| | #1 |

| Team-BHP Support  Join Date: Apr 2013 Location: Madras

Posts: 7,339

Thanked: 20,688 Times

| |

| |  (73)

Thanks (73)

Thanks

|

| | #2 |

| Team-BHP Support  | |

| |  (1)

Thanks (1)

Thanks

|

| | #3 |

| BHPian Join Date: Feb 2013 Location: Kochi

Posts: 565

Thanked: 592 Times

| |

| |  (4)

Thanks (4)

Thanks

|

| | #4 |

| Team-BHP Support  Join Date: Apr 2013 Location: Madras

Posts: 7,339

Thanked: 20,688 Times

| |

| |  (5)

Thanks (5)

Thanks

|

| | #5 |

| Senior - BHPian | |

| |  (6)

Thanks (6)

Thanks

|

| | #6 |

| Senior - BHPian | |

| |  (2)

Thanks (2)

Thanks

|

| | #7 |

| Senior - BHPian Join Date: Dec 2007 Location: CNN/BLR

Posts: 4,341

Thanked: 10,641 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #8 |

| Senior - BHPian | |

| |  (15)

Thanks (15)

Thanks

|

| | #9 |

| Team-BHP Support  Join Date: Apr 2013 Location: Madras

Posts: 7,339

Thanked: 20,688 Times

| |

| |  (4)

Thanks (4)

Thanks

|

| | #10 |

| BANNED Join Date: Oct 2011 Location: Hyderabad

Posts: 12,345

Thanked: 21,452 Times

| |

| |  (2)

Thanks (2)

Thanks

|

| | #11 |

| Distinguished - BHPian  Join Date: Jun 2012 Location: BengaLuru

Posts: 5,956

Thanked: 21,241 Times

| |

| |

| |

| | #12 |

| BANNED Join Date: Feb 2005 Location: Melbourne

Posts: 4,461

Thanked: 5,535 Times

| |

| |

| | #13 |

| BHPian | |

| |  (2)

Thanks (2)

Thanks

|

| | #14 |

| BHPian Join Date: May 2008 Location: delhi

Posts: 308

Thanked: 1,631 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #15 |

| Distinguished - BHPian  | |

| |  (2)

Thanks (2)

Thanks

|

|

Most Viewed

. Have a couple of doubts.

. Have a couple of doubts.

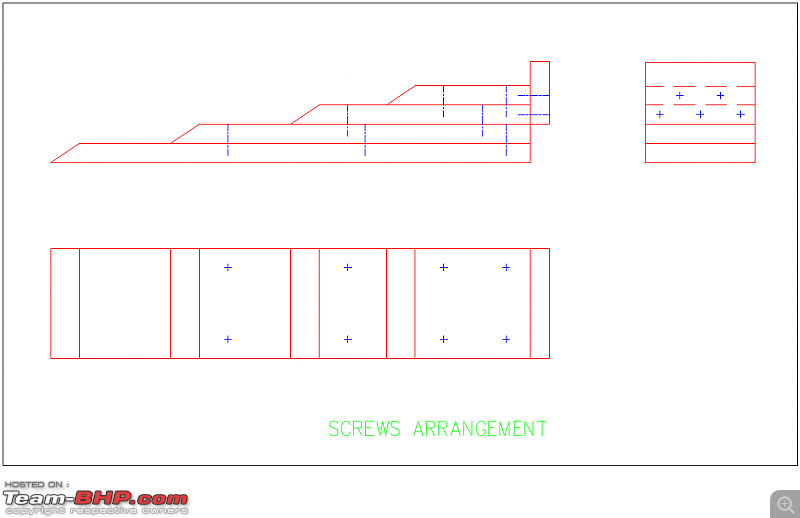

There is some or the other DIY coming from your end and this one takes the crown.

There is some or the other DIY coming from your end and this one takes the crown. .

.