Team-BHP

(

https://www.team-bhp.com/forum/)

- -

Tools for a DIYer

(

https://www.team-bhp.com/forum/diy-do-yourself/88566-tools-diyer-136.html)

Quote:

Originally Posted by ruzbehxyz

(Post 4577425)

Thanks for your input. I appreciate it. However please note I have a Ford Endeavour and the wheel nuts are prone to get swollen with time and normal spanners slip when the nuts are required to be opened

|

Wheel lug nuts do not change dimensions unless you round them off with the wrong wrench/spanner. The reason the wrench is slipping is that either the nuts are over torqued, the threads are rusted or the wrench is of the incorrect size.

And yes, never use a torque wrench for anything but tightening fasteners. It's not a breaker bar.

Quote:

Originally Posted by R2D2

(Post 4577575)

Wheel lug nuts do not change dimensions unless you round them off with the wrong wrench/spanner. The reason the wrench is slipping is that either the nuts are over torqued, the threads are rusted or the wrench is of the incorrect size.

And yes, never use a torque wrench for anything but tightening fasteners. It's not a breaker bar.

|

Thanks. But the Endeavour has a problem and these are from the factory. Many known people have complained. The lug nuts get swollen with time and this problem is accepted by Ford. And Ford is replacing them free of cost.

And as you rightly said, the torque spanner should be used for tightening, it will be useful for me to tighten the nuts to the required torque setting for the Endeavour which is 135nm.

Quote:

Originally Posted by ruzbehxyz

(Post 4577576)

Thanks. But the Endeavour has a problem and these are from the factory. Many known people have complained. The lug nuts get swollen with time and this problem is accepted by Ford. And Ford is replacing them free of cost.

|

I did a search on the Ford Endeavour thread and it does happen due to the aluminium laminate over a steel core. Bad design if you ask me for a critical component with 2 dissimilar metals. Well, this is peculiar problem that I have heard of for the first time. But glad to hear Ford sorted it out. :thumbs up

This mini ratchet set saved my a** today after the painters left without properly fixing the door closer.

This is also a great complementary set of bits to use with my 3/8 socket set.

Quote:

Originally Posted by a4anurag

(Post 4604795)

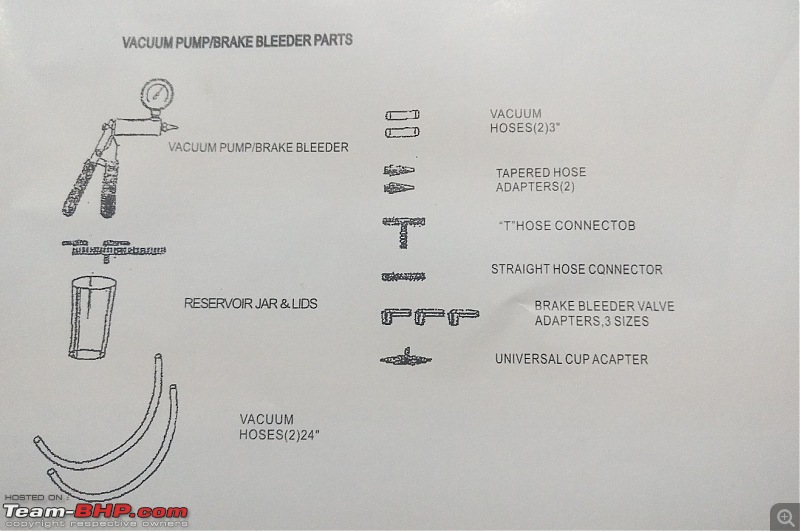

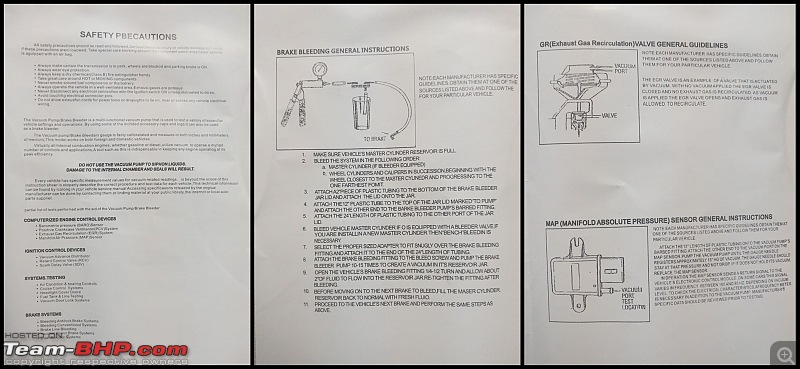

Bought a Brake Bleeder Kit from Amazon.in. Paid ₹1,860 for it, was around ₹1,562 on AliExpress for the same kit so purchased it from Amazon as the delivery will be faster. Link to item: Brake bleeder kit

|

Could you please guide between the

one you bought and the

Vertily Manual Pressure Bleeder?

Both look identical but prices of both are far apart.

Also how easy is it to use for a single person? Does the Manual provide necessary information for using it?

Quote:

Originally Posted by IndigoXLGrandDi

(Post 4633603)

Both look identical but prices of both are far apart.

Also how easy is it to use for a single person? Does the Manual provide necessary information for using it?

|

Both are the same. Just different brands/sellers.

Easy to use and can be done one person. Manual is fairly written but check YouTube videos on the same. Helps better and can understand better.

Guys, where in Bangalore can we purchase Unipatch Puncher repair kits? They make the Omini brand puncher kits and have been told are of good quality.

I've seen it on the internet somewhere before, but no experience.

I suppose a gas flame is hot enough to melt soft solder, so that is not the great thing about this product. The great thing seems to be the combined solder and heatshrink including effective seals excluding gases and moisture from the joint.

Quote:

Originally Posted by Jeroen

(Post 4643064)

Just came across this video / product.

Anybody familiar with it / any thoughts / comments?

Jeroen

|

I have seen a video elsewhere a few months back. Sounds like a good idea - except for one thing: it uses low melting point solder.

A couple of decades ago, there was a major issue with large screen Sony CRT TVs. Every time you replaced its Line Output Transistor, within hours it will die again. Long story short, the normal solder splintered microscopically due to the extreme heat in the soldered joint. The manufacturer started supplying a LOT kit in which a special high melting point solder was added. The problem was eventually resolved - but not before many bench engineers ended up increasing their alcoholic consumption to alarming levels. I was one of them.

Coming back to the new technique, it would surely work for non-mission critical applications. But anything involving high current or a signal line to the ubiquitous CPU - I would prefer the conventional soldering.

Quote:

Originally Posted by Prowler

(Post 4643097)

Coming back to the new technique, it would surely work for non-mission critical applications. But anything involving high current or a signal line to the ubiquitous CPU - I would prefer the conventional soldering.

|

Those are my thoughts as well.

Far from an expert in soldering, but I do have my share of soldering joints coming apart/failing over the years. Notably, on ECUs on older cars. ABS units on Jaguar are known to fail after a few years, as the soldering joints just fail. Mechanical stress of the unit and components being shaken about. Easy fix, but still.

Is there any correlation between mechanical strength and the temperature at which the solder is applied? I.e. does solder with higher melting temperatures result in a better mechanically (and thus also electrical) joint?

Jeroen

Quote:

Originally Posted by Jeroen

(Post 4643140)

Those are my thoughts as well.

Is there any correlation between mechanical strength and the temperature at which the solder is applied? I.e. does solder with higher melting temperatures result in a better mechanically (and thus also electrical) joint?

Jeroen

|

There should be - at least in theory. This is what I found before I joined the rush hour traffic :

http://www.farnell.com/datasheets/315929.pdf

Quote:

Originally Posted by Jeroen

(Post 4643140)

Is there any correlation between mechanical strength and the temperature at which the solder is applied? I.e. does solder with higher melting temperatures result in a better mechanically (and thus also electrical) joint?

|

Silver solder is certainly significantly stronger. Why I don't know.

Conducts electricity too, but better than/ less than 60/ 40 - don't know.

Electrical - Solder where you can't crimp. eg PCBs.

Mechanical - Silver solder where you can't braze or weld.

Regards

Sutripta

Quote:

Originally Posted by Jeroen

(Post 4643140)

.........

Is there any correlation between mechanical strength and the temperature at which the solder is applied? I.e. does solder with higher melting temperatures result in a better mechanically (and thus also electrical) joint?

Jeroen

|

No, mechanical strength will not increase by just increasing the temperature.

Solder's strength and melting point depends on the composition. Softer solders with lower melting point are used for electronics while harder solders with higher melting point are used for joining copper/brass mechanically. The solder used for repair of copper radiators melts at a higher temperature and has much better bonding strength compared to solder for electronics.

For increasing mechanical strength a higher melting point solder is needed. Please note a harder solder will not melt at lower temperature and a softer solder may evaporate at higher temperature.

| All times are GMT +5.5. The time now is 23:28. | |