| |||||||

|

| Search this Thread |  116,659 views |

| | #1 |

| Senior - BHPian Join Date: Nov 2009 Location: Germany

Posts: 2,856

Thanked: 1,545 Times

| |

| |  (3)

Thanks (3)

Thanks

|

| |

| | #2 |

| Senior - BHPian | |

| |

| | #3 |

| Senior - BHPian Join Date: Nov 2009 Location: Germany

Posts: 2,856

Thanked: 1,545 Times

| |

| |

| | #4 |

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,668

Thanked: 6,233 Times

| |

| |

| | #5 |

| Senior - BHPian Join Date: Nov 2009 Location: Germany

Posts: 2,856

Thanked: 1,545 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #6 |

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,668

Thanked: 6,233 Times

| |

| |

| | #7 |

| BHPian Join Date: Aug 2008 Location: Thane-Mumbai

Posts: 492

Thanked: 156 Times

| |

| |

| | #8 |

| Team-BHP Support  Join Date: Feb 2004 Location: Bombay

Posts: 24,198

Thanked: 36,080 Times

| |

| |

| | #9 |

| Senior - BHPian | |

| |

| | #10 |

| Senior - BHPian Join Date: Nov 2009 Location: Germany

Posts: 2,856

Thanked: 1,545 Times

| |

| |

| | #11 |

| BHPian Join Date: Feb 2009 Location: new delhi

Posts: 348

Thanked: 0 Times

| |

| |

| |

| | #12 |

| Team-BHP Support  | |

| |

| | #13 |

| Senior - BHPian Join Date: Nov 2009 Location: Germany

Posts: 2,856

Thanked: 1,545 Times

| |

| |

| | #14 |

| Senior - BHPian | |

| |

| | #15 |

| BHPian Join Date: Dec 2009 Location: Pune

Posts: 86

Thanked: 0 Times

| |

| |

|

Most Viewed

Majority of us here had impression that tubular chassis was tougher but it seems it is used for light weight and inexpensive construction.

Majority of us here had impression that tubular chassis was tougher but it seems it is used for light weight and inexpensive construction. ) and has a monocoupe chassis. So its like this unfortunately; Solid axle front and rear suspension=old world charm!

) and has a monocoupe chassis. So its like this unfortunately; Solid axle front and rear suspension=old world charm!

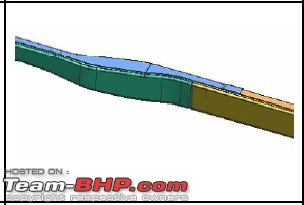

,those outriggers look huge,that is one reason why they have been reinforced with huge gussets to counter shearing loads originating due to cantilever action

,those outriggers look huge,that is one reason why they have been reinforced with huge gussets to counter shearing loads originating due to cantilever action