Team-BHP

(

https://www.team-bhp.com/forum/)

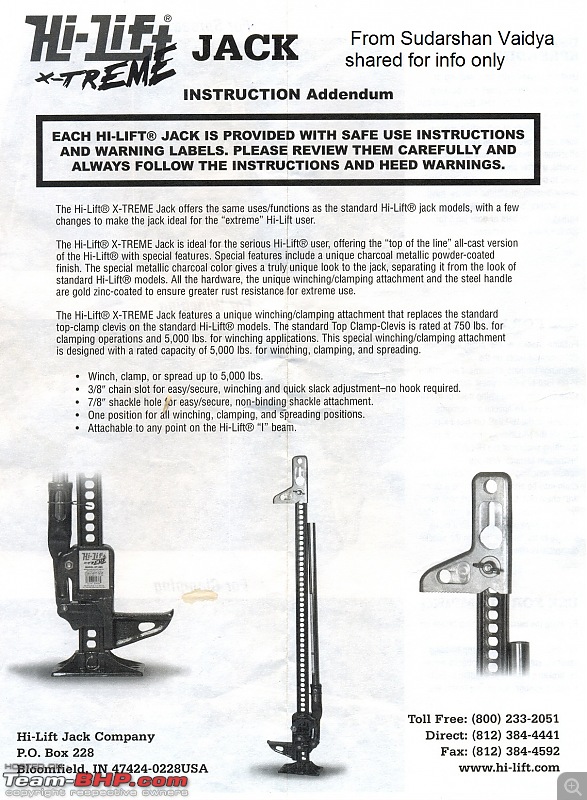

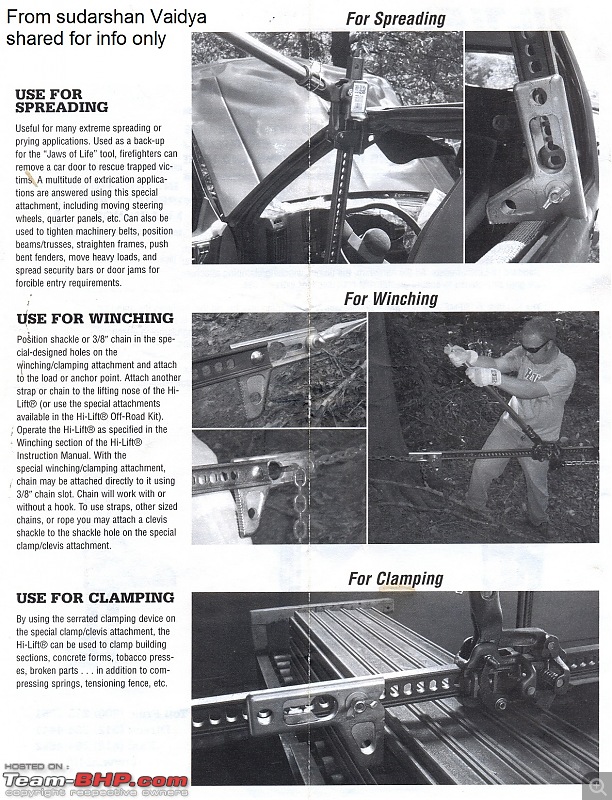

I nearly forgot last two pages ( were separate for my model of Jack )

Adding it here & also the decals ( various warning stickers ) in color for better readability

here , have a look

Sudarshan

Sudharsan ji,

You have always been helpful to many in many ways, i see such kind of attitude in many jeepers.

I specifically mention jeepers because from my personal experience i can say many unknown faces come for your rescue when you stand not knowing how to proceed with things. Jeep bug also has this quality to help others in its venom i hope !!:OT

Undoubtedly you are a gift to T-BHP.clap:

Quote:

Originally Posted by Sudarshan

(Post 2735431)

Recently a friend bought such a jack but apparently there is no manual with it , so it prompted me to share this here . ( could have PMed him but chose to share here )

|

Awesome stuff and thanks for sharing it here:). Would also love to hear more on winches and their practical aspects while in use. I know you have a trick or two up your sleeves.:D

BTW, when you bought this hi-lift jack, how much did it cost you?

Spike

Good Stuff, I also have a manual on Hi- lift jack, I hope this would be useful.. find attached below... This came with a CD brochure when I got the jack..

Also a link to the video from the manufacture of how to properly use the Hi-Lift Jack

http://www.youtube.com/v/MrfbR4REV-s&hl=en

Quote:

Originally Posted by SPIKE ARRESTOR

(Post 2736144)

=== I know you have a trick or two up your sleeves.:D

|

I am developing a sort of tool ( Accessory ) to be used along with both the winch & High Lift at my home workshop , it has passed the concept & drawing stage & half ready -- I will certainly share it after the initial trials* & post it here :)

Quote:

BTW, when you bought this hi-lift jack, how much did it cost you?

Spike

|

It was acquired in 07 (& the winch in 03 ), & been using it for workshop purposes also. Its a great All Rounder tool -- provided you take basic safety precautions (Like stabilizing the load or securing it ) Many times used it for spreading purposes also

Quote:

Originally Posted by Twinn

(Post 2736730)

Good Stuff, I also have a manual on Hi- lift jack, I hope this would be useful.. =====

|

Fantastic job Twinns -- Your manual is more clear than my copy -- & the link you provided too is a very good one Thanks again :thumbs up

If you have bought any accessories with it then please share those too --

Infact I invite everyone to share details here

Sudarshan

Sudharshan,

What did this jack cost you and where did you buy it from?

I very nice utility for an off roader, due to its many other uses than a simple jack but how useful is it for sedan and normal car users?

Also what is the weight like? How heavy is it?

Would definitely like to come and see it some time!

Quote:

Originally Posted by kevinephraim

(Post 2737861)

Sudharshan,

What did this jack cost you and where did you buy it from?

|

I dont remember the exact amount , but it was somewhere around 6 K .

I got it from a friend

Quote:

very nice utility for an off roader, due to its many other uses than a simple jack but how useful is it for sedan and normal car users?

|

I dont think its Suitable for modern day Sedans ( Cars ) as there is no Bumper sturdy enough upon which you could lift the car & the body being rounded, so the lifting Tip of the Jack wont reach the Jack up points provided by the Manufacturer of the car ( See attached Drawing )

Unless

1) the wheel lifting accessory provided by the Jack maker is applied OR

2 ) some special tool/ attachment is made ( that I am trying to make - as mentioned in earlier post )

Quote:

Also what is the weight like? How heavy is it?

|

It depends on the length of the jack ( its mentioned in one of the pdfs I have provided in post # 1 ) ,

My jack weighs up to 15 kg +

Quote:

Would definitely like to come and see it some time!

|

Why not ? anytime , Sure :)

Sudarshan

I want to share an Idea , A Tool to be used with the High-Lift Jack (that I talked earlier )

This will be made of a simple 4" high & some 5 feet long I section steel beam .

This will be made to lift the vehicle from its side -Without damaging any body panel. We all know that there are good lifting points in front & rear of the vehicles ( Jeeps ) in particular , but none on the sides .

I want frank opinions , suggestions . or even if its possible at all or not . ( safety is also another important aspect )

I want to know from people who use High-Lift jacks regularly

Based upon the inputs & opinions & suggestions I am going to make this in my home workshop

have a look

Sudarshan

Quote:

Originally Posted by Sudarshan

(Post 2741394)

I want to share an Idea , A Tool to be used with the High-Lift Jack (that I talked earlier )

This will be made of a simple 4" high & some 5 feet long I section steel beam .

This will be made to lift the vehicle from its side -Without damaging any body panel. We all know that there are good lifting points in front & rear of the vehicles ( Jeeps ) in particular , but none on the sides .

I want frank opinions , suggestions . or even if its possible at all or not . ( safety is also another important aspect )

I want to know from people who use High-Lift jacks regularly

Based upon the inputs & opinions & suggestions I am going to make this in my home workshop

have a look Attachment 914306

Sudarshan

|

Am not one who uses a High lift jack regularly or for that matter even rarely.. haven't used it ever! but just the physics of the whole thing is making me reply to this.

Why would you want to do this when

1. you could get a normal hydraulic jack (with the same SWL) that you can slide under the chassis and lift the jeep?

2. wouldn't using the leverage reduce the actual lifting capability (SWL) of the high lift jack?

3. The

I beam will require a fixable end to prevent sliding when the weight of the jeep starts getting transferred to the jack.

My 2 bits.

Quote:

Originally Posted by kevinephraim

(Post 2741440)

Why would you want to do this when

1. you could get a normal hydraulic jack (with the same SWL) that you can slide under the chassis and lift the jeep?

|

High -Lifts are used mainly for recovery purpose of a 4x4 , & when such vehicles are stuck there is normally no chance for the driver to slide any Jack below the axle ( or thing like that ). One can lift a stuck wheel or raise the chassis to such a height to put something under the stuck wheel making it easier to role out .

Normal Jacks lift the vehicle in inches , but Hi- Lifts like their name lift it high really high , its normally a feet or + depending on safety restrictions .

Quote:

2. wouldn't using the leverage reduce the actual lifting capability (SWL) of the high lift jack?

|

It depends on how far the lifting point is from the Jack end of the I beam

Quote:

3. The I beam will require a fixable end to prevent sliding when the weight of the jeep starts getting transferred to the jack.

My 2 bits.

|

One end of the I beam will always be connected to the Jack & another on ground , IMHO the lifting bracket ( that touches the chassis ) Needs to be 'sliding' on the beam but attached too .

Sudarshan

Hi Sudarshanji,

I've used my jack a few times in my old classic.

Interesting idea you have. In principle, the concept is like a type 2 lever... aka the wheel barrow which is the most efficient lever available.

These are my thoughts; can you elaborate / comment:

- you want to use it for regular tyre change on tarmac or road or for offroad situations when one is bogged down?

- as the jack goes higher, won't there be a chance of slippage of the beam? From both chassis and fulcrum point on the ground?

- won't it be an unnecessary dead weight to carry (unless you use the beam also as a bridging ladder or vice versa, modify a bridging ladder to for for your idea)

- if you plan to use it in an offroad situation where the tyre is bogged in slush, the beam will keep sinking when pressure is applied unless you make a base for it

- why not use a hi lift jack mate which attaches to the tyre? (used for bogged situations of course and not to change tyres)

Regards,

Tejas

Quote:

Originally Posted by Tejas@perioimpl

(Post 2741487)

Interesting idea you have. In principle, the concept is like a type 2 lever... aka the wheel barrow which is the most efficient lever available.

|

Please explain this concept sounds new ( may be I know it by another name )

Quote:

- you want to use it for regular tyre change on tarmac or road or for offroad situations when one is bogged down?

|

That is left entirely on the user & his intelligence

Quote:

- as the jack goes higher, won't there be a chance of slippage of the beam? From both chassis and fulcrum point on the ground?

|

I dont have mathematical calculations with me now , once this Idea gets cleared as feasible by off road experts 'here' I will try it & measure the slide in its actual use

Quote:

- won't it be an unnecessary dead weight to carry (unless you use the beam also as a bridging ladder or vice versa, modify a bridging ladder to for for your idea)

|

the dead weight Issue depends entirely on the vehicle's power to weight ratio . Possibilities are endless

Quote:

- if you plan to use it in an offroad situation where the tyre is bogged in slush, the beam will keep sinking when pressure is applied unless you make a base for it

|

Depends , base plate may be required

Quote:

- why not use a hi lift jack mate which attaches to the tyre? (used for bogged situations of course and not to change tyres)

|

Imagine Endless uses , this Idea is free to be improvised upon or I may simply opt to scrap it ( not actually as I have got the I beam for free :D)

The whole Idea came up when I saw people using leverage to handle Large loads along with other kind of lifting devices .

Sudarshan

sudarshans idea is an interesting one.

I have used the Hi lift quite extensively and like any lifting or winching equipment have found it to be quite dangerous in certain situations.

It can be especially dangerous on uneven ground(which is most off road situations)

The problem with the Hi lift is in a real world situation it becomes very unstable and tends to tip over,as you jack up the vehicle which is also usually unstable.

I have found most times you need one person to operate the jack and another to steady the jack so it does not tip over, really not recommended.

so the main limitation with the Hi lift is it's unstable and any thing you design will have to work around this tendency.

The more complicated the design e.g too many attachments,too heavy and bulky,complicated to use will make it impractical in the field due to weight and space constraints.

It would have to be tested in the field to see if it really works.

| All times are GMT +5.5. The time now is 06:35. | |