News

Behind the scenes: Tata Motors' in-house crash test facility at Pune

Nowadays, everyone associates Tata cars with safety. Their cars have proven themselves in the GNCAP crash tests as well as the recently introduced BNCAP crash tests.

Tata Motors picked up the baton for safety early and that has worked very much in their favour. Nowadays, everyone associates Tata cars with safety. Their cars have proven themselves in the GNCAP crash tests as well as the recently introduced BNCAP crash tests. In an attempt to showcase how they reached this point, the company had arranged a plant visit for the media to display how they crash-test their cars before sending them to GNCAP or BNCAP. So buckle in your seatbelts as we go behind the scenes at Tata’s in-house crash test facility.

The ‘Integrated Safety Centre’ or the crash test facility is situated inside Tata’s passenger and commercial vehicle manufacturing plant in Pune:

We had a quick briefing session before we got to see the different areas of the facility. This facility has been functional since August 1, 1997. The first vehicle to be tested in-house was the Tata Indica:

Here’s a look at the timeline of when different types of tests were introduced:

ADAS-related tests aren’t carried out at this facility. As of now, Tata cars are tested at the NATRAX (National Automotive Test Track), Indore:

Before the cars are subjected to an actual crash test, a CAE (Computer-aided engineering) simulation is done to understand how the car would perform:

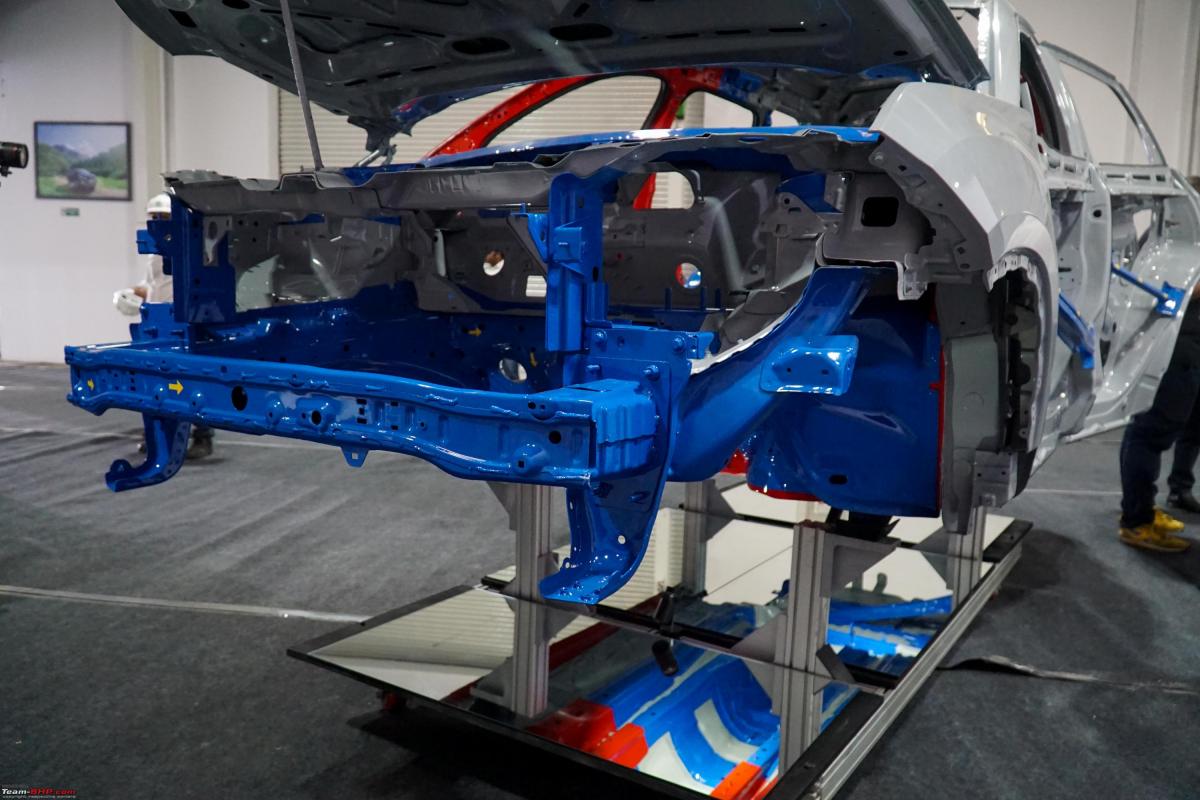

Then we moved on to the structural model of a Safari. The aim here was to show how the load dissipation takes place to keep the passenger cabin structurally intact:

The parts marked in blue are high-strength steel and the parts marked in red are hot-stamped steel which you’ll usually see in the pillar areas:

Frontal area is the crumple zone and is meant for absorption of the impact. The bulkhead area is where the front airbag sensor is placed. It works in collaboration with a unit inside the passenger cabin to determine if the impact is worthy of deploying the airbags:

The small yellow arrows indicate how the impact force is transferred:

Reinforcements inside the doors also help in dissipating the impact force:

Some amount of force is also directed to the floor structure. You can see the arrows here as well:

The model was coded in blue and red for frontal collision. In case of a rear impact, the boot area would be responsible for absorbing the force:

There was another cutout of the Tata Safari on display which showed the airbag positioning:

Continue reading this article for more insights and information on Tata's new crash test facility.