Team-BHP

(

https://www.team-bhp.com/forum/)

- -

Tools for a DIYer

(

https://www.team-bhp.com/forum/diy-do-yourself/88566-tools-diyer-45.html)

Quote:

Originally Posted by dre@ms

(Post 3297026)

Agree, but we need to make a small hole to keep the screws in place and then screw them.

Does the 450RE, help me in screwing and unscrewing too? Does it have the hammer action?

|

I have a Bosch GSB 10 RE

http://www.bosch-pt.co.in/in/en/prof...gsb-10-re.html

Serves me well, has all the options you are looking for.

Drill mode, Hammer mode , Forward/Reverse.

The only missing feature is variable torque setting. I see this missing in all the India models within this price range.

Quote:

Originally Posted by DerAlte

(Post 3297034)

The modern self-tapping screws, with a tapered body and deep sharp threads, don't need a starter hole. Just a punch is sufficient to start. Works well with MDF and soft woods. Driving these screws in hard wood just needs a bit more torque.

|

Just a note to new folks, with these entry drills you cannot drive screws into wood directly using a screw driver bit mounted on the drill. Since they do not have a variable torque setting, a slight press of the trigger will drive the screw all the way in and result in any of the following.

split in the wood , breakage of screw head, major jerk on the drill etc..

Max you can use the smallest available bit and drill a hole, then drive in the screw manually using a screw driver. OR use a cordless screw gun.:thumbs up

Quote:

Originally Posted by Fillmore

(Post 3297055)

... you can use the smallest available bit and drill a hole, ...

|

The smallest bit available in a kit is usually 4mm, and that is too large to drill a screw starter hole. One needs <=2.5mm, for which there are no bits in the kit - one has to buy metal drilling bits. Easy to fashion one out of a nail with a file or coarse emery paper.

Quote:

Originally Posted by DerAlte

(Post 3297248)

The smallest bit available in a kit is usually 4mm, and that is too large to drill a screw starter hole. One needs <=2.5mm, for which there are no bits in the kit - one has to buy metal drilling bits. Easy to fashion one out of a nail with a file or coarse emery paper.

|

+1 to that. The tiny metal bits do not come with the stock kit.

I picked up one such kit. It has bits starting from 1mm, 2mm +. Id say its useful to keep one handy. You will surely need it at some point in time.

http://www.ebay.in/itm/BOSCH-19-PIEC...1#ht_500wt_924

Go for it. Here its about Rs 1,700, but with a set of drill bits free, so Im not surprised of the price.

Quote:

Originally Posted by dre@ms

(Post 3295751)

Guys, visited Metro yesterday and was surprised to see Bosch GSB450RE being sold for 2399/-, which is much lesser than the offer given for Bosch for their employees. I was looking for 500RE, but the price is slightly higher than the offer given for Bosch employees.

I need this to just do my household chores, so which one should I go for ?

450RE or 500RE

I already have the normal hammer, jumper, pliers, screw drivers. I am looking at this kit just to minimize the load on my hands in hitting the jumper with the hammer.

|

I don't know if this has been posted on the forum. My tool collection is becoming larger and my old method of storing them is not working anymore.

I had some heavy tools in boxes like these stacked up as needed.

Just now this box came apart and I was annoyed searching for a hammer and screwdriver. So this is a two minute hackjob which I'm sure all mechanics already use!

A 5 ltr engine oil can! Leave the layer of oil in.its good for the tools!

P.S. use a hacksaw or a blade as shown.easier and safer than any blade or box cutter or knife.

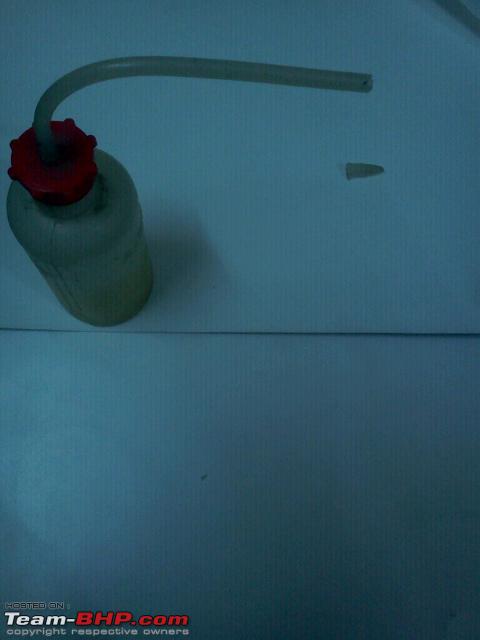

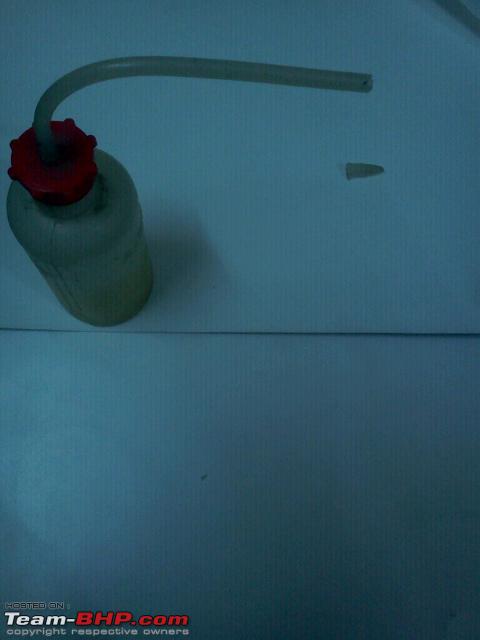

While I'm at it let me show you a contraption for siphoning off petrol or Diesel from a tank safely. Please don't use your mouth.!

This is a bottle with a stopper and nozzle originally bought for topping up battery water on my bullet.but I've found a 20cc syringe is best for that job. :)

This pipe is what gave me the idea.I robbed some off the guy who came to install an RO System!

This is the sweetest component! Robbed the water filter guy again!

This fits perfectly to the pipe and the pipe off the bottle above.

Here's the whole thing attached together. No leaks.

Put the pipe in the tank and squeeze the bottle.about half gets filled. 150 CC or so.

Remove the pipe and attach the nozzle and squirt away!

P.S. excuse the poor pics.its night time and I'm in a hurry.

I found another interesting contraption I built a couple of years ago to Polish away some scratches and to Polish a repainted bootlid.

This is a 100 % cotton microfibre "foot mat " from the mall.

This is a backing plate for an angle grinder and has Velcro backing.

Appropriate sized bolt with the head cut off.

Velcro strips stuck with rubber adhesive to microfibre mat.This is smaller for illustration only.I made a bigger one with a bigger sanding disc.

My trusty drill.

How it all comes together.

Works well for quick and dirty polishing jobs on a small area. Its difficult to control for longer periods. An angle polisher or random orbital polisher works better of course.

I used this small sized one recently to Polish up my headlights.

So one less excuse for not polishing up those pesky scars off your car!

Sidenote:

I bought a couple of these as I have a reverse action and a variable speed trigger on my drill.Absolutely fantastic little bit to remove old stuck up screws of poor /rusted quality.

I, too, have long used my electric drill (reversible, variable speed) as a screwdriver.

It lacks torque at low speed, but it beats doing the whole job by hand, especially if one doesn't have the need to buy and actual electric driver.

Guys. Im planning to do a full wheel /brake service on my car. I want to take apart the calipers and pads and lubricate the sliding pins etc. etc. Now I've read somewhere that brake callipers' sliding pins use silicon based lubricant from the factory. Can someone post a link to such a thing in the Indian market?

I also want to buy sockets for such a job. What ratchet/sockets /accessories are needed to work in the wheel well and on brakes etc.?

Hope you don't take offence, but... it worries me that someone is planning to service their brakes, but having to ask questions about it. It is not a safe area to learn as you go along, and certainly not a safe area to learn by mistakes.

If you have not done it before, it would be a really good idea to find a hand holder with lots of experience.

Quote:

Originally Posted by Thad E Ginathom

(Post 3316601)

Hope you don't take offence, but... it worries me that someone is planning to service their brakes, but having to ask questions about it. It is not a safe area to learn as you go along, and certainly not a safe area to learn by mistakes.

If you have not done it before, it would be a really good idea to find a hand holder with lots of experience.

|

Don't worry about it! :) I'm at my native place and these guys here maintain their tractors,gypsies,boleros and cars and have worked on my wheels / brakes before. I just want to be able to do it myself.

Quote:

Originally Posted by drsingh

(Post 3316516)

== Now I've read somewhere that brake callipers' sliding pins use silicon based lubricant from the factory. Can someone post a link to such a thing in the Indian market?

|

Check this post if its of any use for you

http://www.team-bhp.com/forum/4x4-te...ml#post3016378 Quote:

I also want to buy sockets for such a job. What ratchet/sockets /accessories are needed to work in the wheel well and on brakes etc.?

|

Also check the pic in this post for brake line work .

http://www.team-bhp.com/forum/4x4-te...ml#post2918796 Quote:

Originally Posted by Thad E Ginathom

(Post 3316601)

Hope you don't take offence,===It is not a safe area to learn as you go along, and certainly not a safe area to learn by mistakes.

If you have not done it before, it would be a really good idea to find a hand holder with lots of experience.

|

Plus one

Quote:

Originally Posted by drsingh

(Post 3316629)

Don't worry about it! :)

|

Please take care :)

Sudarshan

Quote:

Originally Posted by Thad E Ginathom

(Post 3316507)

I, too, have long used my electric drill (reversible, variable speed) as a screwdriver.

It lacks torque at low speed, but it beats doing the whole job by hand, especially if one doesn't have the need to buy and actual electric driver.

|

Quote:

Originally Posted by drsingh

(Post 3316495)

I have a reverse action and a variable speed trigger on my drill.Absolutely fantastic little bit to remove old stuck up screws of poor /rusted quality.

|

Use a bit of caution when you use slow speed in your drill. The other day I took apart a friend's drill to change the carbon brush. I noticed that the triac (the device that helps the motor to go slow) had no heatsink. That meant you can't use the drill in slow speed settings for a long duration. It will overheat and die.

You will say - the main drill itself is not designed for long continuous duty. You could notice that when you drill a deep hole especially in the concrete - the motor heats up and emits hot air.

The trouble with brake maintenance is that one is likely to discover the mistakes in the worst possible circumstance. Even some lubricant in the wrong place could have fatal consequences for self or others. Not bleeding the system properly will severely affect the performance.

I know ...that I don't know enough!

Prowler, yes I am sure you are right about drills. Screwing (if I can put it that way!) at low speeds leads to the motor stalling, and I am sure that will lead to burn out. I tend to use the drill for the "easy" bit, just to get most of the length of the screw in. If it is tight at the end then better to use a manual screwdriver.

Quote:

Originally Posted by Prowler

(Post 3316772)

... I noticed that the triac (the device that helps the motor to go slow) had no heatsink. That meant you can't use the drill in slow speed settings for a long duration. It will overheat and die.

You will say - the main drill itself is not designed for long continuous duty. You could notice that when you drill a deep hole especially in the concrete - the motor heats up and emits hot air.

|

If there is no heatsink, it is not necessary it will overheat and die at low speed. The "triac" doesn't dissipate heat inversely proportional to speed. The "triac" doesn't help the motor go slow, it modulates the speed by allowing a fraction of a sine wave to pass through. It doesn't dissipate the rest of the sine wave as heat - it is just like a switch opening and closing at the correct time.

The heating you notice in the air coming out of the drill is the dissipation of heat from the motor coils, not the "triac". As long as you are not getting that faint burning smell (that comes when a new drill / motor heats - it is the insulation varnish evaporating), everything should be fine. Don't bother about the hot air, it is meant to be like that.

| All times are GMT +5.5. The time now is 01:30. | |