pending. I like things just in the way they come from factory.  Hence added it today. Hence added it today. Regards, Shashi Last edited by Leoshashi : 11th June 2016 at 18:37. | ||

| |  (9)

Thanks (9)

Thanks

|

| The following 9 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, saket77, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| |

| | #87 | |

| Distinguished - BHPian  Join Date: Jul 2007 Location: MUMBAI

Posts: 3,060

Thanked: 5,406 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

. You must hit the root cause. Did you locate the terminal at the other end of the wiring connections coming out of the alternator? If yes, what is the result and if no, please locate and see it, then tell me the result. If sulphating is there, remove the connector and connect the wires directly. My take on the alternator is very simple, Nippondenso parts are very costly and original parts are not easily available. Even if you overhaul the alternator, it will cost you nothing less than 90% cost of a new Lucas SA15. So you must replace the alternator instead of wasting your time. 3 lakh kilometres life is good enough. . You must hit the root cause. Did you locate the terminal at the other end of the wiring connections coming out of the alternator? If yes, what is the result and if no, please locate and see it, then tell me the result. If sulphating is there, remove the connector and connect the wires directly. My take on the alternator is very simple, Nippondenso parts are very costly and original parts are not easily available. Even if you overhaul the alternator, it will cost you nothing less than 90% cost of a new Lucas SA15. So you must replace the alternator instead of wasting your time. 3 lakh kilometres life is good enough.Best regards, Behram Dhabhar | |

| |  (10)

Thanks (10)

Thanks

|

| The following 10 BHPians Thank DHABHAR.BEHRAM for this useful post: | baby_antu, karuvally, Leoshashi, MAKMADDY17, rajvardhanraje, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #88 | ||||||

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

Quote:

Helped me reach the connector you were mentioning. Helped me reach the connector you were mentioning.Quote:

Quote:

Hunting begins  Spotted the wire behind right HL  I believe you were suggesting about these two connectors  Quote:

No Sulphating  Quote:

1. New Denso Alternator 50A,12V- Rs.11,245/- 2. New Lucas Alternator 50A,12V- Rs.5,786/- 3. Maximum Cost of overhauling Denso- Rs. 7,200 approx. 4. Maximum cost of overhauling Lucas- Rs. 3,500 approx. All connections made, with electrical grease to prevent oxidation  After convincing myself that all connectors are clean, I paid a visit to my MASS. They checked all parameters, and came to a conclusion that my current battery is bad, and that my alternator is perfect. 5641 at MASS  Voltage values with my current battery 1. At idle(No load)- 13.4V 2. At idle with stock headlamps ON- 12.9V 3. At 2500rpm(No Load)- 13.8V[This is the maximum its going with my battery connected] Voltage values with another known good battery 1. At idle(No load)- 13.6V 2. At idle(HL ON)- 13.2V 3. At 2500rpm(No load)-14.4V Battery charge with car turned off-Apologies for bad quality picture  Voltage with car at 2500rpm[No Load]  I am relieved that its not the alternator I have to worry about.!! Regards, Shashi | ||||||

| |  (9)

Thanks (9)

Thanks

|

| The following 9 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, saket77, Scarlet_Rider, sidindica, Simat, sumitsinha0280, tacho9000 |

| | #89 |

| Distinguished - BHPian  | re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Update- Amaron replaced the faulty battery with a brand new one yesterday, and I then checked the charging myself. Here are the results post replacement of battery: 1. Charging Voltage at idle(No load)-13.8V 2. Charging Voltage at idle with HL on-13.65V 3. Charging Voltage at 2000rpm(No load)-14.52V 4. Charging Voltage at 2000rpm with HL on-14.38V I believe everything is fine now. As they say, every cloud has a silver lining, this battery episode made me check my alternator in perhaps the most comprehensive way.  Special thanks to Dhabar Sir who took pain to guide me wherever I was going wrong. Its always awesome to interact with you, Sir. My 800 is lucky to have a mentor like you.  Next problem to sort out- As I had mentioned a few posts back that the speedometer has developed a fault, where it got stuck at 20 and 40kmph marks. I opened the speedometer and tried to fix it myself. Although I have managed to fix the speedometer to perfection, the odometer is probably screwed now. It moves too slowly and for a distance of 2km, it shows just 700m. I'll take a detailed look into it this Sunday, and will try to fix it. If not, I guess I will have to buy a new speedo. Regards, Shashi |

| |  (10)

Thanks (10)

Thanks

|

| The following 10 BHPians Thank Leoshashi for this useful post: | baby_antu, karuvally, MAKMADDY17, rajvardhanraje, saket77, Scarlet_Rider, sidindica, sumitsinha0280, tacho9000, viXit |

| | #90 | |

| Distinguished - BHPian  Join Date: Jul 2007 Location: MUMBAI

Posts: 3,060

Thanked: 5,406 Times

| re: The love of my life - A 2000 Maruti 800 DX 5-Speed. EDIT: Gets export model features on Pg 27 Quote:

). I don't blame them, in "our" way of working, it is like this only! Still go for it, best-to-best you will learn and worst-to-worst you will lose nothing. Tell me also what you learn, I've not really probed the inner construction of a battery, time to see the "party's proposal drawing" I guess! ). I don't blame them, in "our" way of working, it is like this only! Still go for it, best-to-best you will learn and worst-to-worst you will lose nothing. Tell me also what you learn, I've not really probed the inner construction of a battery, time to see the "party's proposal drawing" I guess!  . .For speedometer, it is a very delicate part. The forces required to assemble it have to be very closely controlled and monitored. Work on it and learn, all the best, but if it doesn't work, be prepared to change the whole thing and be done with it. Best regards, Behram Dhabhar | |

| |  (9)

Thanks (9)

Thanks

|

| The following 9 BHPians Thank DHABHAR.BEHRAM for this useful post: | baby_antu, karuvally, Leoshashi, MAKMADDY17, saket77, Scarlet_Rider, sidindica, sumitsinha0280, tacho9000 |

|