News

Some details on the Jimny Rear Trackbar Relocation Bracket

Panhard bar / trackbar risers are generally are three kinds based on how it goes on the stock riser.

BHPian Sankar recently shared this with other enthusiasts:

There is some confusion here regarding the same because of the captive nut on the 5 door's rear axle. All Gen 4 Jimny's, 3 door and 5, have the same rear axle and the same captive nut to secure the trackbar to the rear axle. All Gen 4 Jimny trackbar relocation brackets fit the 5 door. Even Gen 3 axles have same captive nut on the stock riser. Some risers are made to fit both Gen 3 and Gen 4 axle, the only difference is the location and size of two small holes on the side of the bracket.

Panhard bar / trackbar risers are generally are three kinds based on how it goes on the stock riser.

- Overlaps the stock riser at both front, rear and LHS and has somewhat of an more elaborate fitting. Eg: OME, MF etc.

- The other type overlaps the stock riser at the rear and LHS and the front part goes inside the stock riser. Eg: Taniguchi, Showa garage, Masterpiece, Hardrace etc.

- The type that sits inside the stock riser completely front, rear and LHS. Eg: Xshock dakar, 4xForza (which is inspired by Xshock) etc.

A Taniguchi trackbar riser bracket installed on the Jimny 5 door.

Check out BHPian comments for more insights and information.

- Tags:

- Indian

- Jimny 5 door

- Jimny

- car technology

- 4x4

News

Mahindra Tech Day : Technologies used in BE 6 and XEV 9E explained

Mahindra had arranged for a Tech Day where they showcased all the technology that has gone into the development of these cars

BHPian Omkar recently shared this with other enthusiasts:

Mahindra has been betting big on its electric SUVs and rightly so. We drove these cars recently and were mighty impressed with the overall product. The cars will soon be on Indian roads, but meanwhile, Mahindra had arranged for a Tech Day where they showcased all the technology that has gone into the development of these cars. It was a 2-day event that took place in Mahindra’s factory in Chakan, Pune. This is where as of now, the batteries are being assembled and the cars are also being manufactured. Let’s take a look at the highlights of the event. Do share some additional technical highlights that you can from the pictures.

Day 1

Of course, the two cars in question were parked at the venue. Both cars share the same INGLO architecture and despite the different sizes, they both have the same wheelbase:

There were a total of 8 stalls displaying details of different areas of the car:

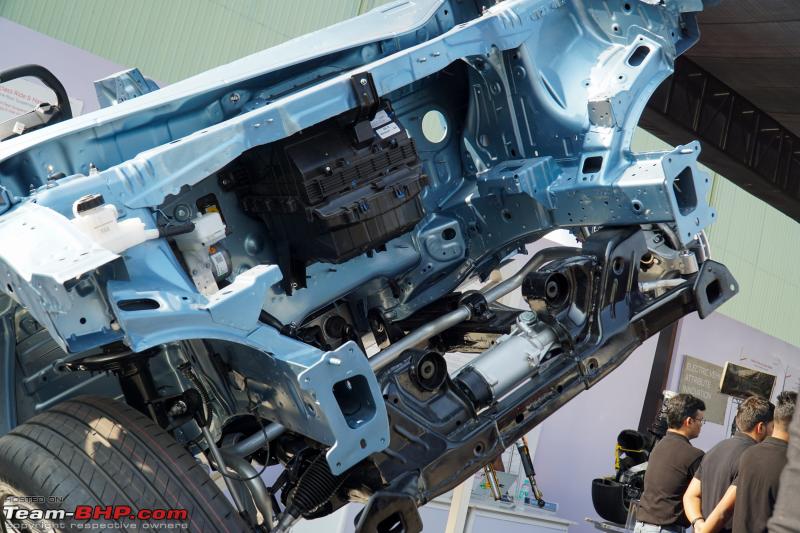

We’ll start off with the display of the inclined chassis of the INGLO architecture:

A closer look at the inside. You can see the steering mechanism and the HVAC mechanism as well:

On the other side, you can see the remaining part of the HVAC unit and also the brake booster unit on the left:

A look at the front suspension system and the frame:

This was just a miniature mode assembly of the car displaying the suspension and braking systems:

A cut section of the front and rear suspension. These are continuously variable semi-active dampers. There’s a solenoid valve at the bottom (green-coloured switch) that is responsible for performing continuous variable damping:

This is the front suspension system. Mahindra claims that the system has the highest suspension travel of 185 mm:

If you look closely, you can see that the lower control arm is split into 2 links. This allows the engineers to tune the comfort and handling characteristics separately:

As you can see, the steering rack is mounted in the front of the front axle which is something that’s possible on EVs and not IC engine cars. Without getting into much detail, the front-mounted steering rack improves high-speed understeer. With a rear-wheel drive car, you don’t want oversteer where the rear end steps out:

This is the independent multi-link (5 links) rear suspension assembly. The rear suspension has a travel of 205 mm:

The horizontal link that you see in front of the strut is the toe link that is claimed to improve camber linearity. Even the sub-frame design is claimed to have been optimized for battery protection in case of a rear crash:

A look at the frame in detail. The red arrows that you see here show the load path in case of a frontal crash. The green arrows show the load path in case of a side pole impact:

In case of a frontal impact, there are three major zones in the front of the car – crumple zone, absorption zone and resistance zone. In the absorption zone, Mahindra has added a cradle load path which is the part that you see in the middle. This cradle basically crumbles below and is claimed to provide 3x energy absorption in comparison with ICE cars:

As mentioned earlier, the green lines display the load path for side impact. Note that the battery pack also acts as a part of the frame and hence adds to the rigidity of the structure. The load distribution is 52% by the structure and 48% by the battery pack frame:

This is the BIW material distribution model of the BE 6. Unfortunately, I couldn’t find the exact distribution of different types of steels:

There was also a demonstration of the airbag deployment sequence. The basic idea is that in different types of crashes, the sensors relay the message to the airbag ECU which in turn sends signals to the respective airbags and also cuts off the high-voltage system:

This multilayer sheet that is placed above the inverter is claimed to reduce the noise and improve NVH:

Here’s a look at the steering system. It has a turning circle of less than 10 meters and has 2.65 turns from lock to lock. You also get a rack assist motor for better response. Note that the cars come with ADAS features and also auto park assist:

The steering rack has a variable gear ratio. This means that the pitch is narrow in the middle and wider towards the ends:

Here’s a better explanation of the variable gear ratio:

This is the steering column assembly:

The INGLO platform cars get brake by wire. This includes an integrated electronic brake booster. This assembly that you see here has a brake booster, vacuum pump and ESC controls integrated. Also, next to it, you can see the front brake caliper:

Here’s the rear brake caliper and the brake discs. The discs have a tiger claw design for better thermal stability:

These are the wheel hub assemblies for driven and non-driven wheels. Externally, there’s not much difference, but they are different on the inside:

The tyres have foam in them to reduce noise levels. The claimed reduction is 3-4 decibels:

Here’s a look at the Gen 2 compressor along with other parts of the HVAC system. You have the water pump at the back right and the chiller at the right:

Here’s a look at the HVAC assembly:

You have an active grill shutter assembly. This reduces aerodynamic drag by closing the grille opening area to the required level at higher speeds. This helps in improving the range:

A look at the compressor and the chiller with electronic expansion valve:

Continue reading BHPian Omkar's post for more insights and information.

News

What are the critical technologies that influence your car purchases

When turbochargers were released, there was a certain sector of people who would only buy vehicles with NA engines.

BHPian vj123 recently shared this with other enthusiasts.

Automotive technologies have been evolving significantly since the last decade and its up to anyone's imagination on how things will be by next decade or even towards the end of this decade. When turbochargers were released, there was a certain sector of people who would only buy vehicles with NA engines and one can compile a long list in the current market starting ICE vs EV / Hybrid. Creating this thread to discuss one automotive technology which was or is a huge deal breaker with your recent or upcoming vehicle purchase.

In my case, vehicle infotainment is a primary deal breaker. IMO OEMs have gone too much with infotainment development and personally, i would not buy or even consider a vehicle which has tablet like infotainment screens without physical buttons for a commonly used application like temperature control. By going into a couple of menus to perform a simple action, the driver loses muscle memory and can be highly distracted. I feel thats more dangerous than a person who is holding on to a mobile phone while driving. Personally, I rushed into buying a 2022 BMW with iDrive 7 just because of the fact that the next MY of the same vehicle was going to get iDrive 8. iDrive 8 removed most of the physical buttons and was poorly integrated on to the dash which looked like an after thought. As another example, Ford has done a similar thing to the upcoming Mustangs.

BMW iDrive 7:

BMW iDrive 8:

Mustang - Current generation:

Mustang - Next generation:

Here's what GTO had to say on the matter:

Safety tech is a huge influencer for us! As an example, the 3 most used cars in our garage all have ESP (over & above airbags etc.). Absolutely love new tech like hybrids which are continuously evolving, and electric cars (also consistently evolving).

On the flip side, I hate unnecessary tech like electric exterior door handles (e.g. XUV700) or climate control buttons moving to the touchscreen. Lastly, as Shreyans said, I hate subscriptions in cars. Manufacturers should stop obsessing over the "subscription" race & realise they aren't Netflix or Dropbox.

Here's what BHPian Shreyans_Jain had to say on the matter:

A technology that is a legit dealbreaker for me is the subscription model for extra features or performance. I will be happy to pay upfront for anything additional on my car. But it cannot be that you turn one of the big ticket purchases in life into a cheap joke by providing the hardware and then deliberately locking it. 25bhp extra for Rs 10000/- per year? No thanks.

Another something that bugs me connected everything. I do not want the car company or the insurance company to be keeping track of where my car is at what time and at what speed. No amount of convenience or benefit can entice me on this. It is bad enough that Google, Apple, Meta and the myriad apps on my phone are keeping track of everything. Car is on of the few remaining bastions of relative privacy, and it should remain that way. Especially in a country like ours with basically inexistent privacy laws.

Here's what BHPian SNA411 had to say on the matter:

Literally none.

I'm one of the rare people who, even in this day and age will actively avoid tech, sometimes even going to the extent of buying a base model.

All I want in a car is:

AC (not climate control), Power Steering, power windows, remote locking (not keyless).

That's it.

Here's what BHPian wheelnpaddock had to say on the matter:

The trouble with being an enthusiast is you can be forgiving of a lot of bad things in a car. For me if a car has the power I need, handles like I want it to and gives me the pleasure I desire I tend to overlook any other flaw.

I don't care too much for the music as my sport exhaust would take care of it. I dont drive too much in the city as its a chore. I look at the hugely positive side of the car and the way it fulfills my enthusiast needs and forgive everything else as it would just be minor irritants.

Here's what BHPian Kosfactor had to say on the matter:

ADAS - I gave this suggestion to the M&M`s factory engineers , they said they will consider it for Scorpio N as well as their newer releases.

I probably wont buy a new car without ADAS, like the one found in XUV7OO, there is no joy in driving on access controlled roads , may as well take some assistance from the robots who are not bored like us.

Here's what BHPian Cresterk had to say on the matter:

Keyless entry. I couldn't bring myself to spend 60L+ on a Mercedes or BMW when they couldn't offer something as basic as keyless entry on many of their models while it is present on many sub 10L hatchbacks. I don't understand why they specced them with phone app based lock/unlock, Push button start but no door handle sensors for keyless entry.

I find keyless entry to be one of the most convenient features out there. No need to juggle whatever bags, covers, folders, phone, laptop etc you are holding to reach into your pocket and fumble around to find the unlock button. Just reach out and pull the door handle and you are good to go. I think this is especially important for women since most of their dresses don't have pockets and they have to open their handbag and dig around for the keyfob.

Same thing applies when you get out of the car and you need to lock it. Just touch the handle and you are good to go.

Here's what BHPian amalji had to say on the matter:

Tech that will positively influence my purchase:

- Safety - ABS, ESP, Hill Hold Assist, Atleast 6 Airbags, Radar Cruise Control with Low speed follow, Lane Keep Assist, Blind Spot monitor

- Ergonomics - Physical buttons for Climate control and common tasks

- Infotainment - Android Auto and Apple car play ( atleast wired )

- Charging ports - Atleast one 12v charging socket so that it is future proofed to evolving solutions.

- Reliable Transmission - Torque Converter > CVT > No transmission ( EVs )

- Engine/Motor - Hybrids with Flex fuel engines > Hybrids with E20 compatibility > EVs

- Turbo combination - Big Engine small turbo combination rather than small engine big turbo to have a better torque spread ( read drivability )

- EV battery - Lithium Iron Phosphate battery with liquid cooling for safety reasons.

- Hybrid Battery location - Under the seats instead of using up the boot space.

- Ventilated seats

- Keyless Entry

On the fence:

- Automatic Emergency Braking ( Especially in Indian conditions )

Absolute No Gos:

- Subscription for performance and features to send the right message to the manufacturers

- Transmission - DCTS & AMTs due to their lack of abuse friendliness

- Engine - BS6 Diesels due to long term reliability concerns

- Lack of E20 compatibility Assurance in writing

- Not having a non-sunroof topend model and more importantly, if that's the only variant with the best of safety features, I'll rather not buy the car and will instead wait especially if this is going to be my primary car.

- Compromised thigh support on the seats of EVs due to the battery placement on the floor.

- Lack of height adjustment and steering adjustment

Here's what BHPian Sandy Damodaran had to say on the matter:

I feel like a dinosaur here, with some company though! All I'd like to have in the vehicle is ABS/Airbags/EBD/Best possible Brakes/power windows. If really reliable, then TPMS. Never have driven a Auto too yet!

Things I wont like, I guess, As I have never used them yet:

- Electronic Parking Brakes.

- ADAS/Adaptive CC.

- Subscription services.

- Tracking services.

- Connected car and allied gimmickry.

- Sun roof/moon roof etc.

- Speed warnings!!

I just want a vehicle which wont breakdown due to some electronic wizardry and wont act on its own like ADAS/Adaptive CC etc does.

I don't drive in the city and my take is if its boring to drive, don't drive...

Check out BHPian comments for more insights and information.

News

Joints: Different types & their contribution to the automotive industry

What I want to show is how a simple joint changes everything and what do quality obsessed companies do to a simple hardware to make it timeless.

BHPian aquavivarium recently shared this with other enthusiasts.

I have been reading this portal since 4 years and joined recently. I guess the core thought behind this group is the sharing of original, unbiased and unique ideas. Each of us is special and thinks differently.

We all had experiences and our own learning curves. Being in different parts of the globe, having different backgrounds and social positions adds new dimensions to the conversations. Irrespective of such a vibrant mix we all have one thing in common – love and commitment for our set of wheels, be it cars, bikes etc.

Since humans invented assisted means of mobility the world has changed faster than men could fathom, wheel is the numero uno invention. From experimental to novelty and then mass production. A metal or wooden box with initially 3 then 4 wheels, propulsion and control surpassed every other type of transport. It was for a simple reason STABILITY, this design did not require balancing, was easy to maneuver, could be modified easily to suit utility and gave a comfortable ride.

No wonder this design was chosen to be pulled by domesticated animals, we had two wheel designs but the instability is obvious:

Patent for the first “Benz” car was registered in 1886, as a few bold people thought to replace horses with Horsepower. Still these were restricted to experimental models OR for a very few elite.

“Necessity is the mother of invention” proved true as First world war lead to development of Piston engines on a large scale. Carbon based fuel powered engines entered main stream, massive industries were set up , piston engine proved its might and became the backbone for providing power and transport . Although the driving force was war a few began to imagine and develop the idea of a personal means of transport using similar engines for the masses.

At the end of First world war ,we saw the emergence of “ Car “ , it was a fun machine for the few lucky , was mostly handmade and assembled with focus on just one thing –Quality. Customers now were the bourgeoisie, the rising class and then we had the second war. With the piston engine well established now was the turn of the Jet propulsion. Post 2nd war , car was already a common sight and manufacturers already aimed for mass production. Now Quality was in focus but not top priority, still a few remained committed and to this day give us products which “ feel “ different and “age” differently.

Remove all branding from a 10-15 year old Lexus OR Maybach and compare with a average family car of same type & age , what is it that keeps a good quality machine going on and on, answer lies deep inside in a simple Bolt and Nut “ joint ”. And this is precisely my topic and I intent to explain “Quality” by the most elementary and innate feature of any machine . Starting from the simplest cycle to the Large Hadron Collider, everything we make and assemble has a “Joint “.

Difference between a Rolls and a Maruti is very obvious. In fact, it is stupid to compare, yet both serve the same purpose. Let us assume we take all the major parts of a Rolls eg – chassis, engine, upholstery and everything we see in a Rolls, and assemble it in a Maruti plant, will we get a Rolls?

Please note I don’t intend to downgrade Maruti, I have bought their cars and always appreciate their suitability to Indian ecosystem . What I want to show is how a simple joint changes everything and what do quality obsessed companies do to a simple hardware to make it timeless. I have mostly made the pics myself, they are not technically accurate and still convey the underlying message .

Now lets start by example:

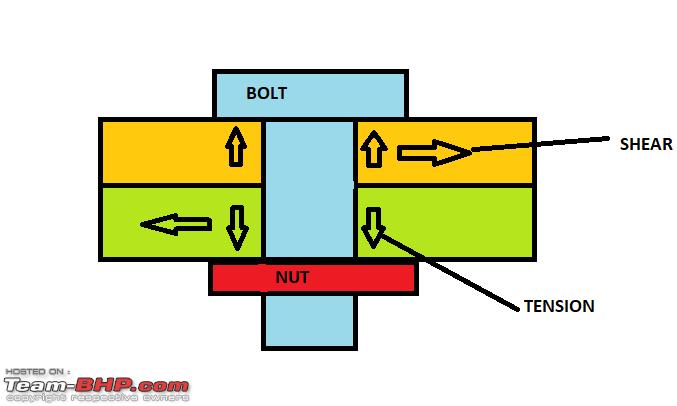

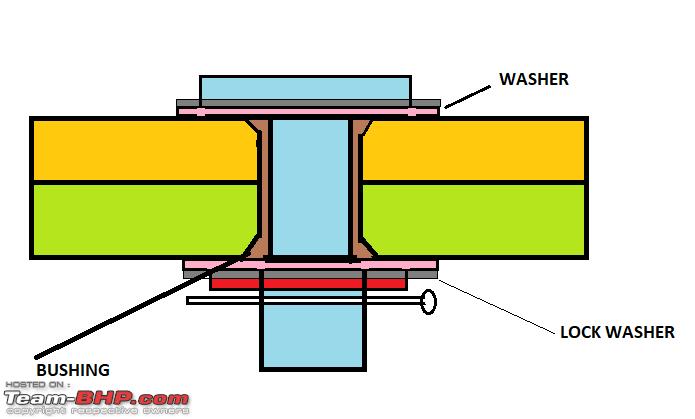

Our joint will consist of two metal pieces joint by a bolt and nut. We shall continue to improve the same and give reasons alongside:

Basic: As shown, we have joint two metal pieces by a bolt and nut, they can take all the tension and shear loads, torque is fully tightened by hand tool, this is a fairly sturdy joint. We see this happening at most repair shops.

Calibrated Torque (use of torque wrench): Anyone with basic mechanical knowledge knows the importance of correct torque, it depends on the bolt/nut size, thread type, material etc. It is a measure of how hard the threads of the two will engage with each other OR amount of friction lock. Less torque will loosen and more will create undue stress on the joint and might lead to a material failure. Torque values for nut and bolt are different and must be kept in mind. In high temp. areas to prevent jamming of the nut a "neverseez“ compound is also used on the bolt threads.

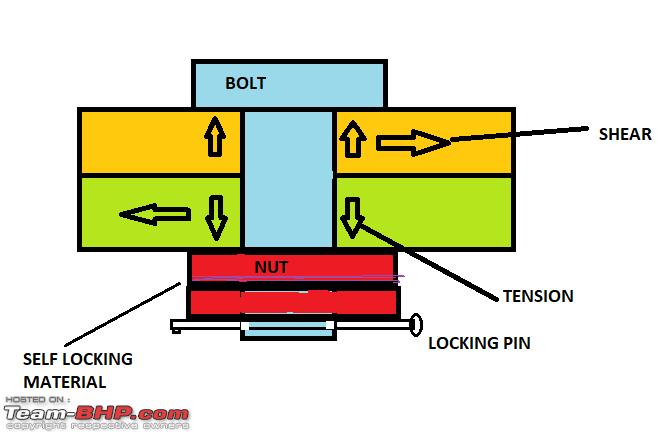

Locking NUT: All joints are subject to vibration and/or thermal cycles, over a period of time the nut is bound to get loose and results can be catastrophic, and various ways are used to lock. As shown, we can use two nuts, lock nut or a cotter pin in the hollow shank of the bolt which prevents the nut from unscrewing itself. Bolt head also can have a provision for wire locking. Lock wiring is a skill, which takes time and will to learn.

I have experienced bloody fingers and much resentment myself, but to complete a complex lock wiring job gives a satisfaction like art work. In aviation, wire locking bolt is a very widespread.

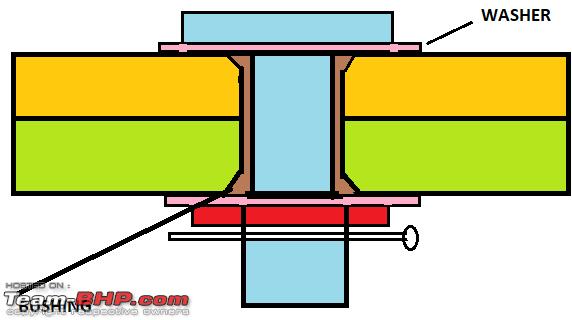

Chamfering/beveled edge: Loads paths in materials tend to accumulate at sharp corners, thus edges are rounded for a larger surface area contact to prevent edge cracks. As shown above notice the edges are now cup shaped thus sharp edges are avoided.

Washers/Bushings: They serve two purposes; Distribute the load on a larger surface thus prevent the damage to sheets and they are made of softer material thus they wear out protecting the main hardware. Washers can also be lock type.

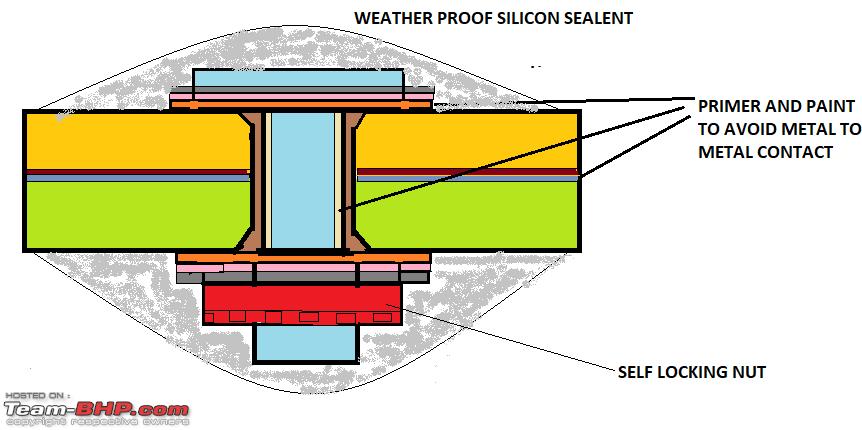

Surface protection: Metal corrodes or oxidizes to slowly weaken and give away, especially in high temp, acidic and abrasive environs . Dissimilar metal corrosion also happens at joints. Thus electroplating, primer, paint , enamel coating is done on the hardware and the sheet to make it long lasting.

Sealing the Joint: to make the joint lifelong Or in places with extreme environs like fuel tank, bridges, under ocean etc . The complete joint is made invisible by completely covering it with sealants like silicon etc.

Thus we see the evolution, might not be technically spot on ,but the message is loud and clear: Quality and character of a machine is more built in then visible, what it gives is feel, handling, running dynamics and graceful ageing than the bling bling we experience . High quality products are so because their creators do different things AND things differently. It is the zero-compromise culture with continuous improvement and an eye for detail that these manufacturers strive fo , be it a engine mount or a upholstery clip, they know that it is just not the quality material but also the way it connects to others which effects the final product.

Perfect execution of a sharp turn on a long winding road is motorists heroin. In those moments no one is looking at a 10 inch screen or hearing a BOSE sound , at that time your vehicle is your song and a good engineered machine will give you that pleasure all its life.

Car buying decision has biases, we see the Koreans pulling customers by increasing touch screen size, putting fancy white lights and adding chrome. Very well engineered products like the Compass are not people's favorite, Fiat Palio was a hot hatch still had a early demise. My suggestion to people before buying is to read long term reviews and If Germans ask for a premium price, its not for what you see but what's inside right up to each nut and bolt.

I am an engineer and work on commercial aircraft like the Boeing 737 and Airbus 320. I have visited factories where they are built and assembled. Will post on commercial aviation soon.

Check out BHPian comments for more insights and information.