News

Why do cars have a clock spring? Replacing the one in my Jeep

Earlier, cars used to come with only one button on the steering wheel, the horn. Now, there are many, and an airbag too.

BHPian Jeroen recently shared this with other enthusiasts.

Ever wondered why cars have clock springs? Read on and all will become clear!!

According to Wikipedia:

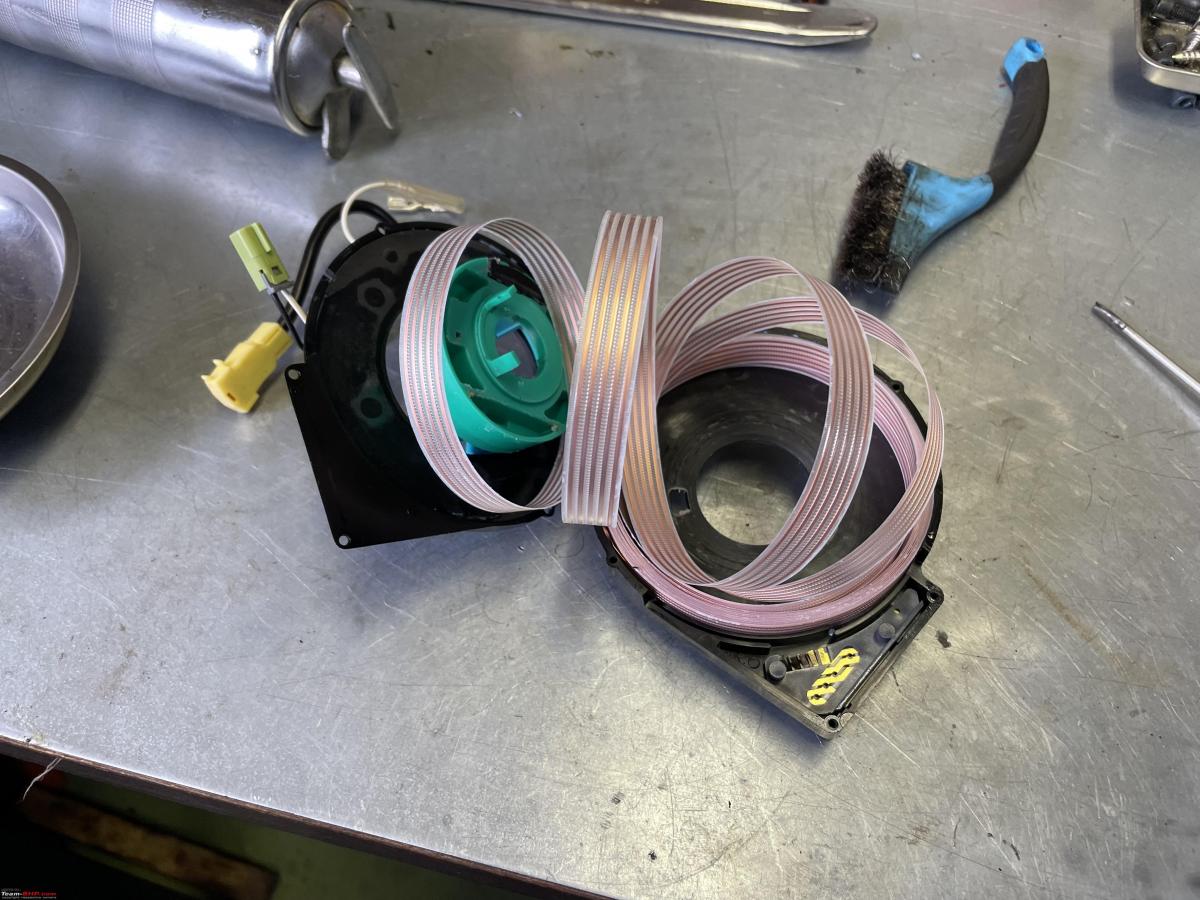

In vehicle steering systems a clock spring or clockspring is a spiral-wound special rotary electrical connector which allows a vehicle's steering wheel to turn while still making an electrical connection between the steering wheel airbag and/or the vehicle's horn and other devices and the vehicle's electrical systems. The clock spring is located between the steering wheel and the steering column.

In the "old and simple" days, you had only one button on the steering wheel, the horn. And there have been a few cars, that did not even have that. The horn was mounted on a stalk or worse. Even so, it means you need to establish an electrical connection between the rotating steering wheel and the steering column. Fairly easy with only one wire. It is usually a brass ring mounted on the steering column and a carbon brush mounted on the back of the steering wheel. Very simple very effective.

But these days, steering wheels have multiple buttons and also an airbag!! My Jeep also has cruise control buttons on it. And you might also find audio controls on it and plenty of other stuff. Enter the clock spring to connect all of this.

A broken clock spring is easily identified because none of the buttons on your steering wheel will work and the airbag light is on permanently. So in my case, the airbag light was on, the horn did not work and neither did the cruise control.

Here is my old clock spring I opened up. It is called a clock spring because it looks, you guessed it, like a clock spring. Duh.

And here you see what is broken, the end of the clock spring has been torn off the base plate. These are simple soldering connections.

A clock spring can only be turned a certain number of turns, usually about five, which is also about the norm of your steering wheel full lock left to full lock right.

Clock Springs break, because sometimes of age. Or in my case as I was working on the steering box. To remove the steering box I had to disconnect the steering column from the steering box. You really need to fix the steering wheel so it doesn't turn. Because if it does and it does more than 2,5 runs either left or right, the above is the end result.

Clock springs are expensive to buy!! But usually fairly easy to install. Let's have a look.

First of all and this is really important, you need to check the workshop manual on safety instructions regarding the airbag!! In the case of the Jeep, you need to disconnect the battery and wait at least two minutes before starting to work on the airbag.

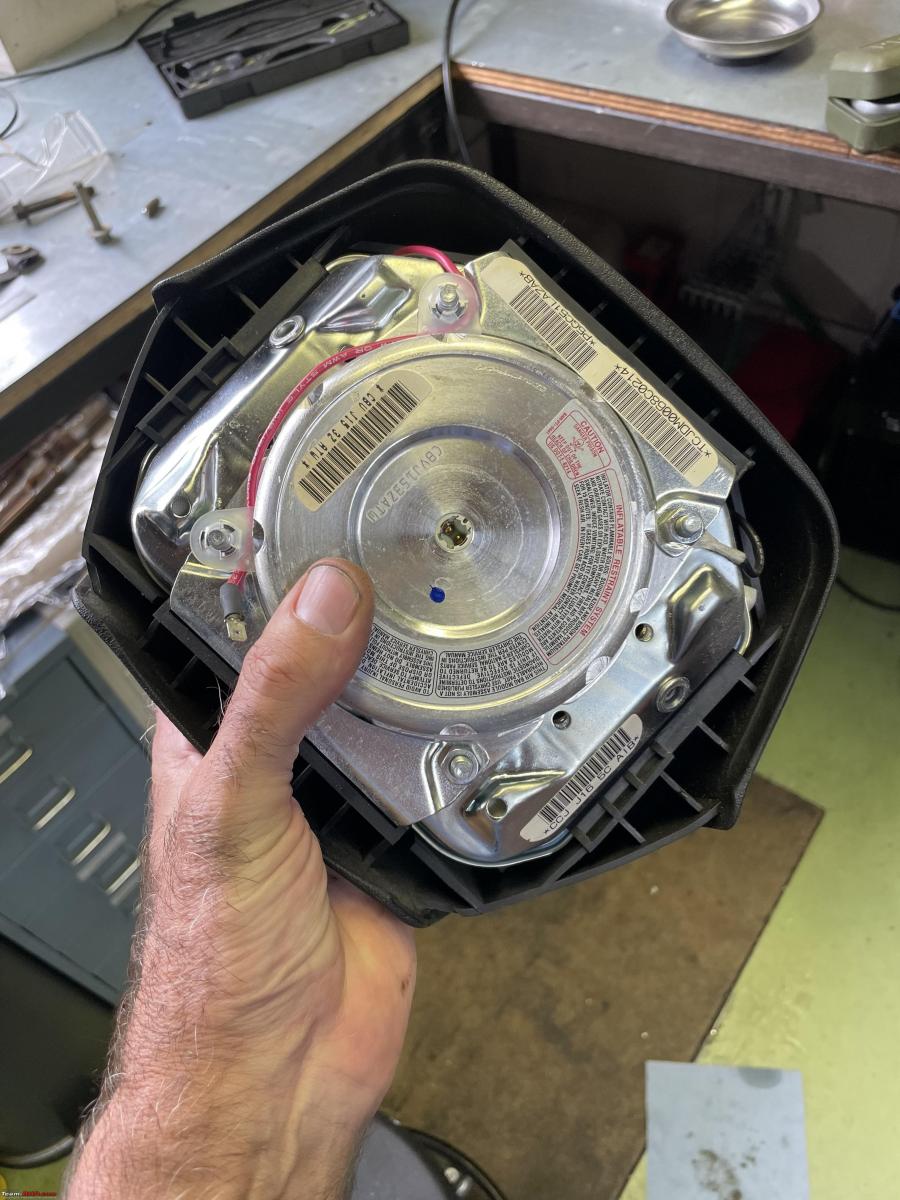

The airbag unit is held in place with two small bolts at the back. Once you undo those two bolts you can take the airbag out partially. You need to disconnect the three wires.

One airbag and horn assembly!

One airbag and horn assembly!

This is what your steering wheel will look like with the airbag removed.

Undo the central nut partially.

You will need a proper pulley puller or steering wheel puller to get the steering wheel off the column. Leave the nut on. It will provide some extra space for the puller and it will prevent the steering wheel from jumping in your face when you tighten the puller!!

This little puller set has served me well. Very handy!!

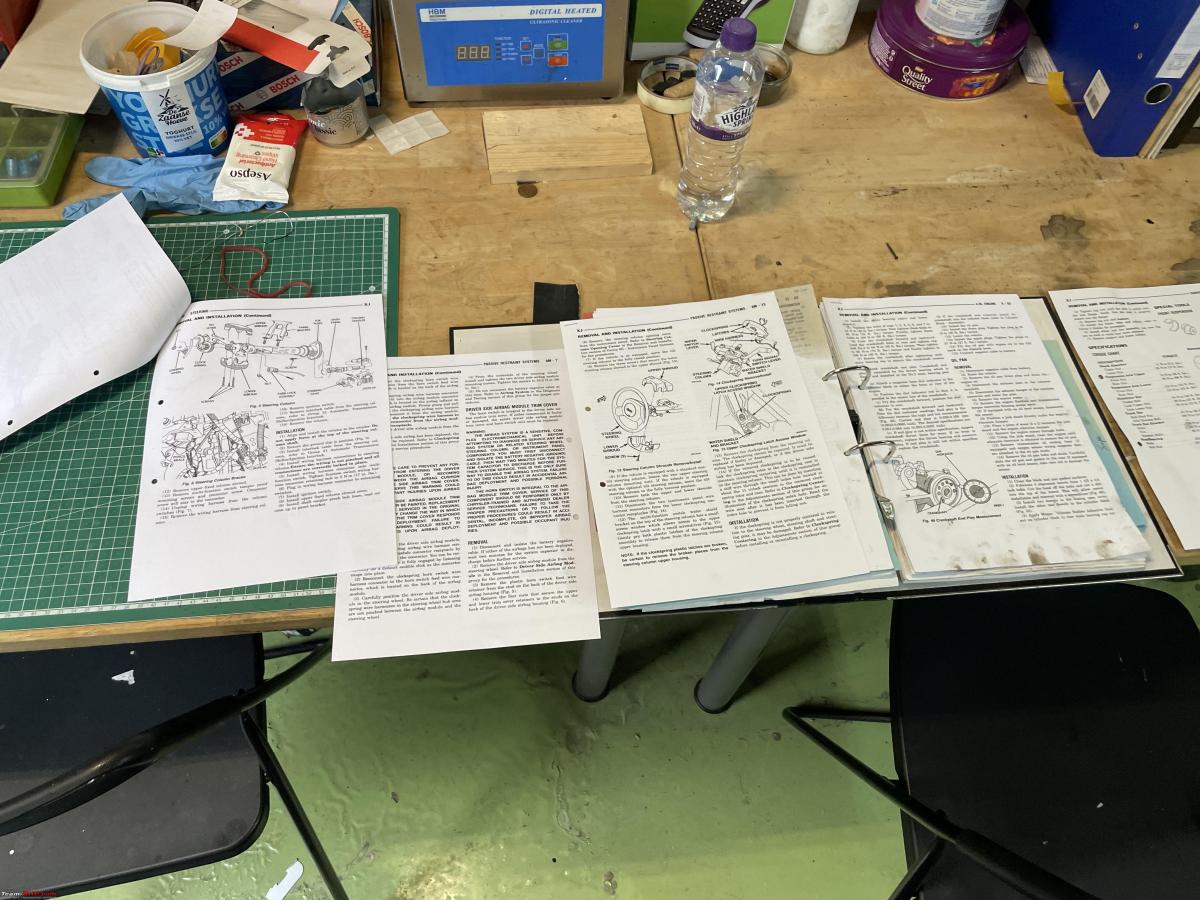

Although this is a simple job, as always I do read up on my manuals and I check some YouTube videos.

Next, various bits of trim need to come off.

The clock spring is held in place with two small plastic clips and it has two electrical connectors. With the trim removed, you have easy access and can pry it all apart and remove it from the steering column.

As per my "Standard Operating Procedure" checking old and new parts.

New clock springs come centred with a special locking pin inserted to hold it in place. It is important to first mount it correctly on the steering column before removing that pin.

With the locking pin removed, everything can go back on and is torqued to spec.

With everything back together, reconnect the battery, fire up the engine and check everything is working properly once again!

In all honesty, I could have just soldered the broken clock spring back onto the base plate. My Jeep workshop manual also has a procedure for centring a clock spring. (New ones should come centred with the locking pin). But even though clock springs are expensive, I decided to go for a new one. I just don't like any potential problems with my steering wheel airbag not working. Also, according to Murphy's law, it is very likely to fail again the day I need to take it for its MOT. No horn is an immediate fail!

I have come across a guy on YouTube who fixed his Jeep clock spring. Somehow he had managed to snap the actual flat cable in the middle. No idea how he did it, but he just soldered the two ends back together and claimed it never gave him any trouble. I am all for restoring old parts, but with the clock spring, I don't take any chances.

Check out BHPian comments for more insights and information.