Team-BHP

(

https://www.team-bhp.com/forum/)

- -

Tools for a DIYer

(

https://www.team-bhp.com/forum/diy-do-yourself/88566-tools-diyer-145.html)

Hey DIYers, I have neglected my backyard for years. So much that I never felt like spending much time there. This year, I decided to add an outdoor living area. Bought some pressure treated lumber, drilled holes in the concrete, installed anchors, added sunscreen, rolling privacy screens, HD antenna, and electrical stuff. Then I painted it all to match the rest of the patio. I may add LED string lighting later. This summer is going to be great!

Before

After!

About an year ago I had got the

B&D 550W Drill Machine.

I earlier had a 450W one from Bosch that is currently with my dad.

While the Bosch has been doing good for a very long time now, there appears to be some issues with the accessories of the B&D one -

1) The (carbide) cutting edge is worn out in one of the drill bits - with very low usage.

2) One of the masonary drill bits had the body of bit bending after some use!

3) One of the wooden drill bits has its (sharp) point worn out

Never had these problems with the drill bits that came with the Bosch unit. Have to now try and get hold of Addison or Bosch drill bit units to go with the B&D machine.

In case anyway has bought this (or I guess any) B&D drill machines, you may need to watch out for the quality of the drill bits and possibly plan ahead to have backup bits.

Drill bits are consumables --- but some last longer than others. I have a boxed set branded Bosch that I consider bad to very bad. The twist bits are not sharp and the spade bits are completely blunt.

Quote:

Originally Posted by Thad E Ginathom

(Post 4803025)

Drill bits are consumables --- but some last longer than others. I have a boxed set branded Bosch that I consider bad to very bad. The twist bits are not sharp and the spade bits are completely blunt.

|

Thank you, Sir Thad.

In about a little more than 10-years of my using drill machines for various at-home uses, this is the first time I have had a drill bit bending shape!

Any particular brands you have used that you could classify as durable? I can source them from US and UK as well.

Thanks.

Quote:

Originally Posted by Miyata

(Post 4803054)

In about a little more than 10-years of my using drill machines for various at-home uses, this is the first time I have had a drill bit bending shape!

|

Is it a minor bend like a wobble or a visible bend? I have had a wobbling bit once but the rest of my drill bits just broke when I went wrong with the drilling direction and tried to put sideway force on the gun. But never faced a bent bit.

Bent? Only? Almost all the drill bits except masonry ones have broken long time back while drilling normal wood. I replaced them with stuff bought from general hardware stores and they are holding up well until now. Better than Bosch. So obviously I don’t rate Bosch bits very highly. Driller, hammer, pliers in the drill set are of excellent quality but bits were a big letdown.

Quote:

Originally Posted by Miyata

(Post 4802988)

Never had these problems with the drill bits that came with the Bosch unit. Have to now try and get hold of Addison or Bosch drill bit units to go with the B&D machine. In case anyway has bought this (or I guess any) B&D drill machines, you may need to watch out for the quality of the drill bits and possibly plan ahead to have backup bits.

|

I believe the added bits in kits are kind of 'starter' quality just to get you up and running with a few jobs around the house after which they go bad and you need to buy yourself a new set. I'd recommend you look at the packaged Bosch, Addison, B&D drill bits that come in a set for e.g.

here

Quote:

Originally Posted by Miyata

(Post 4802988)

1) The (carbide) cutting edge is worn out in one of the drill bits - with very low usage.

2) One of the masonary drill bits had the body of bit bending after some use!

|

Agree with Thad. These masonry bits are disposable. We can never be sure about how these masonry bits handle a job. The masonry/concrete bits I buy last me one or two jobs. For the patio project (posted below) I bought a carbide concrete Milwaukee bit (Made in Germany). I was able to drill 2 holes of 6" depth. It is useless now. Things that may have gone wrong. I may have hit a rebar. Applied excess pressure. Held it for too long to cause the bit to overheat. It is best to be patient and give breaks of 30 secs. In typical usage cases, I never know if I hit rebar, if I hit a rock, or the temperature. I do not want to drill a new hole, no patience, and just power through. clap: By the time I realize something, its too late. The bit had already turned blue. See attached pic taken after drilling 2 holes.

This is the reason, I buy a single bit for a specific job/project. When I buy a concrete anchor, I buy a drill bit for that exact size, instead of buying boxes of bits of all sizes. The bits I use with wood seem to last much longer. I start with a DeWalt set, and then replace the most used bit with that single bit. Usually higher quality DeWalt/Makita/Milwaukee bit.

Quote:

Originally Posted by audioholic

(Post 4803070)

Is it a minor bend like a wobble or a visible bend?

|

Quite a major bend - attaching an image below.

Quote:

Originally Posted by saket77

(Post 4803073)

Bent? Only? Almost all the drill bits except masonry ones have broken long time back while drilling normal wood. I replaced them with stuff bought from general hardware stores and they are holding up well until now.

|

Thanks. I think for now that's what I'll have to do - get few select bits from the nearest h/w stores.

Quote:

Originally Posted by R2D2

(Post 4803098)

I'd recommend you look at the packaged Bosch, Addison, B&D drill bits that come in a set for e.g. here

|

Thanks, I did suspect they may eventually need replacement. Did not expect that to be this soon. Will replace them now.

Quote:

Originally Posted by GutsyGibbon

(Post 4803141)

Things that may have gone wrong. I may have hit a rebar. Applied excess pressure. Held it for too long to cause the bit to overheat. It is best to be patient and give breaks of 30 secs. In typical usage cases, I never know if I hit rebar, if I hit a rock, or the temperature. I do not want to drill a new hole, no patience, and just power through.

|

It's possible I may have impatient with this! I had some official work lined up and wanted to get back to it after "quickly" finishing this home-chore!

Quote:

Originally Posted by Miyata

(Post 4802988)

About an year ago I had got the B&D 550W Drill Machine.

I earlier had a 450W one from Bosch that is currently with my dad.

While the Bosch has been doing good for a very long time now, there appears to be some issues with the accessories of the B&D one -

1) The (carbide) cutting edge is worn out in one of the drill bits - with very low usage.

2) One of the masonary drill bits had the body of bit bending after some use!

3) One of the wooden drill bits has its (sharp) point worn out

Never had these problems with the drill bits that came with the Bosch unit. Have to now try and get hold of Addison or Bosch drill bit units to go with the B&D machine.

In case anyway has bought this (or I guess any) B&D drill machines, you may need to watch out for the quality of the drill bits and possibly plan ahead to have backup bits.

|

As mentioned drill bits are consumables. Depending on quality some dull faster than others. What you got can be classified as a "sweetner" inexpensive bit set to get you started.

Fifty years ago when I bought my first drill and bits, there were no consumer grade drills or bits available. All were for use by professionals. Those bits are still going strong after drilling thousands of holes in walls and stone. In contrast I bough a few Chinese long masonry bits which were consumer grade and they have started dulling after a couple of hundred holes.

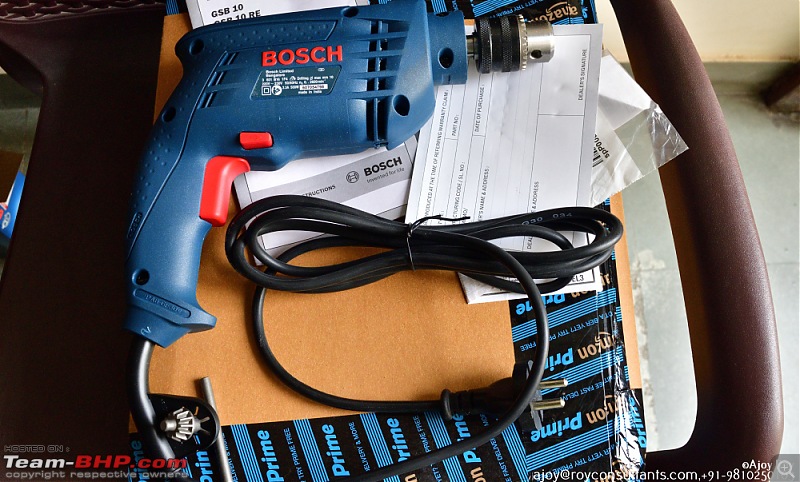

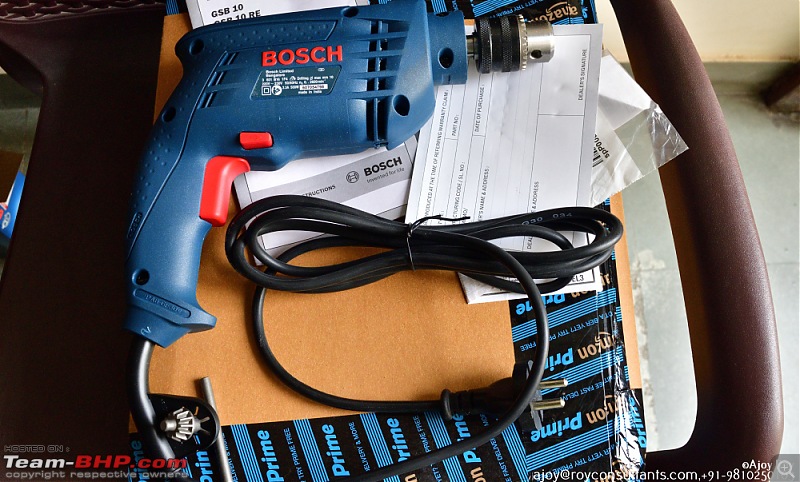

Bosch drill that I got in 2016

Wolf Drill bough nearly 50 years ago. It is true 1/2" rated for 1/2" in steel and weighs thrice the Bosch.

Quote:

Originally Posted by GutsyGibbon

(Post 4803141)

Things that may have gone wrong. I may have hit a rebar. Applied excess pressure. Held it for too long to cause the bit to overheat. It is best to be patient and give breaks of 30 secs. In typical usage cases, I never know if I hit rebar, if I hit a rock, or the temperature. I do not want to drill a new hole, no patience, and just power through. clap: By the time I realize something, its too late. The bit had already turned blue. See attached pic taken after drilling 2 holes.

|

Won't drilling through the re-bar, especially if it is in a load bearing structure not affect the structural integrity of the structure?

Quote:

Originally Posted by Aroy

(Post 4803276)

Wolf Drill bough nearly 50 years ago. It is true 1/2" rated for 1/2" in steel and weighs thrice the Bosch.

|

Ah! That's reminds me of an old drill of about the same age, that my father bought in 1972. :) It's a Black & Decker, made in England and constructed of metal like the Wolf you have.

It's not as powerful as my current approx. 700 W plastic clad B&D hammer drill (or even the cordless B&D hammer drill purchased in 2003) but there are so many memories attached to the old machine including yours truly learning how to use one in my early teens guided by my Dad. It will be with me for keeps. I will dig it out take a photo and share here soon. :)

Quote:

Originally Posted by Miyata

(Post 4803054)

In about a little more than 10-years of my using drill machines for various at-home uses, this is the first time I have had a drill bit bending shape!

|

Quote:

Originally Posted by audioholic

(Post 4803070)

my drill bits just broke when I went wrong with the drilling direction and tried to put sideway force on the gun. But never faced a bent bit.

|

Quote:

Originally Posted by Miyata

(Post 4803233)

Quite a major bend - attaching an image below.

|

I must have been asleep not to react to this before. I am not

sure about masonry bits, where it is only the should-be-carbide insert that does the work, maybe their shanks are of a softer steel, but... twist drills must be hard, and snapping, not bending, is indeed the usual way of destroying them. (edit: I suppose they should be made of High Speed Steel)

Also, when I say

consumables, I mean that they are consumables for those who can't sharpen them. In practice, that means most of us, because even those among us who have a clue how-to probably don't have a grinding machine.

I have a clue. Only. It is decades since I last sharpened a bit, and I was never an expert. Expert sharpening is needed in the machine shop: for diy woodwork around the house it is not: no-one measures a hole for perfect size and roundness before putting a woodscrew in it!

Quote:

Originally Posted by saket77

(Post 4803073)

Bent? Only? Almost all the drill bits except masonry ones have broken long time back while drilling normal wood. I replaced them with stuff bought from general hardware stores and they are holding up well until now. Better than Bosch. So obviously I don’t rate Bosch bits very highly. Driller, hammer, pliers in the drill set are of excellent quality but bits were a big letdown.

|

I think the kits we get here are Bosch-

branded. I don't think Bosch sell this stuff under their own name in Europe. Just my theory.

We get what we pay for. Bits are not cheap. I'm surprised, though, at Bosch selling their brandname for use on rubbish.

Quote:

Originally Posted by sagarpadaki

(Post 4803325)

Won't drilling through the re-bar, especially if it is in a load bearing structure not affect the structural integrity of the structure?

|

Yes, that would be an important consideration. I would not do this on an apartment beam. I drill the concrete floor in my backyard to install a holder for wood columns. To keep things from moving.

Once a hole is drilled, a metal anchor is inserted in it. I would think the load will be passed on through this metal, and may be fine. Note that, I am not a structural engineer.

Next time, try and source Hilti TE-CX bits. They are made with the purpose of going through rebar without any issues. I still have burnt through one of them by pushing too hard, but that happened after more than 50 holes. With Rotary Hammer drills, it is not a good idea to push when drilling. Even when one comes across a hard rock, or rebar in my case, just let the drill do it's job without applying unnecessary pressure.

| All times are GMT +5.5. The time now is 03:59. | |