Team-BHP

(

https://www.team-bhp.com/forum/)

Dadu,

Any idea what ECU does Tata use for the Safari ?

thanks

Thats what I am trying to figure out, the SA told me they use a laptop with software provided by TATA to diagnose the ECU. Rest all terms like OBD etc were greek to him.

No other clues yet.

Quote:

Originally Posted by smsrini

(Post 900358)

Dadu,

Any idea what ECU does Tata use for the Safari ?

thanks

|

Ignorance is bliss - to the TATA house atleast!

Finally got a chance to read this thread in detail!

A super compilation there Dadu! You've given a great overview without getting too technical. :thumbs up

Any info on how exactly the engine load is calculated/measured?

cya

R

Mind you, most of this ECU technology has evolved to meet the stringent emmission standards, rest all are its added benefits.

All ECUs are simply programmed to understand the engine hardware it is trying to control and the sensors that are being used to control the engine. The hardware being controlled includes the engine turbochargers, electronic throttle bodies, various control solenoids, and engine sensors including the critical MAF/MAP sensor. In order to meet ideal emission standards, the ECU is programmed to achieve 1 Lambda (or an Air/Fuel ratio of 14.68:1 for petrol fuel) during idle and light cruising conditions. To achieve this, OEM calibration engineers will spend extensive time working with sensor manufacturers, testing, and analyzing data in order to establish proper ECU calibrations. A major component of these calibrations includes the calibration for the MAF/MAP sensors.Loads are measured using these sensors i.e - MAF(Mass airflow) sensors and MAP (Manifold Absolute Pressure) sensors.

MANIFOLD PRESSURE (MAP) SENSOR

A MAP sensor is a pressure sensor that's connected via a hose to the intake manifold downstream of the throttle. In the case of a naturally aspirated engine, the MAP sensor reads manifold vacuum only, while those fitted to forced induction engines measure vacuum and boost. The output of the MAP sensor is fed into the ECU where it is referenced against revs and intake air temperature. These inputs allow the ECU to calculate the engine's mass intake flow, enabling it to provide the appropriate fuelling and ignition timing.

An electronic sensing element converts engine vacuum (or pressure for turbo/superchargedapplications) into an electrical reading, which the ECU interprets as an engine load signal. As engine load changes, so does the engine’s inlet manifold vacuum, the corresponding signal reflects this.

MASS AIRFLOW (MAF) SENSOR

The MAF calibration is programmed to correlate the ratio of the MASS of fuel being injected in the engine with the MASS of air entering the engine. This information is then used by the ECU to achieve the fuel targets dictated in the fuel table/s. Once the ECU has been properly calibrated, it will then be able to calculate accurate Lambda (or Air/Fuel) values.The ECU will use the MAF sensor readings to make initial fueling calculations.

The ECU will then use another sensor, which is located in the sealed exhaust system, to measure the actual Lambda (or Air/Fuel ratio) achieved by the engine. This sensor's measurements are then used to make corrections to the fueling of the engine in order for the engine to achieve it's fueling and emissions goals. All other components used for making fueling calculations need to be properly calibrated within the ECU to achieve this.

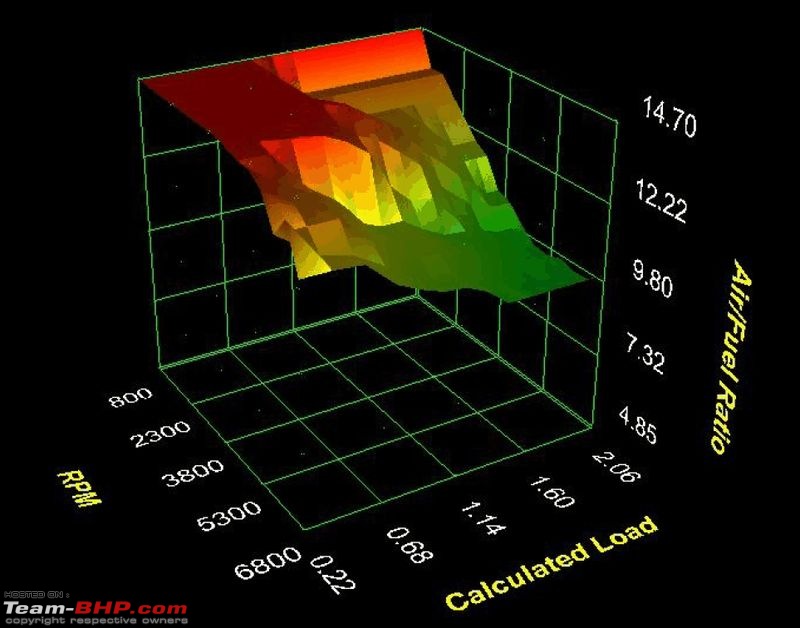

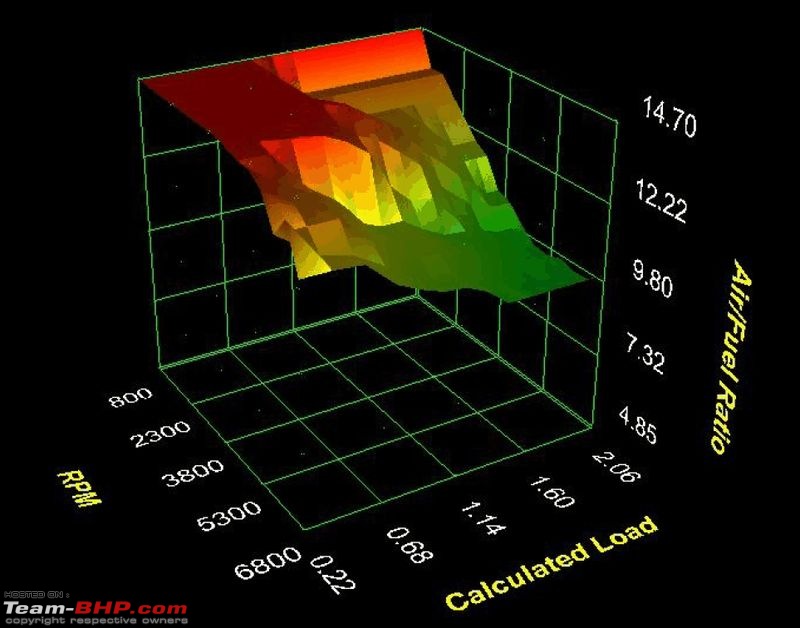

An example of a modern fuel look-up table.

The ECU is programmed to make more than one correction for fueling, it can actually make several STFT and LTFT corrections across the MAF sensor range.

Wonder why Maruti could only think of "A" star whilst the minimum should be 5 stars. You have it Dadu :)

The layman in me had a tough time digesting all the hardcore information provided by dadu:)

Will I be wrong in putting it in simpler terms, that we are not anymore directly revving the engine by pressing the accelerator pedal, but the ECU does it by comparing to a map, after taking into consideration the parameters provided by the different sensors?

I have felt in the Chevy Beat that the response is a bit delayed [not at all measurable, but still I 'feel' the minutest of delay] comparing to older generation cars where I felt that my foot is mechanically connected to the engine. What could it be?

One questions though - why does the ECU depend on a map? Is it because it will be much slower to respond if the output is always calculated (using formulas), instead of retrieving the value from a map?

Quote:

Originally Posted by thoma

(Post 2589629)

... why does the ECU depend on a map? Is it because it will be much slower to respond if the output is always calculated (using formulas), instead of retrieving the value from a map?

|

Yes. It would be a criminal waste of time solving an equation with a given set of inputs every time, just to get an answer which is invariant with the same set of inputs.

It is simpler to solve the equation off-line with input values varying as desired, and storing the results in a 'map'. This is a conventional computational technique - using reference tables. Saves computational time and cost - one can use a less powerful microprocessor and save overall cost of the ECU. Conversely, one can use the computational power of a microprocessor for lot more functionality if you save on time spent on calculations that are frequently / constantly repeated.

There are many other examples that predate usage of 'maps' in ECUs. Anyone who has used 'Steam Tables' in mechanical engineering should be able to recognize that, along with a couple of other graphs used for heat cycle calculations. Imagine what would have happened to our limited (and really hassled) brain power during exam time had such tables and maps not been present. :D

Quote:

Originally Posted by DerAlte

(Post 2589888)

Imagine what would have happened to our limited (and really hassled) brain power during exam time had such tables and maps not been present. :D

|

Even with the steam tables, I had a tough time finding how to use it, to arrive at a sensible answer:uncontrol

The software engineer in me has been dominating over the mechanical engineer over time, and asked about using formulas as he thought he could get a perfect answer every time if one is using a formula rather than a map. This was because, since the number of parameters are more and for the same set of parameters, a formula would give the same result than a map.

Maybe, we can compromise on the accuracy than the time. Imagine a humorous situation where we are overtaking a lousy truck driver and we step on the gas, when the ECU asks for a break, getting confused calculating over the ever changing input parameters:eek:

Great thread!

The yellow light (emission control sensor) on my Swift (K-series, 2010/2, 7500 km) prevented the car from starting up yesterday. This morning the car started but the light didn't go off. I disconnected the battery for 15 minutes and put it back on and now the light is gone. Is this a good way yo deal with this problem? Do I still need to go to a MASS for running diagnostics?

After (supposedly) resetting the ECU (by disconnecting the battery for 30 minutes), I drove the car for about 25 kms and parked it. When I tried to start it later for another trip same problem appeared. I gave a short self and the car wouldn't get to idling after picking up with yellow light staying on. I took the key out and tried again with a full length self and the car started with the yellow light on. Today I took it to MASS and they said it is an accelerator actuator problem with K-Series and generally happens when there is low voltage. Low voltage could be present when battery is low or when car is push-started. Also, K-Series ECU is not reset by disconnecting the battery. I don't have any battery problems or a push-start instance so it could be due to a short self I gave (I am used to shorter cranking). He did a reset on the ECU and now it is looking good. Seems like a bug!

Mods: I wasn't able to edit my previous post so had to post a reply. Please let me know if I am missing something here.

Quote:

Originally Posted by heysac

(Post 3368102)

Today I took it to MASS and they said it is an accelerator actuator problem with K-Series and generally happens when there is low voltage. Low voltage could be present when battery is low or when car is push-started.

|

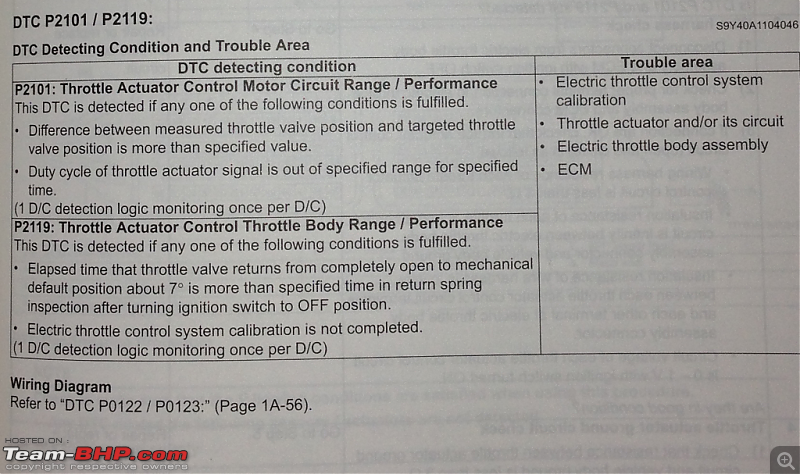

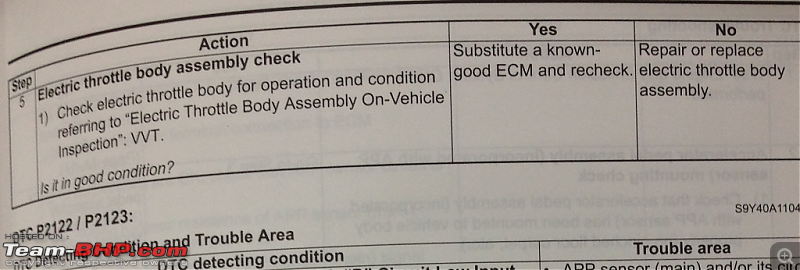

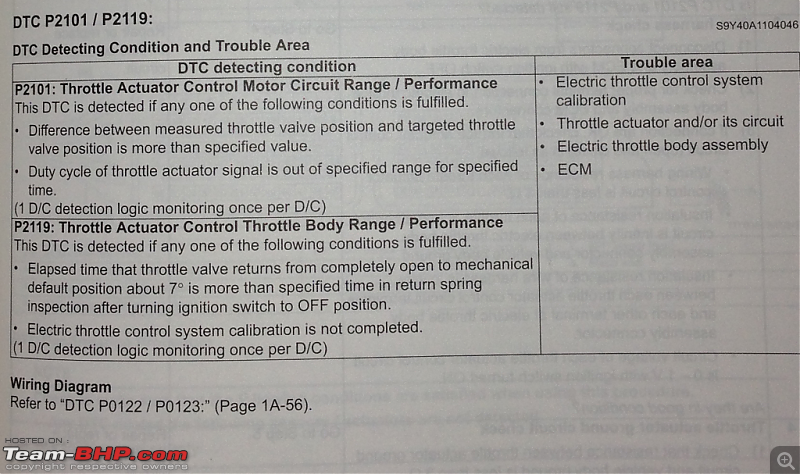

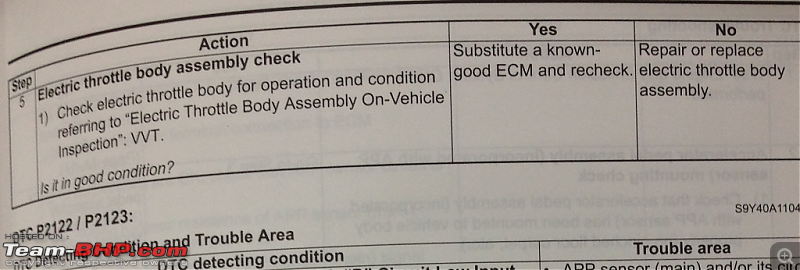

Here's the diagnostic procedure for the P2101 error from the service manual...

Quote:

Originally Posted by heysac

(Post 3368102)

I gave a short self and the car wouldn't get to idling after picking up with yellow light staying on. I took the key out and tried again with a full length self and the car started with the yellow light on.

|

What you're noticing could be not due to your 'short self', but what the ECM considers a "Driving Cycle" - which is why the diagnostic procedure mentions turning the ignition 'ON' for a minute & then turning it 'OFF' for a minute, & repeating this a couple of times. For most errors the ECM keeps track of how often errors occur & the 'Check Engine Light' is lit only when certain 'rules' or conditions are fulfilled. For some errors the ECM triggers the 'Check Engine Light' only after the error is noticed for more than one driving cycle. For certain errors, the 'Check Engine Light' is automatically 'unlit' once an error noticed earlier (thus causing a 'lit' condition) does not occur for two continuous driving cycles.

The diagnostic procedure above is from the SX4 VVT Service Manual. You'd be surprised how much parts sharing & software gets reused, I'm sure the Swift's service manual has the very same content as the SX4 service manual.

Thanks for the info! My Swift is not VVT.

Where can I get a copy of the service manual? Is it available at MASS?

What should be my next step, wait and watch?

Quote:

Originally Posted by heysac

(Post 3368382)

Where can I get a copy of the service manual ?

Is it available at MASS ?

|

If the service center you visit is an authorized one, it should have the Service Manual.

You can buy the service manual from an authorized MGP store.

Visit the

MGP web-site to find one near you.

Quote:

Originally Posted by heysac

(Post 3368382)

What should be my next step, wait and watch ?

|

Yes, looks like your service center has cleared the DTC.

If the DTC comes back, then they'll need to systematically go through the procedure mentioned in the Service Manual.

Folks,

My brother's Chevy Spark met with an accident some months ago and has been with the service centre for more than 2 months (reason being the ECU was also damaged and needed to be replaced, but a replacement was not available) The part was to arrive from Bangalore (God knows why !) and since it's been so long, they've come with an alternate solution - get another car's ECU, clean swipe it, reload all relevant software and install it in the Chevy..!!

We are confused that should we agree to this arrangement, specially since the car's been in the service centre for more than 2 months due to un availability of replacement ECU ?

Woud appreciate some insight on this..

Cheers !

RD

| All times are GMT +5.5. The time now is 15:26. | |