Team-BHP

(

https://www.team-bhp.com/forum/)

-

Motorbikes

(

https://www.team-bhp.com/forum/motorbikes/)

Quote:

Originally Posted by CLASSICREBORN

(Post 5770134)

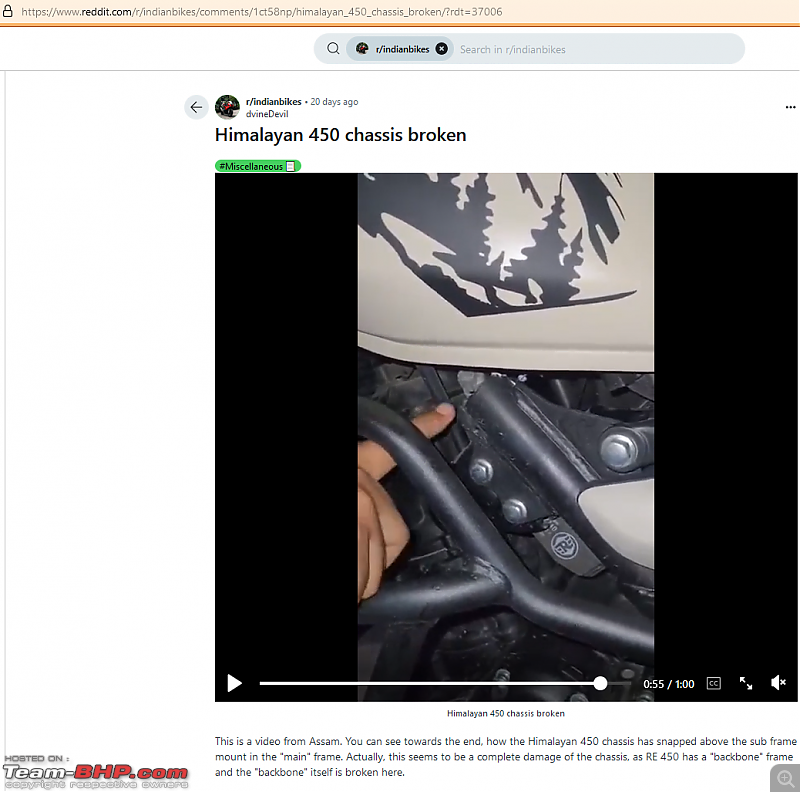

Link to first HIMALAYAN 450 Chassis breakdown I found on YouTube. I think it is from Tinsukia Assam.

I don't know if it has already been posted in the forum.

|

Clean shear of round section tubing. I think he's saying he jumped it over a speed breaker. Thanks for the share. Its the first one I'm seeing.

Cheers, Doc

Quote:

Originally Posted by CLASSICREBORN

(Post 5770134)

|

Looks like it broke right above where the subframe mounts. Quite a weird area to fail.

Quote:

Originally Posted by b16h22

(Post 5770247)

Looks like it broke right above where the subframe mounts. Quite a weird area to fail. Attachment 2606146

|

Weak-ened lever point. It broke at the first section of unsupported tubing after the subframe bolting plate cross truss.

Cheers, Doc

@ebonho, b16h22

It is very strange to see that Royal Enfield has not taken care of this chassis breakdown issue of the Himalayan. I have not seen this on any other bike from RE.

I think it is really a point of discussion if Royal Enfield has any issue with manufacturing ADV format of bikes.

Previous Himalayan had this issue and now the new one.

It will be very helpful if owners of New Himalayan or some expert can throw some light on it.

I really like the bike and was planning to get one untill now.

Quote:

Originally Posted by CLASSICREBORN

(Post 5770134)

Link to first HIMALAYAN 450 Chassis breakdown I found on YouTube. I think it is from Tinsukia Assam.

I don't know if it has already been posted in the forum.

|

Quote:

Originally Posted by b16h22

(Post 5770247)

Looks like it broke right above where the subframe mounts. Quite a weird area to fail.

|

It would be hard to dissect the events preceding to this failure, but it seems it's a fatigue crack to have happened and it's alarming to say the least, and this soon in its service life.

There are two points where the split subframe attaches to the chassis. Incidentally, the shear point is not at the point where the subframe attaches to the chassis eyelet, but well above the bolt eyelet point which is the backbone downtube of the frame itself. Sad!

Hoping this is a one-off occurrence and RE looks into this with zeal and helps the poor user for the foreseeable future. Definitely going to leave sour taste with the current and potential owners alike -- and at the wrong time.

Cheers!

VJ

Quote:

Originally Posted by CLASSICREBORN

(Post 5770134)

|

Wow, the video has been taken down!

That was a fantastic job RE!!!

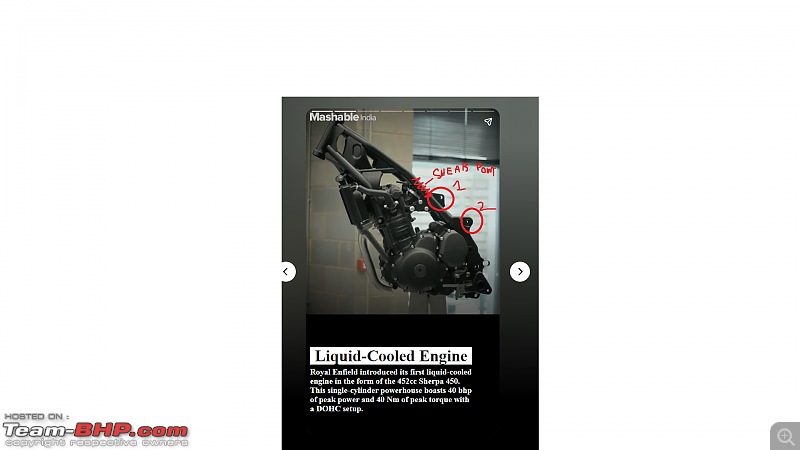

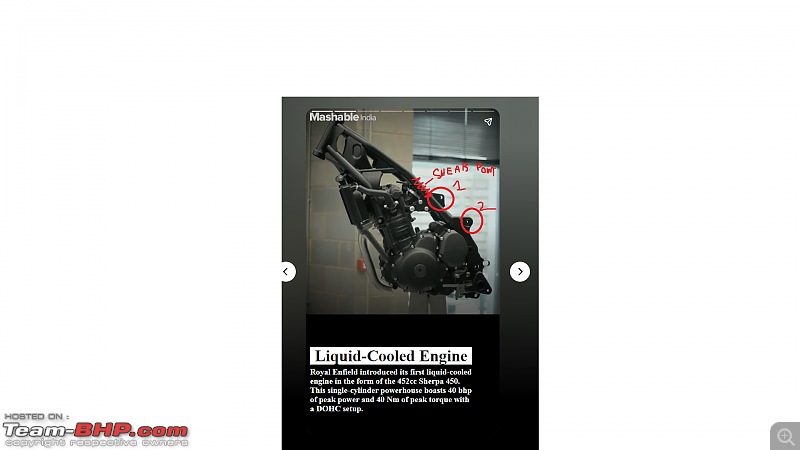

Chassis Breakage #2!!

Not sure about the preceding events, but sharing it as received.

Cheers!

VJ

Quote:

Originally Posted by VijayAnand1

(Post 5781341)

Chassis Breakage #2!!

Not sure about the preceding events, but sharing it as received. Attachment 2612640

Cheers!

VJ

|

Oh snap! it's breaking from the same stress point we discussed about in the previous case. Certainly not going to be a one-off case this. And on such a new and low miles frame too. Certainly a design oversight. :unhappy

Quote:

Originally Posted by VijayAnand1

(Post 5781341)

Chassis Breakage #2!!

Cheers!

VJ

|

Do we need to wait for #3 before it dawns on the factory that we have a serious problem teetering on the brink of a recall?

Ditto same spot shear as #1.

Cheers, Doc

Quote:

Originally Posted by VijayAnand1

(Post 5781341)

Chassis Breakage #2!!

Not sure about the preceding events, but sharing it as received. Attachment 2612640

........

Cheers!

VJ

|

I am just taking a wild guess here, looking at the picture of the current failure and the earlier failure.

Have you noticed that both the bikes had a top plate attached? any chance it is because of overloading the rack portion? The bike with the earlier failure has a top box mounting nubs. Whereas the current failure you can see the steel top plate and a bungee loosely handing from it.

Not everyone follow the limits ( 5 kg?) as in no one really measures their luggage weight before loading the bike right?

Not blindly supporting RE here, but don't you think they would have been EXTRA EXTRA careful after the previous gen fiasco?

Regards,

Viknaraj

Quote:

Originally Posted by VijayAnand1

(Post 5781341)

Chassis Breakage #2!!

Not sure about the preceding events, but sharing it as received. Attachment 2612640

Cheers!

VJ

|

With my amateur analysis, I feel this is exactly what is happening with the two frames that have broken at the same place. The forces from the front end and back end is putting the frame under stress near that breakage point and the weakest link gives up, which seem to be the non-reinforced steel tubes above the reinforced engine mounts + the engine as a stressed member. The long wheel base and weight of the bike is not helping I guess. Front engine mount seems to be acting as a pivot as well.

Quote:

Originally Posted by skviknaraj

(Post 5781432)

Not everyone follow the limits ( 5 kg?) as in no one really measures their luggage weight before loading the bike right?

Not blindly supporting RE here, but don't you think they would have been EXTRA EXTRA careful after the previous gen fiasco?

Regards,

Viknaraj

|

The top box weight limits are dependent on the strength and weight carrying ability of the rear rack and not the rear sub-frame. If an extra 5kg can break the frame in two pieces, how can we carry a pillion? Bikes have loading limits for pillion + rider and if you are riding solo and have a top box, you are still well within the weight limits of the rear sub-frame. Unless you have a really heavy pillion and rider onboard, the extra 10KGs is not going to make a difference. Secondly, the sub-frame should fail before the main frame. That's why most recent ADVs come with a sub-frame so the owner doesn't have to replace the whole frame in case of a mishap.

Quote:

Originally Posted by b16h22

(Post 5781433)

Attachment 2612701

The top box weight limits are dependent on the strength and weight carrying ability of the rear rack and not the rear sub-frame. If an extra 5kg can break the frame in two pieces, how can we carry a pillion? Bikes have loading limits for pillion + rider and if you are riding solo and have a top box, you are still well within the weight limits of the rear sub-frame. Unless you have a really heavy pillion and rider onboard, the extra 10KGs is not going to make a difference. Secondly, the sub-frame should fail before the main frame. That's why most recent ADVs come with a sub-frame so the owner doesn't have to replace the whole frame in case of a mishap.

|

While I do agree with your statement about the overall weight would not have exceeded the allowable kerb weight and hence top box overloading should not be a problem.

Please see the above sketch with my scribble in blue. The load on the edge will have the most lever arm and hence a higher moment. This moment will resolve as a push and pull forces where the sub frame connects. Steel being able to take more tension, the sub frame escapes. The same becomes shear for the main frame. The bottom portion of the main frame is thicker as the pivot connection and other frame components converge here.

Looking at where the subframe top connects, you have a comparatively thinner tube. And looking at the failure pictures, there seems to be shear failure of the material at that portion and no yielding.

So yes you are correct at the failure point the stresses are high. This can also happen if the material is not treated properly after welding, the welding stresses it self would have the made the material weak there ( Strain hardening). Usually, after welding, the materials should be heat treated to relieve welding stress. If this was required as per design and RE has not done it during production, it is a serious lapse in QC.

Lets see what RE has to say regarding this.

Regards,

Viknaraj

Quote:

Originally Posted by skviknaraj

(Post 5781447)

So yes you are correct at the failure point the stresses are high. This can also happen if the material is not treated properly after welding, the welding stresses it self would have the made the material weak there ( Strain hardening). Usually, after welding, the materials should be heat treated to relieve welding stress. If this was required as per design and RE has not done it during production, it is a serious lapse in QC.

Lets see what RE has to say regarding this.

Regards,

Viknaraj

|

I completely agree that there will be cantilever stresses on the sub-frame mount points but any competent frame designer is going to design the top rack or it's mount points to fail first in case of an overloading scenario. And followed by the failure of the sub-frame or it's mount points. The main frame should be the last of the failure points.

What got me thinking is the fact that the front engine mount bolts have been sheered off and that indicates some kind of strong upward force on the front end. If this happened purely due to the overloading of the subframe, that wouldn't be there.

I hope it's a material issue/heat treatment or a bad batch of frames from RE. If it's a design oversight, they'll need to recall all of the initial batch vehicles to replace the frame with a redesigned and stronger unit.

There are plenty of ADVs in this world with very well designed frames and subframes to take pillion and luggage without any failure. I sincerely hope this doesn't turn into another frame-failure saga for RE as these bikes are very new unlike the old Himmys which had fatigue failures in the headstock section with lots of miles on the clock.

| All times are GMT +5.5. The time now is 22:59. | |