Fellow members, I have one question. Can the adaptations , as posted in the thread done by coding service providers like CodemyVAg ? Actually I don't want to do these coding by myself. I am specifically looking at the AC tuning done by the others. Will they be able to do this ? Also how do I know whether the coder had taken a back up code of the original adaptations ? Will they share it with me?

Thanks in advance .

Anyone has managed to unlock a new version of rpm meter in Kushaq/Taigun/Virtus/Slavia? Attaching a picture of the same.

A quick question to the Gurus in here. I would like to purchase a VCDS HEX V2 kit. Any good alternative to the Ross Tech version? I am looking at an alternative as Ross Tech version is too expensive.

Hello everyone, there have been multiple posts on the tweaks which are there for VCDS, but this is not one of them. In this post I am going to show you how to monitor some of the most vital components of your vehicle so that one gets an overall idea of what would be wrong, or even avoid repairs which would significantly dent the pocket. These are the values which are measured and are available in most of the vehicles as well.

NOTE: We are not going to do any adaptations, coding to any of the modules, this is only indicates what the values are and what they signify as well. This can be applied specifically to VAG group cars without any changes, and can correlate to other vehicles as well with respective Diagnostic Systems.

Tools needed to get started:

1. A VCDS cable HEX V2 supporting your vehicle.

(This was done with an original cable, so if you are doing with a counterfeit cable I am not sure about the readings as well, and any repairs based on readings is on you personally and I do not take any charge of the same).

2. A laptop which can run the software.

I will be showing various measurements and the logic behind them, so lets start. These measurements are on a Audi A6 2.0 TDI. Depending on your vehicle you may/or may not get the Advanced Measured Blocks, but most of them will have it.

1. Measuring the stretch on the Timing chain/belt

The vehicle when approaches a certain mileage or age will lead to the timing chain/belt to get stretched. There is a way to measure the timing stretch in the form of angles. The logic behind this is that VCDS measures the total stretch by comparing the angles of the crankshaft and the camshaft. Ideally the timing chain/belt stretch should be showing 0 degrees which would never be possible. Suppose the camshaft is out by -2 degrees and the crankshaft is out by +3 degrees, then the difference between the will give you a value, and this value is measured and showed in VCDS. So a timing stretch can be caused by many things but mostly worn out guides and tensioners. So if this is bad you will get poor performance, increased misfires in the engine, and also knock. The steps to do this are:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values

3. Search for "Camshaft Adaptation Intake Bank 1: Phase Position" and add it.

4. If you add this and your engine is not running it will show 0 degrees and once you start the engine it will give you a value (mostly as far as I know a negative value).

Now you have the total degrees by which your Camshaft with respect to Crankshaft is out by. Anything above the -5 degrees, say -6 degrees and so on is considered bad. Anything between the -5 to 0 is still fine. If you get a value say -6 approx., then you will need to do replace the timing chain/belt in this case and by doing this, you are protecting the engine before hand and avoiding a major repair in the future. A snapshot of what I am talking about is here.

So in this case, it is almost due for a replacement, and you can even measure the value post replacement as well to verify a good workmanship as well.

2. Measuring the Alternator System

Alternators can be easily measured by multimeter when car is idling and should show a value between 13.5 to 14.5 V which is normal. There may be some components in your vehicle which may be sucking more power once you get onto the throttle say like a LPFP would consume more current at higher RPMs as the duty cycle demand increases. So result is a more current draw is drop in these voltage values. The steps are as follows:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values

3. Search for Engine speed, supply voltage: terminal 30, voltage terminal 30, and add it.

4. Click on log (if you want to see behavior at varying loads), Save the File, find a gear where speeds are low and just drive normally but with a little more throttle, so you get a good number of data entries at different loads.

5. Stop , now when you log it will be in form of CSV, convert it to a graph(many online tools available).

6. Once you convert it into a graph then you will be able to see the troughs and crests of the voltage system. Usually the supply voltage and actual voltage will mostly be the same as the battery and alternator will not vary much and delta would be minimal. If at the peak you should be close to 14.5V for a good system, and at the lowest bottoms you should be more than 13.5V for a good system, and the graph should oscillate between this two voltages i.e. 13.5V-14.5V. Now this is not a really important test and can be performed without running the vehicle as well, but usually when you are not driving and measuring on idle, your loads are almost constant( even with turning on all electrics).This will show you for varying loads and this is the only difference. Some people may say its unnecessary, but then there are many cases where I have heard the problems only existing in some areas of RPMs and while driving. This may be that if the voltage drops below a certain threshold the sensors would read a blank value, and hence this is a supporting answer for doing the test. A snapshot of the MVB here:

3. Measuring Test for Misfires in any given cylinders

Misfires can be due to bad coil packs, bad spark plugs, improper spark plug gaps and many other things. But as we know VWs notorious injector failures as well, so this can be a test for misfire before arriving at a conclusion to replace parts.

Important: Many times people may have heard from sources, that they have changed their normal spark plugs to something called as Iridium Spark Plugs when they are pushing in more power from the engine. To understand the science behind this, it is the spark plug gap. When you are tuning a petrol for more power, for example, you are feeding in more boost into the combustion process, then essentially all the other components of the engine remain the same, be it piston, coil packs, injectors. Say you are increasing the boost from 18psi to 26psi, you are going to bring in more amount of substance volume into the cylinder as well for it to combust. But here is the main part, when the compression happens your spark plug gap is at a level where the spark might not even reach the top and will be improper resulting in an substandard/inefficient combustion. So what we do is reduce the gap of the spark plug so that it ignites the volume up much better. And many go ahead and change the spark plugs and coil packs to get even more better result. So this is the science between why people change this part when tuning. And there is a reference and relation between the gap and the boost in psi a engine is running. Here it is:

Boost <=15psi/ 1.03 bar ----Plug Gap 0.028"-0.032"

15psi<Boost<30psi/2.06 bar ----Plug Gap 0.022"-0.028"

Boost>30psi/2.06 bar ----Plug Gap 0.018"-0.022"

Back to the topic. Steps are as follows:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values.

3. Search Engine Speed, Charge air pressure: Actual Value, Misfires per 1000 revolutions of cylinder 1.

4. Repeat the third step for cylinder 2,3,4...up to how many cylinders your car has.

5. Add misfire sum counter as well to know the total.

6. Click on Log, Save in an appropriate place.

7. Click start and go for a short drive for about 3 minutes but make sure you vary the load and cover most of the RPM range as well.

8. Once done, stop, now when you log it will be in form of CSV, convert it to a graph(many online tools available).

9. See for the misfires if any, if you get something then corresponding to that particular cylinder you will have to look into the spark plug, coils etc. If you get 0 for all then nothing is wrong with the car, or the tune as well if any. You will get a flat line in the chart where you convert something like this:

4. Measurement of Intercooler Function

Intercooler is the part which cools down the air temperatures before it enters into the engine, this hot air is usually coming from the turbo, entering intercooler located at front, intercooler cools down and feeds cold air to engine. Simple. Sometimes due to various reasons some may be suggested to replace intercooler, so in this test there are 3 things:

1. The temperature keeps on increasing

2. Stays flat or returns to mean value quickly

3. Temperature decreases.

So the 3rd one is what you really want but for most normal vehicles we can see a increase and then return back to mean value when letting of the throttle. This would be ideal way for the intercooler to function.

So the steps for the same are as follows:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values.

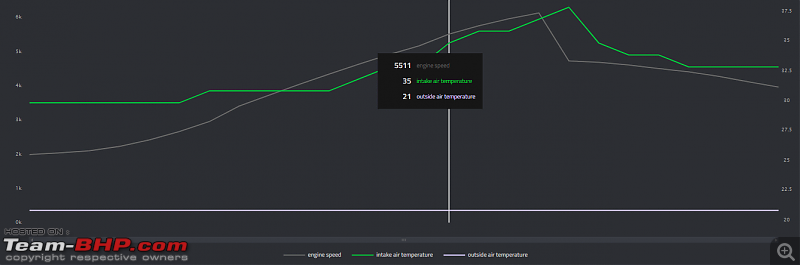

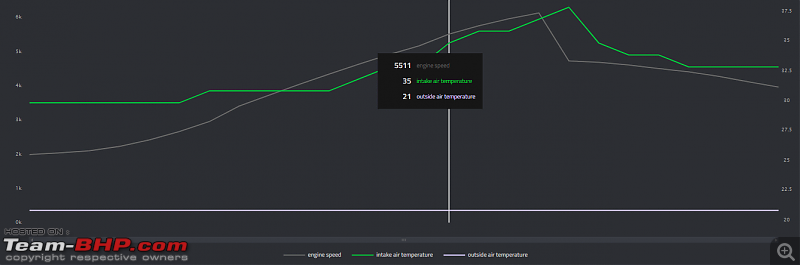

3. Search for Engine Speed, Intake Air Temperature, Outside Air Temperature/Ambient Temperature and add it.

4. Click on Log, Save in an appropriate place.

5. Click start and go for a short drive for about 3 minutes but make sure you vary the load and cover most of the RPM range as well. Do a third gear pull if you really want to see at peak RPMs

6. Once done, stop, now when you log it will be in form of CSV, convert it to a graph(many online tools available).

7. You will now be able to see an increase or somewhat flat type of line in the graph. Generally it will be an increase if you are running a boost map and have not upgraded the intercooler. Dropping temperatures is the best, but usually means mounting an extremely big intercooler which may not even be available for your make. So return to mean value or close to mean value is the best you can get from an intercooler. When you push in more boost and working the turbo more, you are also increasing the IATs as well, this is why sometimes an intercooler upgrade is necessary as well.

Important: Sometimes you may see white deposits on your spark plugs, this can be due to running too lean or improper fueling, or running to hot. If your IATs are increasing substantially by more than say 8-10 degrees then it is direct indication of running to hot, and problems with the intercooler. Usually for tuned vehicles this can also catch a variety of problems from fueling issues, injector issues, pump issues. But for stock vehicles it can also serve to check the fuel system once you see these white deposits due to improper fueling.

A graph of the same is here for reference:

5. Measuring Ignition Retardation on cylinders

As we know the ECU is a complex unit and can control the engine at varying scenarios and this is what brings me to show you how it actually controls the combustion process by controlling the timing of the engine. The timing is the most crucial and can cause series of problems if not correct. Now let us understand it in quite some detail as well. So before talking about timing/ignition retardation, let us talk about how normal combustion occurs in the cylinder. Experts can skip this part, newbies are welcome:

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

To understand this you firstly need to know about the compression stroke of the engine. Now the cylinder can be labelled as top dead center which is basically a mark in the cylinder where the piston is at its maximum stroke length. So this is the TDC of the cylinder. When the piston is at the bottom most point of its stroke length it is know as Bottom Dead center or BDC. The volume of the cylinder when the piston is at BDC : the volume of cylinder when the piston is at TDC, this ratio is known as the compression ratio. Will get back to this later. So when the compression stroke occurs, in a petrol engine, the air and fuel are a mixture and the piston is compressing this mixture as of now. We need to fire the spark plug before the TDC of the cylinder to create a good combustion process, so that the combustion happens in a laminar flame front, and is even as well. Combustion flame speeds are comparable to piston speeds as well and both are around the same ballpark, for instance the piston speeds can be 17m/s at redline(just an example, and depends on many other things as well). This is measured in degrees with respect to the crankshaft, so when we fire the spark plug before say 28 degrees before TDC then the piston will reach TDC and the maximum combustion pressure will be built after the TDC and when the piston is on the power stroke. Let us assume it to be 17 degrees is at where the maximum combustion pressure occurs. So this is the normal combustion, and when the spark plug is fired before the TDC it is known as

Ignition Advance.

Now comes the destructible thing of most of the engines which is knock. Knock is basically an uniform or rather non laminar flow of the flame front after the spark plug ignites. Just assume the spark plug has ignited the mixture and the flame front is laminar, but there are some pockets or rather say areas of this mixture which will self ignite due to higher pressures and temperatures, when this non laminar flame front and uneven ignite of pockets of mixture happens this is known as knock. There are knock sensors which listen to your combustion process and once the knock is detected this signal is sent to the ECU so that it can control the process. Now coming to the ECU logic, when knock is detected it will either reduce timing (take out timing) or add more fuel to the process. Now when the ECU detects knock and decides to fire the spark plug later then this is known as

Ignition Retardation. Say before the spark plug was firing at 28 degrees before TDC and the max combustion pressure is at 17 degrees after TDC, and now knock occurs. Now the ECU decides to fire the spark plug at 24 degrees before TDC and the max combustion pressure builds later because we are firing it later, say at 20 degrees. This is the complete explanation of Ignition Retardation and Advance. Hence Ignition Retardation is actually saving your Engine till an extent to where the knock does not occur, if it is retarding too much then there are issues as well.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Steps to see Ignition Retardation are below:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values.

3. Select Engine Speed, Timing Angle Retardation cylinder 1/2/3/4, and also Ignition Timing Adjustment for any of the cylinders you wish, this is what the ECU tells to do and the real time timing as well, we will select cylinder 1.

4. Click on Log, Save in an appropriate place.

5. Click start and go for a short drive for about 3 minutes but make sure you vary the load and cover most of the RPM range as well. Do a third gear pull if you really want to see at peak RPMs

6. Once done, stop, now when you log it will be in form of CSV, convert it to a graph(many online tools available).

7. Once you see a graph, there will be a negative value for retardation for the respective cylinders, and this value as per benchmark should not be more than -4/-5 is the average and is fine for most of the vehicles, and -2/-3 is really good if running for good performance, anything greater than -10 is an issue. This will give you a complete idea about how the compression stroke is happening for your engine. If the timing is too off then it indicates something wrong with the spark plugs/ignition coils, so need to check for them. There are many ways to improve this, most simplest one would be by filling higher octane/grade fuel which will reduce chances of knock, and not retard too much of timing. One can also do a comparison of 92RON/95RON/100RON as well through this test.

Here is a picture of how the retardation process works and the graph for the same: Picture here:

6. Measuring the Fuel System

There above in the same thread.

7. Measuring the TurboCharger boost

There above in the same thread.

8.Measurement of Boost Control Solenoid Valve

Boost control solenoid is responsible for the proper functioning of the turbo by modulating the wastegate actuation. Not going into details of this as it may be too long. If your Solenoid is going bad, or is faulty, your vehicle will throw an error code, but sometime may need to diagnose this solenoid. These are the steps to diagnose the solenoid as follows:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values.

3. Select Engine speed, charge air pressure: specified value, charge air pressure: actual value, charge press: ctrl :spec value.

4. Click on Log, Save in an appropriate place.

5. Click start and go for a short drive for about 3 minutes but make sure you vary the load and cover most of the RPM range as well. Do a third gear pull if you really want to see at peak RPMs

6. Once done, stop, now when you log it will be in form of CSV, convert it to a graph(many online tools available).

7. Now there will be a graph, and this may be little difficult for a novice to understand, your boost control will work in the form of percentage of open/close relative to the wastegate actuator. So if it is say 95 percent, then your wastegate is closed, letting the turbo to build the boost, and when the wastegate opens the exhaust gases escape from here. So now, the charge air pressure or the boost specified value is the value what the ECU is requesting, and the charge air pressure: actual value is the value what the turbo is delivering. So now you have both these curves, and the actual value should be somewhere close to the specified value, and the both should not have a big delta between them. If the actual value is over the specified value it means that your vehicle is overboosting, and vice versa, if the actual is below the specified value then turbo is not meeting the requirements set by the ECU which may be either a turbo problem itself, or a Solenoid problem.

So when the turbo is overboosting means that the solenoid should be set to open a little more, to open the wastegate. If it is underboosting then the solenoid should close, to close the wastegate and let the turbo build the pressure. So this might be a too technical things for those who do not know about the boost controls, and what I am talking about, but mostly this could be the simplest way I could explain. Below here, I will attach a picture of what the graph looks like for reference, in this particular vehicle, the solenoid is not correct and is overboosting. Picture here:

9. Measurement of STFT and LTFT

Now this is a advanced way of measuring the AFR or Lambda, and there is a a very simple way as well, which is short and explained here: Go to Engine ----> AMV(advanced meas value)----> Oxygen sensor or lambda sensor from the list bank 1----> Get a log of the same, and it should oscillate close to 1 for a reference point.

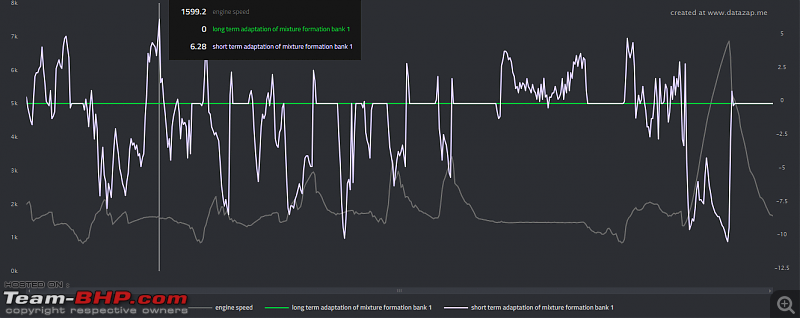

Now back to the STFT, since we know the basics of lambda, it is the AFR in the combustion process, and Lambda reference is set to 1, which is the best stoichiometry to be followed. So if you are going above 1 you are running lean, and below 1 you are running rich. So the ECU will have a data table for different things, and there are short term tables and long term tables stored in the ECU. The ECU will be running tables of values for the lambda as well in its memory and this values are derived from various sensors like ambient air temp, pressure, IATs etc. So there will be value in tables in the ECU. So now short term tables are the ones which are changed and updated by the ECU on a constant interval of time, which basically means real time. So short term tables in laymen terms are real time tables. And long term tables are derived from the short term tables over a sustainable period of time. And this entire process of updating the calculated data in short term, and then over a period of time, updating it to the long term is known as

Adaptations.

When the short term fuel trim are adjusted by the ECU in real time, then later on over some specified time these will be entered into the long term tables. These tables will exist for most engine parameters.

Suppose now you start the vehicle in the morning, cold temperatures, ambient conditions are varying, so your STFTs are altered immediately to ensure smooth running. Say everytime at 2750RPM then STFTs are running to rich and are adjusting the same. So over a period of time the ECU will monitor this and then update this thing in the LTFT table. So the next time when the conditions remain the same, you reach 2750RPMs your STFTs do not need to be doing adjustments are already met to the value in the LTFT table. So your LTFTs are the ones which will be default and will dictate the things for STFTs to alter the values based on the conditions. We can measure this in order to eliminate various problems or weaknesses of the vehicle, and also this will change if any of the thing such as fuel quality is bad, weak HPFP etc. This is a brief explanation of this, Fuel trim are in %,and to measure this you need to follow the steps below:

1. Open VCDS, select Engine Module Address 01

2. Click on Advanced Measured Values.

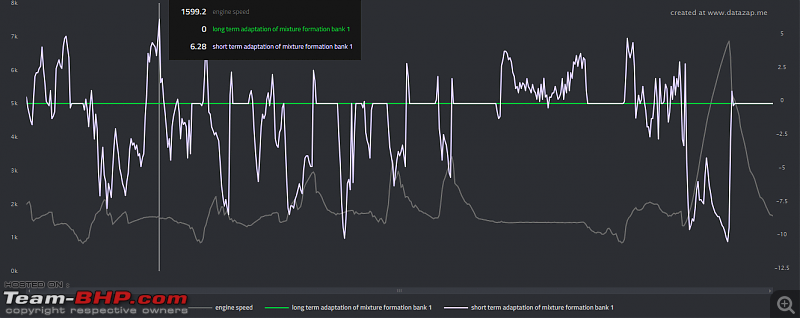

3. Search and add Engine Speed, Short term adaptation of mixture formulation bank 1, Long term adaptation of mixture formulation bank 1.

4. Click on Log, Save in an appropriate place.

5. Click start and go for a short drive for about 30-40minutes but make sure you vary the load and cover most of the RPM range as well. Do a third gear pull if you really want to see at peak RPMs

6. Once done, stop, now when you log it will be in form of CSV, convert it to a graph(many online tools available).

7. Now you will have a graph, a reference here, the STFT should not vary more than 10% as a general rule, and the LTFT should not vary more than 5%. If you have negative % it means you are removing fuel from the system and vice versa. Here is the picture of the same:(here LTFT are not picking up as I drove for less time):

10. There are many self explanatory Measurement Value Blocks as well, but some complex ones which I will cover.

AC Compressor Torque: Can check if the clutch is actuating properly or not.

Refrigerant Pressure: Can check for leaks in lines or condenser by using this MVD, should show between 150-250PSI

Injection amount deviation cylinder 1/2/3/4, should be not more than -3/+3 mg/str, this can be used to check injectors.

Coolant Fan, to check if running properly, actuation is fine.

Pre Injection, Post Injection Activation and Durations, Injection SOI, indicates the start of injection of fuel in terms of Crank angle degrees CAD relative to TDC. Here is why I told about the retardation above.

Brake Actuation, if you by any chance the brakes are held by something when running, same goes for the clutch as well.

Immobilizer Snapshots, the exact coding of the immobilizer when you command it, immobilizer changes codes and should match ECUs to start the vehicle, this is the snapshot of that coding.

ECU Status Type Sample: If this says "production" then ECU not tuned, if says "sample" it is tuned. This is for the people who think the remap will not be noticed by the dealership. A simple VCDS MVB can show if the ECU is tuned or not. Thank me later!

That is it for now guys. There are a lot of other things to cover which I will be posting slowly as I find time, and will cover all the values for most of the vehicles from the VAG stable. So stay Tuned for that. Hope all of this helps you to monitor and diagnose the important variables of your vehicle by yourself, and not fall prey to false information and diagnosis. I would be more than happy if this gets a separate thread altogether. Hope you find this useful.

Happy Motoring!

Guys, can someone help me with this. For my Polo Tsi 2020.

I am looking to buy OBDeleven from their official website. Or VCDS with cable.

1) My need is basic diagnostics, which one will suit me better?

2) Which is a good site selling a proper VCDS cable ?