Team-BHP

(

https://www.team-bhp.com/forum/)

Honda BRIO turbo build - part 1

Hey guys, writing this to share my thoughts about my new turbo build. Yes, Iam doing a turbo build for myself after quite a few years. Starting my build with an all stock Honda Brio.

Has it ever crossed your mind that you could have used another 50-100HP in your daily drive...a car that will be more fun compared to some of the newer breed of NA hatches ...or.. you don’t like how some of the newer car looks... or ...like me, cant afford the new hot hatches. Hmm, hopefully my Honda BRIO Turbo will deliver similar or better levels of performance ! A lot of us have very similar ambitions for our cars. We often have a special bond between ourselves and the machine we’re drive. I think we create a new sense of ownership by taking on such a project. I always enjoyed working on engines and ECUs and meeting other enthusiasts. My earlier builds have not changed my view on what I want from my everyday car. I want my daily drive to be more fun and rewarding while looking all stock and also expect it to be reasonably fuel efficient.

The 7+ year itch !!

I have always tried to treat myself to a simple and clean build. I often think of doing a build for myself (it remains in my thoughts for the most part) but it usually doesn’t happen that often though. Like most car guys, I love high revving N/A motors. That said, I also love boosted dailys for its power & practicality. Well, the itch has finally got to a point that I decided to buy a used BRIO. So, I bought this Honda BRIO sometime back with the sole intention of turbocharging it and making it a fun, not-so-fuel thirsty daily drive. I figured that there still are a few out there who wish to do such builds or enjoy reading up about someones build journey. This thread will not be a start to finish complete build thread that covers the removal of every nut/bolt, the splicing of every wire, etc. This is more about the journey and why I choose to build cars for my self besides the fact that I cant afford the new breed of fast turbo cars!!

Honda BRIO turbo build - Part 2

The plan..

The plan is no different to most of my earlier personal builds - to have a very stock-ish looking turbocharged car with all creature comforts. A clean turbo setup with an engine put together with OEM Honda parts. Obviously most of the turbo related parts would be aftermarket non Honda parts. If you’ve seen my old builds - Baleno G16 turbo build, they were pretty much stock engine with original factory pistons, rods, rings and bearings. I only ran a modest 9-10lb boost though. However, Maruti 800 turbo ran about 14 PSI though. I intend to push about 10-12 psi on this setup with a very conservative tune. I would need beefier internals to push any further. Going with a bigger displacement engine - L15 heart instead of the L12. Engine would be disassembled to ensure its running right clearances / tolerances for this build and the transmission will receive a new custom clutch to handle expected levels of torque. Please dont bash me for reasons like doing a turbo build on OEM Honda internals.

So let me begin with what I have in mind -Starting with stock Honda L15 engine with OEM intake manifold and throttle body and a modified Air filter box, routing the Turbo plumbing to appear like stock. Before the engine goes in the block, drilled and tapped to accommodate the turbo oil return line. Turbos oil feed line will be taken from oil pressure switch location using a custom oil splitter. I had a few options for turbos – mainly from Garrett, MHI, IHI family. I usually opt for these brands for customer cars, my Baleno had a TRD IHI and my Maruti 800 had an MHI turbo. With my BRIO Iam considering a Holset. In case I plan to push it further I can rebuild it with forged parts and throw a ton of boost at it.

Turbo selection.

Having a fair amount of knowledge and experience with turbos, I started by comparing a few different compressor maps. These are some of turbo brands and sizes that I thought would work well for this setup. The Garrett GT25 mid to large trim seemed like a good turbo, as did the MHI TD04 big trim or a TD05 small trim. The GT25 and TD04 turbos would spool quickly, but at higher boost these turbos relatively small turbine side could cause high back pressure. The larger turbos like Garrett GT30 or the smallest Borg (too large for this) turbo might be laggier compared to the other smaller ones. The other turbo I was considering was Holset which I have used before. Holset turbos are mostly meant for large diesels and industrial applications. They have been used in some high HP / high boost gasoline applications. That said its usually very laggy as-is for street turbo applications. For our requirement we would need a small frame Holset with a tight turbine side – hence a Holset custom Hybrid turbo. This hybrid Holset runs a relatively smaller A/R turbine side and should be able to support upto 250HP, and should not be very laggy and also have a fair bit of headroom for tomorrow. Besides the turbo size the other important differences are the trims of the compressor wheel and turbine & the aspect ratio A/R. All things equal turbo with larger trims support more air flow.

These are some of the turbos used on builds in the past.

1. TRD IHI turbo (Baleno 1.6 turbo)

2. Garrett GT28 (Civic 1.8)

3. Garrett GT14 (Abarth)

4. Comp Turbo (Civic 1.8)

5. Holset hybrid (Swift 1.3)

6. MHI TD04 (City 1.5)

7. MHI TD04 (Abarth)

8. Aisin turbo (Maruti 800 carb)

9. MHI TD025 (Maruti 800 FI) .....

10. And now a Holset Hybrid

Honda BRIO turbo build - part 3

BRIO engine is out as we speak and health check-up for donor engine.

Things to do before disassembling the engine:

Engine health check –

-Oil Pressure:

Check oil pressure at idle. though optimal oil pressure readings may vary from engine to engine - manufacturers/ models. Usually you should see around 20+psi at near idle, under acceleration the oil pressure should rise to around 60 psi. If your oil pressure is low, you have to root cause and remedy it, which may require replacement of bearings and or replace oil pump.

-Spark Plugs:

Spark plug condition can tell you a lot about an engines health.

-Oil fouled plugs means - valve stem seals are leaking or there is blow by and oil is being burned in the combustion chamber.

-Wet plugs (fuel). Fuel injector dumping excess fuel or injectors are too big and ECU is not able to reduce injector open duration enough.

-Leaned out plugs. If you find white-ish electrode tip, the cylinder may not be getting proper fuel and or spark plug being used is not of appropriate heat range.

*A thumb rule is to use colder plug when you go NA to turbo. On low boost applications, stock plugs may work fine though.

-Compression Check: If your compression numbers are more than 8-10 psi lower than factory recommended numbers, i would recommend fixing the issue before boosting it. Adding a little bit of oil can tell us if the piston rings are worn out. if you have a cylinder thats low on compression that jumps up quite a bit in compression due to the wet test, that can mean that the piston rings are worn.

A question often asked - Can NA Motor be Boosted reliably ?

The answer is – YES, It can make a fair amount of more power and also a whole lot more torque. In the early 2000's there were a few individuals that did turbo their na motors. Some of these builds were quite reliable and met the goals that it was built for. Some others weren’t as successful. The biggest reasons came down to GREED, fuel quality and tuning. Lets start with greed. Boost is addictive and often when we get much more out of an NA motor, we get more greedy to extract even more out of it !! And that my friends is a one way street to disaster... unless the engine is build ground up to deliver much more. Fuel quality was also limited to pump gas unlike high octane fuel options and octane boosters available today. Low octane fuel is more prone to detonation in a NA -forced induction motor owing to higher C:R in NA motors. Last but not the least – a safe tune. There were limited tuning options back then. Most stock OEM ECUs couldn’t be reflashed and aftermarket programmable ECUs were lets say new to users in India. I have heard stories of many turbo builds marred with issues and some even deciding to go back to stock but I believe if you don’t cut corners and do it the right way without getting overly greedy for power, a reliable build is quite possible.

Honda BRIO turbo build - Part 4

Intercooler selection -

Selection is mainly based on the application and budget. Getting a HUGE intercooler capable of supporting 1000hp may be detrimental to performance on a 300hp application. The smaller the IC volume, the quicker it fills. A huge IC takes much longer to fill. Ideally, an intercooler should be sized to how many lbs/min the turbocharger can flow. End tanks also play a very important role to direct air flow. Air doesn’t like to go around corners. Air slows down in IC with bigger cross section and speeds up when the cross section is small. Front mounted IC is straight forward good option but often adds other challenges like additional intercooling plumbing (volume), modifications required for routing.

My search for intercooler took a fair amount of time. Started from taking exact measurements of available space for intercooler installation to checking various websites and going to auto stores godowns looking for suitable IC. Finally found a Mahle brand intercooler of the right size that was near perfect for my application.

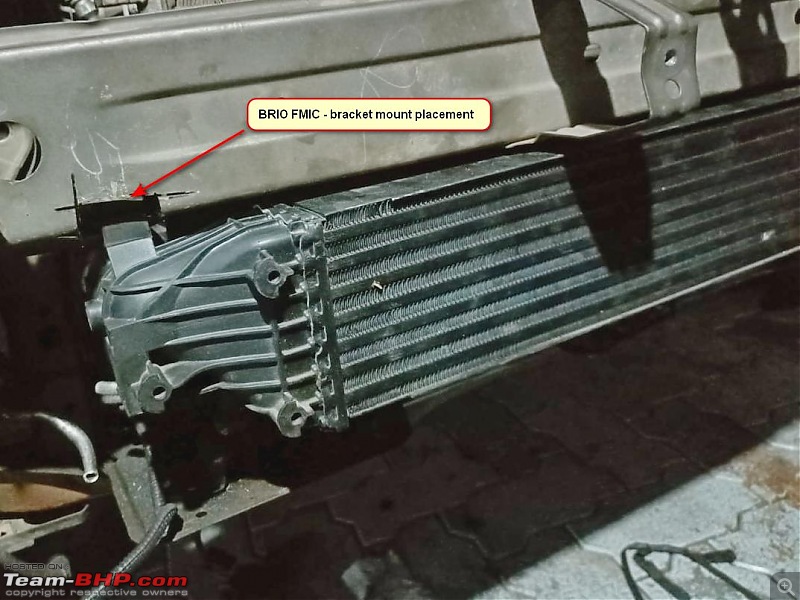

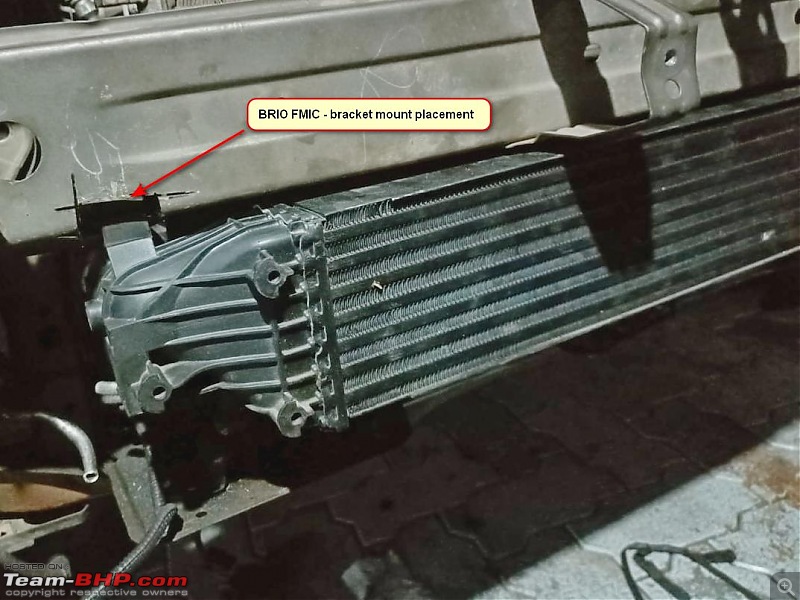

BRIO FMIC setup.

Most of the plumbing was done with stainless steel pipes and OEM intercooler hoses from different makes. Based my intercooler plumbing pipe diameter based on my Compressor outlet diameter. Had to upsize my turbo plumbing for the IC pipe going out from the intercooler to the throttle body for it match the size of TB. I got all the pipes, clamps and hoses locally. Some of them were custom machined though.

Turbine outlet is a V band type and since I did not find a suitable V band clamp, we machined one that could do the job well. Not the best looking V band clamp though.

The length of the intercooler was just right, it starts and ends at the exact window size as my bumper lower grill. Had to make a small cut and weld onto the metal frame behind the bumper to get the intercooler fastened firmly and securely.

A whole lot of time and effort is going into how to do the plumbing to make it appear almost like a stock car. Most of the plumbing will not be quickly visible when you look into the engine bay. I think I may even loose a little power in the quest to make the plumbing least visible and retain stock like engine bay looks. For those of you thinking about building your own FMIC setup, by all means go for it.

Here's some pics of the IC pipes installed on the car. Most of these pics are taken late in the evening with my old phone.

Honda BRIO turbo build - part 6

Standalone ECU, piggyback & OEM engine management system (EMS) –

All of the above categories of ECUs are good in its own ways. Each has its own strengths and it would be unfair to say any one is best. Each one is appropriate for specific application, where one may not be a perfect substitute for the other.

Back in the day (90s) I used piggyback ECUs like Greddy - e-manage (blue) and APEXI SAFC for NA - turbo builds. They were relatively easy to set it up and tune. They appeared to work fine but it had its fare share of short comings. Seeing this I wanted to try my hand at standalone ECU but I couldn’t afford one at the time.

Standalone ECU, piggyback & OEM engine management system (EMS) –

Later during my Baleno G16 turbo build, I used a Race Dynamics RD601 ECU which was upgraded to RD901 thereafter. This was a steep learning curve for me coming for piggyback ECUs. Race Dynamics (Karthik) was very helpful during my early days of standalone tuning journey. I used to have a small laptop under my car seat that I could pull out whenever I need to upload a new tune. Over the years I experienced some limitations of the standalone ECU and also learned much about my tuning capabilities, rather lack of it. Race Dynamics ECUs did not offer closed-loop target AFR on their ECUs back then. After repeated requests and pleading, they made me a custom daughter board for my ECU to enable closed loop fueling. This was a moment of absolute joy for me since I was beginning to understand the challenges of tuning “part throttle” and “transient load” areas. By this time, I felt that tuning for daily driving on a standalone ECU is possibly more challenging than tuning for flat out wide-open-throttle. Back then, people accepted the fact that cars that run standalone ECUs may not offer you a smooth driving experience like what an OEM ECU offers. I think this was mostly because of the lack of tuning expertise and to some extend lack of tuning features available on ECUs.

Standalone ECU, piggyback & OEM engine management system (EMS) –

A few years later, It was time for my Maruti 800 MPFI turbo build. Race Dynamics had their new Piggyback ECU was ready by then. This ECU had an amazing feature I was really looking forward to – this could advance and retard ignition timing in a different way as compared to mainstream piggyback ECUs like Apexi SAFC etc in which you altered MAP voltage to change ignition timing/ fueling. The downside being that - change in MAP voltage would change both ignition timing and fueling together. RD piggyback had the ability to change fueling and ignition timing independently. So, life seemed to have come a full circle – from piggyback ECU to – Standalone ECU – back to piggyback ECU !! This piggyback gave me all the convenience and refinement of a stock ECU while also allowing me to make fueling and ignition correction on boost. Not saying that this is perfect, but this definitely made tuning off boost (transient and part throttle) a breeze while also handling boost related corrections with ease. Needless to say, it was much easier to come up with a tune on the piggyback than on a standalone ECU.

My ECU looked similar to the pic here (taken from Team BHP)

Standalone ECU, piggyback & OEM engine management system (EMS) –

Later, in the 2000s, I had opportunity to work with other ECUs like Haltech, Link, ECUMaster etc and Honda specific Hondata & Neptune. Working on various projects at Blackworks helped me evaluate strong points of each of these ECUs and helped me put things in perspective. The first thing I figured was that, wiring was not my cup of tea. My work mate Venkat, was the go to man for everything ranging from wiring to “solid works” design work. By this time new generation cars were getting more complex with newer technologies like Drive-by-wire (DBW) and also more electronics and dedicated control modules for different functions and use of CANBUS for various vehicle internal communication. This started making things more difficult for installing and tuning aftermarket ECUs on new generation cars. These cars often needed a more capable advanced ECU and sometimes the need to reverse engineer CANBUS communication to make the Standalone ECU to talk to OEM instrument cluster / dashboard functions. Use of piggyback ECUs had its short comings on many of these new generation vehicles due to having limited to no control over DBW, VVT and other OEM ECU native functions.

Standalone ECU, piggyback & OEM engine management system (EMS) –

Around this time, OEM ECU reflash (aka remap) was getting more popular and I was quite eager to learn more about it. Working with the guys at Wolf Performance gave me a chance to understand OEM side of things much better and I now have a new level of appreciation for the OEM calibration engineers. It is unfair to compare a race calibration guy with an OEM calibration team though. Both have very different objectives and goals. Total respect to race calibration specialist since they often have to deliver results as a one man army (or few guys) where as OEMs may a have a bunch of calibration engineers for each project.

The best part of my journey has been making good friends that helped me widen my horizon and learn a fair bit over the years. I was also fortunate to meet some of these bright minds in my journey, with whom I would later work on multiple automotive projects. Here are some of the business entities I work with on automotive projects - Wolf Performance, BlackWorks, RACEWERKS, Tech & Tantra and a few others. I cant emphasise enough how much each of them have helped me to learn and grow over the years. My thanks and gratitude to everyone !!

Honda BRIO turbo build - part 7

EMS related things that I intend to approach differently -

The plan is to work on the Honda BRIO stock ECU - to enable the stock ECU to handle boost related functions and make necessary fueling and ignition correction by itself. I will be working with my good friends at Wolf Performance to create a custom solution for OEM Honda BRIO ECU to operate seamlessly and handle boost related requirements effectively. While I am comfortable tuning Standalone ECUs, I totally love the idea of making the OEM ECU do much more than what it was originally meant to handle (Naturally aspirated motor). I am quite hopeful since Wolf Performance team has successfully developed and implemented such a solution for a Hyundai NA- turbo ECU project. I totally enjoyed being a part of the Hyundai NA - turbo project, mainly due to the fact that the factory ECU was made to handle various aspects of boost – fueling and ignition correction. Standalone ECUs are great and offers a lot of flexibility which is very difficult for OEM ECU to match. That being said, if you could get the OEM ECU to do most of the work, the result would be amazing to say the least. The challenge - it often takes many months to reverse engineer the OEM ECUs working / code and then make it capable enough to see and respond to boost appropriately. This is not going to be easy by any means but it would definitely be a great learning experience. Worst case scenario – I can always setup a standalone / programmable ECU and get the build running if need be.

The Hyundai NA – turbo project was very insightful, it helped us understand various limitations we faced within OEM ECU architecture and also helped us in finding new ways to overcome those limitations. There were times we felt we had everything in place and expected the OEM ECU to handle boost....but it just did not !! The best part was the learning that we got from working on that project - how versatile and capable the OEM ECU is, but taming it to make it do what you want is whole another ball game. For an NA- turbo build you would typically consider an aftermarket ECU for its ability to have features like wastegate control, boost by gear, traction control, trigger outputs for fuel systems etc can be easily achieved with a capable aftermarket EMS. Like I mentioned before, the goal here is not about building a race car but more of my journey in building something I love and learning something new at every step of the way.

Working on the OEM ECU lmitations for running NA - turbo setup :

The goal is to make the OEM BRIO ECU adequately respond to and handle boost related duties with respect to fueling and ignition. Ideally we wouldn’t want it to run open loop always, the real trick is to get them to run factory like while on boost ! Tuning these OEM ECUs for forced induction also involves getting proper load axis re-scaling in the ECU which will help the OEM ECU deliver approporiate amount of fuel and spark timing based on Engine Load and air flow. Achieving this is easier said than done, where you want to rely on proper modelling for fueling than relying just on the stock 02 sensor for fueling needs. You need fueling compensation to be pro-active instead of re-active which can be done effectively based on OEM ECU's native logic system (with tweaked logic code). In most stock OEM ECUs, many of the boost related functions are not directly based on manifold pressure instead its based on load. And if we are able to achieve that, we have a winner! You can also use native “knock control” abilities to your advantage as a safety feature to keep the boosted engine safe. Getting the OEM ECU to cooperate is not an easy task; It needs a fair bit of rewriting in the ROM hex, more so than just making changes to specific table by changing the numbers (like in a remap). That's where things tend to get interesting and difficult at the same time. While its totally acceptable to run a race car on open loop all the time with appropriate comp tables for temp corrections etc, it may not be the best option for a street car.

Honda BRIO turbo build - part 8

Injector and fuel system upgrade -

Fueling is tricky on these cars with returnless fuel system. Injectors will be upgraded to these Bosch 630cc high impedence injector. These injectors are not a straight swap plug and play. It would need a few mods to make it work. This would need new injector couplers and also some mods to the fuel rail for proper fitment. The other options available are to upgrade to a higher rated fuel pump and or convert this into custom return type fuel system with fuel return lines separate from the factory fuel system. Iam also considering going for a PWM fuel pump system that would increase fueling based on load/boost in phase 2 of the build. The downside to this would be that I would need an aftermarket controller and the stock Honda ECU will not be able to control this PWM fueling system.

Transmission and Clutch:

The transmission in the BRIO will be stock for the moment. A custom clutch with more surface area and different pressure plate with higher clamping force will be installed. This will help to achieve a not-so-hard pedal feel .I dont enjoy dailying a stage 3 race clutch !!).

Honda BRIO turbo build - Part 9

BRIO Turbo manifold - Integrated Exhaust Manifold

In case of a cylinder head with an integrated exhaust manifold (IEM), the ideal turbo manifold is no manifold, where the exhaust flows right into the turbine housing inlet without having to transition through a turbo manifold. The primary job of a manifold is to channel exhaust gases from the cylinder head through turbine housing to the turbine wheel with least obstruction as possible. OEMs can achieve this easily by getting their turbine inlet flange design to match the IEM exhaust port design or vice versa.

For the BRIO cylinder head with IEM, I chose a turbocharger with turbine inlet flange opening of a similar dimension to the IEM exhaust port allow which gets a bit trickier. This allowed me to have a short turbo manifold that allowed me to place the turbo very close to the exhaust port allowing it to harness as much of the exhaust energy at the turbine wheel.

BRIO Turbo - 3" downpipe with V-band flange

I'd like to briefly go over my experience building the BRIO turbo downpipe. We took accurate measurements of the factory fitment location in order to make the jig used to build the downpipe. This part took a fair amount of time since everything needed to line up correctly before doing all the fabrication work and welding. I decided to machine a V-band flange on the 3" downpipe inlet that would conform to the exit on the turbine side. I also went with a reducer at the other end to make the transition for the exhaust gases smoother to the smaller diameter exhaust. I will be mating this to an almost stock exhaust system for the time being and after some preliminary testing got with a full exhaust system. we installed everything (downpipe + wastegate) back on to the engine over the weekend. All of the materials used are 304 stainless steel. Rest of the exhaust. I'd like to personally thank Magnum motors for all of the assistance and support during this project. This project would not have been possible without their help.

Honda BRIO turbo build completed- Part 10

Brio Turbo build was completed long time ago but things were far from over... Saying OEM ECU development part for Brio ECU took far too long is an understatement. The in-house software development team at Wolf Performance had already successfully implemented this for a NA turbo build for Hyundai i20 1.2L BS4 couple of years back... development work for Brio still took fair bit longer than anticipated.

After spending lot of time on logging stock ECU with turbo setup to understand revised airflow and short term and long term trim correction, we tried to integrate and implement this learning into the new model Wolf software team created earlier.... things did not work as expected. Team quickly figured that we had two problems. We received wrong MAP sensor, not what he had really wanted, they also tweaked the software algorithm to better suit Brio application.

With the correct MAP sensor and revised software algorithm, car started and idled fine, with some idle hunting. After a lot of logging and calibration revisions, car felt like an OEM car all the way till boost...but we had inconsistent performance once in boost region (1-4 psi initially).

OEM ECU does a lot of things to keep the vehicle safe (OEM safety strategy). Some OEM ECUs like the one in Brio, has extremely conservative ignition number beyond a certain load. Being turbocharged, ECU would often reach or exceed this load level, which in turn would have a cascading effect on ignition timing. This was probably the longest battle for the software team. It was as though - Wolf software teams algorithm was fighting against the OEM ECU algorithm !

Fast forward 5-6 months and going through lot of different approaches in the algorithm, Wolf software team won the battle with the OEM ECU, we got the engine respond well on boost. Boost hovers around 5-7 PSI and I have driven around 3500kms this far. This is by no means a very powerful or fast car, but it definitely is a fun car that looks and feels very much like a stock turbocharged car...

Brio Turbo build completed.

Will update this thread as and when I decide to push higher, later !

It's been such a long process and I see you began in 2022, hope you are happy with the results and I must say a great initiative on your part

Congratulations @swiftboost on your Honda Brio Turbo build!

Can you please share the new power and torque figures? Also, have you modded the car aesthetically? If so, please share some pics for viewing pleasure.

Quote:

Originally Posted by bijims

(Post 5812374)

It's been such a long process and I see you began in 2022, hope you are happy with the results and I must say a great initiative on your part

|

Yes, physical part of the build did not take that long. That said, it would take us a whole lot of time and effort to get the stock ECU to handle added responsibility of turbocharged engine... So yes, it took us a lot of time but it was worth it for the learning it gave us...

Quote:

Originally Posted by sharmanova

(Post 5812376)

Congratulations @swiftboost on your Honda Brio Turbo build!

Can you please share the new power and torque figures? Also, have you modded the car aesthetically? If so, please share some pics for viewing pleasure.

|

I don't know exact power figure...it hasn't been dynod yet. Guessing around 140hp hopefully. Aesthetically, it looks all stock from the outside !!

Nice work. But my question is "Is it worth it?"

Years ago when the Honda City, Mitsubishi Lancer, Suzuki Baleno were the cars that people modded by doing Turbo Installs or Engine Swaps, there were few options for fast cars. Either you spent a whole lot of cash on a premium German Car or went the Turbo/Swap route. The average Joe could not afford a German. So there was only option 2.

But since Skoda entered the Indian market, things have changed. Modding any of the stock turbo cars is very easy. You can just do a remap and achieve the same result as a turbo install on a NA car at a fraction of the cost and without compromising reliability. Then you have the option of Stage 2 and Stage 3.

So is a turbo install or engine swap worth it? IMO a big No. A friend of mine dis a K24 swap on his City. He's not ready to say how much he spent but he know he would have spent less if he picked up a Laura and got it up to stage 3.

| All times are GMT +5.5. The time now is 23:01. | |